Movable feeding device for cross slide seat

A technology of feeding device and cross slide, which is used in feeding devices, large fixed members, metal processing machinery parts, etc. The effect of stable and reliable quality, high degree of automation and flexible processing capacity, high degree of automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

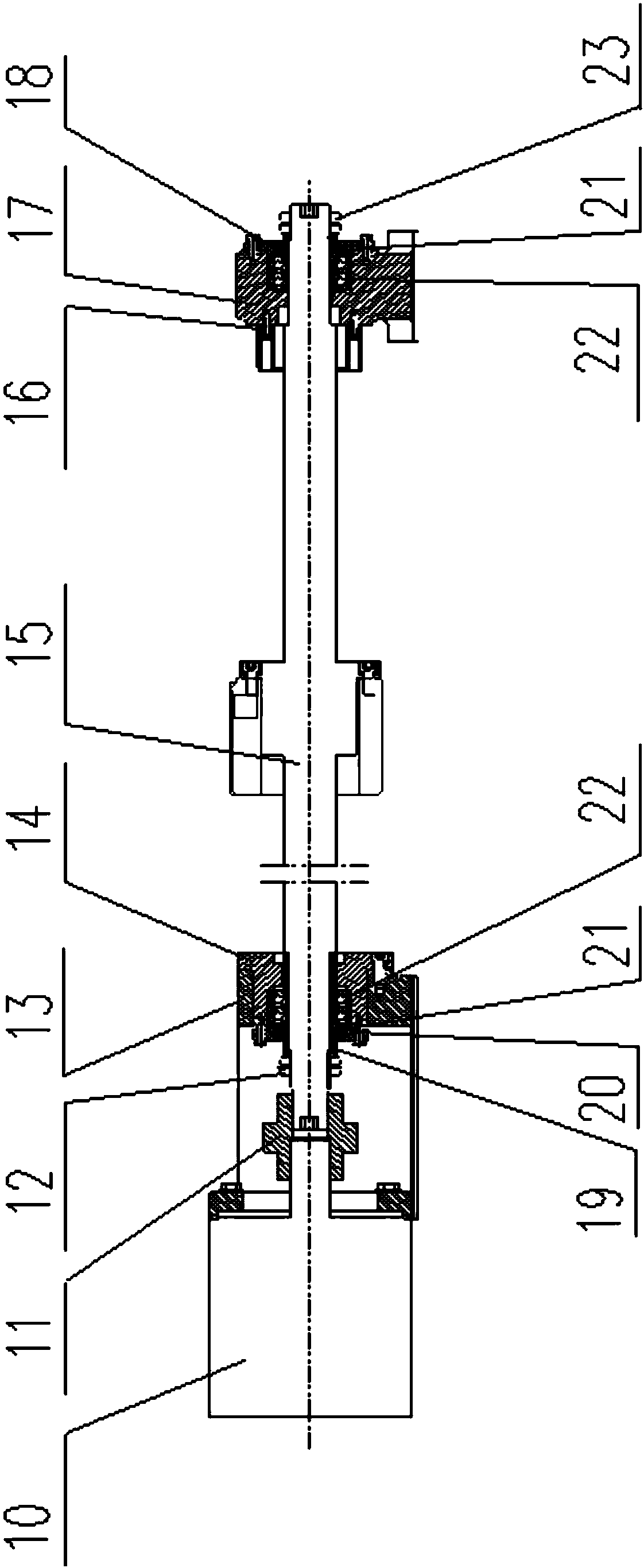

[0022] The moving and feeding device of the cross slide of the present invention will be further described in detail with reference to the drawings and embodiments.

