Patents

Literature

39results about How to "Simple regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-Microbial Implant

ActiveUS20090088809A1Simple regulationStreamlines regulatory processSuture equipmentsInternal osteosythesisSpinal implantBiomedical engineering

Owner:DEPUY SYNTHES PROD INC

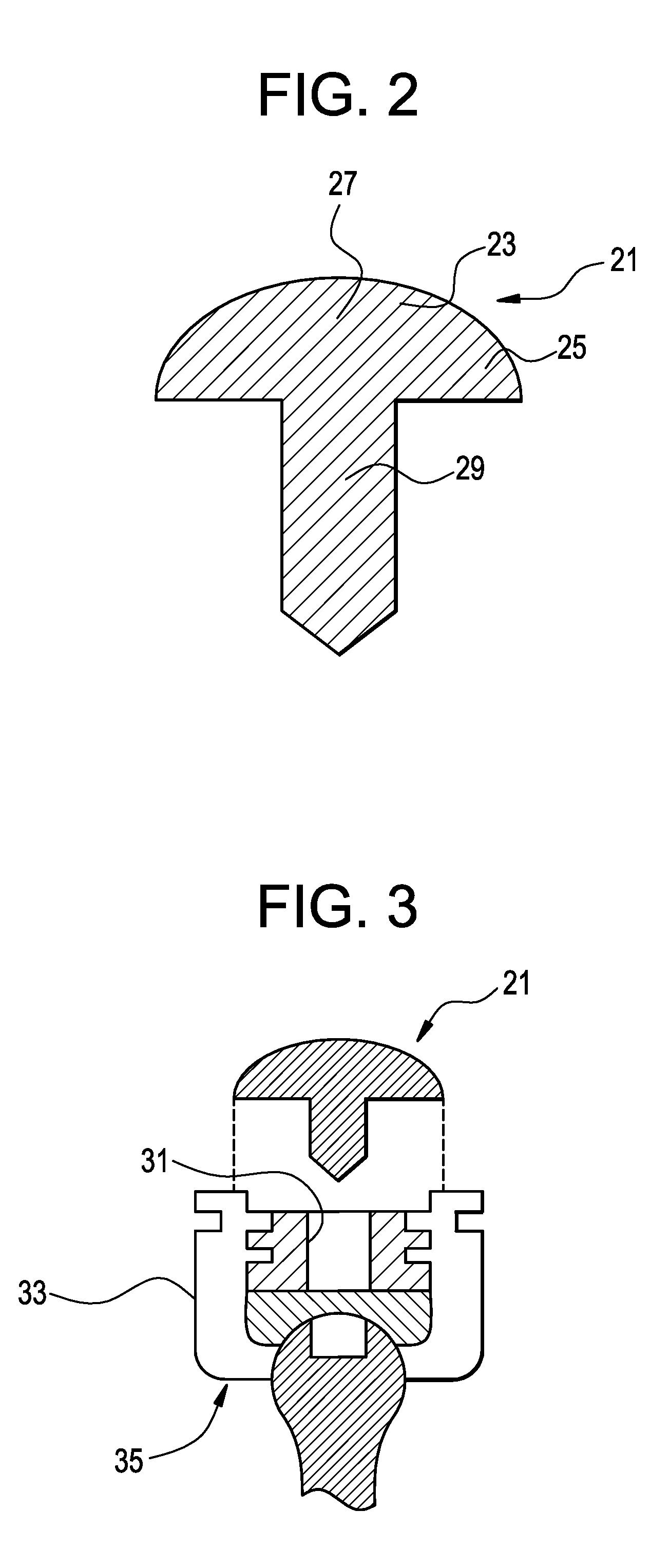

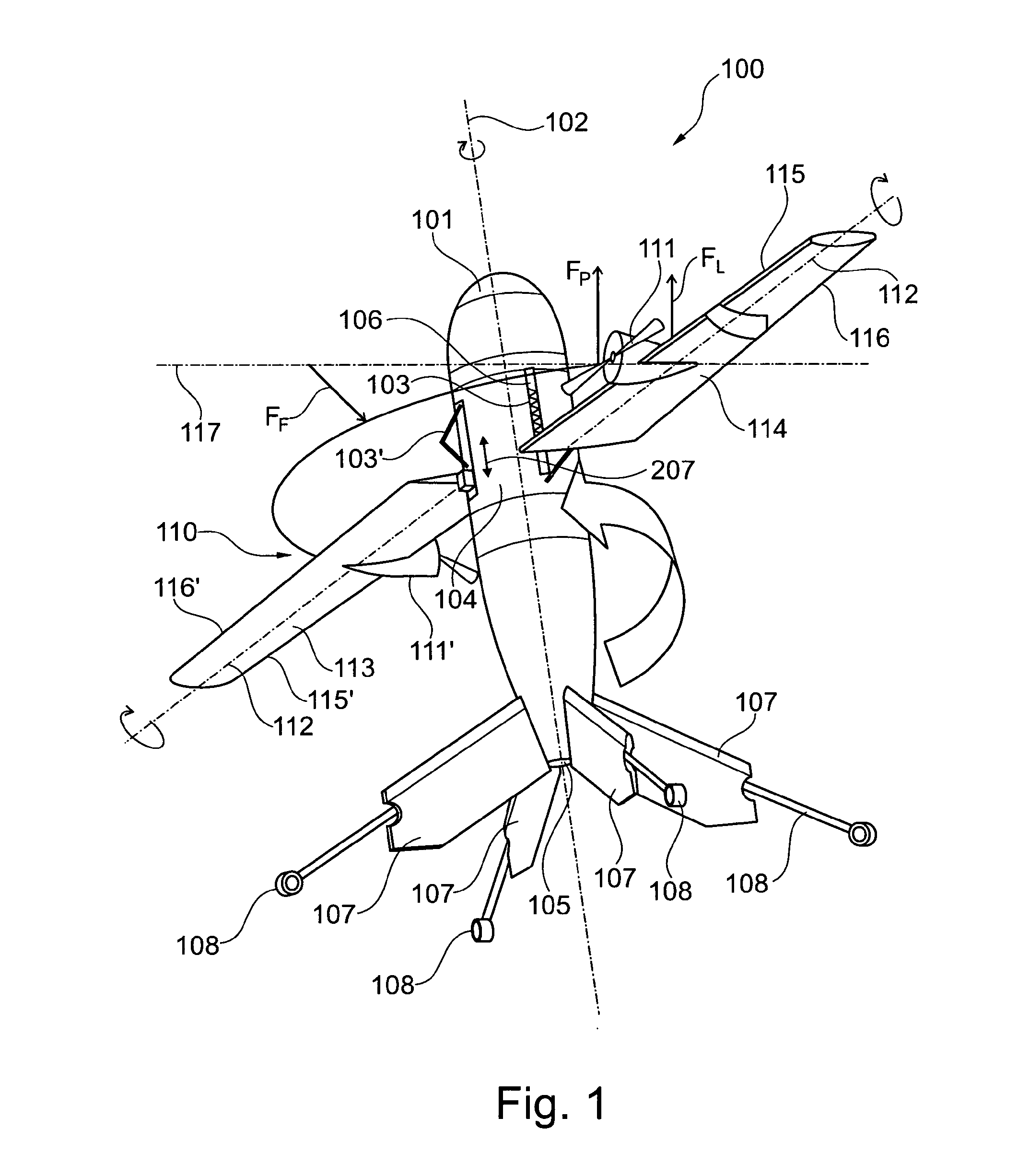

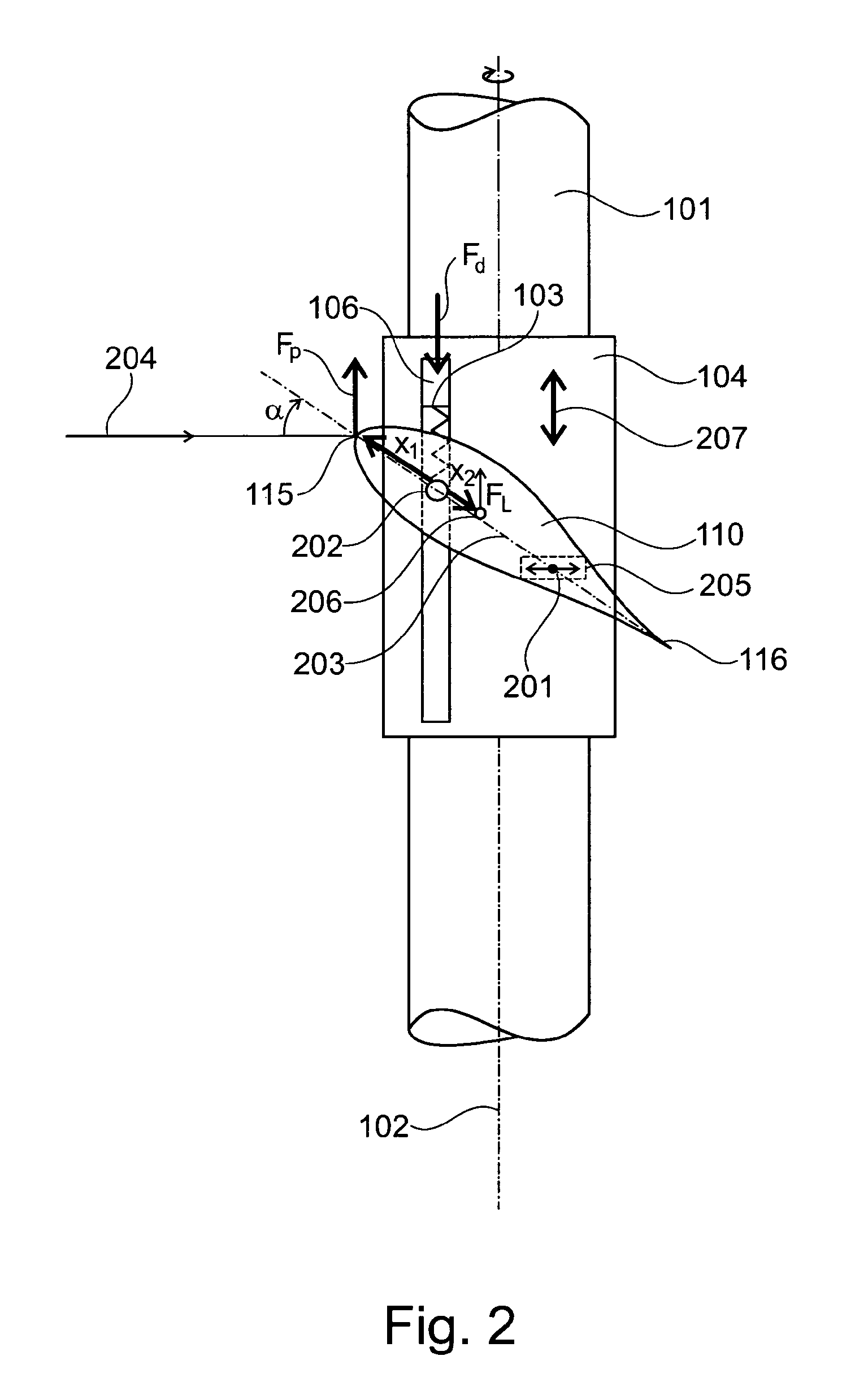

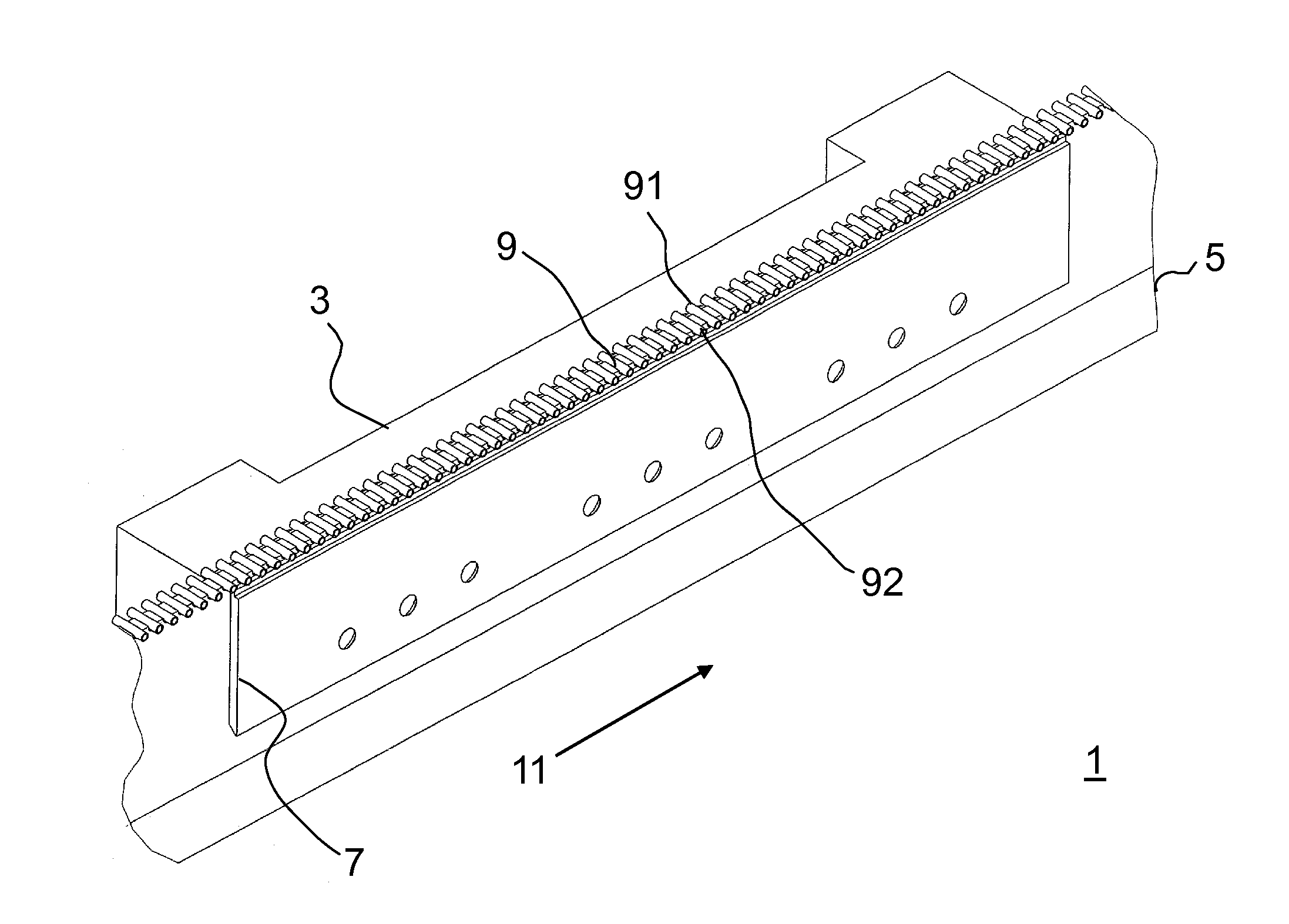

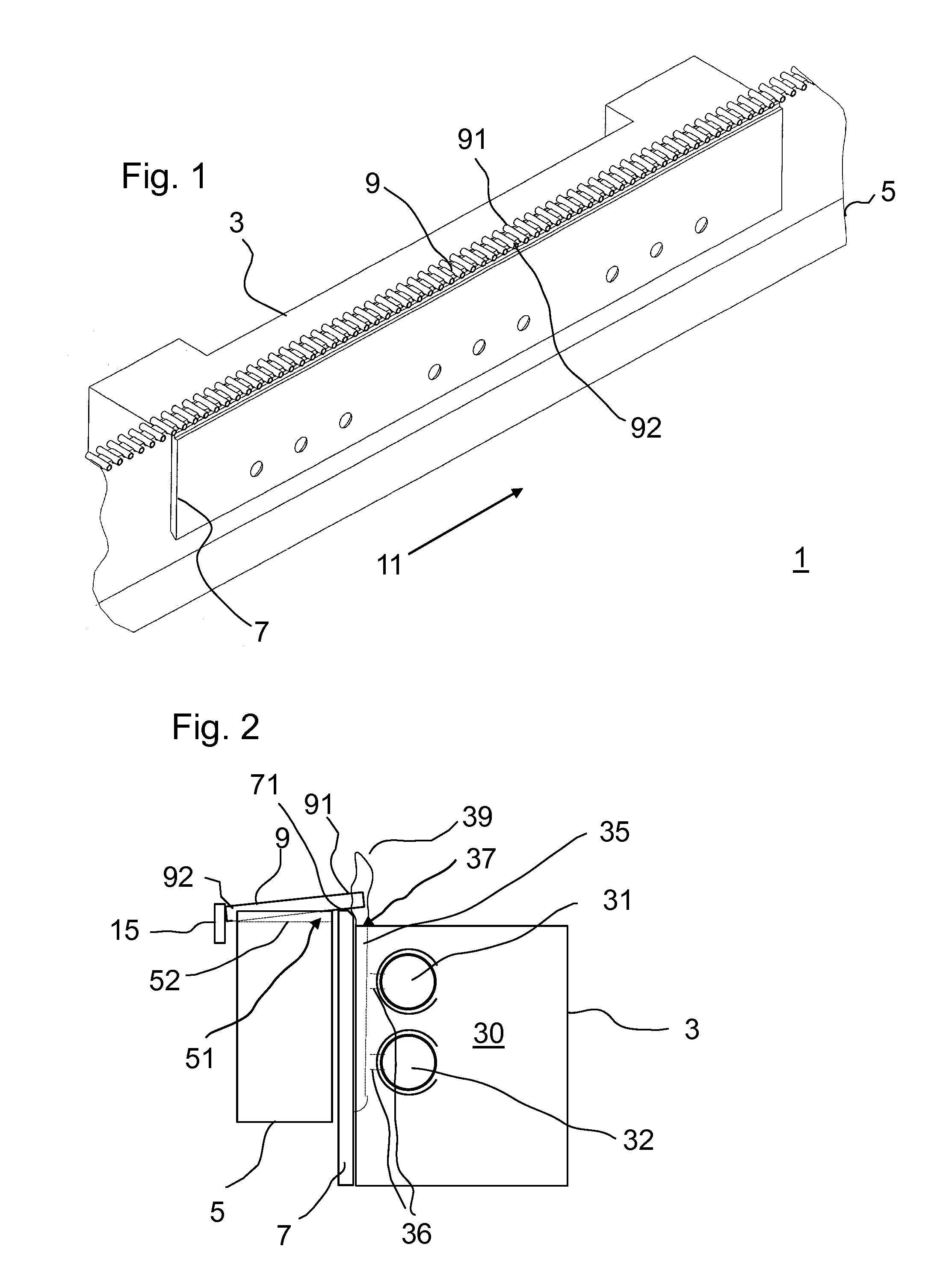

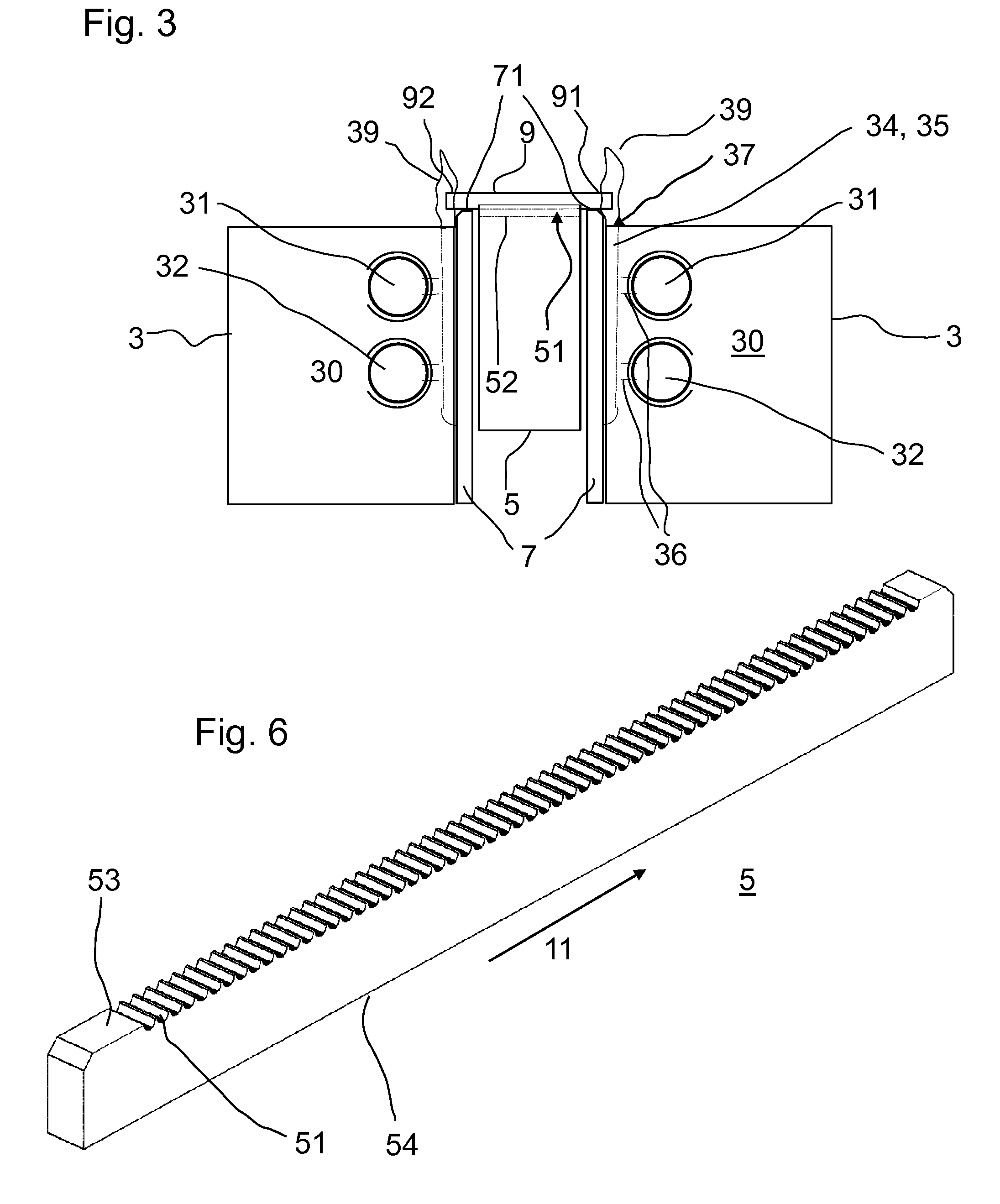

Wing adjusting mechanism

InactiveUS20150028155A1Reduce angle of attackReduce resistanceRemote controlled aircraftWing adjustmentsPrecessionFuselage

