Sharp-edged dual-stage replaceable casing drill for hole-making of fiber-reinforced composite materials

A composite material and fiber-reinforced technology, applied in twist drills and other directions, can solve the problems of easy clogging of diamond particles by chips, low quality of final holes, poor chip removal, etc. The effect of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

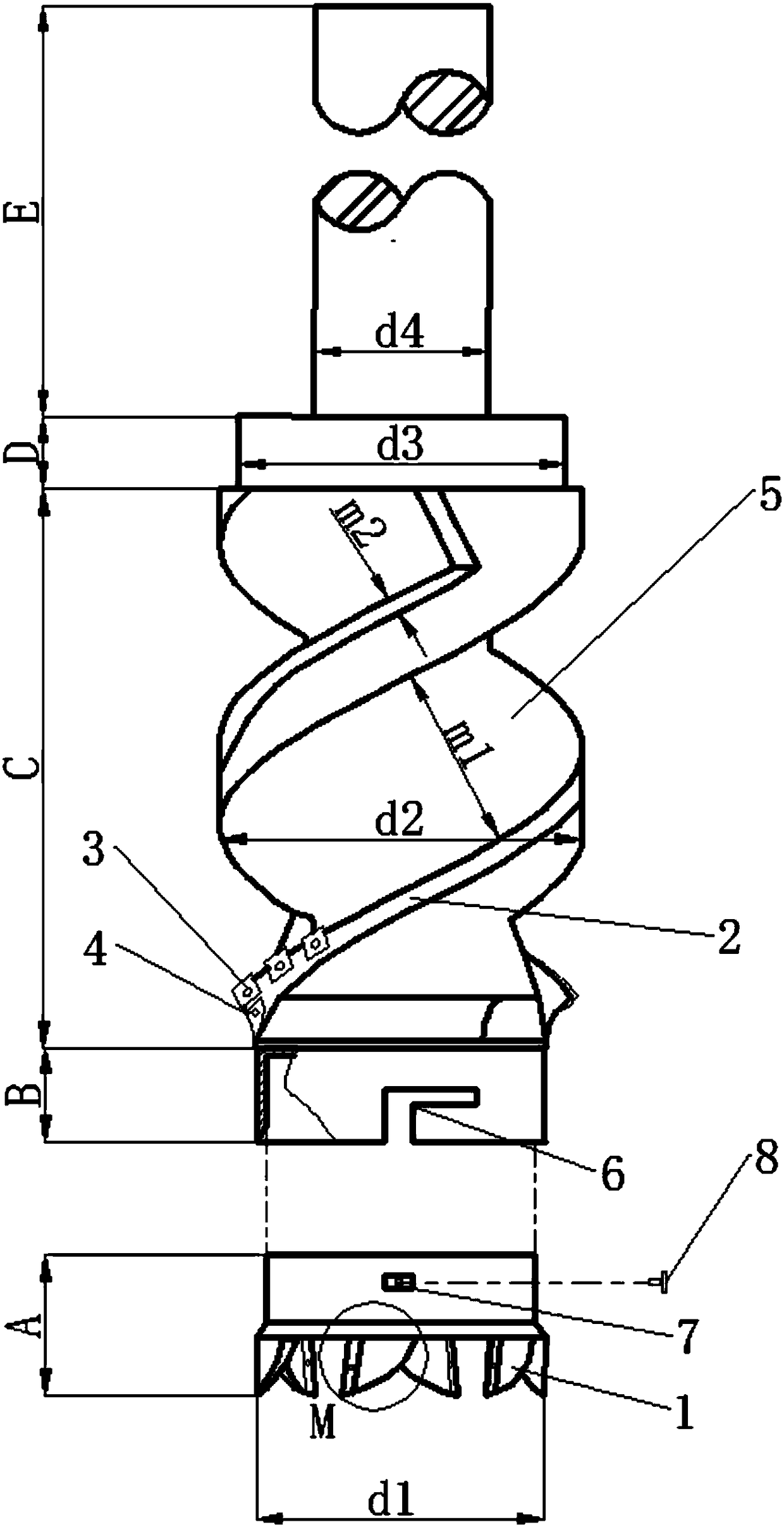

[0013] figure 1 Front view of a sharp-edged dual-stage trepanning drill for making holes in a fiber-reinforced composite material, figure 2 yes figure 1 Partially enlarged three-view view of the middle sharp edge. Such as figure 1 , 2 As shown, the drill mainly includes five parts: the sharp edge cutting mechanism (A), the sharp edge connecting ring (B), the reaming cutting area (C), the variable diameter area (D), and the clamping area (E).

