Electric guide plate and torque protection device thereof

A protection device and guide plate technology, which is applied in the direction of safety devices, transportation and packaging, load suspension components, etc., can solve problems such as damage, internal components and drive components of the reduction box, and achieve the effect of ensuring versatility and uniform dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

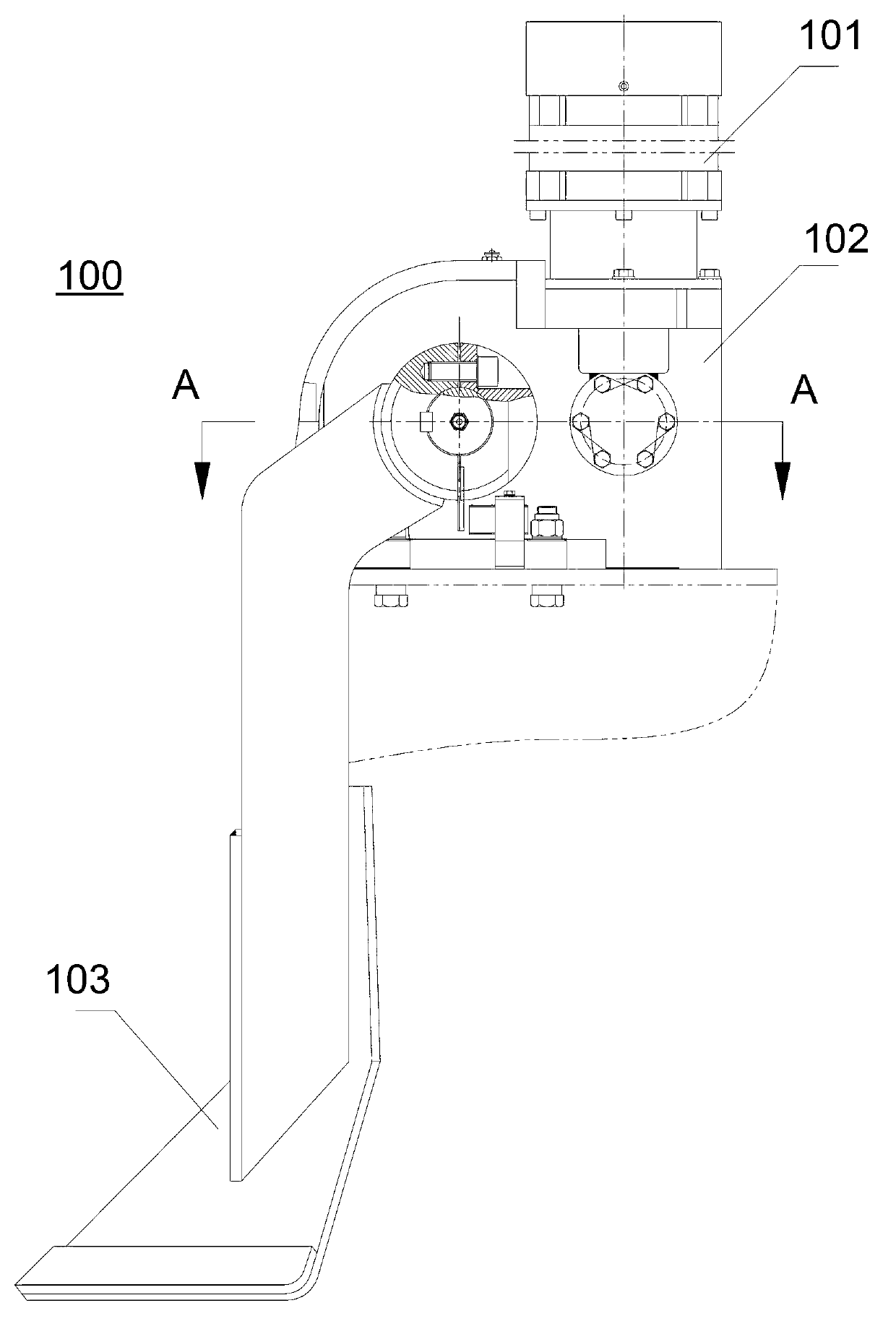

[0018] refer to figure 1 as shown, figure 1 Disclosed is a general assembly diagram of an electric guide plate mechanism according to an embodiment of the present invention. This electric guide plate mechanism 100 includes a drive motor 101, a gear box 102 and a guide plate structure 103, the drive motor 101 is connected to the guide plate structure 103 through the gear box 102, and the drive motor 101 rotates to drive the guide plate structure 103 to swing up and down, for example, to swing up and down 180° .