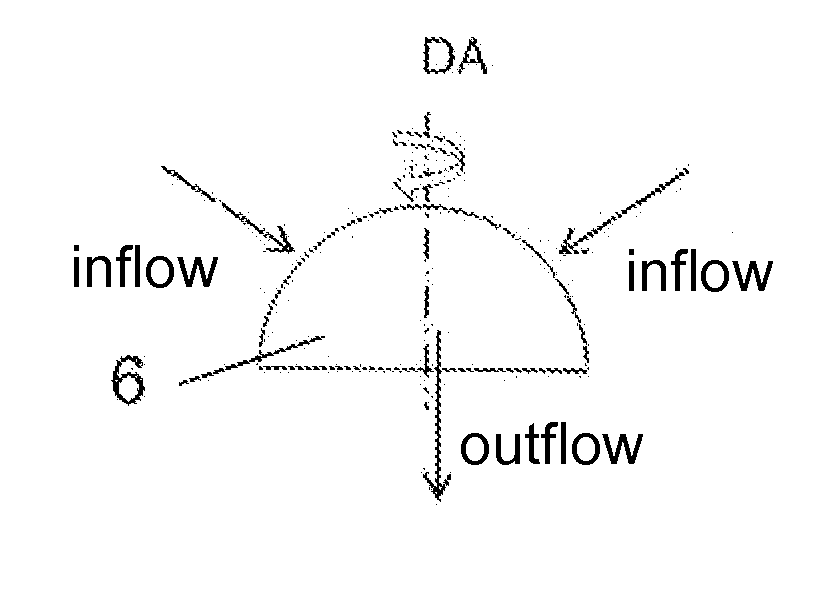

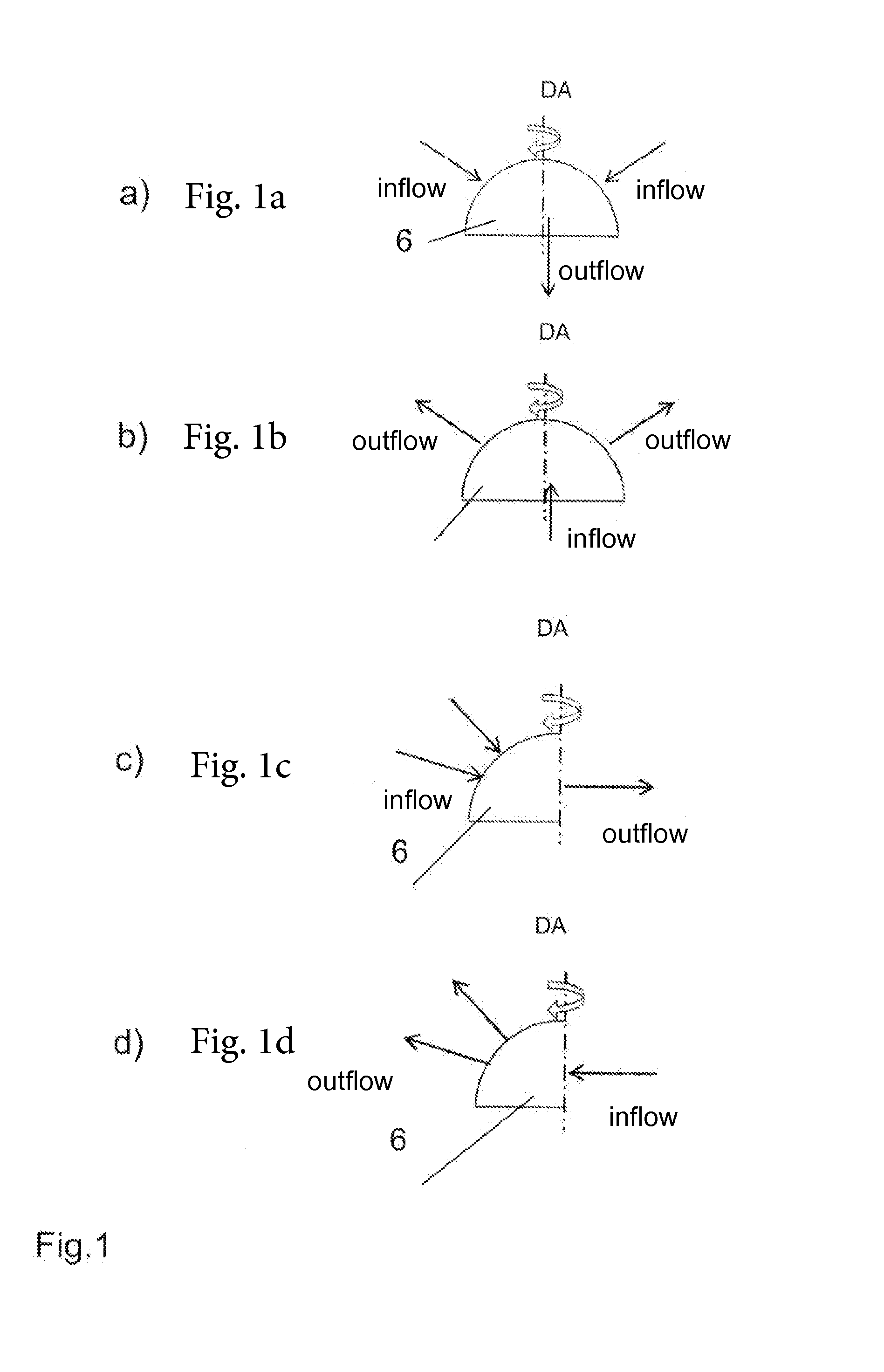

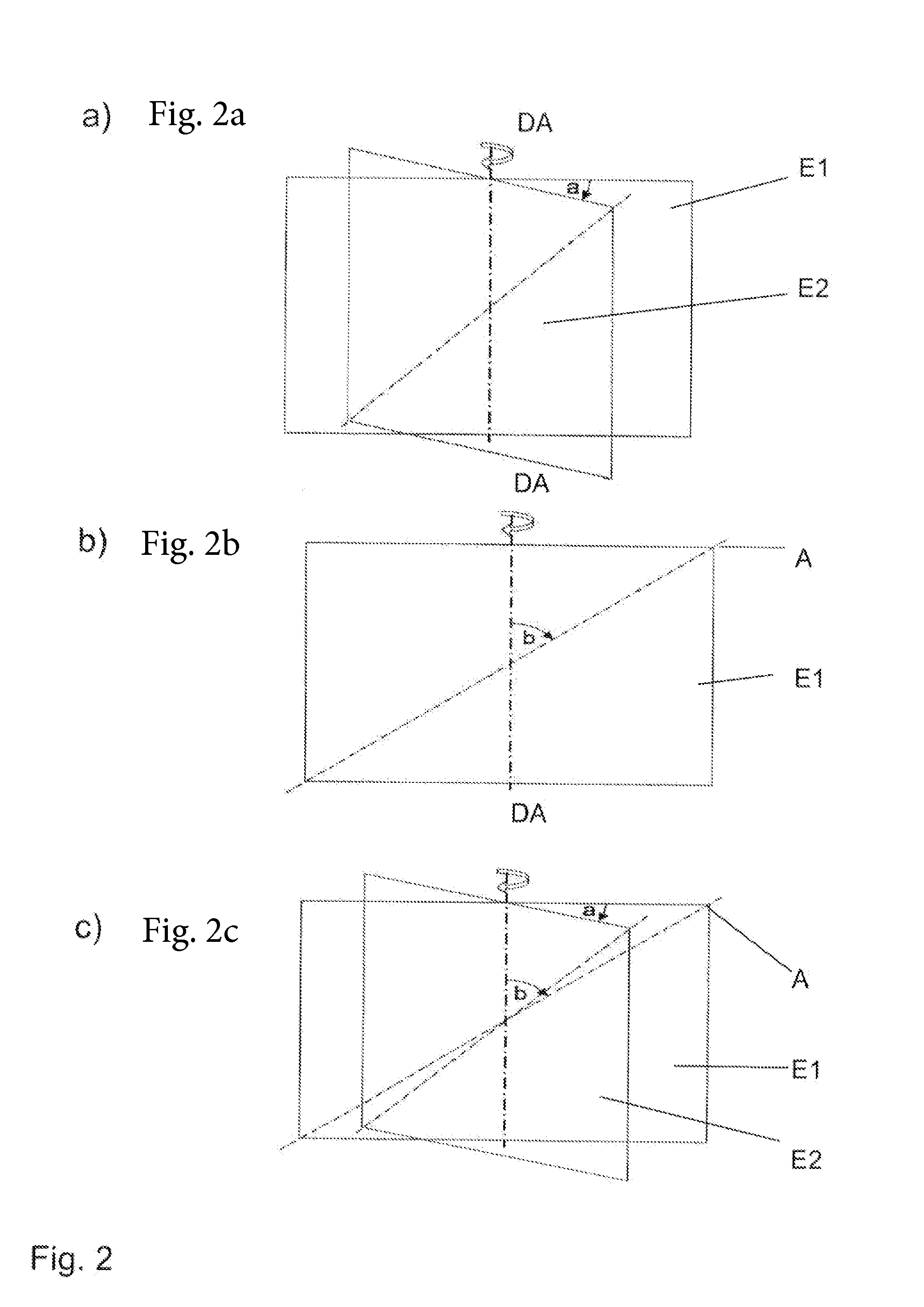

The present invention relates to a device for generating aerodynamic lift and in particular an aircraft (100) for vertical take-off and landing. A wing arrangement (110) comprises at least one propulsion unit (111), wherein the propulsion unit (111) comprises a rotating mass which is rotatable around a rotary axis (117). The wing arrangement (110) is mounted to a fuselage (101) such that the wing arrangement (110) is tiltable around a longitudinal wing axis (112) of the wing arrangement (110) and such that the wing arrangement (110) is rotatable with respect to the fuselage (101) around a further rotary axis that differs to the longitudinal wing axis (112). An adjusting mechanism adjusts a tilting angle of the wing arrangement (110) around the longitudinal wing axis (112) under influence of a precession force (Fp) which forces the wing arrangement (110) to tilt around the longitudinal wing axis (112).

