Inserted chassis diagonal-brace structure of tower crane

A technology of tower cranes and diagonal braces, which is applied to cranes and other directions, can solve problems such as high weld quality requirements, inconsistent space dimensions, inconvenient loading and transportation, etc., and achieves strong transportation convenience, low manufacturing cost, and strong The effect of condition improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

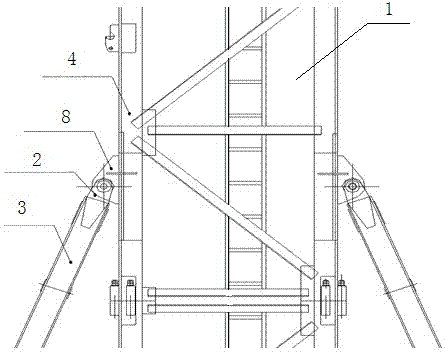

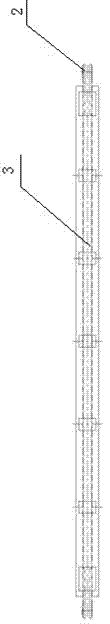

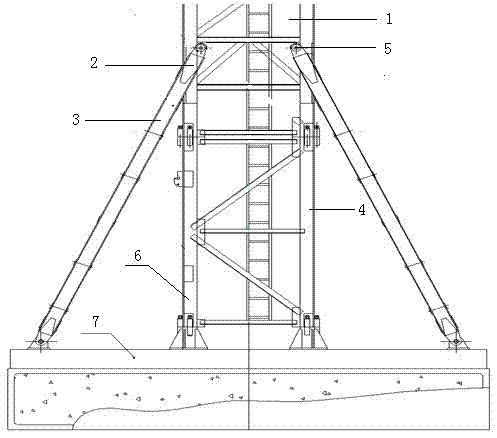

[0020] Such as Figure 3 to Figure 5 As shown, the present invention is an interpolated underframe diagonal brace structure of a tower crane, which is mainly composed of a foundation section 6, an underframe section 1 and a diagonal brace 3, and the bottom end of the foundation section 6 is vertically and fixedly connected to the cross beam 7; The bottom end of the chassis section 1 is fixedly connected to the top surface of the foundation section 6; the diagonal brace 3 is arranged obliquely to the cross beam 7, its bottom end is fixedly connected to the cross beam 7, and its top end is fixedly connected to the bottom frame section 1. The top of the diagonal strut 3 is provided with a "U" structure double ear plate 2 fixedly connected with it, and the inner file size of the "U" structure double ear plate 2 is matched with the width dimension of the main chord 4 to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com