S adapter tube manufacturing method

A manufacturing method and short tube technology, which are applied in the field of processing and forming of pipe fittings, can solve the problems of low processing efficiency and low degree of automation, and achieve the effects of improving production efficiency, reducing chip generation, and improving automation and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

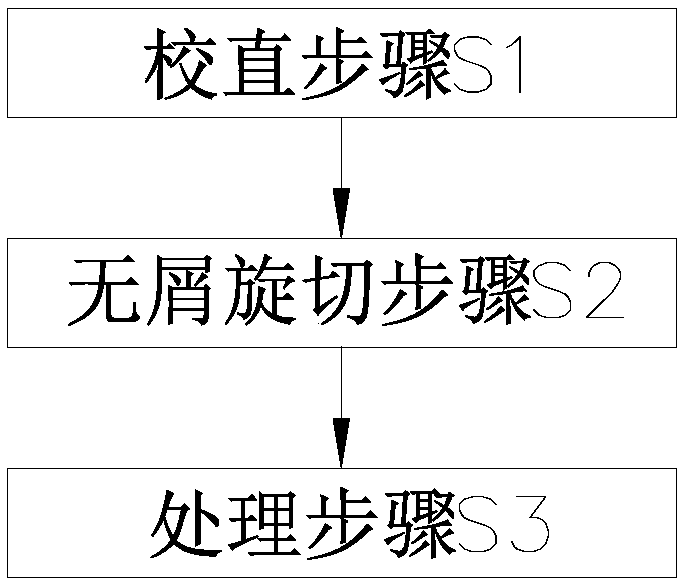

[0044] see figure 1, The manufacturing method of the S connector of the present invention includes a straightening step S1, a chipless rotary cutting step S2 and a processing step S3. The manufacturing method adopts as Figure 5 to Figure 18 The line shown is executed.

[0045] see Figure 5 to Figure 9 , the production line 1 of the present invention includes a control unit, a frame 100, and a pipe section loading and unloading system 11 installed on the frame 100, a processing and forming system 15, a material transfer system and a collection unit 19, and the material transfer system is used for the pipe section loading and unloading system The short pipe sections cut out in 11 are supplied to the processing and forming system 15 according to a predetermined procedure, and the collecting unit 19 is used to collect the S pipes processed and produced by the processing and forming system 15 . The control unit includes a processor, a memory, and a control panel 101. The contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com