Owner:REITER JOHANNES

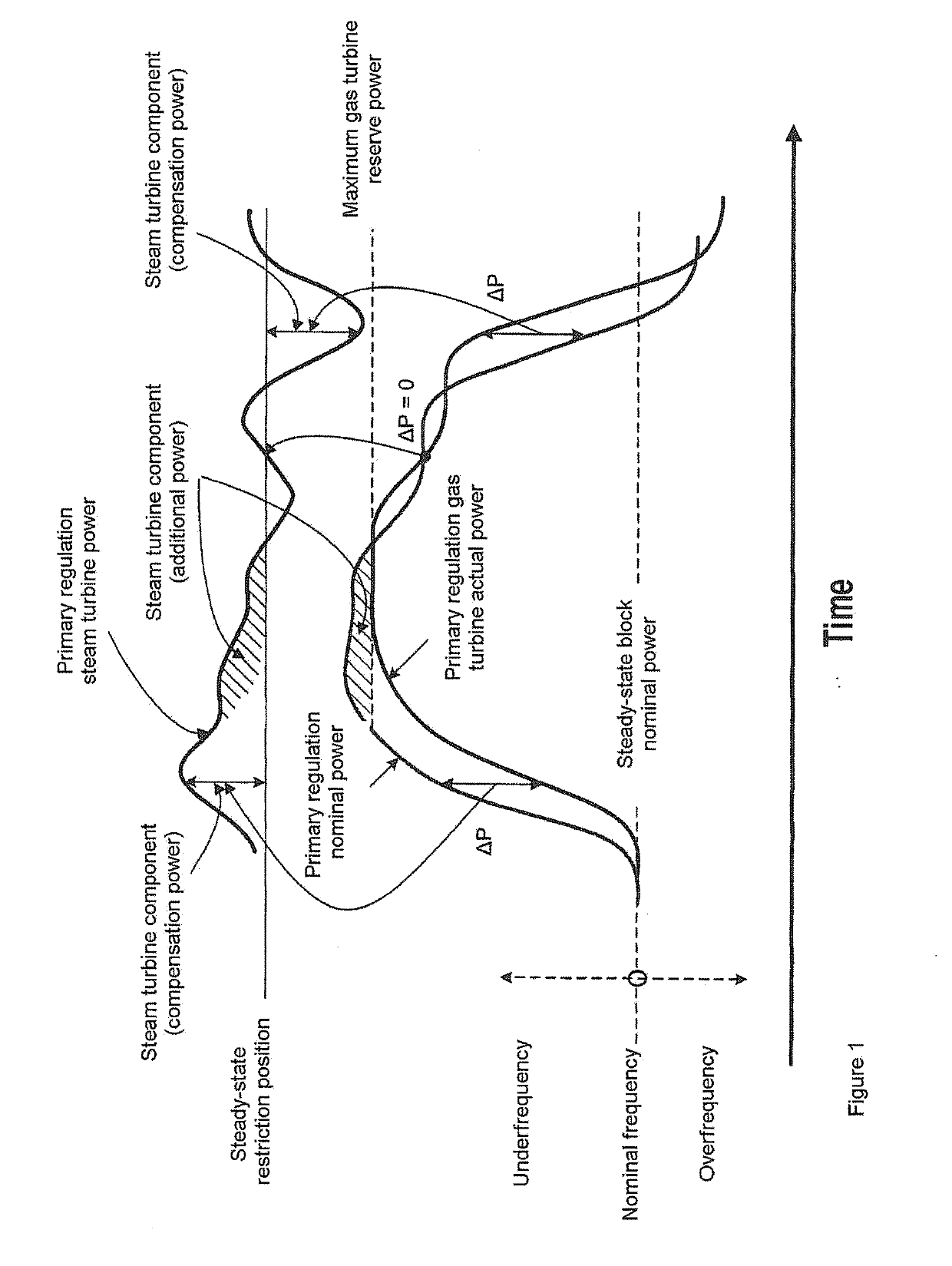

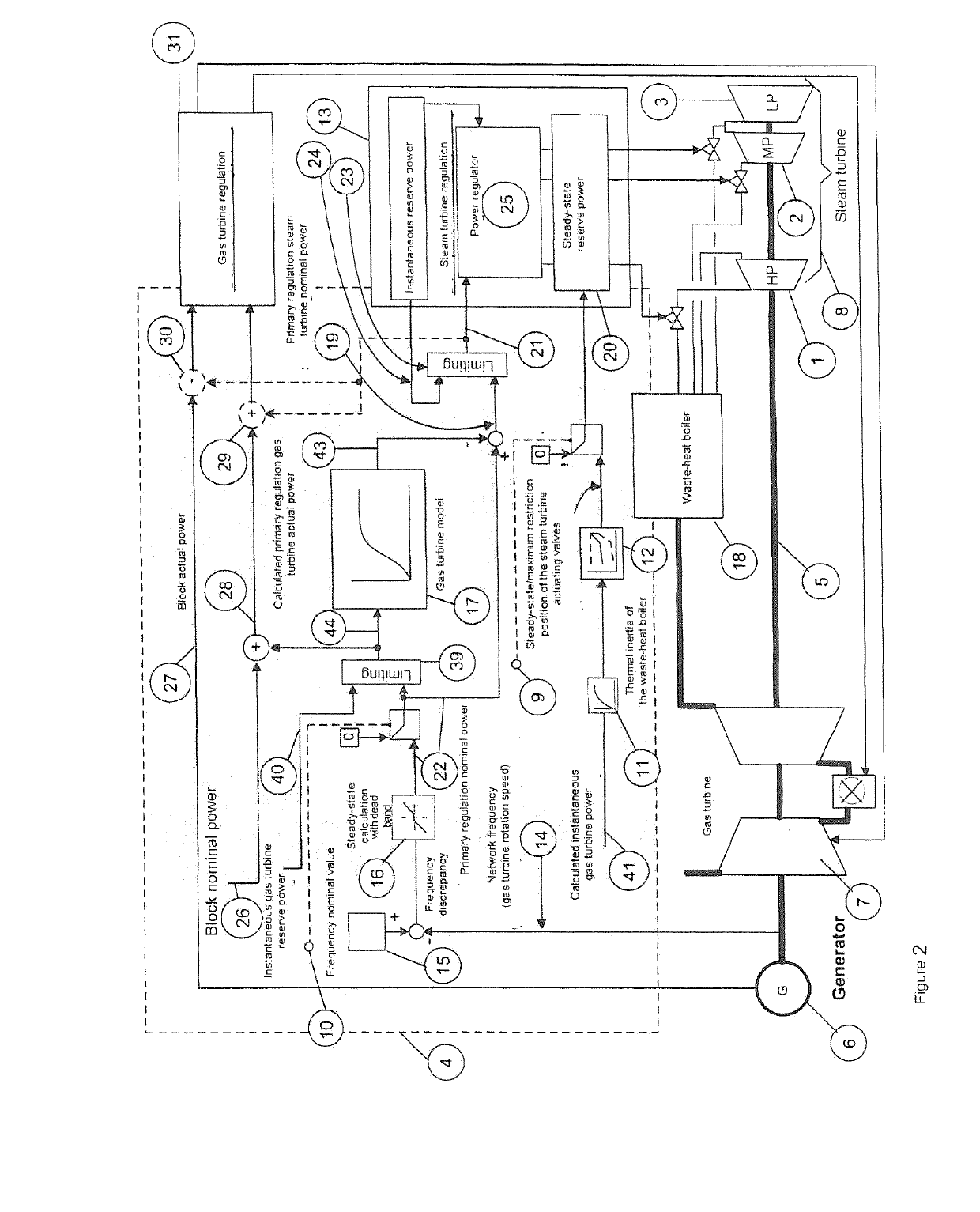

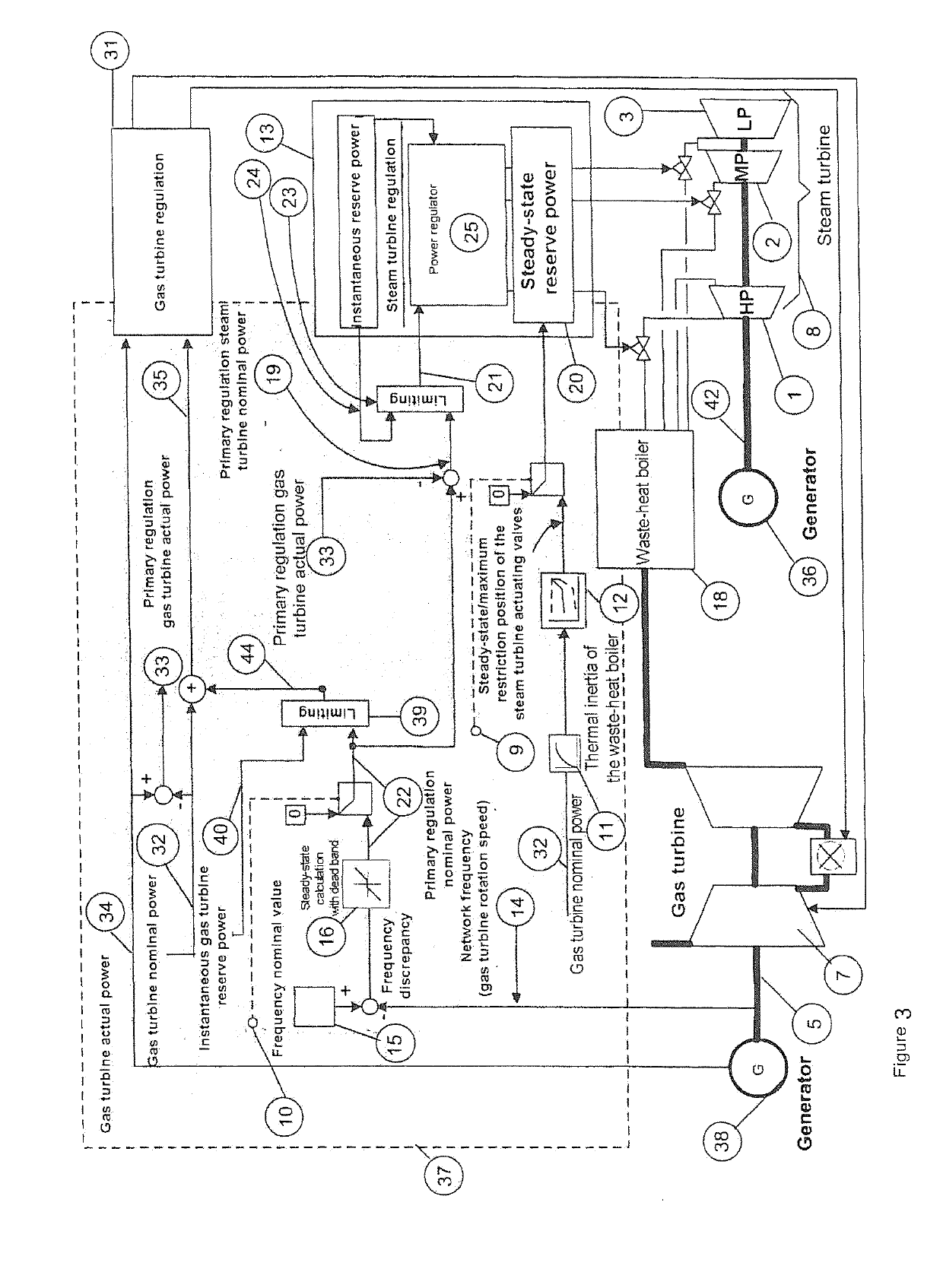

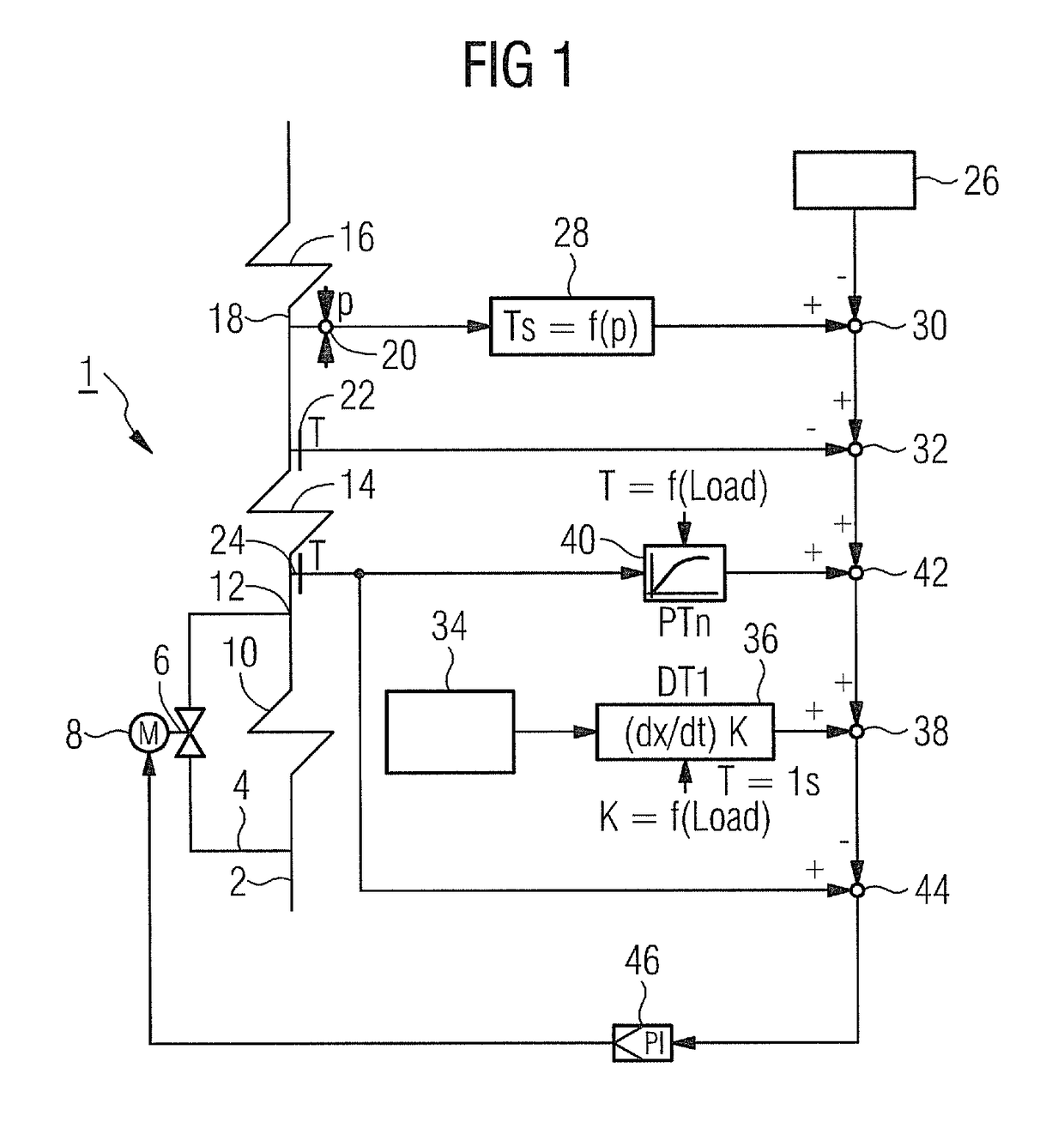

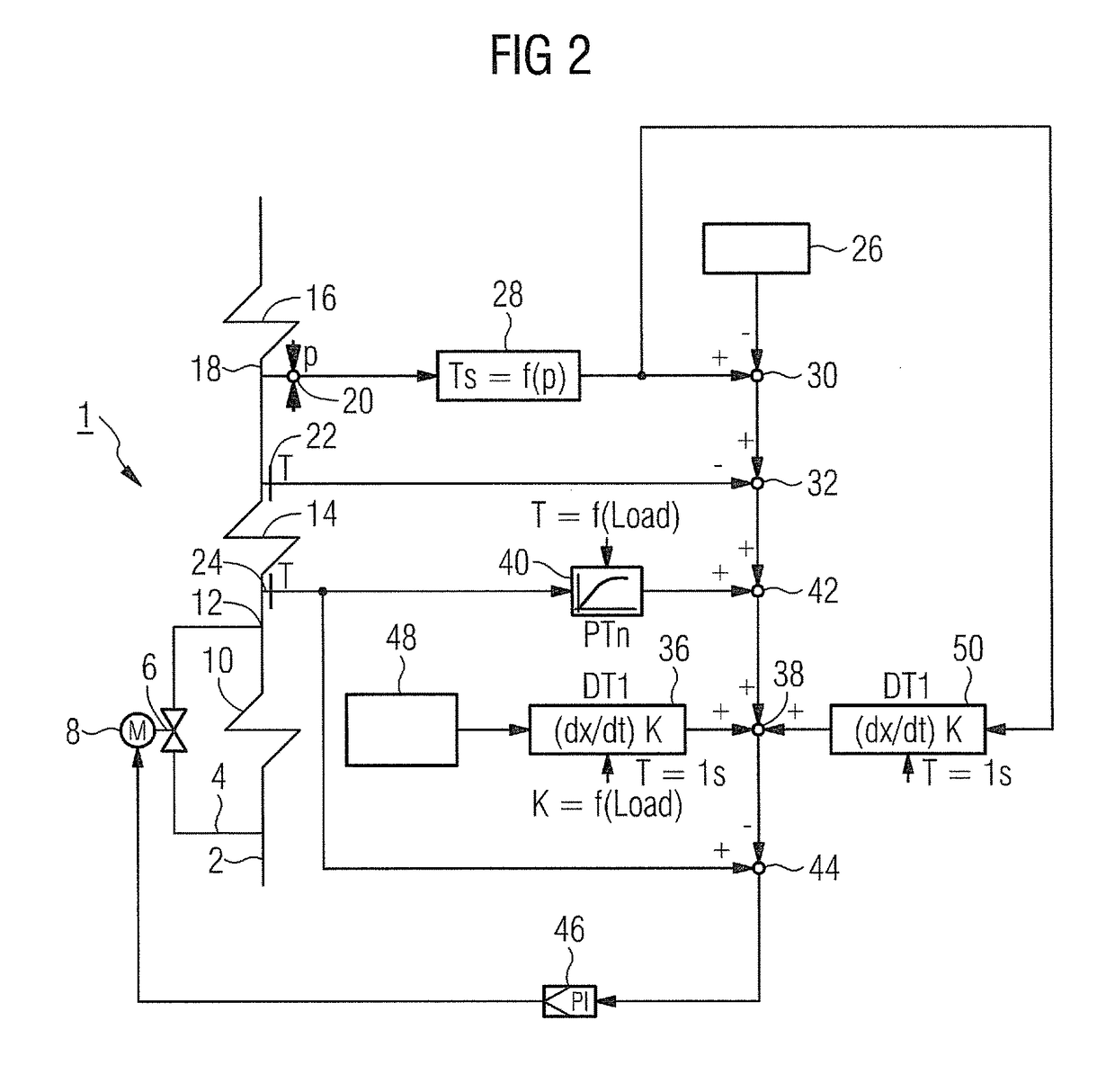

Method for primary control of a combined gas and steam turbine arrangement

ActiveUS20090320493A1Valve position is simplifiedSimple regulationGas turbine plantsEngine componentsGas turbinesVALVE PORT

A method for primary regulation of a combined gas and steam turbine installation in network operation, wherein the combined gas and steam turbine installation includes a gas turbine and a steam turbine arranged along at least one shaft includes operating at least one steam turbine actuating valve on a restricted basis along a working steam supply line to at least one pressure stage of the steam turbine so as to provide a steady-state steam turbine reserve power, wherein the at least one steam turbine actuating valve is changed to a less restricted state if a network frequency decreases so as to require network frequency support.

Owner:GENERAL ELECTRIC TECH GMBH

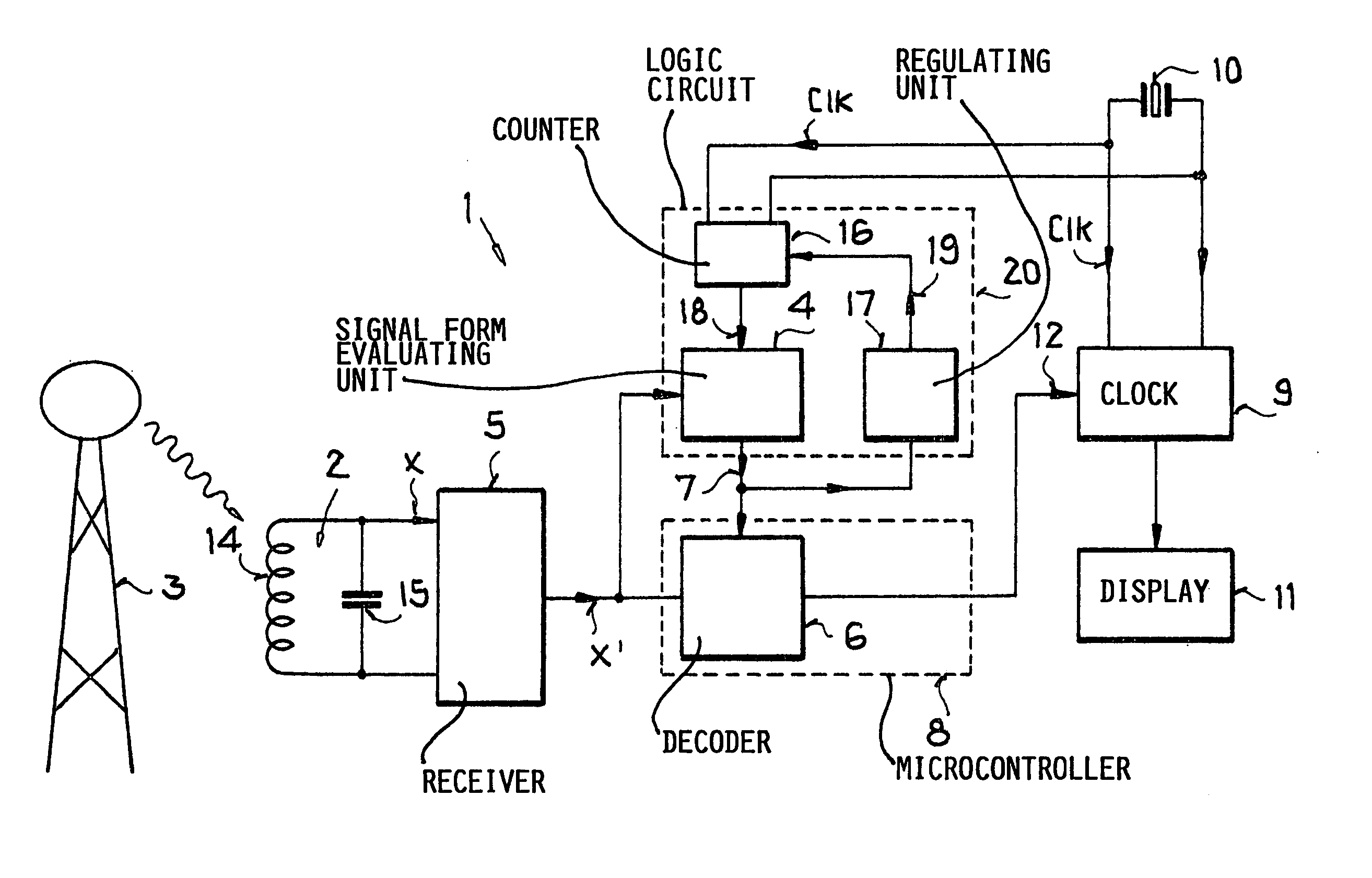

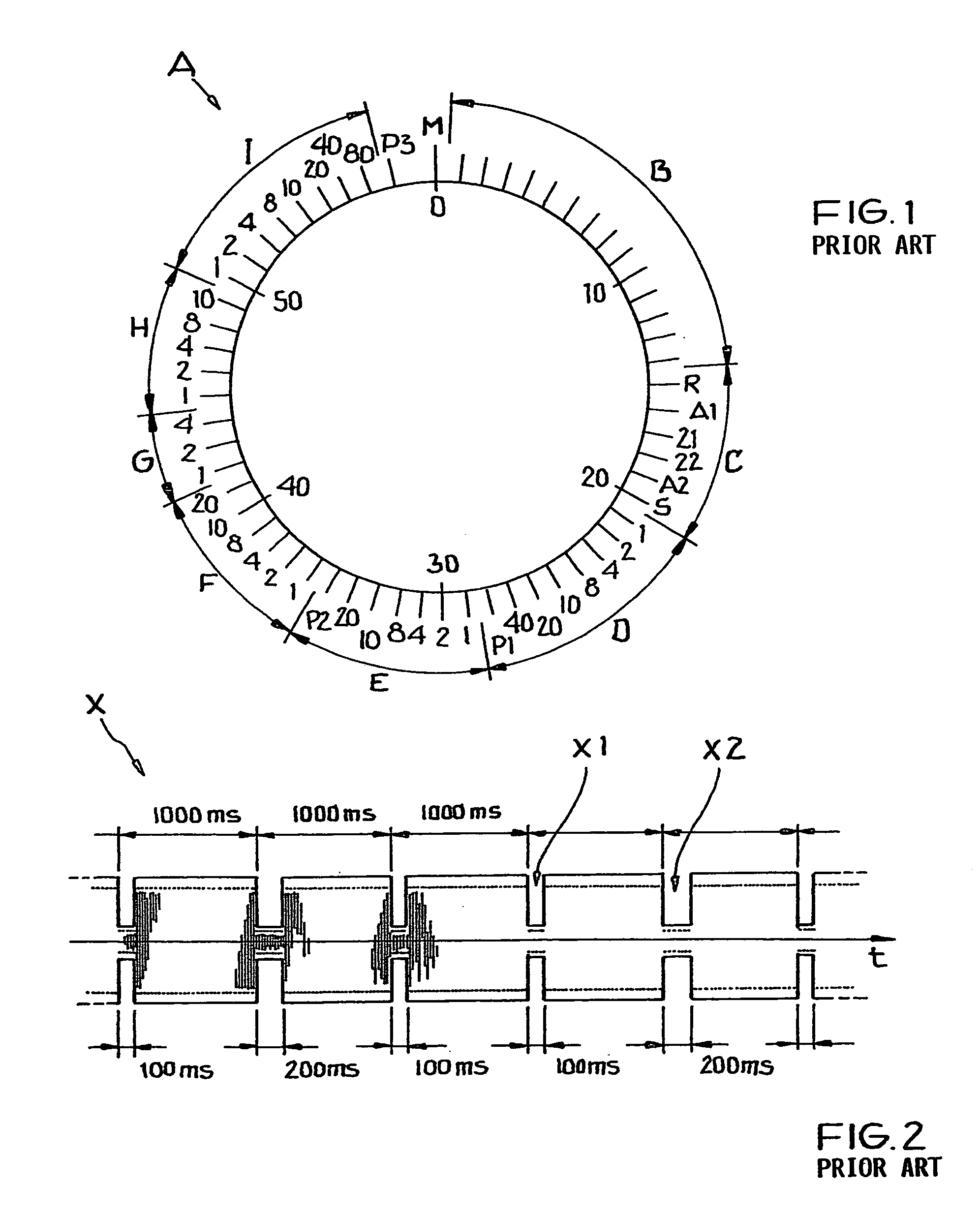

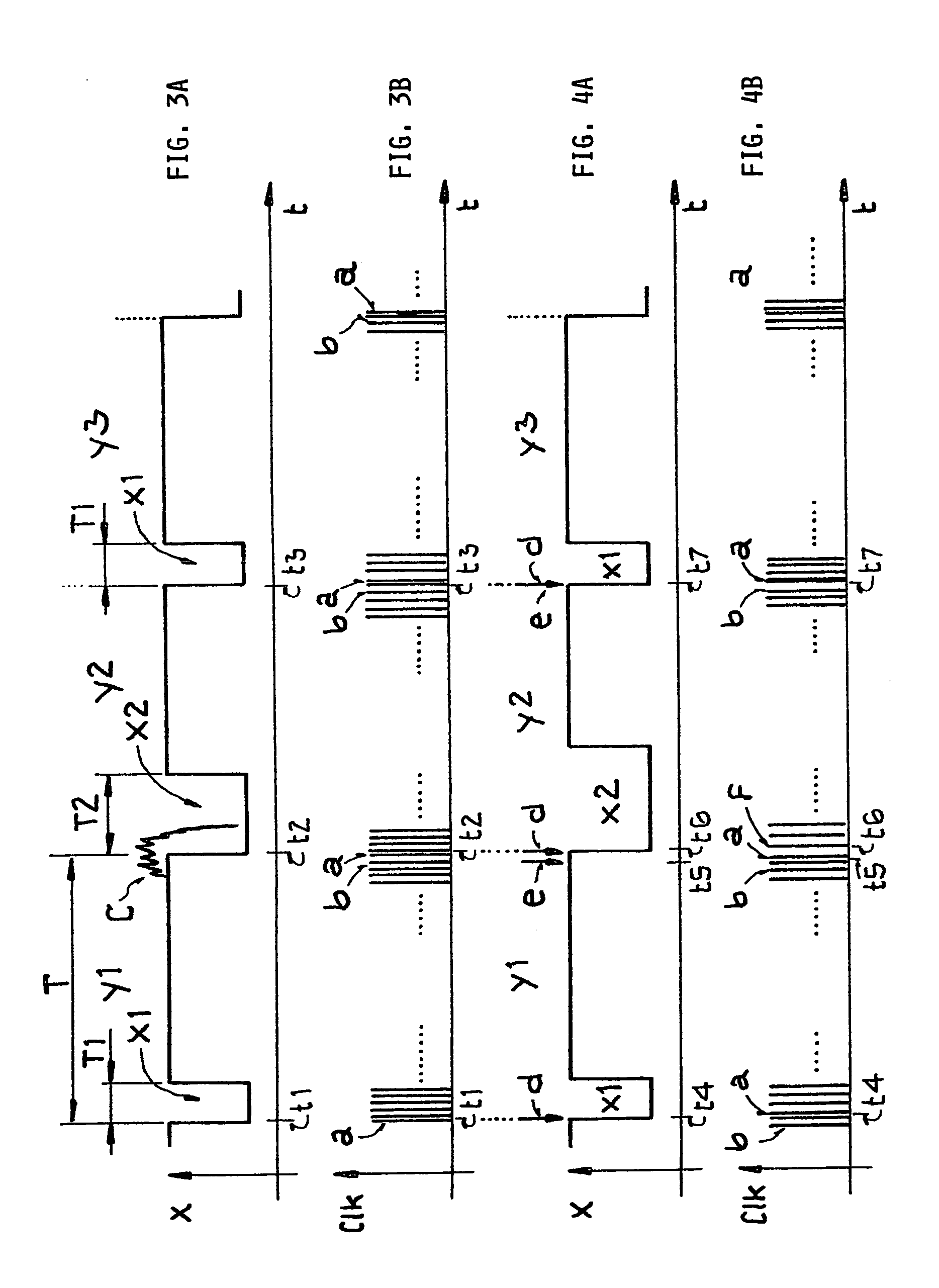

Radio-controlled clock and method for determining the beginning of a second from a transmitted time signal

InactiveUS20050147080A1Simple regulationConvenient ArrangementTime-division multiplexCircuit switching systemsTime informationComputer science

A transmitted time signal carries encoded time information in a succession of time frames of constant duration. An amplitude variation of the time signal indicates the beginning of a second within a time frame, but may be obscured by interference. Once an actual second beginning is known, e.g. unambiguously detected without interference, then a counter counts up a prescribed number of timing pulses of a reference clock signal to calculate the next expected second beginning of the next time frame. If the next actual second beginning is obscured by interference, then the calculated second beginning is used, otherwise the next actual second beginning can be used, in the decoding and evaluation of the time information. The counter is reset and counts up to calculate the successive next expected second beginning. A circuit for performing this method includes a signal form evaluating unit, a counter, a regulating unit and a reference clock signal generator.