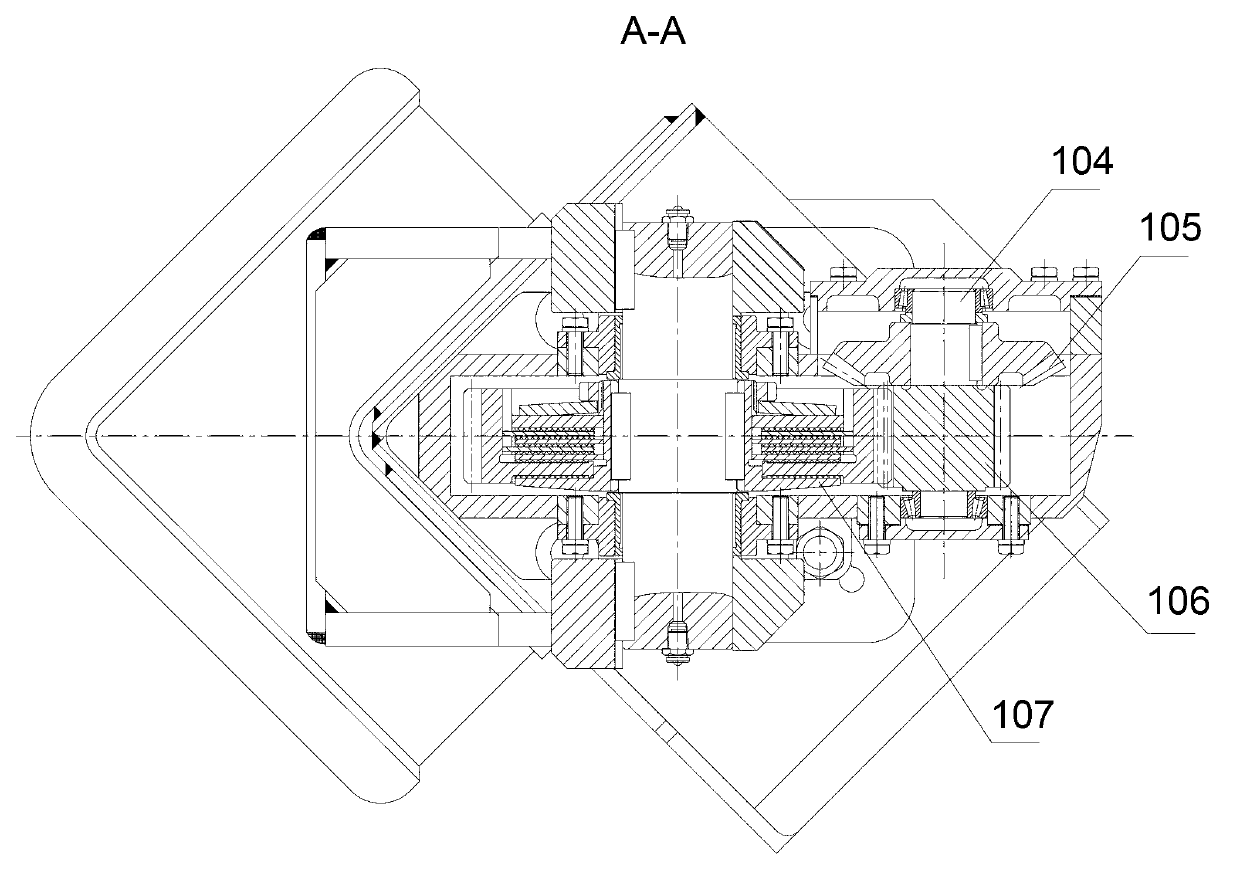

[0019] refer to figure 2 as shown, figure 2 revealed figure 1 View from direction A-A in the embodiment shown. The gear box 102 includes a gear shaft 104 , a bevel gear 105 , a pinion 106 and an electric flipper torque protection device 107 . The driving motor 101 is connected to the bevel gear 105 and drives the bevel gear 105 to rotate. The bevel gear 105 is connected to the pinion gear 106 through the gear shaft 104. The pinion gear 106 meshes with the teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com