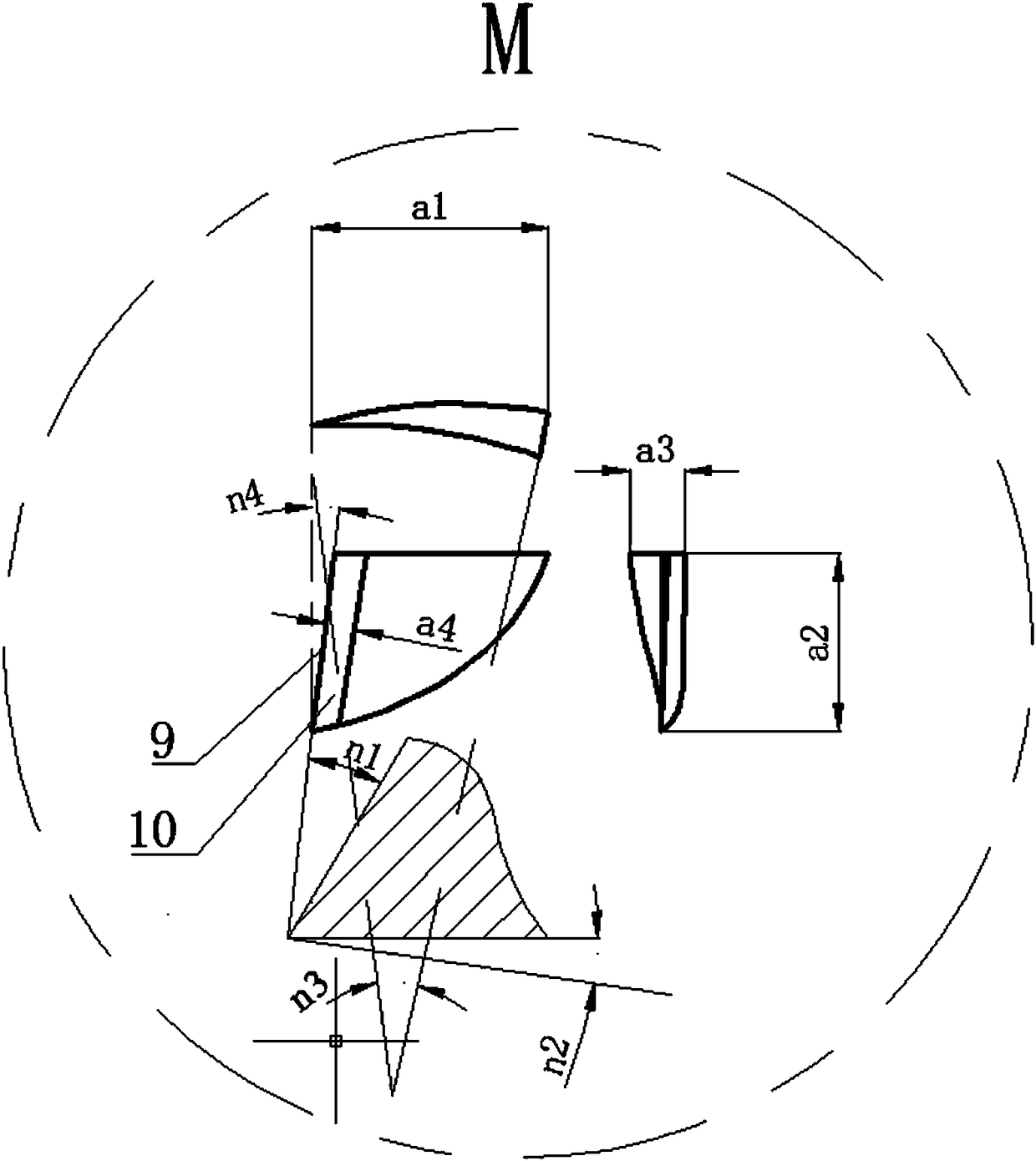

[0014] The sharp edge cutting mechanism A is located at the front end of the tool, and n sharp edges 1 are distributed. In this embodiment, n is selected as 6, and the size and shape of each sharp edge 1 are the same, as figure 2 As shown in the partially enlarged three-view M of the middle sharp edge, the main cutting edge 9 of each sharp edge 1 is ground to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com