Owner:ATMEL GERMANY +1

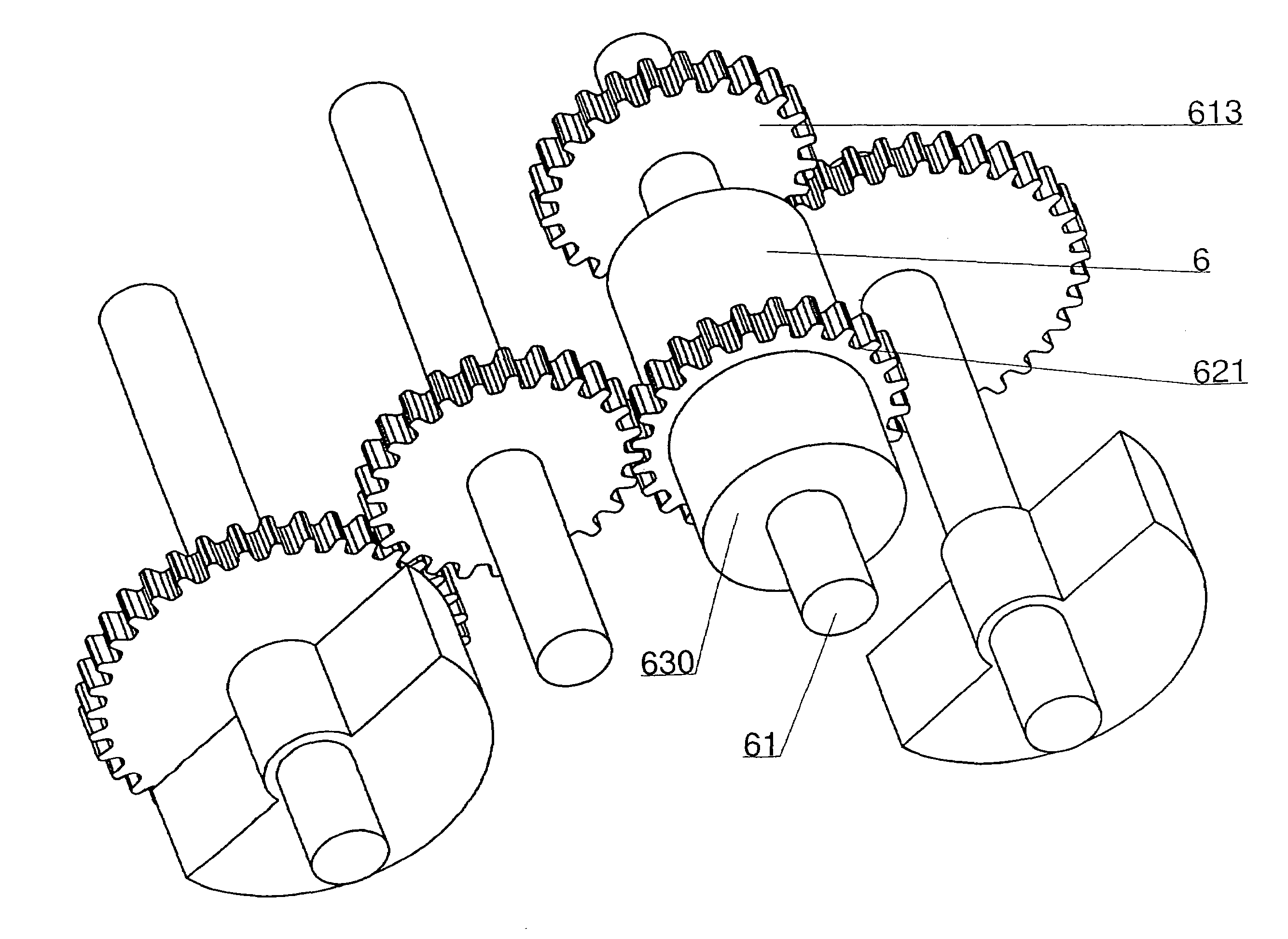

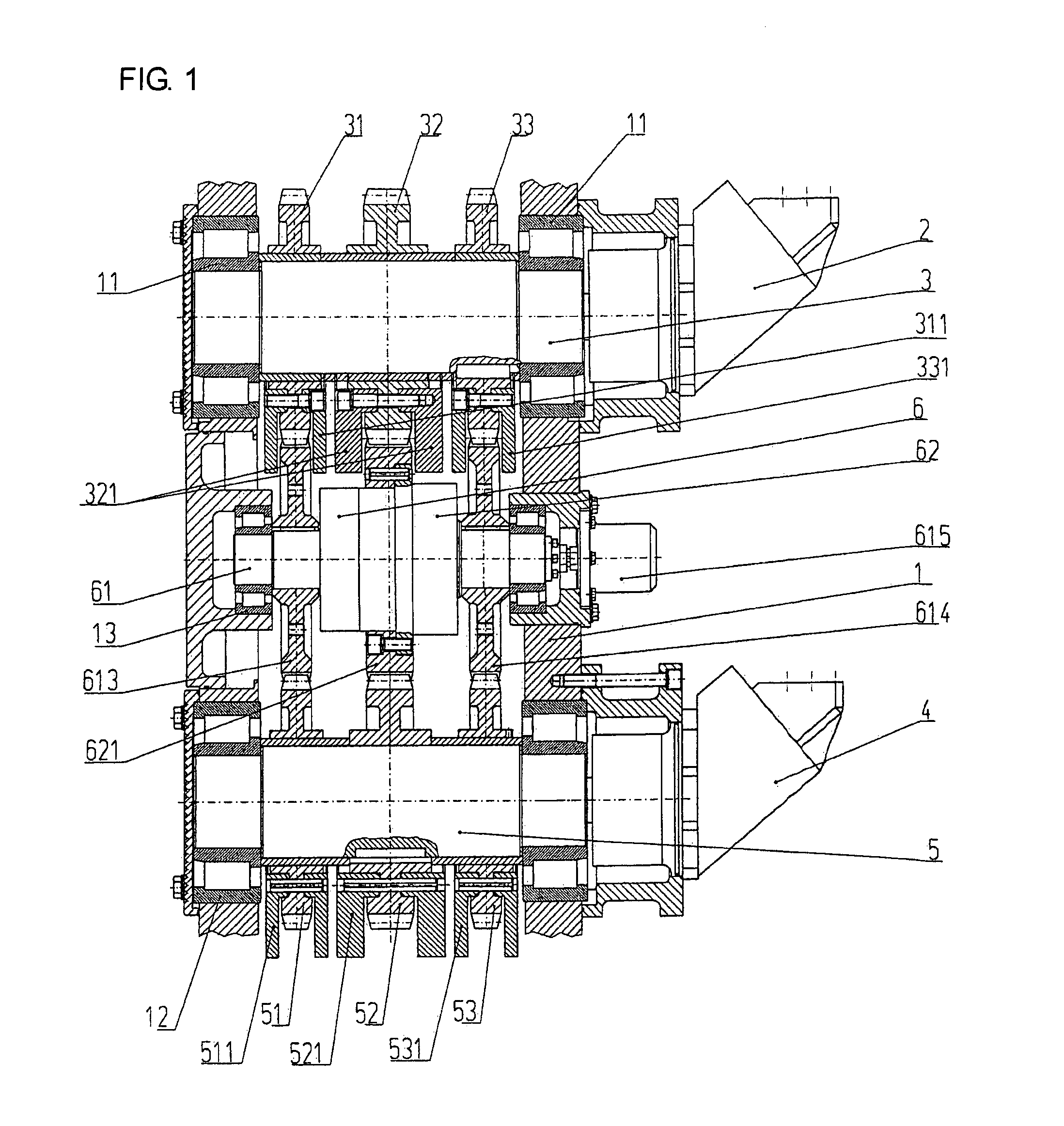

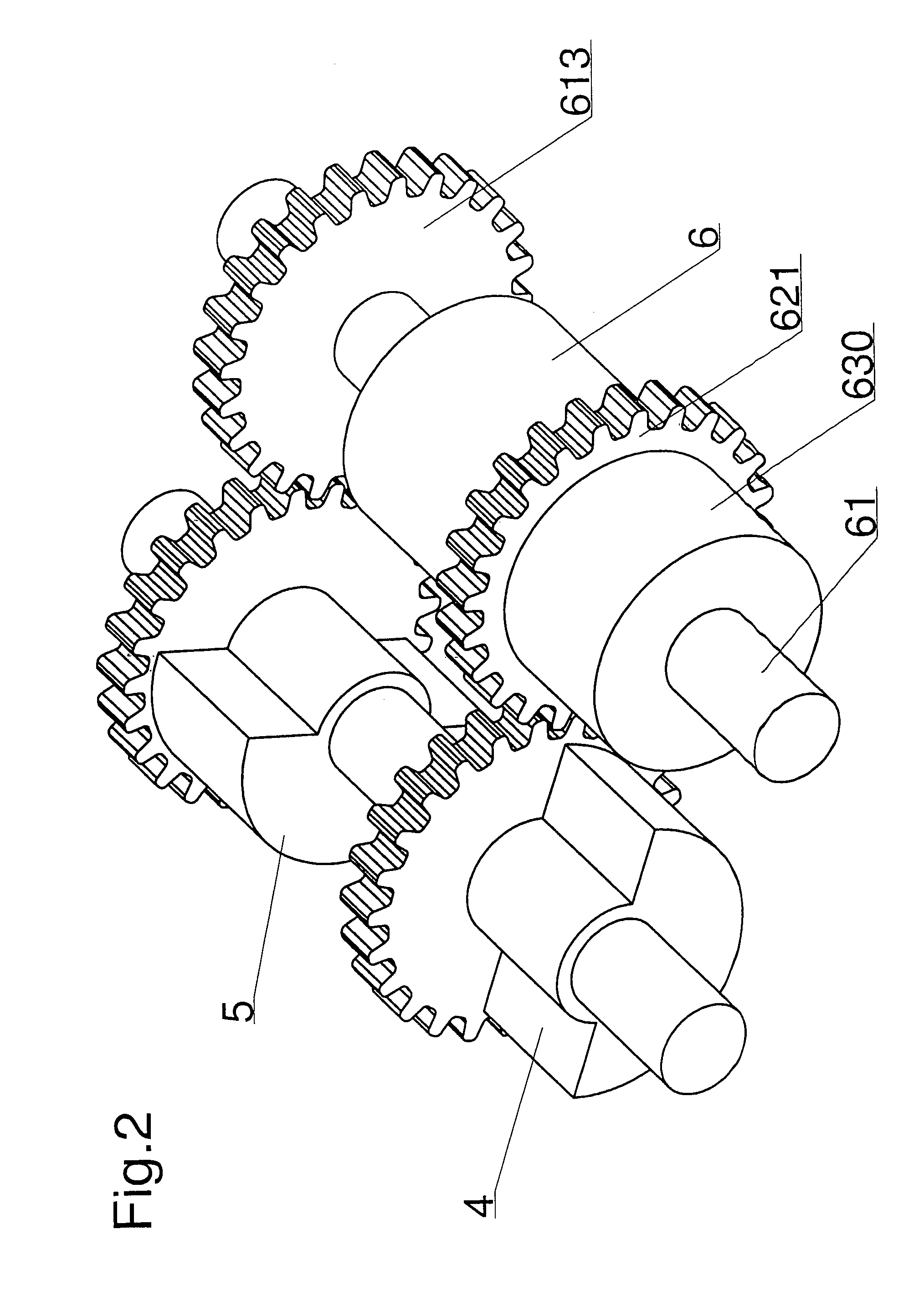

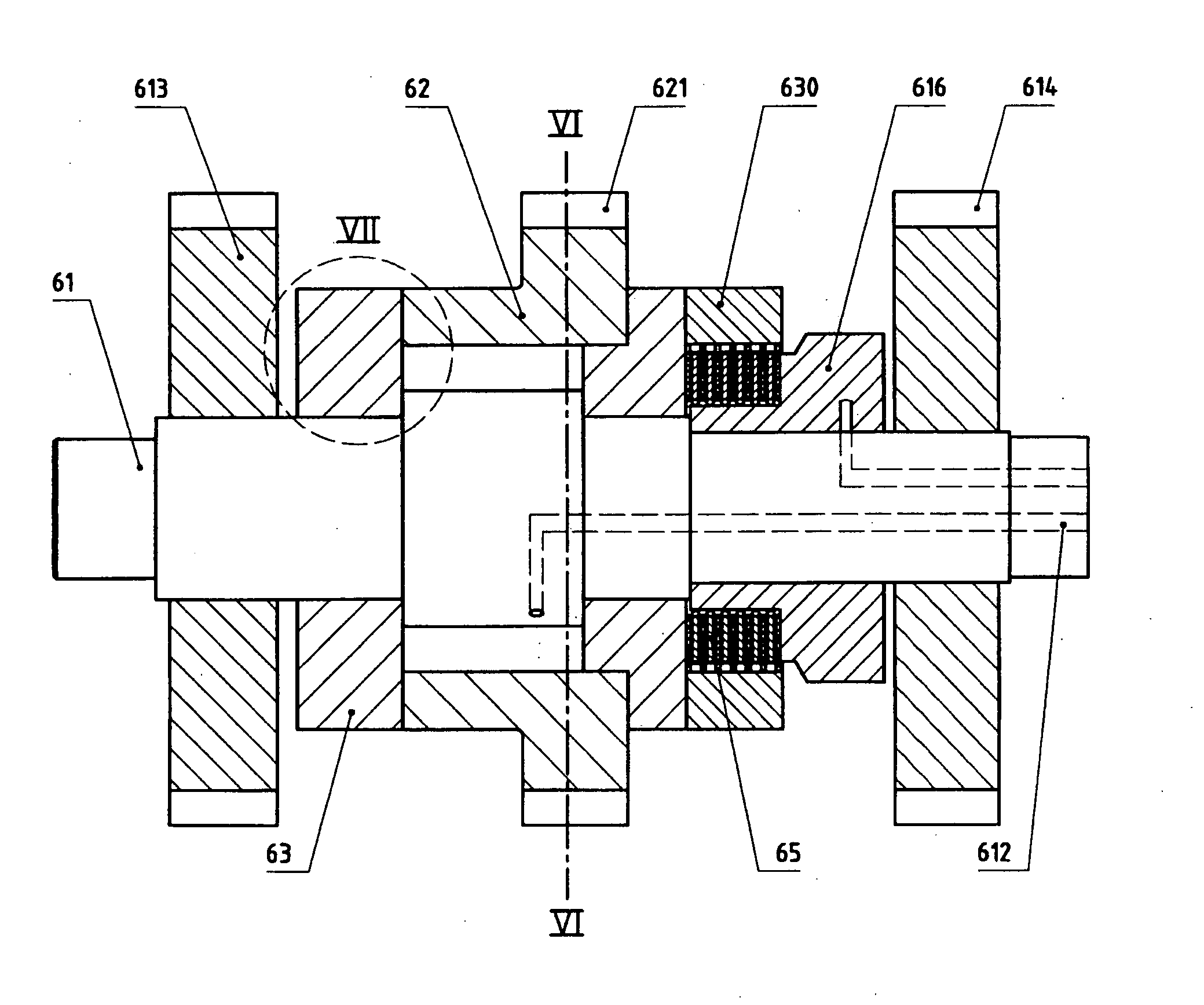

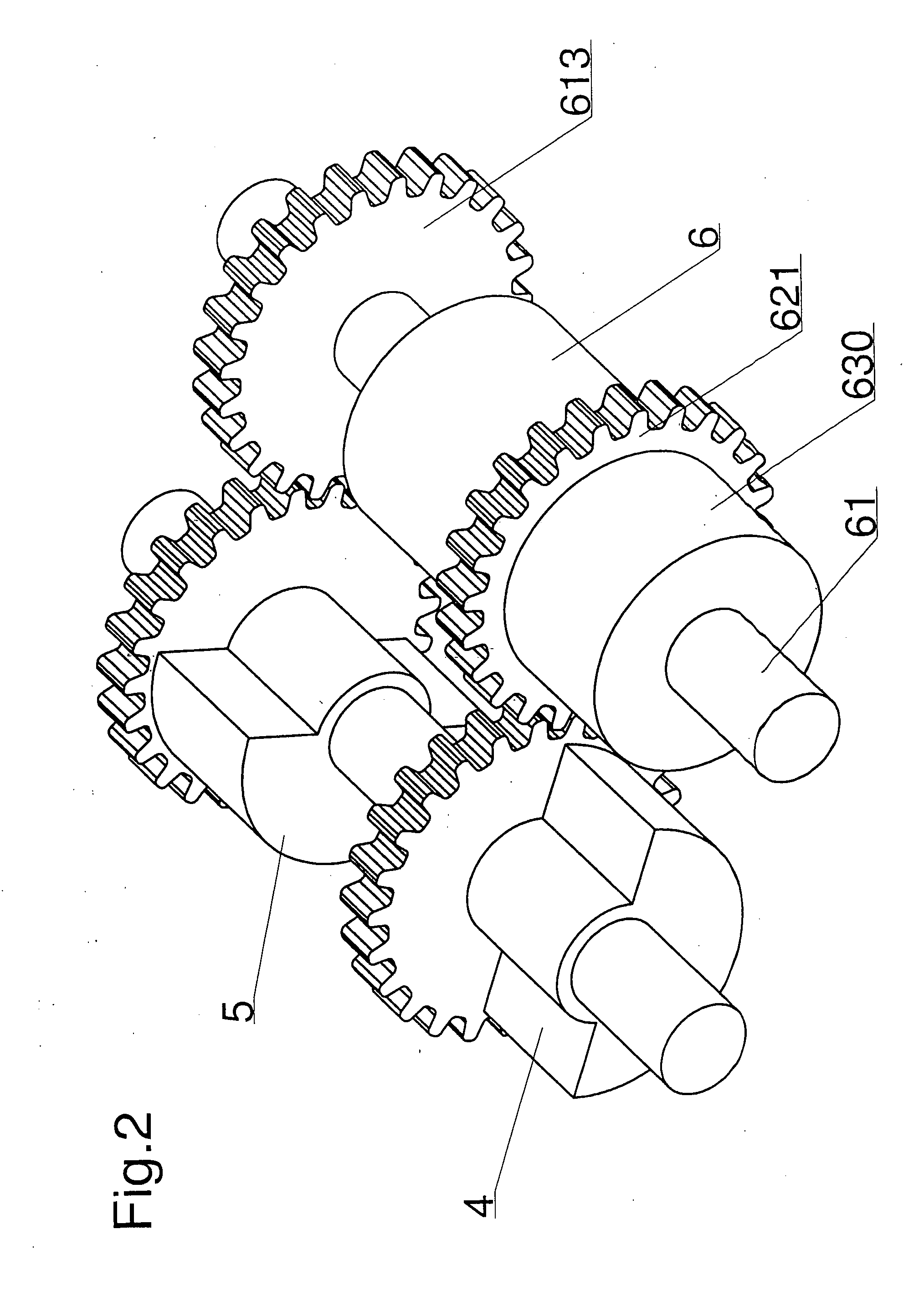

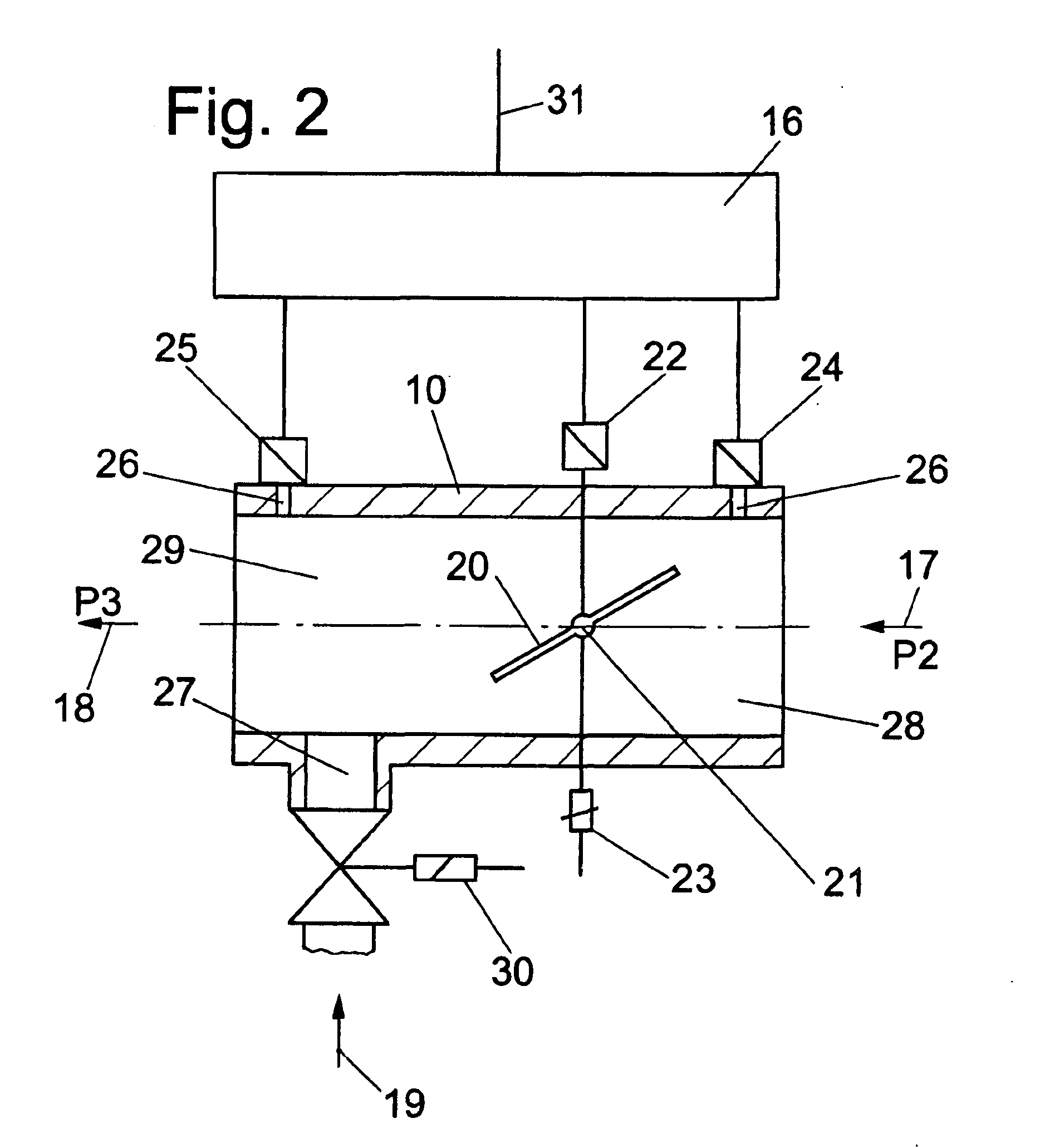

Vibration exciter

InactiveUS7598640B2Effective vibrationCompact structureGearingMechanical vibrations separationEngineeringVibration exciter

A vibration exciter has at least two axles disposed parallel to one another, as well as at least two imbalance masses, which are attached to one or more of the axles. The relative rotary position of the imbalance masses can be adjusted relative to one another by a rotary oscillating motor having a rotor shaft and a stator housing. The rotor shaft is an integral part of one of the axles, and the rotary position of the stator housing relative to the rotor shaft can be changed. The stator housing can be locked to the rotor shaft. The oscillating motor has a rotor shaft and a stator housing, between which working chambers are formed. The stator housing can rotate about the rotor shaft and can be locked relative to the rotor shaft.