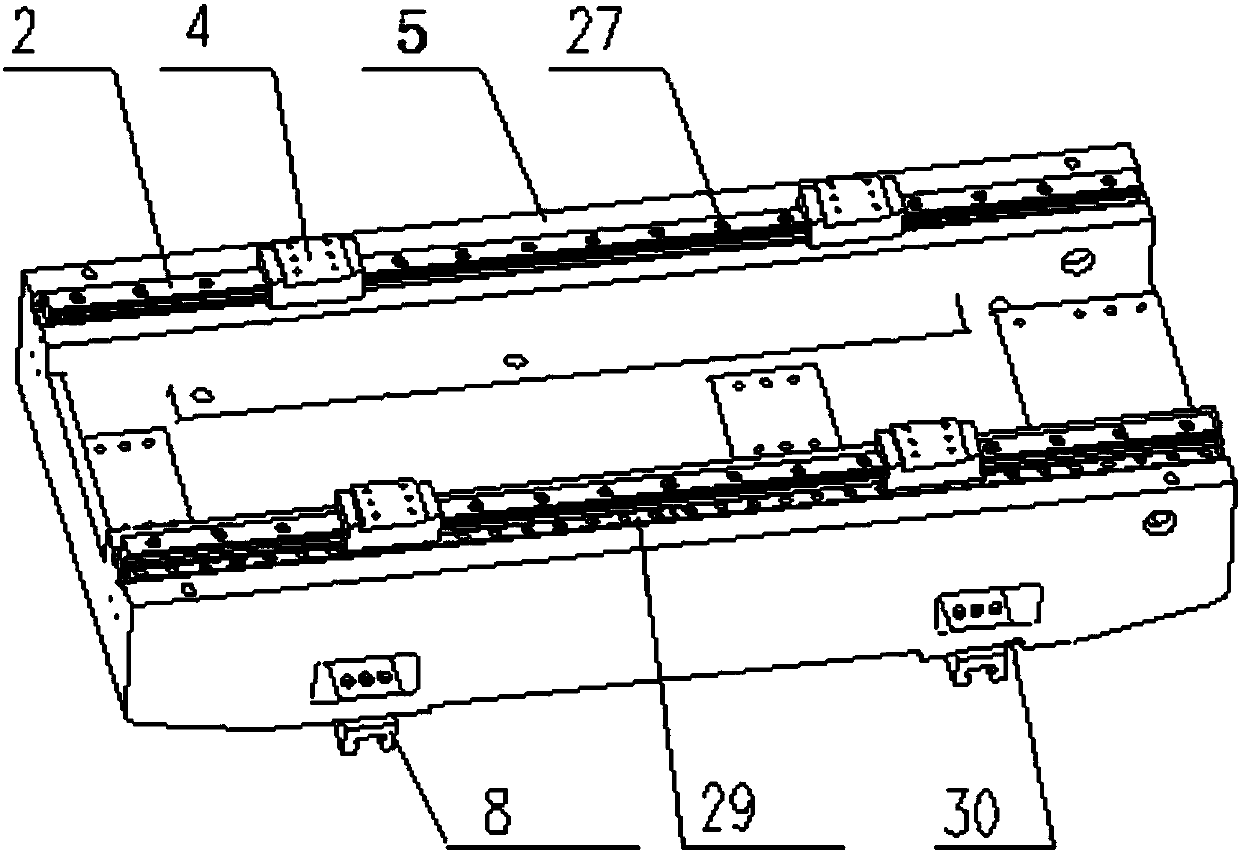

[0023] A cross slide moving and feeding device. The device adopts a roller screw drive. It is composed of a cross slide and a feed mechanism (ball screw pair and rolling guide). The cross slide adopts a casting structure with straight balls on both sides. The guide rail and the feeding mechanism in the middle are driven by a ball screw pair, which can achieve stable transmission and high guiding accuracy, thereby ensuring the relative position accuracy of each component. The bottom of the sliding seat is equipped with a sliding block and a nut, which can move longitudinally on the base.

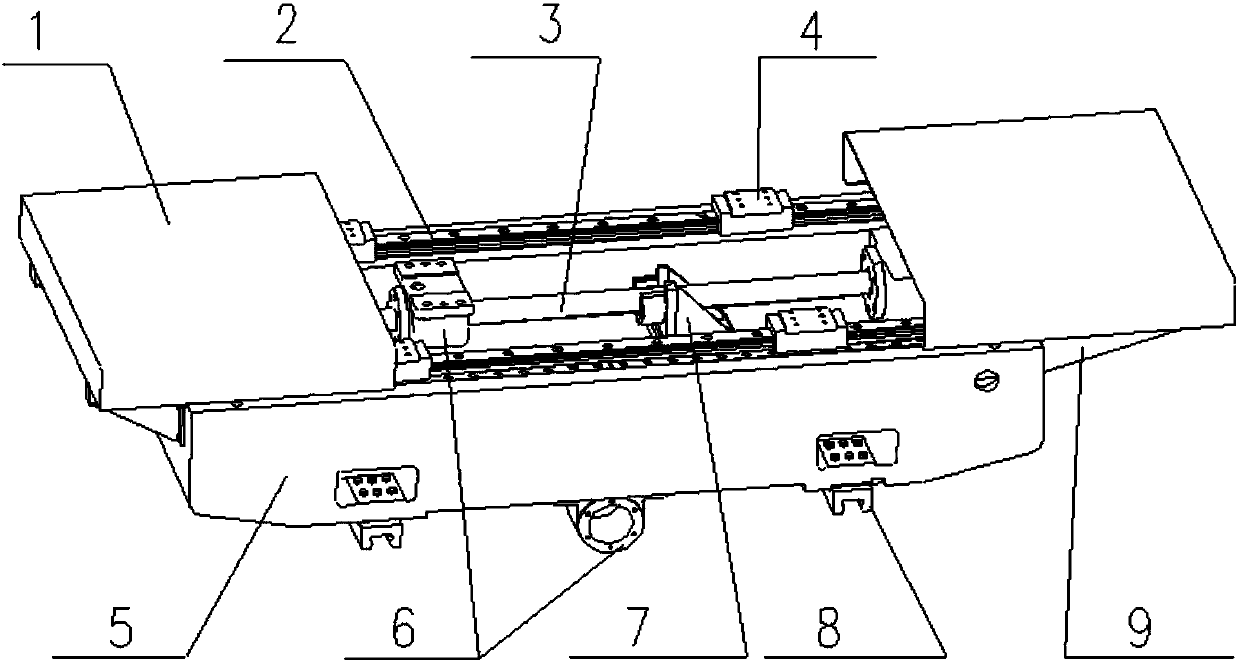

[0024] figure 1 The outline structure of the sliding seat moving mechanism of the present invention is given. The figure shows that the upper part of the sliding seat 5 is equipped with a rolling guide rail 2 and a ball screw 3 trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com