On-site combined type rectangular high-low frequency mixed loading connector

A combination and connector technology, applied in the direction of connection, coupling device, two-part connection device, etc., can solve the problems of occupying the installation panel space, inconvenient equipment maintenance, and inability to disassemble, so as to achieve reasonable overall structure design and high working performance Stable and reliable, easy to assemble and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

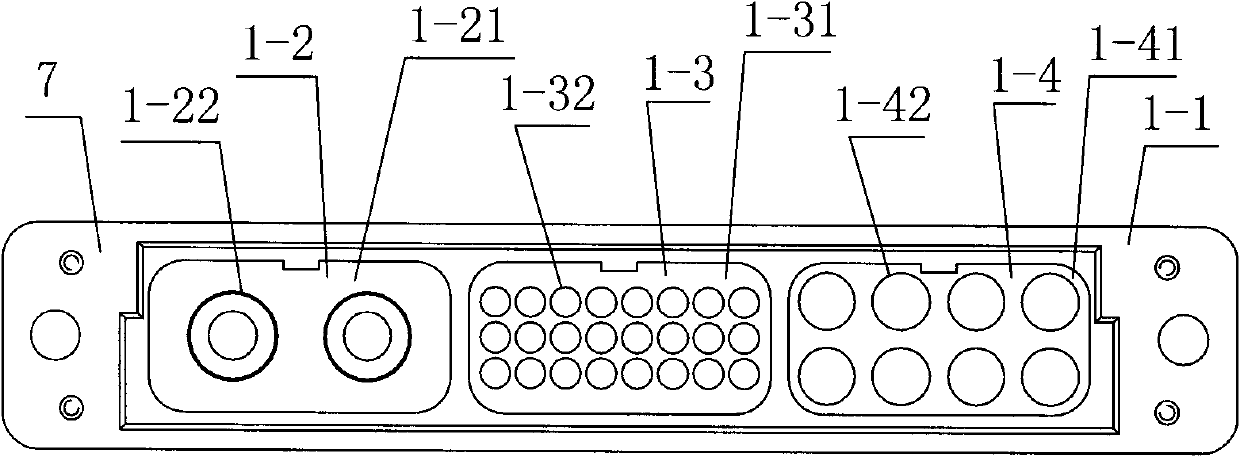

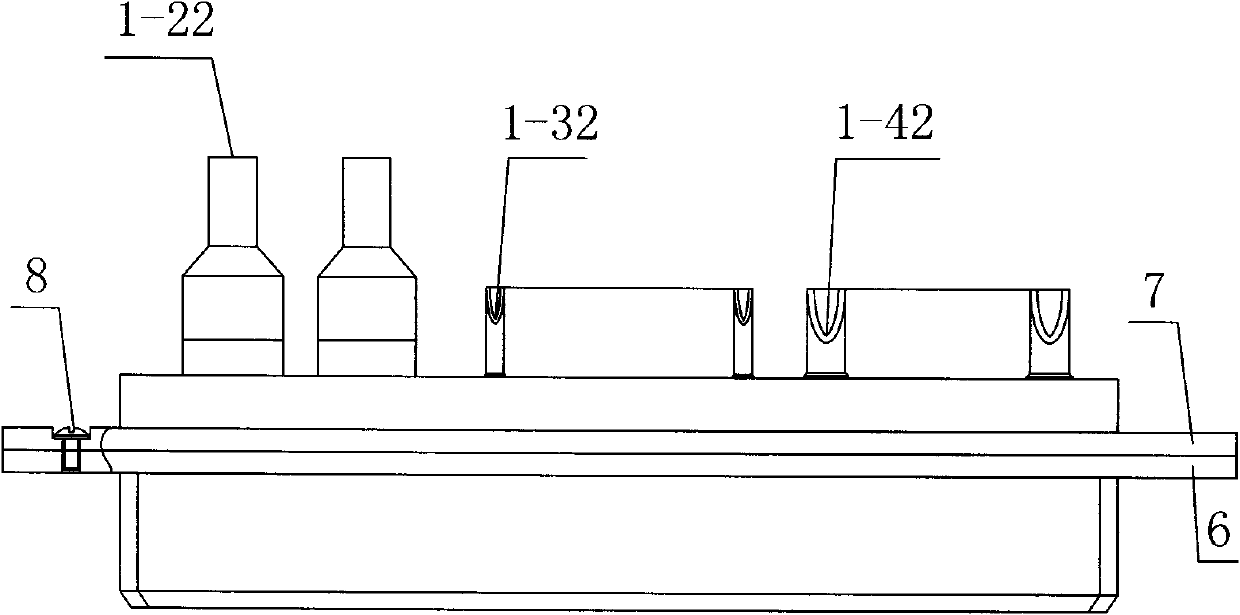

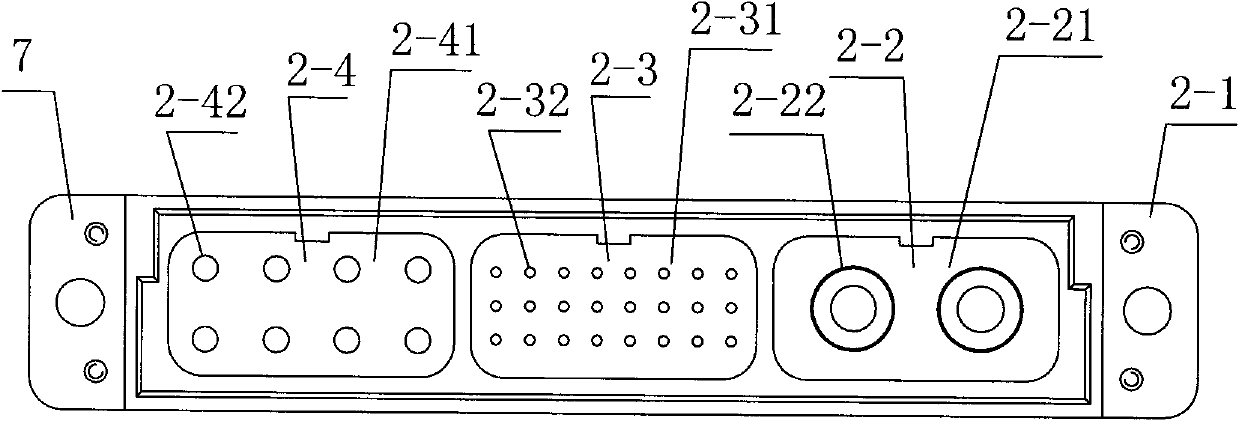

[0066] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a connector plug 1 and a connector socket 2 used in conjunction with the connector plug 1 . The connector plug 1 includes a plug outer shell 1-1 and a plurality of plug modules that can be installed on the plug outer shell 1-1 in various combinations and form various types of combined plugs accordingly. It includes two types of plug modules, high-frequency plug modules 1-2 and low-frequency plug modules. The connector socket 2 includes a socket outer shell 2-1 and a plurality of socket modules that can be installed on the socket external shell 2-1 in various combinations and form multiple types of combined sockets accordingly. Including high-frequency socket module 2-2 and low-frequency socket module two types of socket modules. The combined socket structure installed on the socket outer housing 2-1 corresponds to the combined plug structure installed on the plug outer ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com