Owner:ABI +1

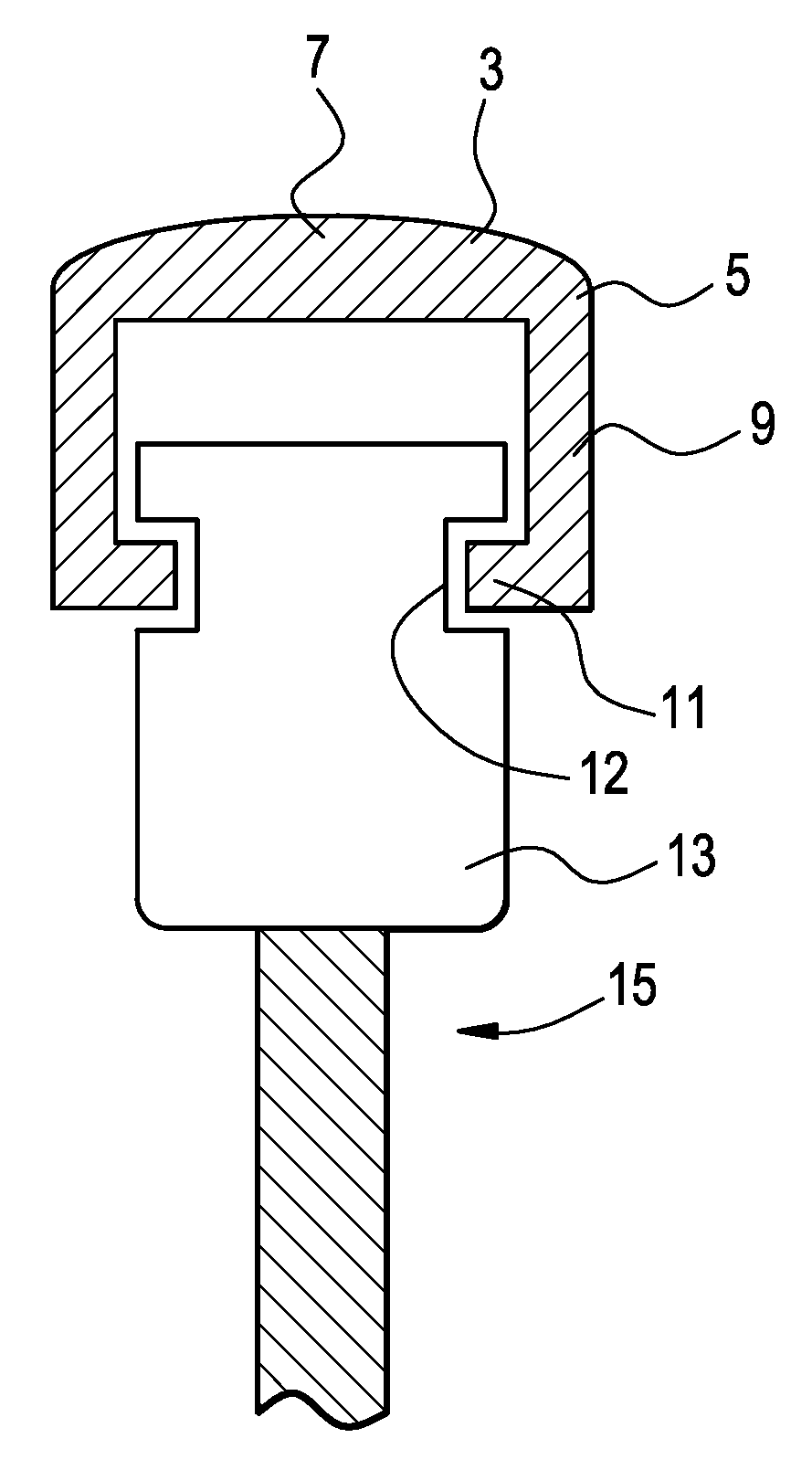

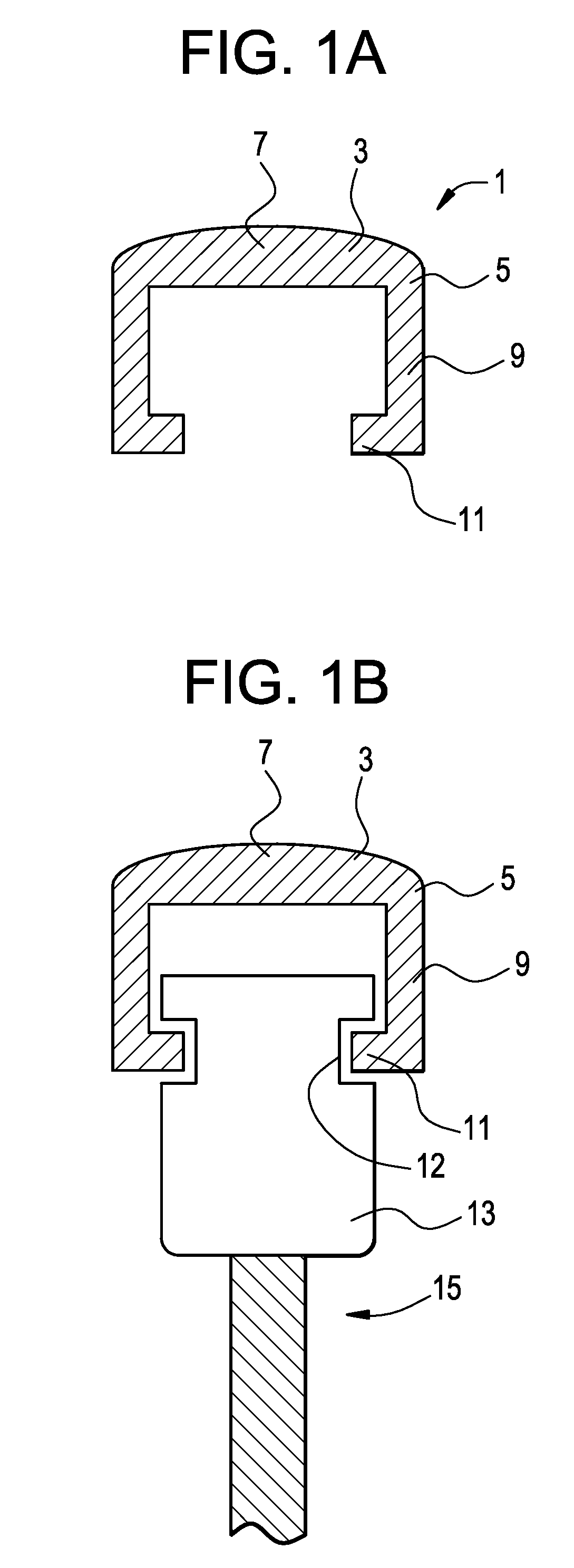

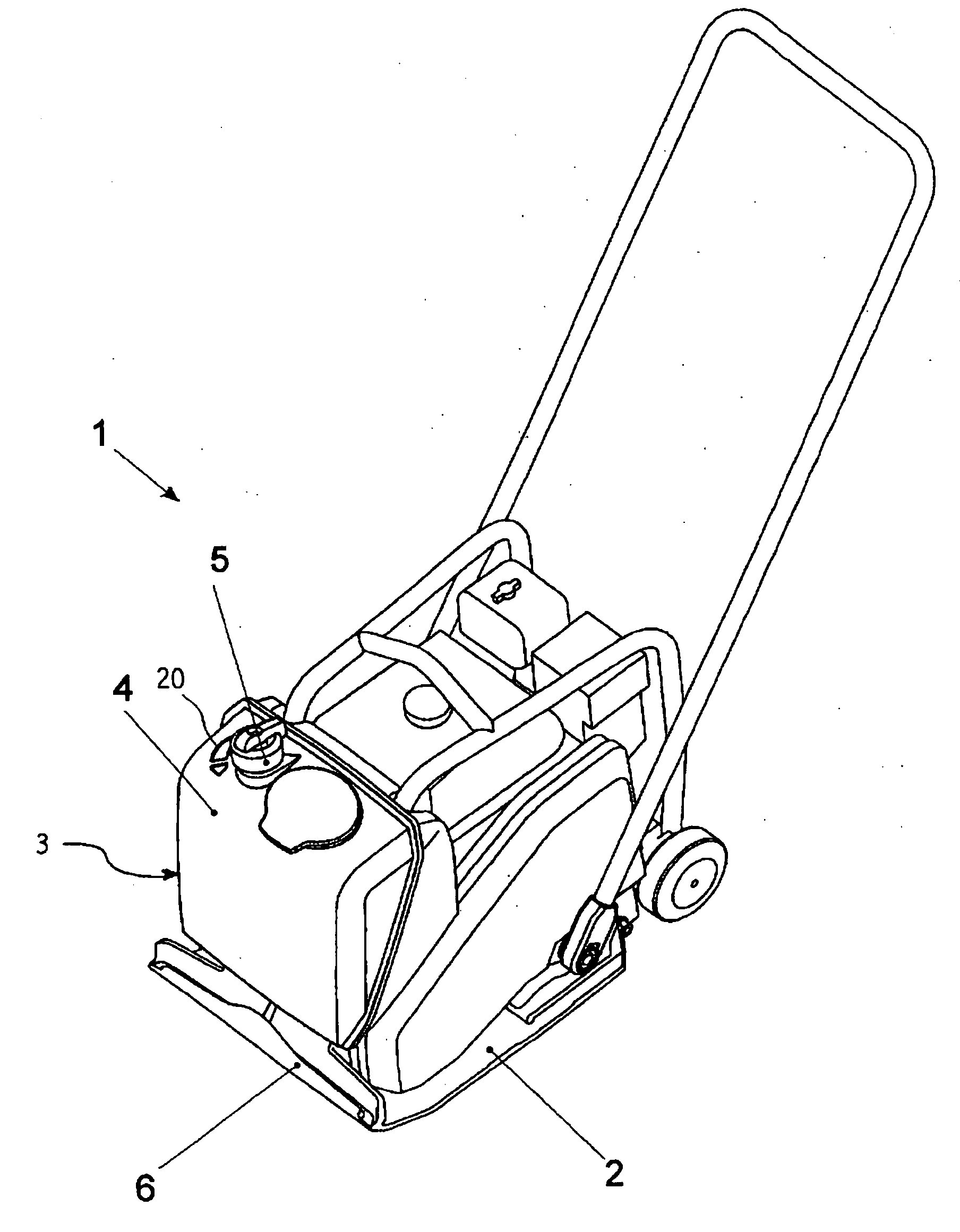

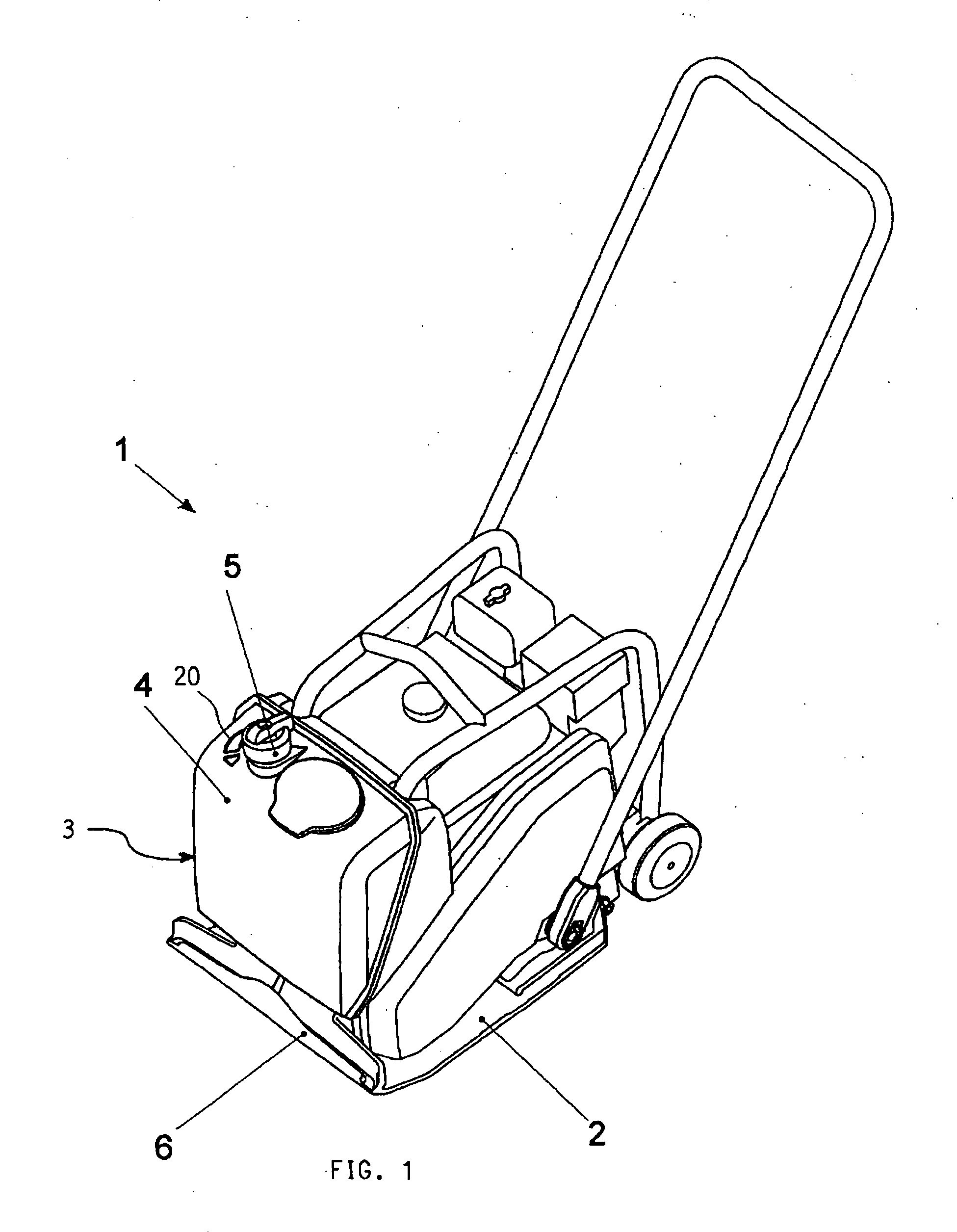

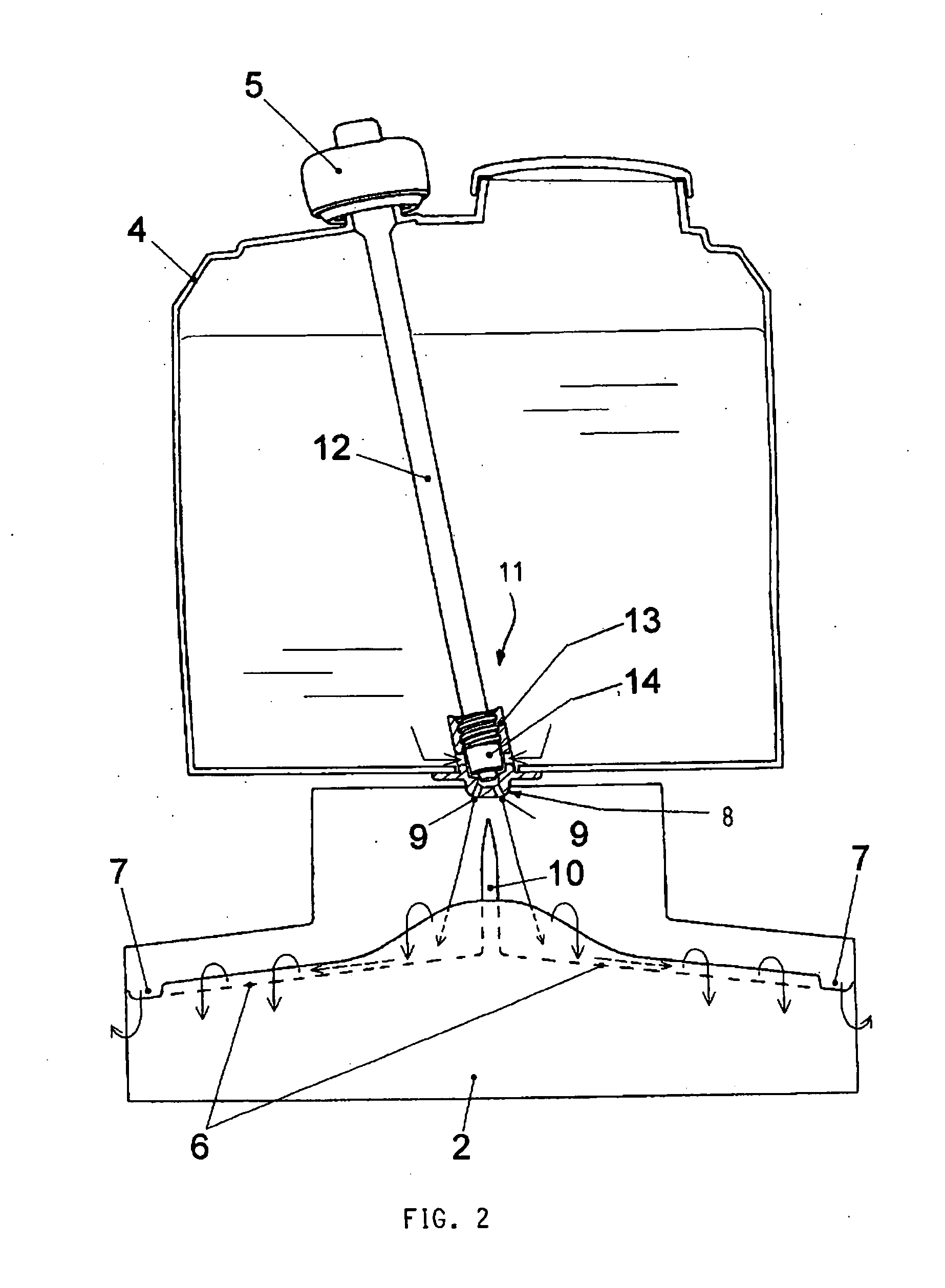

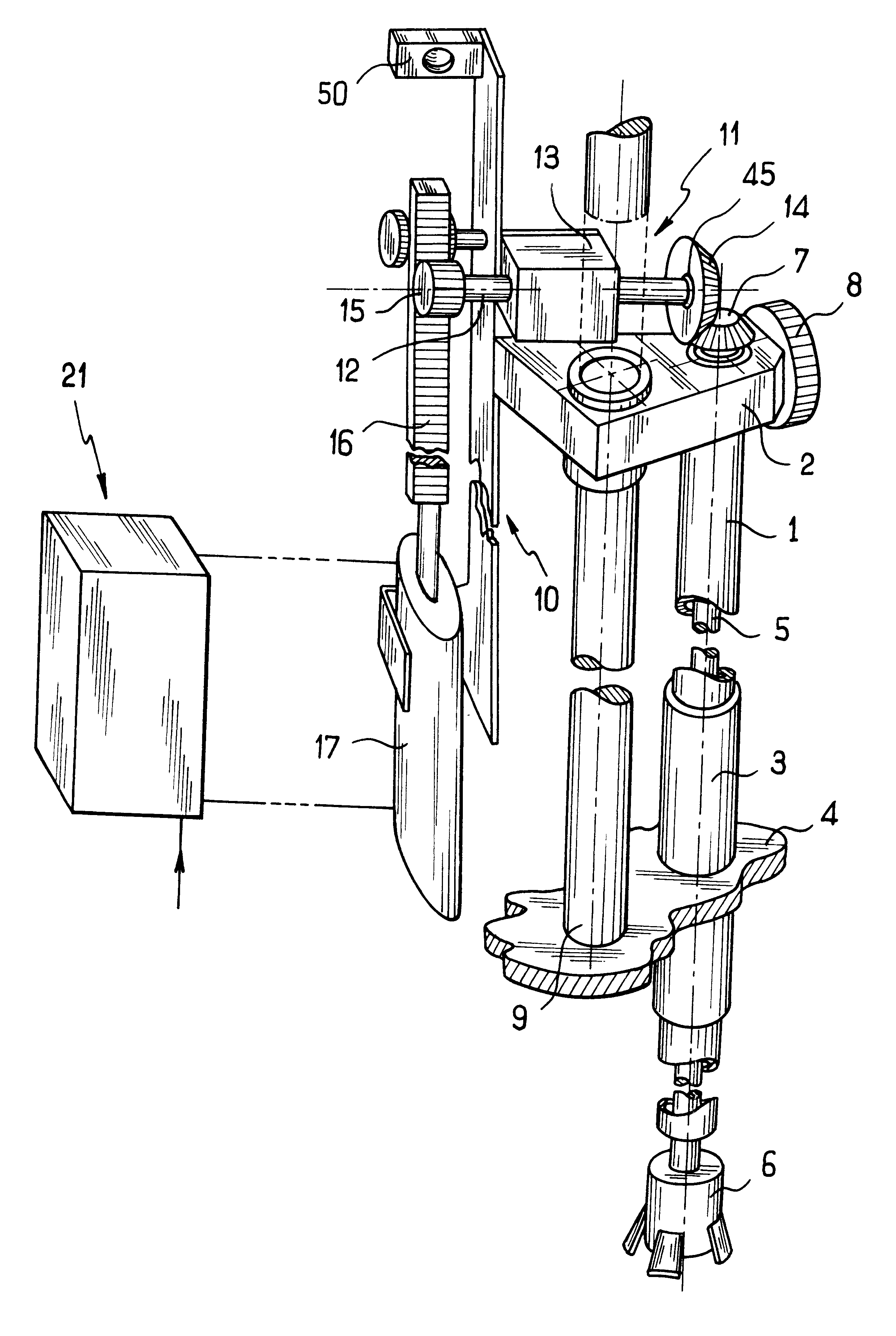

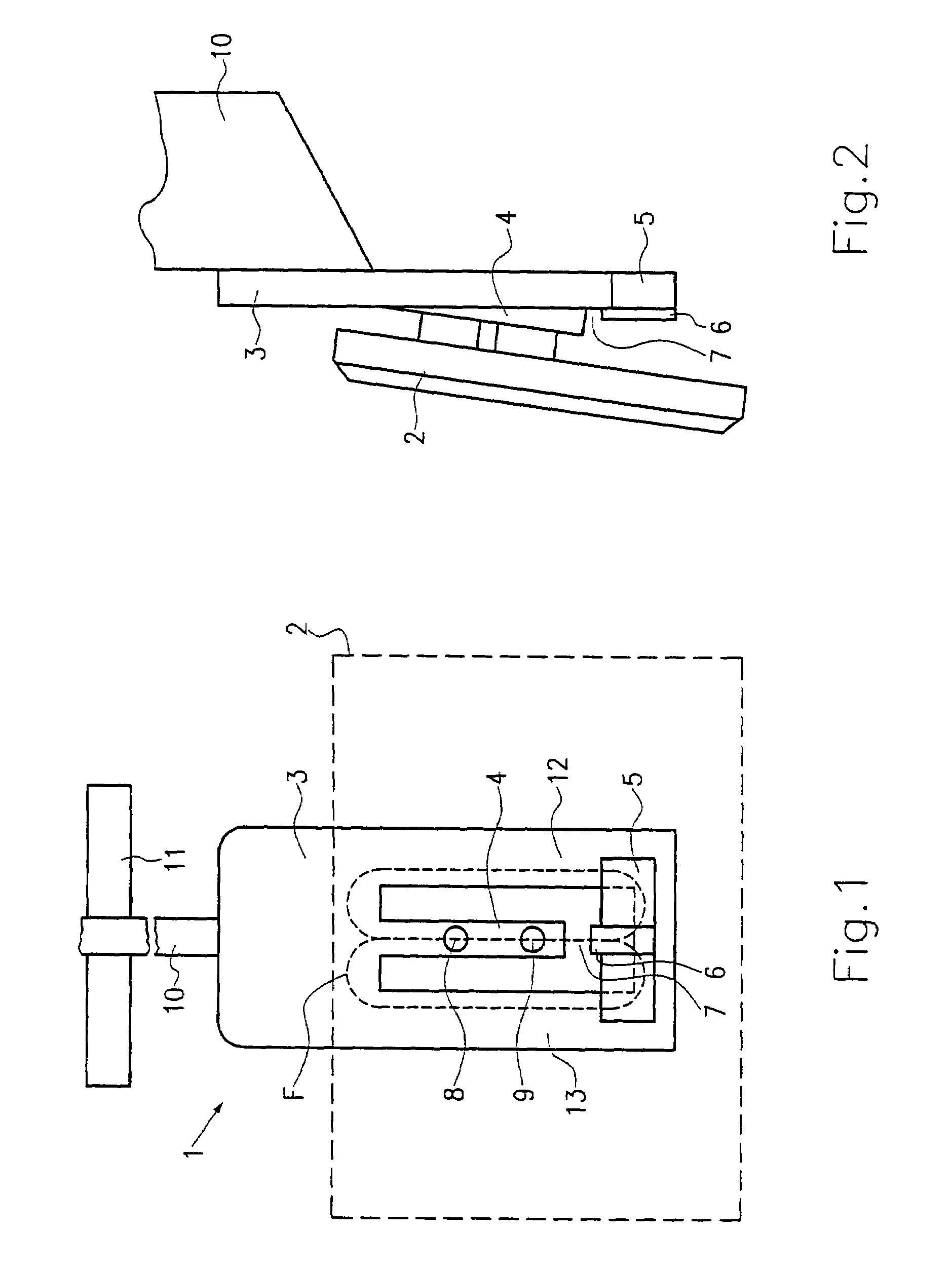

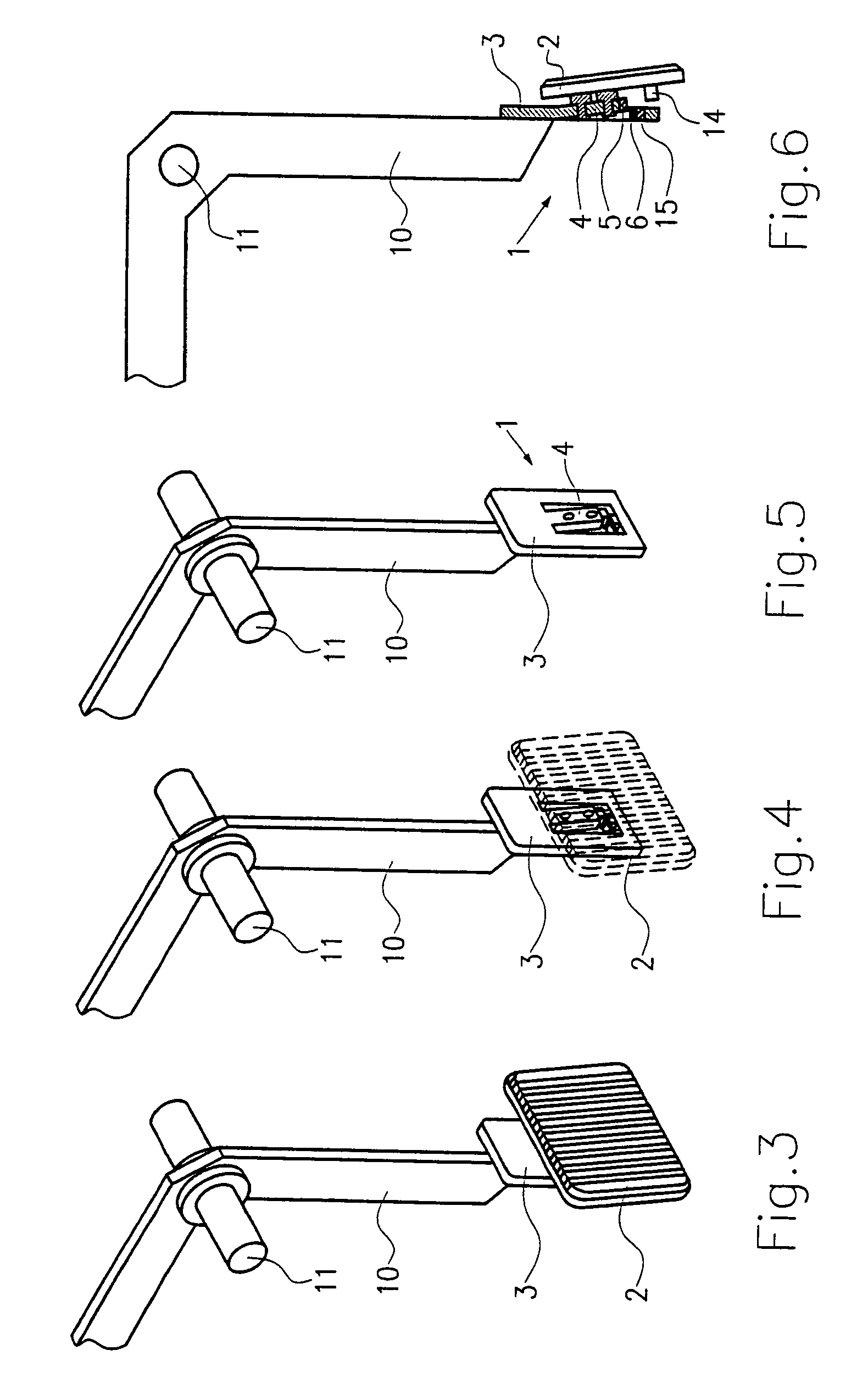

Vibratory plate

ActiveUS20080003058A1Easy to reachRisk minimizationSpray nozzlesRoads maintainenceEngineeringFront edge

A vibratory plate includes a sprinkler device (3) for wetting the underside of a base plate (2) of the vibratory plate (1). The vibratory plate also includes a water tank (4) and the sprinkler device (3) has an outlet (8) for passing the water, a valve (11) to control the release of water and a knob (5) for the operation of the valve. A channel (6) guides the released water and is arranged along the front edge of the base plate (2). The channel (6) is arranged with descending inclinations along and from the middle of its length and to both side edges of the base plate (2). The outlet (8) is only arranged for the release of water to the middle of the channel (6).

Owner:HUSQVARNA AB

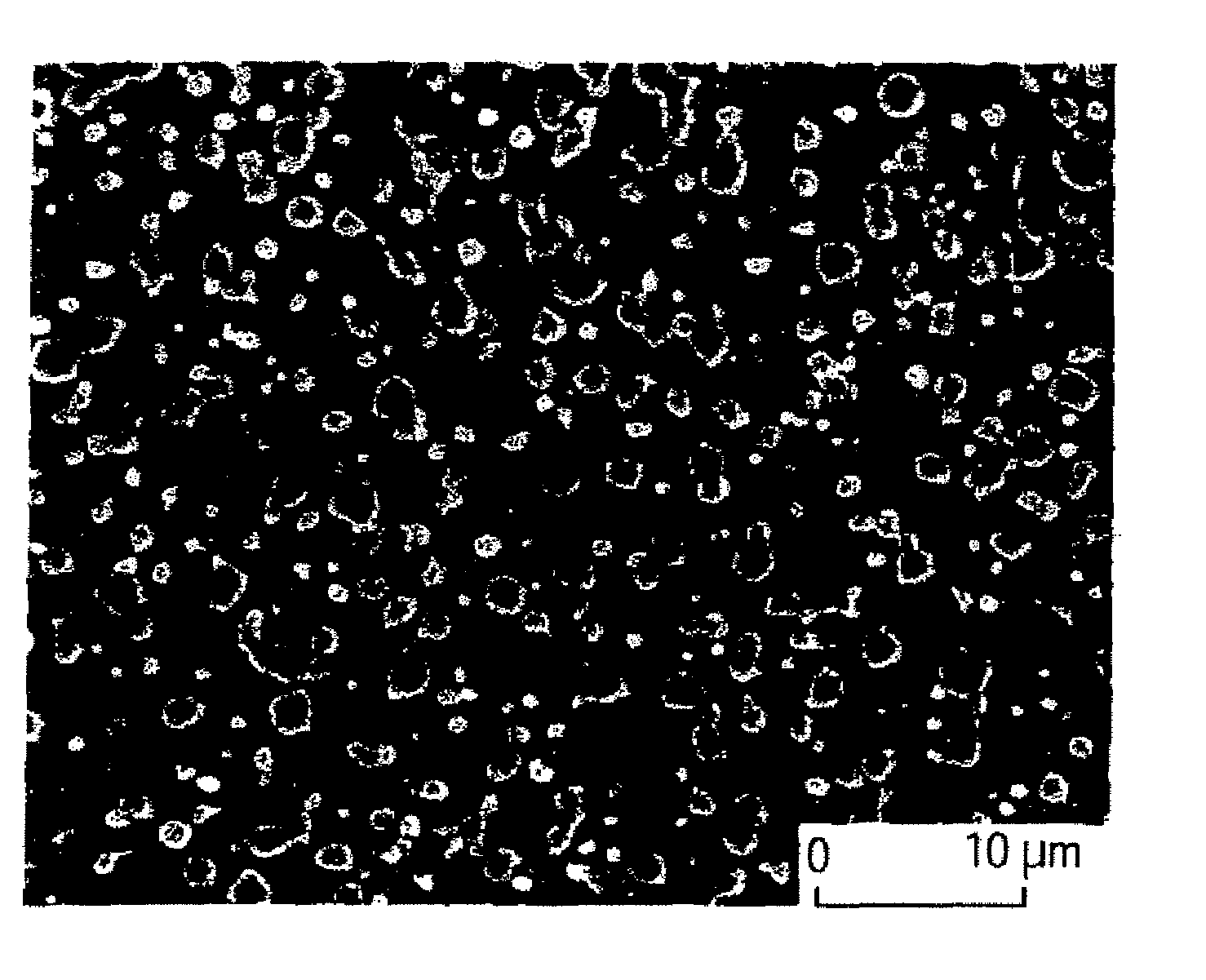

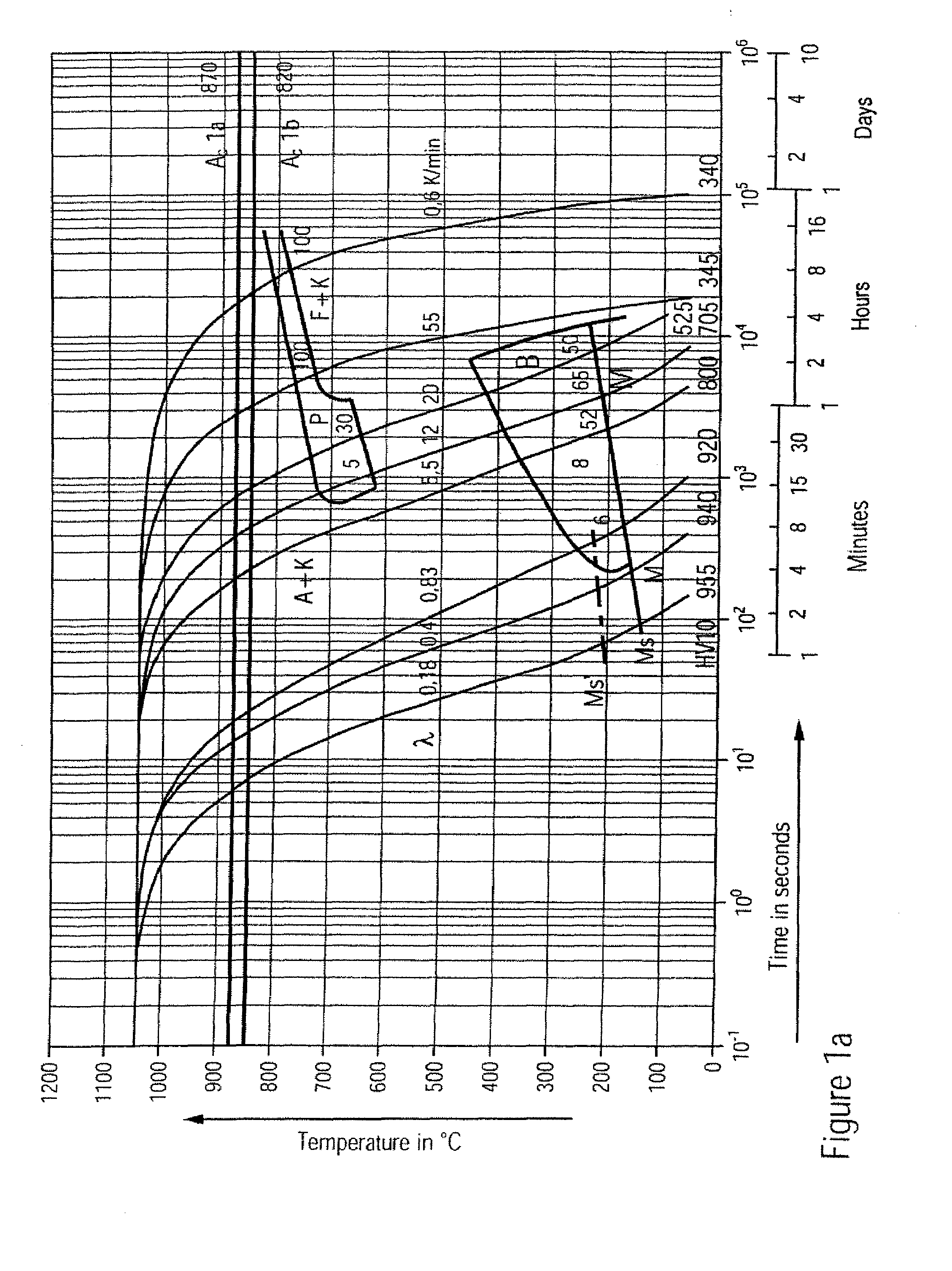

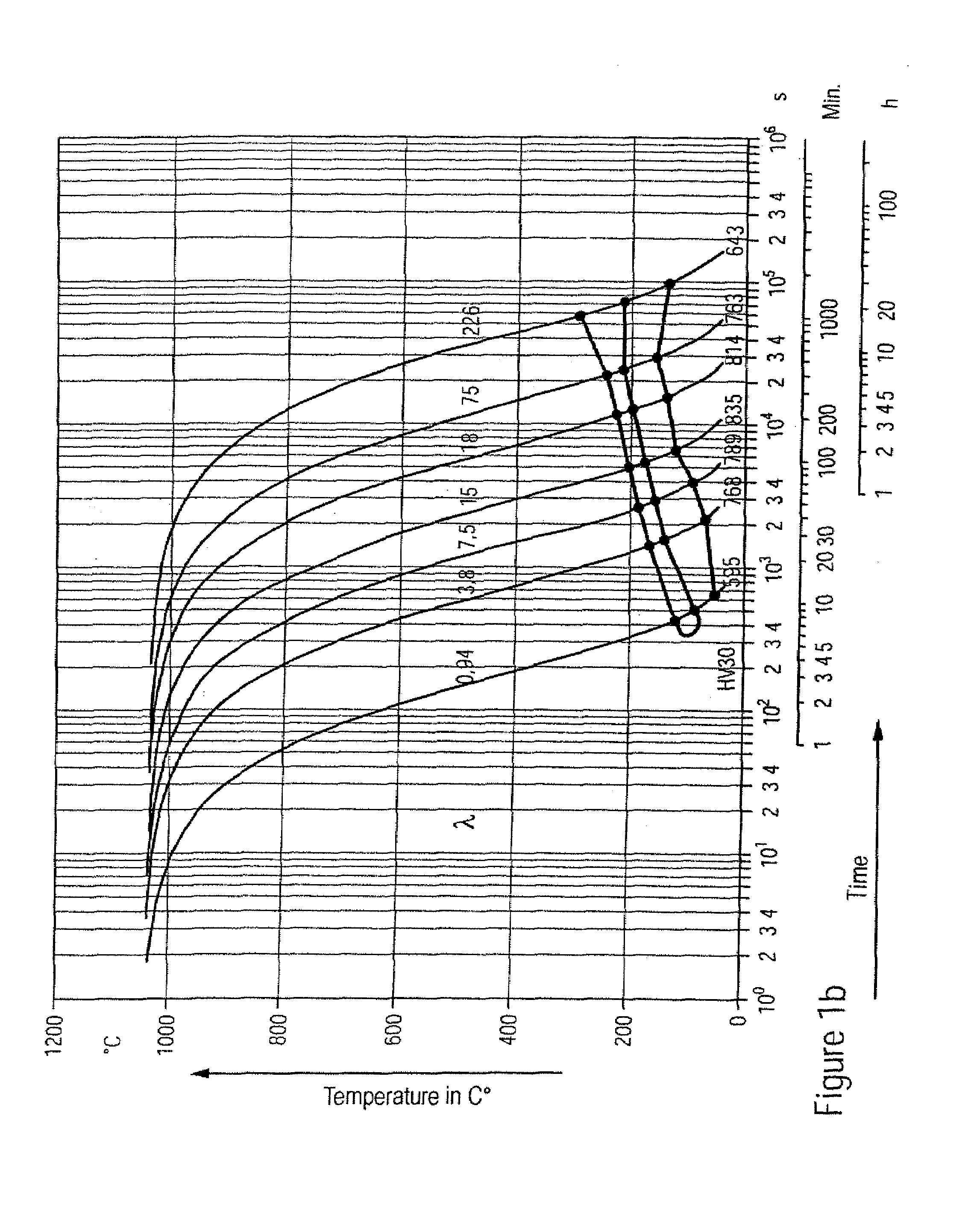

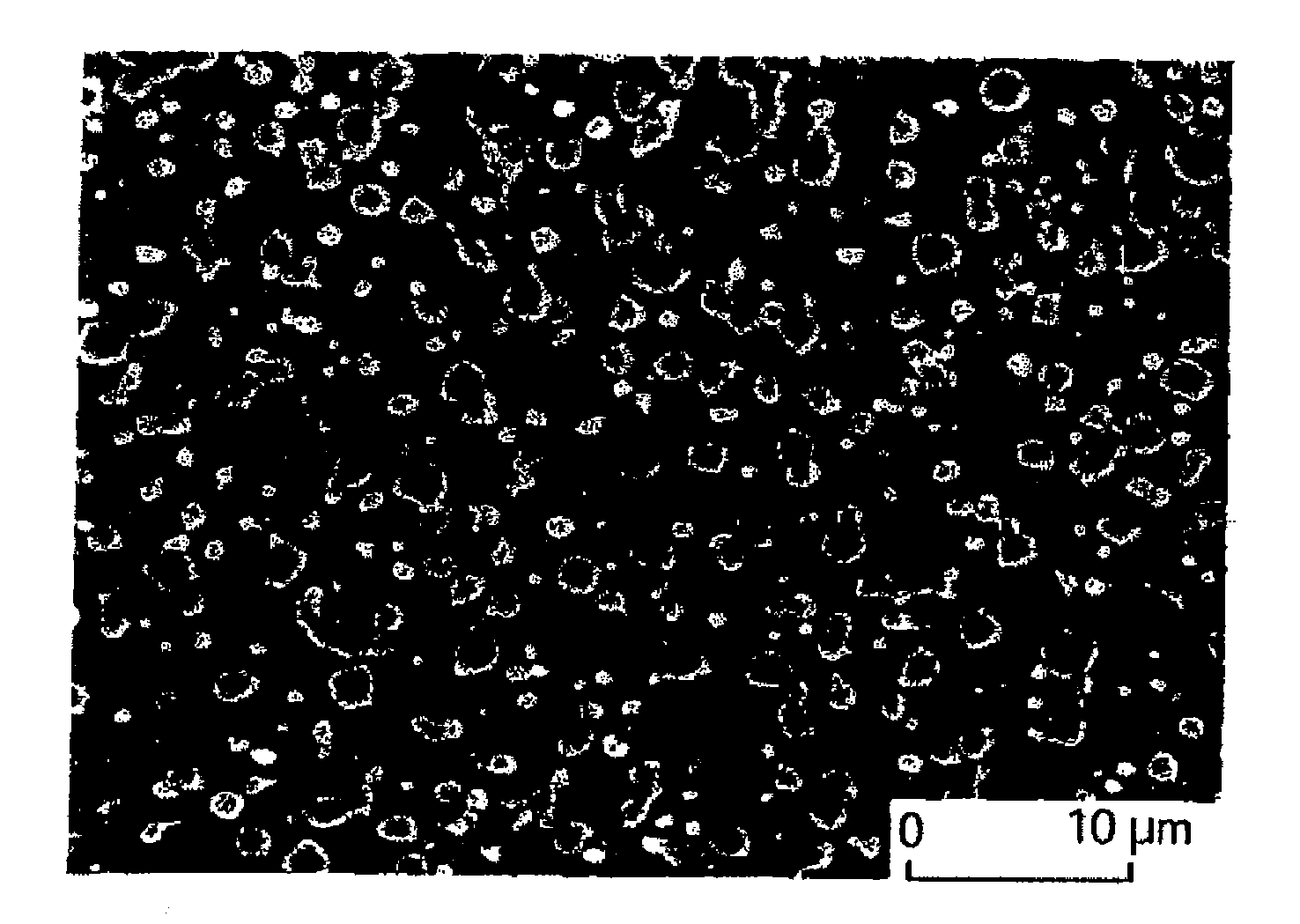

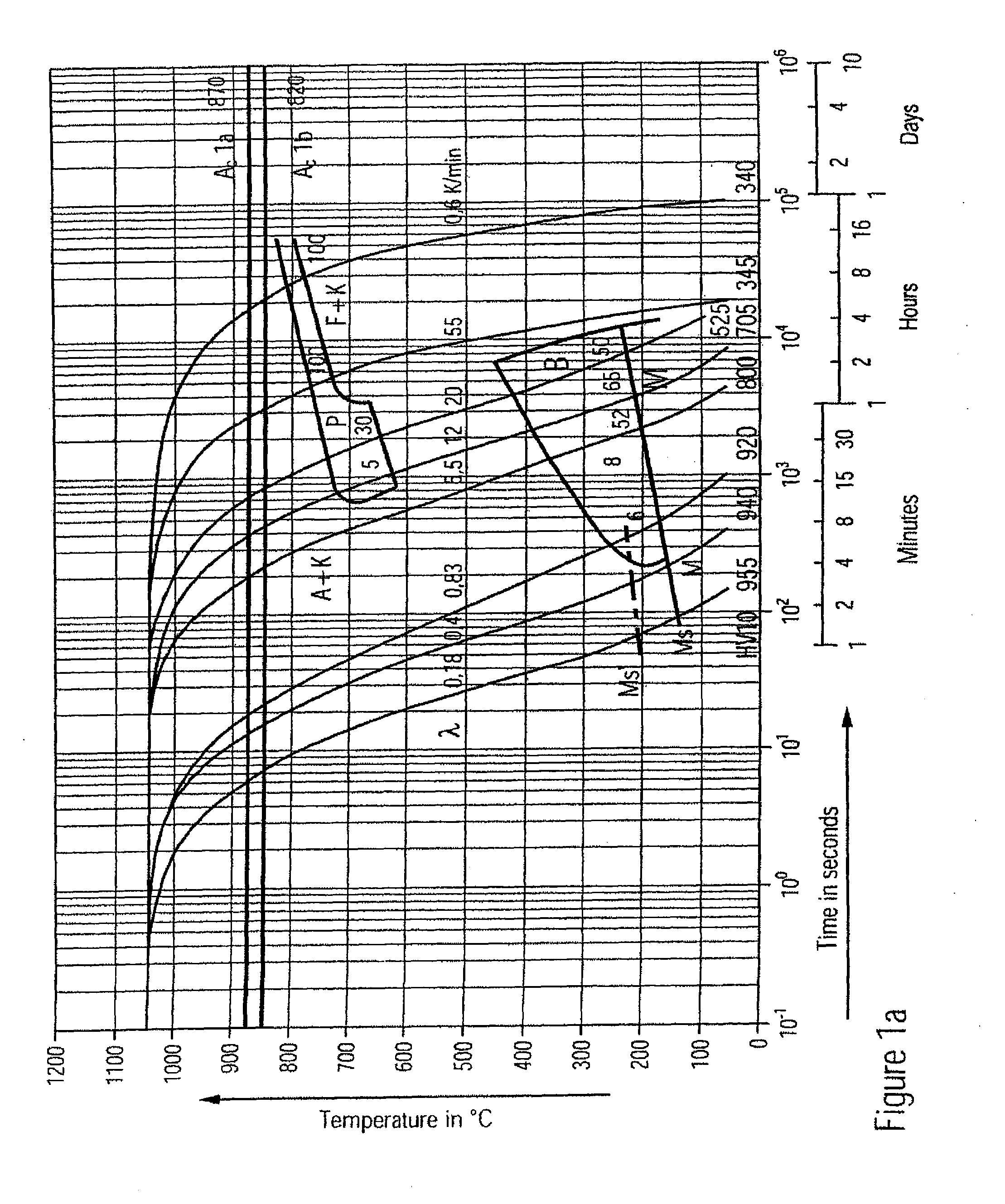

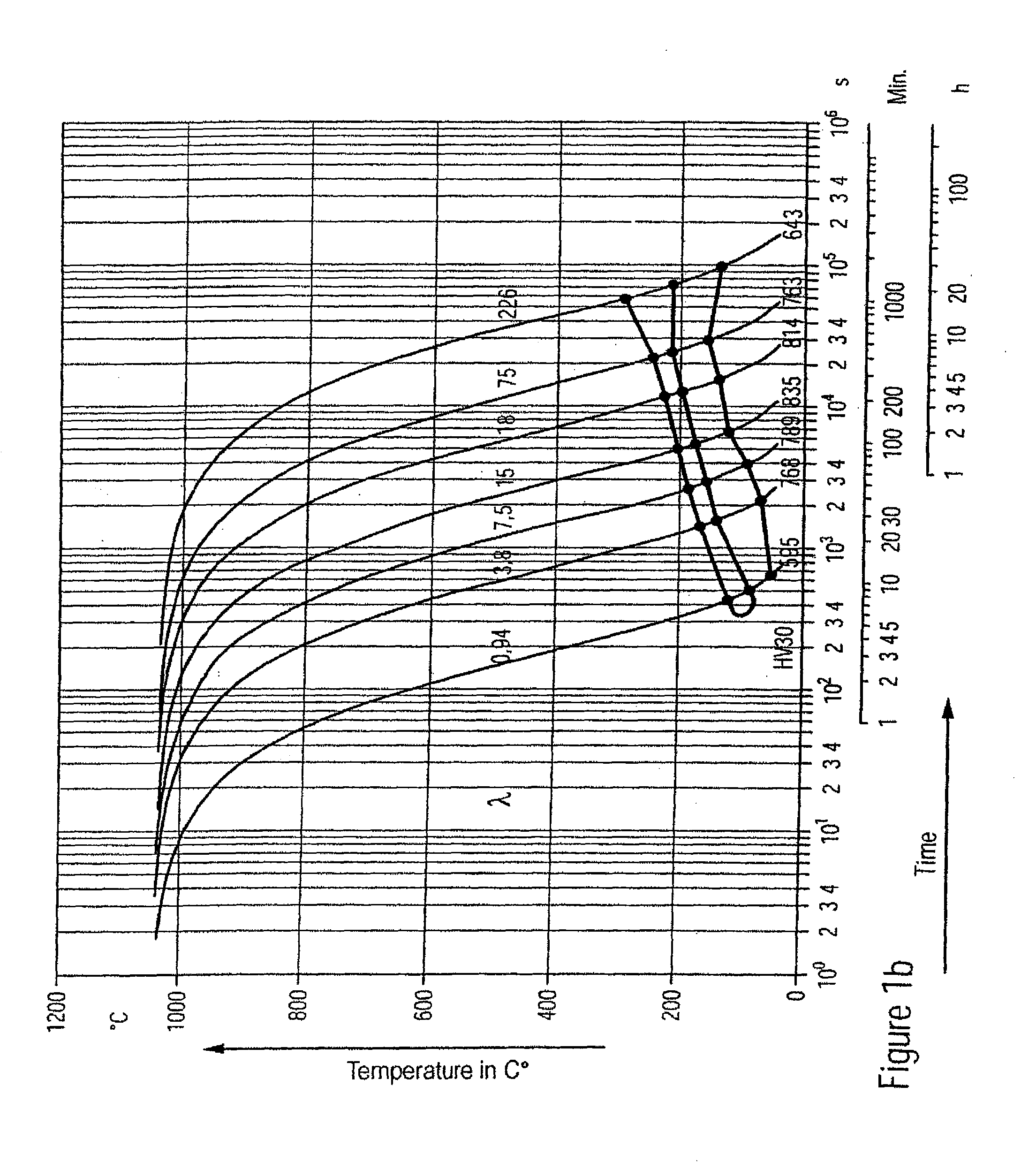

Powder-Metallurgically Produced, Wear-Resistant Material

InactiveUS20080253919A1Simple contentImprove the level ofThin material handlingNiobiumWear resistant

A wear-resistant material comprising an alloy that contains: 1.5-5.5 wt. % carbon, 0.1-2.0 wt. % silicon, max. 2.0 wt. % manganese, 3.5-30.0 wt. % chromium, 0.3-10 wt. % molybdenum, 0-10 wt. % tungsten, 0.1-30 wt. % vanadium, 0-12 wt. % niobium, 0.1-12 wt. % titanium and 1.3-3.5 wt. % nickel, the remainder being comprised of iron and production-related impurities, whereby the carbon content fulfils the following condition:CAlloy [w %]=S1+S2+S3where S1=(Nb+2(Ti+V−0.9)) / a, S2=(Mo+W / 2+Cr−b) / 5, S3=c+(TH−900)·0.0025, where 7<a<9, 6<b<8, 0.3<c<0.5 and 900° C.<TH<1,220° C.Also. method for producing the wear-resistant material and to uses of the material.

Owner:KOPPERN ENTWICKLUNGS GMBH & CO KG

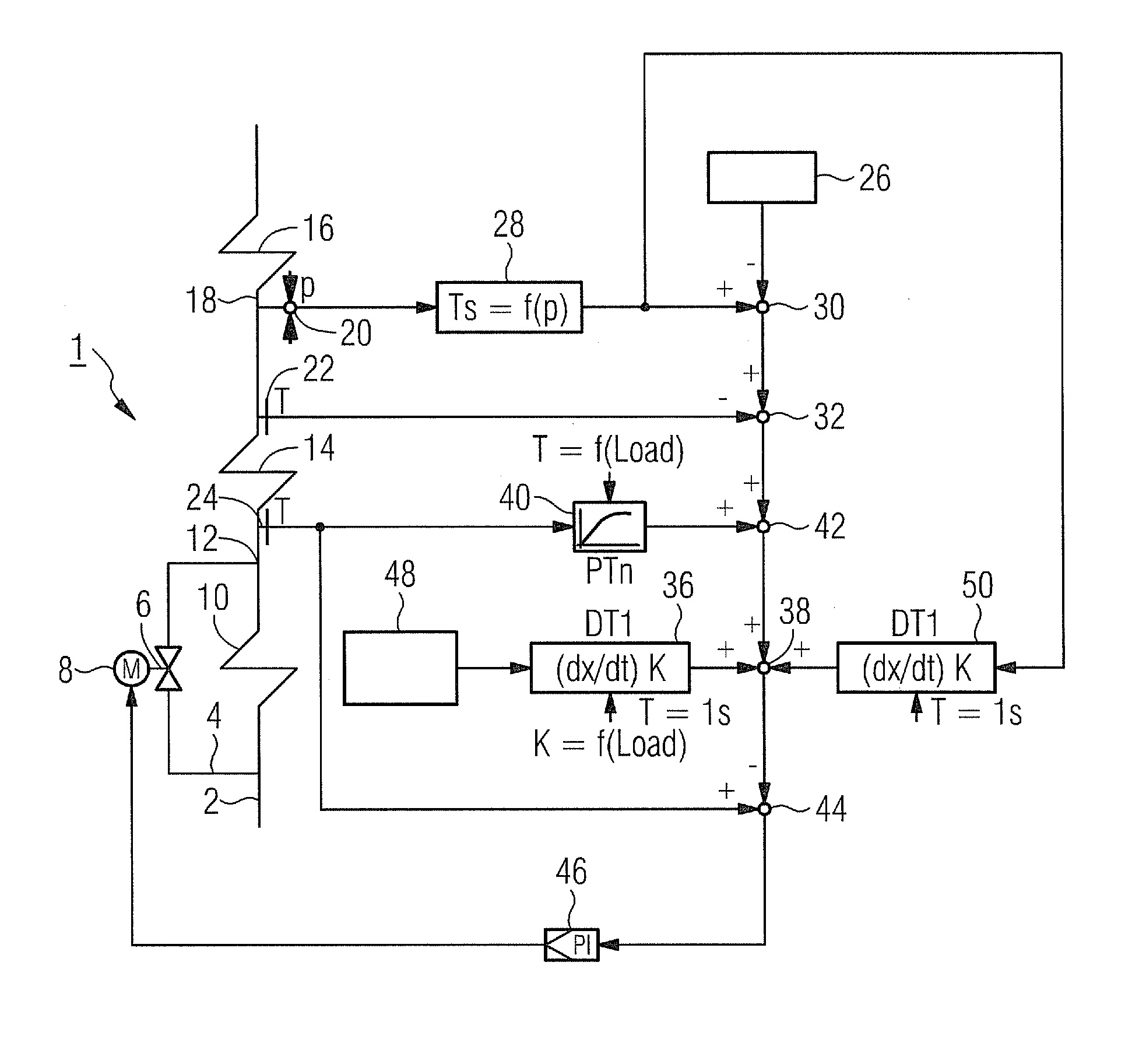

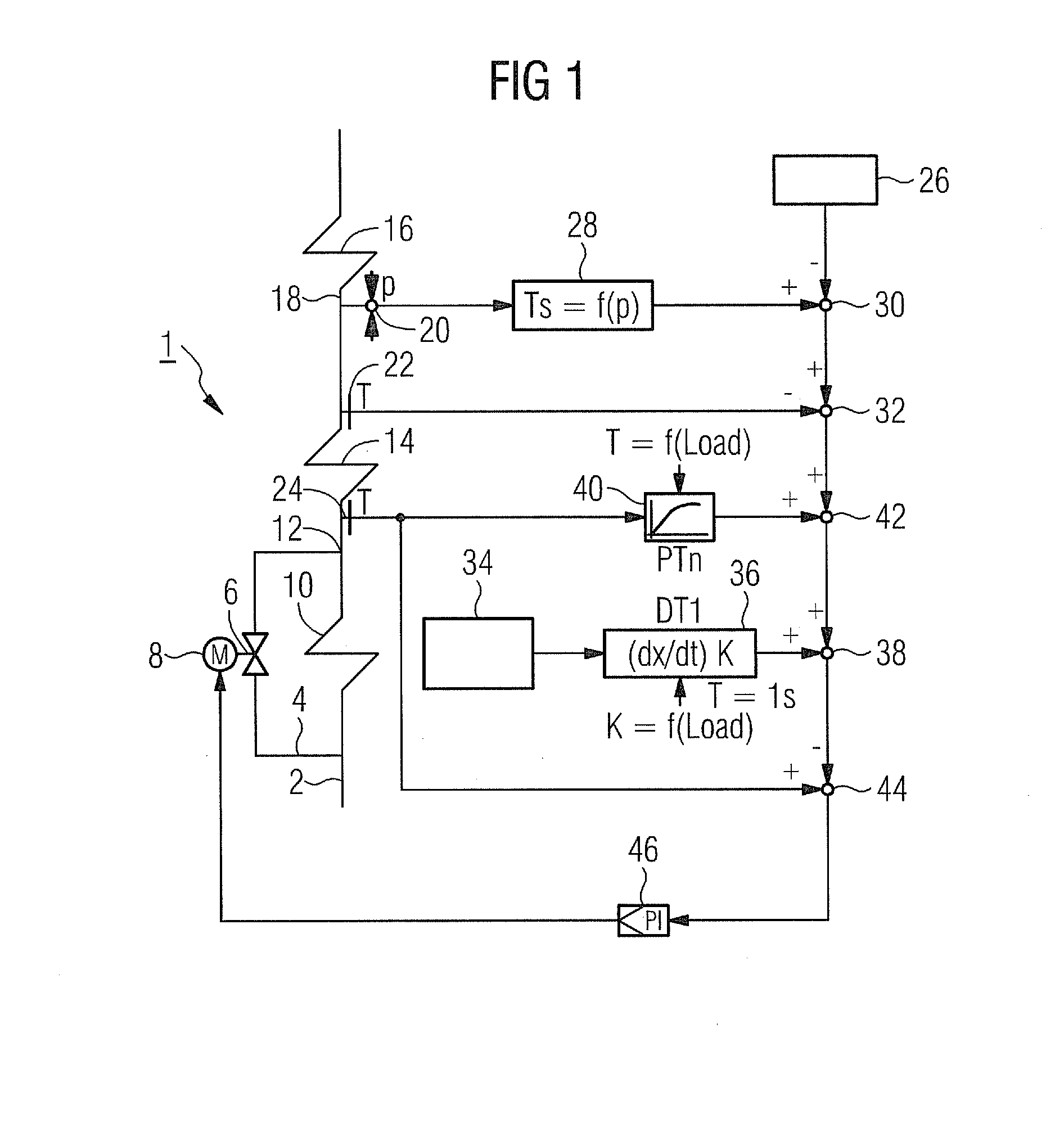

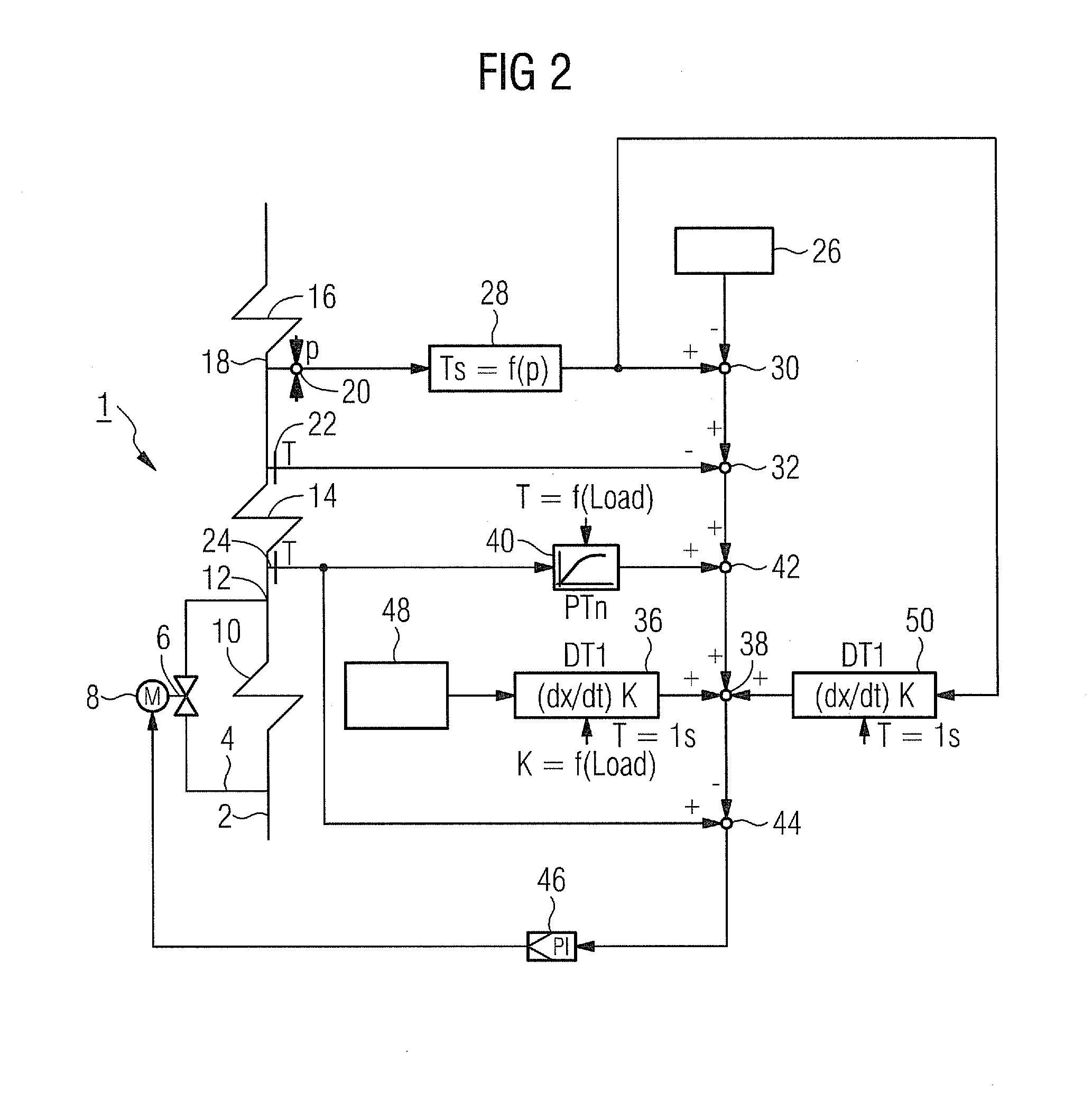

Method for Operating a Waste Heat Steam Generator

ActiveUS20110225972A1High level of operational safety and reliabilityReduce flow rateBoiler controlSteam engine plantsThermal energyEngineering

A method for operating a waste heat steam generator including an evaporator, an economizer having a number of economizer heating surfaces, and a bypass line connected on the flow medium side in parallel with a number of economizer heating surfaces is provided. The method makes possible higher operational safety and reliability in the control of the waste heat steam generator. For this purpose, a parameter that is characteristic of the thermal energy fed to the waste heat steam generator is used to control or regulate the flow rate of the by-pass line.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

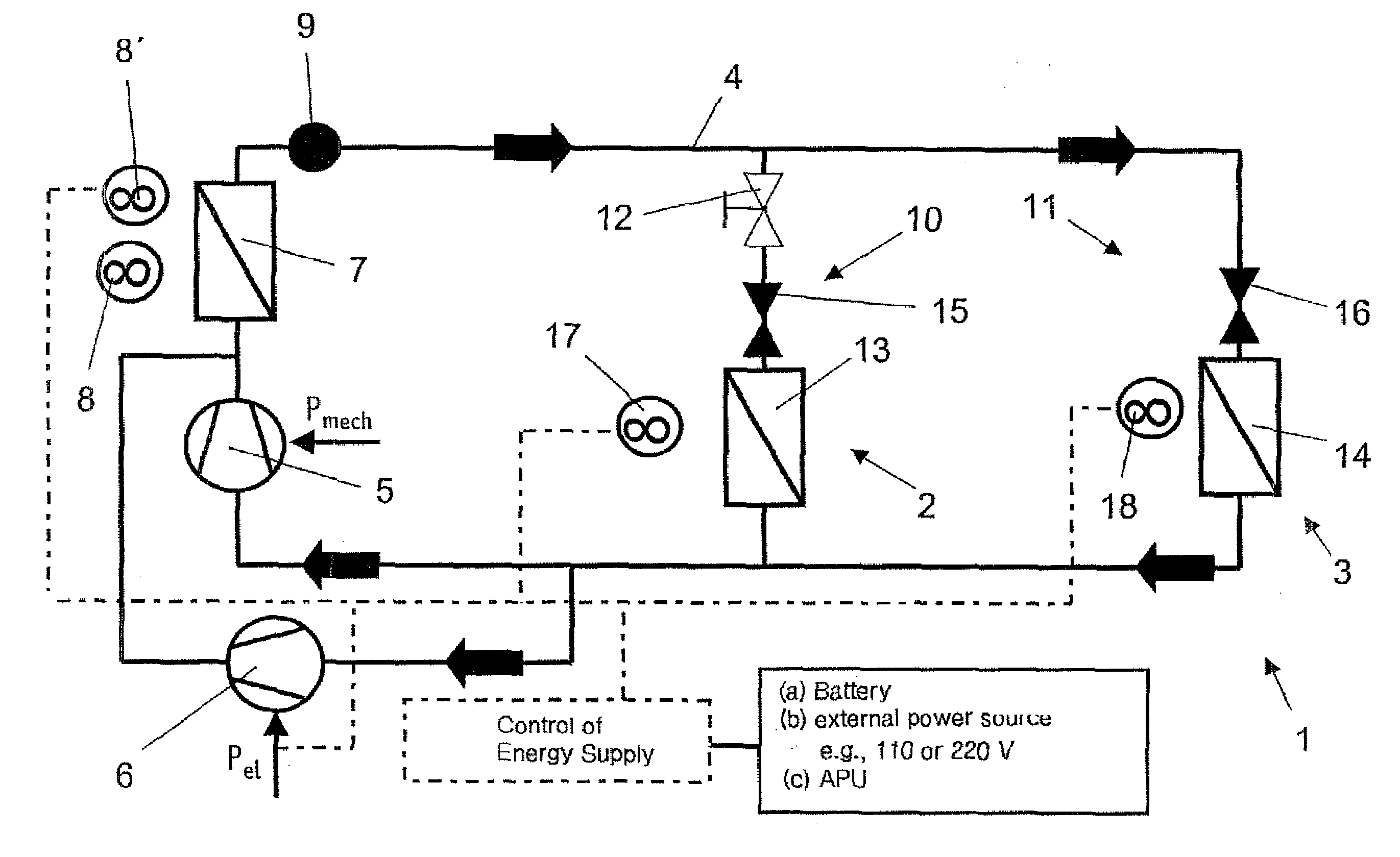

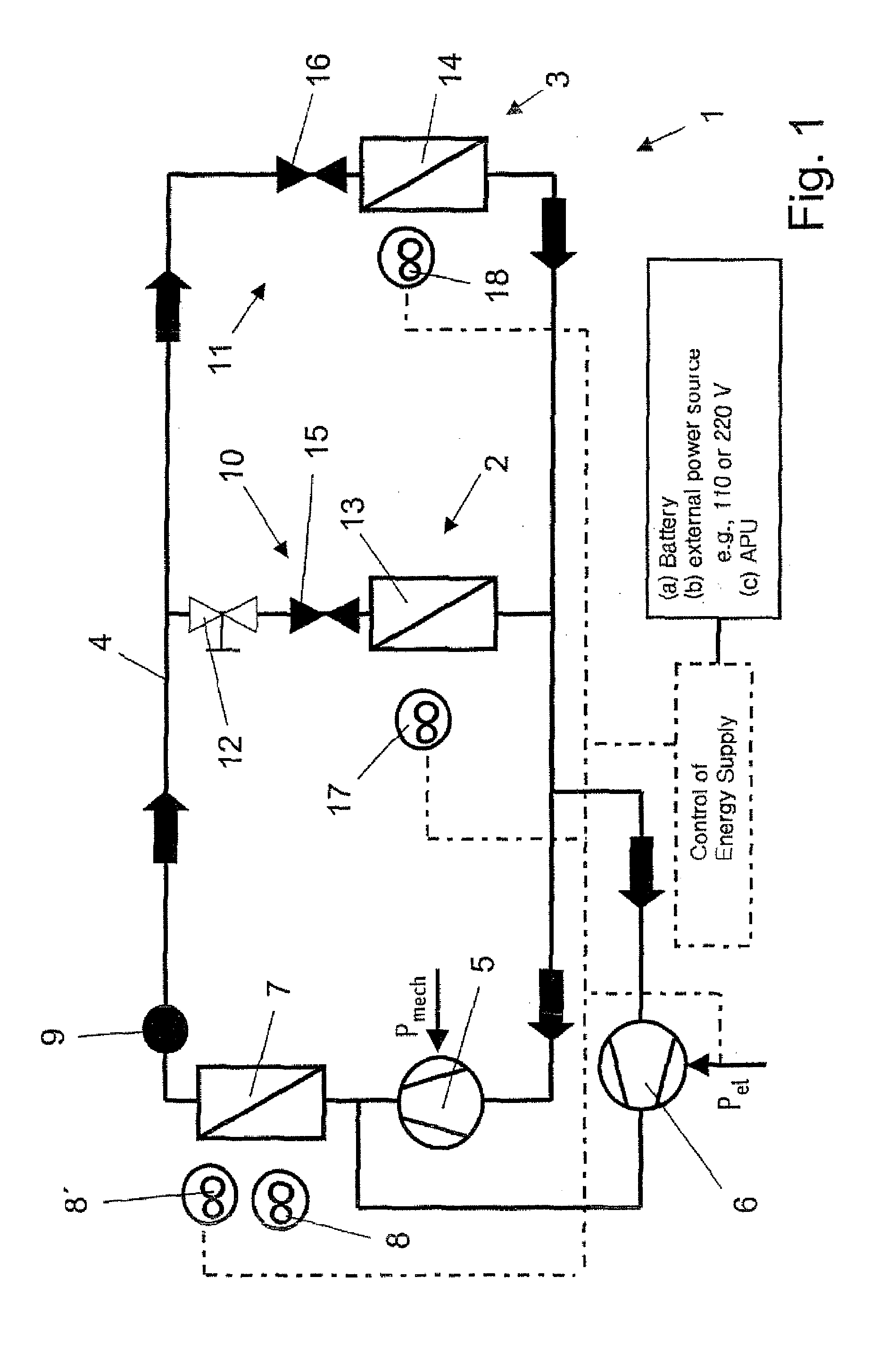

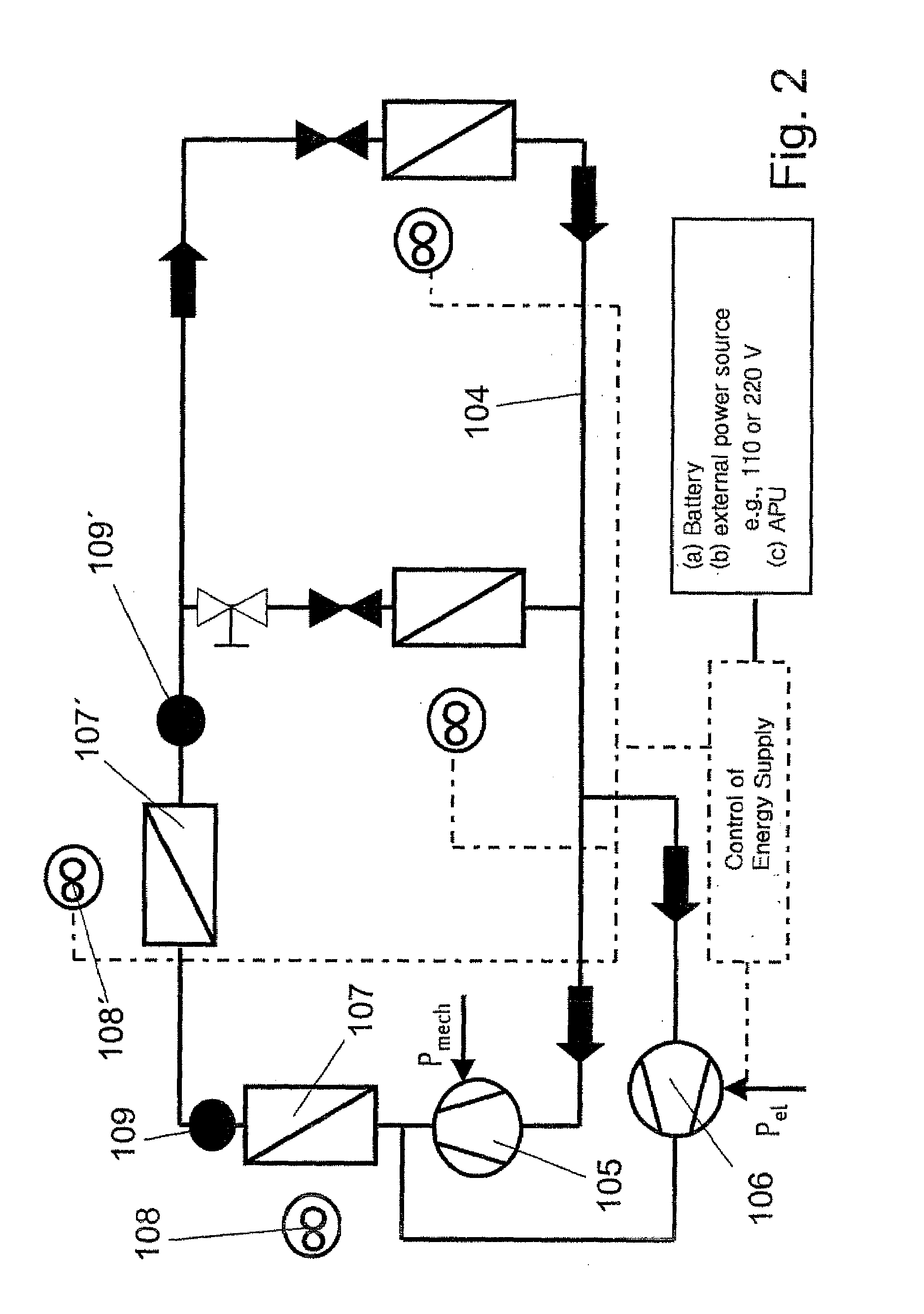

Stationary vehicle air conditioning system and method

ActiveUS7290400B2Improve overall utilizationSimple regulationAir-treating devicesCompression machines with several condensersMechanical energyAir conditioning

The invention pertains to a stationary vehicle air conditioning system with a refrigerant circuit, in which a compressor circulates refrigerant through a refrigerant circuit including at least one condenser. The one compressor may be powered by the vehicle's mechanical power, by an electrical source, or by a combination of these driving forces. Depending on desired operating characteristics, a plurality of condensers may be arranged in a series or parallel configuration within the circuit, and a second compressor also may be added, which second compressor may be powered by a source other than the mechanical energy of the vehicle's engine. A plurality of fans may be positioned and selectively operable to provide cooling air streams to one or more of the condensers, with the vehicle engine mechanically driving one fan and an electrical power source driving another fan. At minimum, at least one fan is provided to provide a cooling air stream to one or more condensers, wherein the fan is a hybrid drive unit that is capable of being driven through mechanical or electrical means.

Owner:BEHR GMBH & CO KG

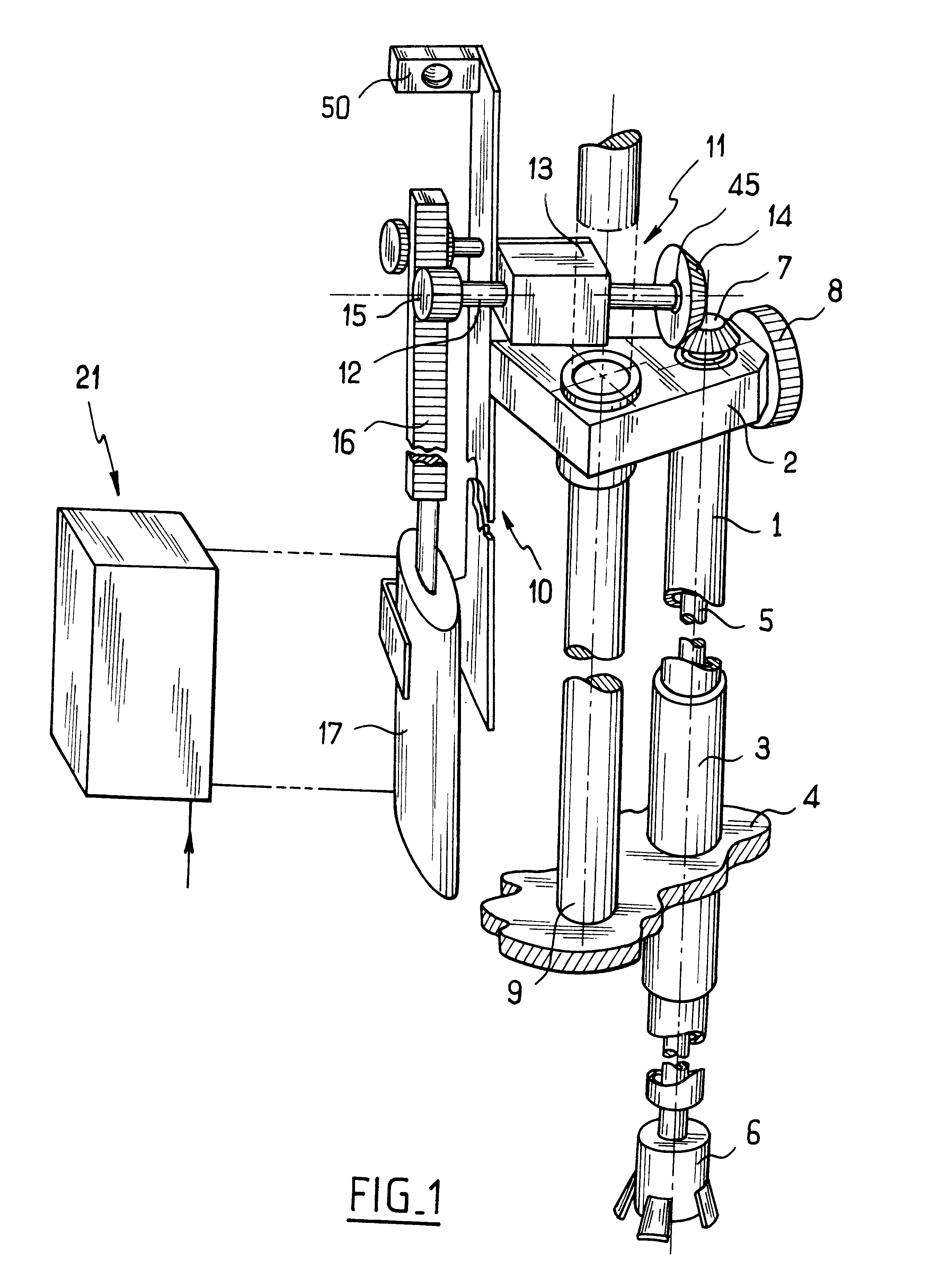

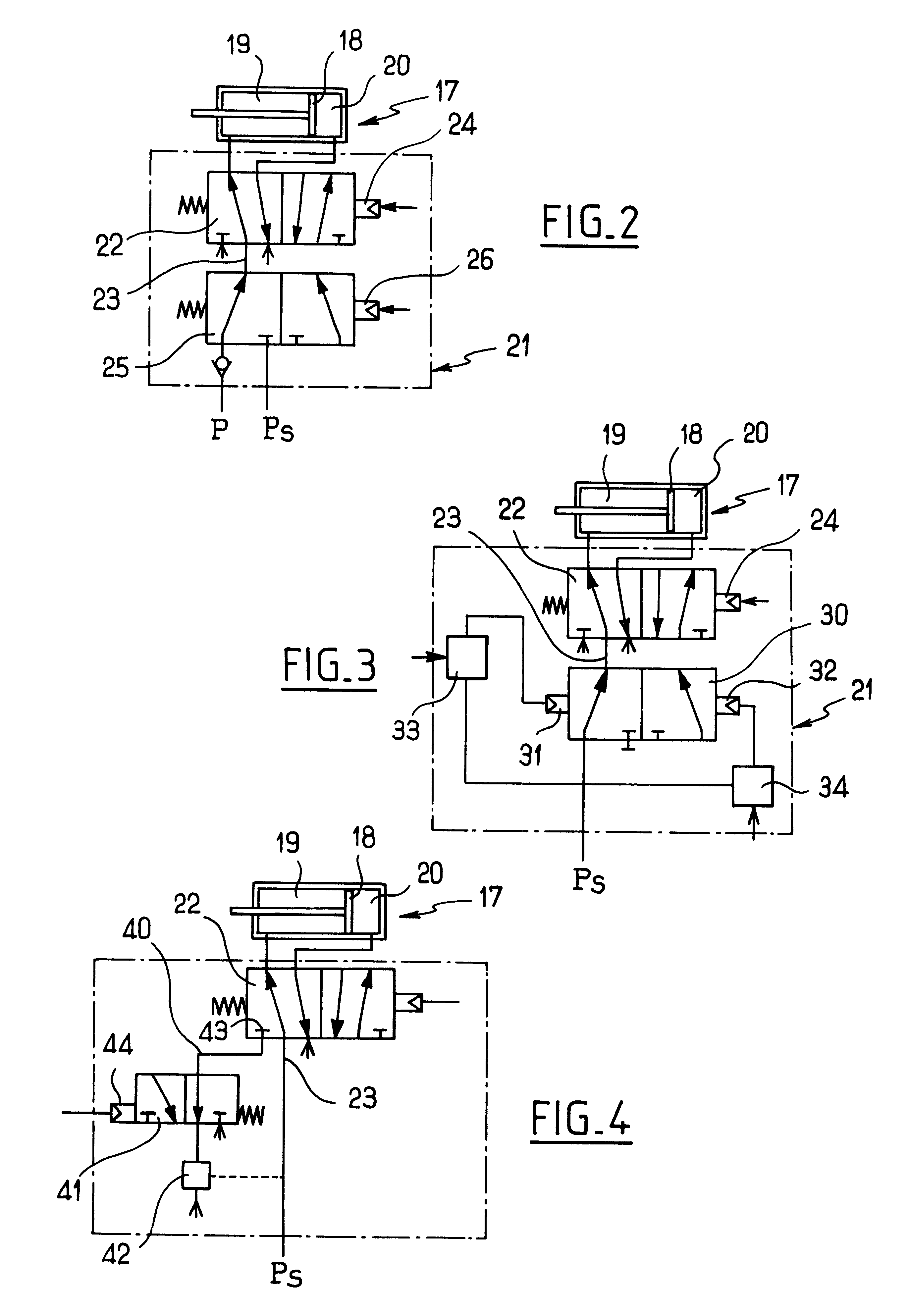

Method of controlling a screwing spindle

InactiveUS6263742B1Accurate acquisitionSignificant fluid savingsCapsThreaded caps applicationRotation velocityNominal condition

A method of controlling a screwing spindle comprising a fluid-fed motor and having a drive member connected to a spindle shaft to rotate it, the method comprising the step of feeding the screwing spindle under nominal conditions of pressure and flow rate that generate a required tightening torque, and a prior step during which the screwing spindle is fed under conditions that are weaker than the nominal conditions by a ratio that is sufficient to ensure that the spindle shaft has a speed of rotation that generates kinetic energy producing a torque that is less than the required tightening torque.

Owner:SERAC GROUP

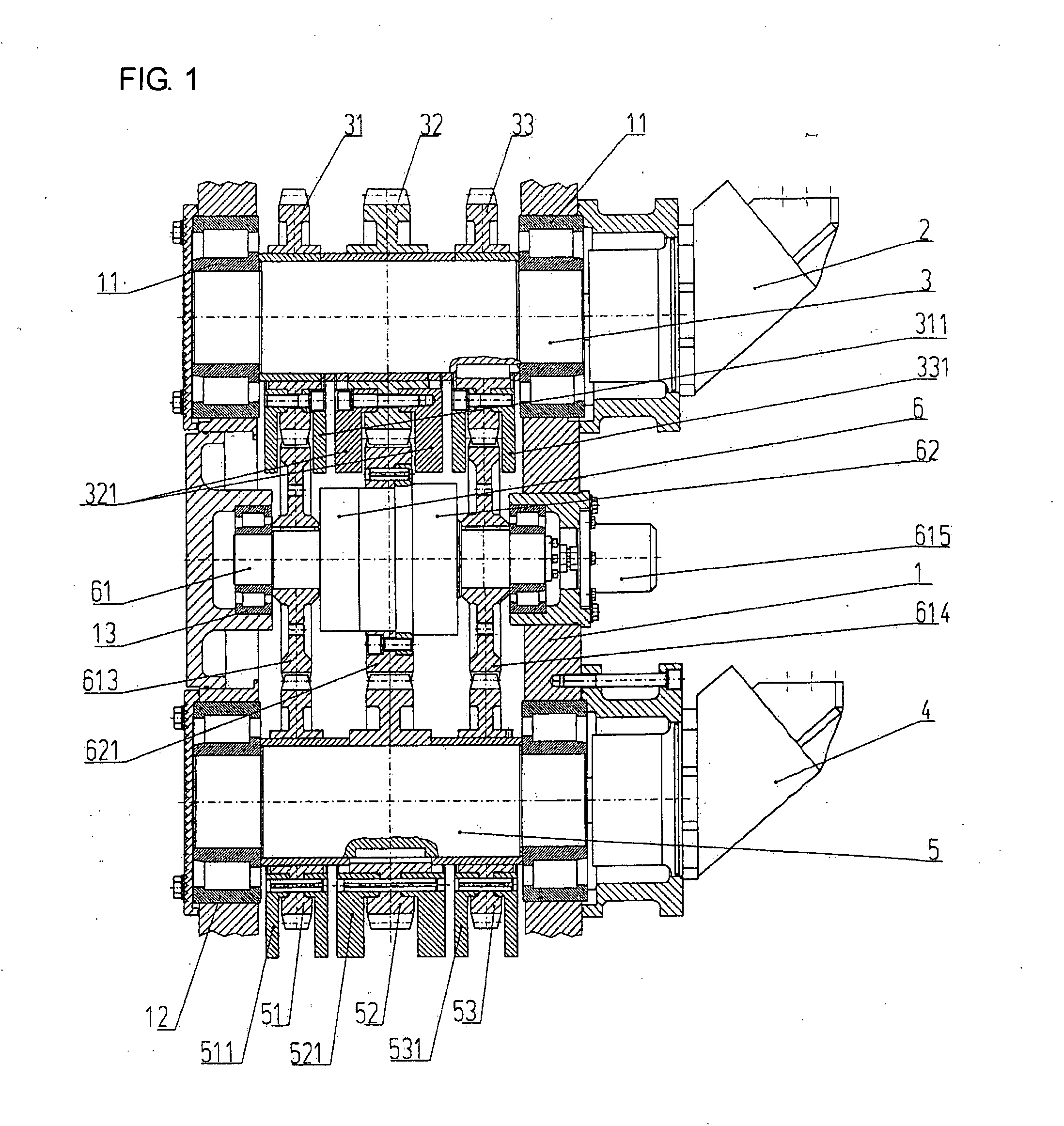

Vibration exciter

InactiveUS20080218013A1High rotational speedIncrease torqueGearingMechanical vibrations separationStatorMechanical engineering

A vibration exciter, particularly for a vibration pile driver, comprising at least two axles disposed parallel to one another, as well as at least two imbalance masses, which are attached to one or more of the axles. The relative rotary position of the imbalance masses can be adjusted relative to one another by at least one rotary oscillating motor having a rotor shaft and a stator housing. The rotor shaft is an integral part of one of the axles, and the rotary position of the stator housing relative to the rotor shaft can be changed. The stator housing can be locked to the rotor shaft. An oscillating motor suitable for use in a vibration exciter, comprises a rotor shaft and a stator housing, between which working chambers are formed. The stator housing can rotate about the rotor shaft and can be locked relative to the rotor shaft.

Owner:ABI +1

Powder-metallurgically produced, wear-resistant material

ActiveUS20130084462A1Simple contentImprove the level ofPig casting plantsIngot casting plantsNiobiumWear resistant

A wear-resistant material comprising an alloy that contains: 1.5-5.5 wt. % carbon, 0.1-2.0 wt. % silicon, max. 2.0 wt. % manganese, 3.5-30.0 wt. % chromium, 0.3-10 wt. % molybdenum, 0-10 wt. % tungsten, 0.1-30 wt. % vanadium, 0-12 wt. % niobium, 0.1-12 wt. % titanium and 1.3-3.5 wt. % nickel, the remainder being comprised of iron and production-related impurities, whereby the carbon content fulfils the following condition: CAlloy [w %]=S1+S2+S3 where S1=(Nb+2(Ti+V−0.9)) / a, S2=(Mo+W / 2+Cr−b) / 5, S3=c+(TH−900)·0.0025, where 7<a<9, 6<b<8, 0.3<c<0.5 and 900° C.<TH<1,220° C.

Owner:KOPPERN ENTWICKLUNGS GMBH & CO KG

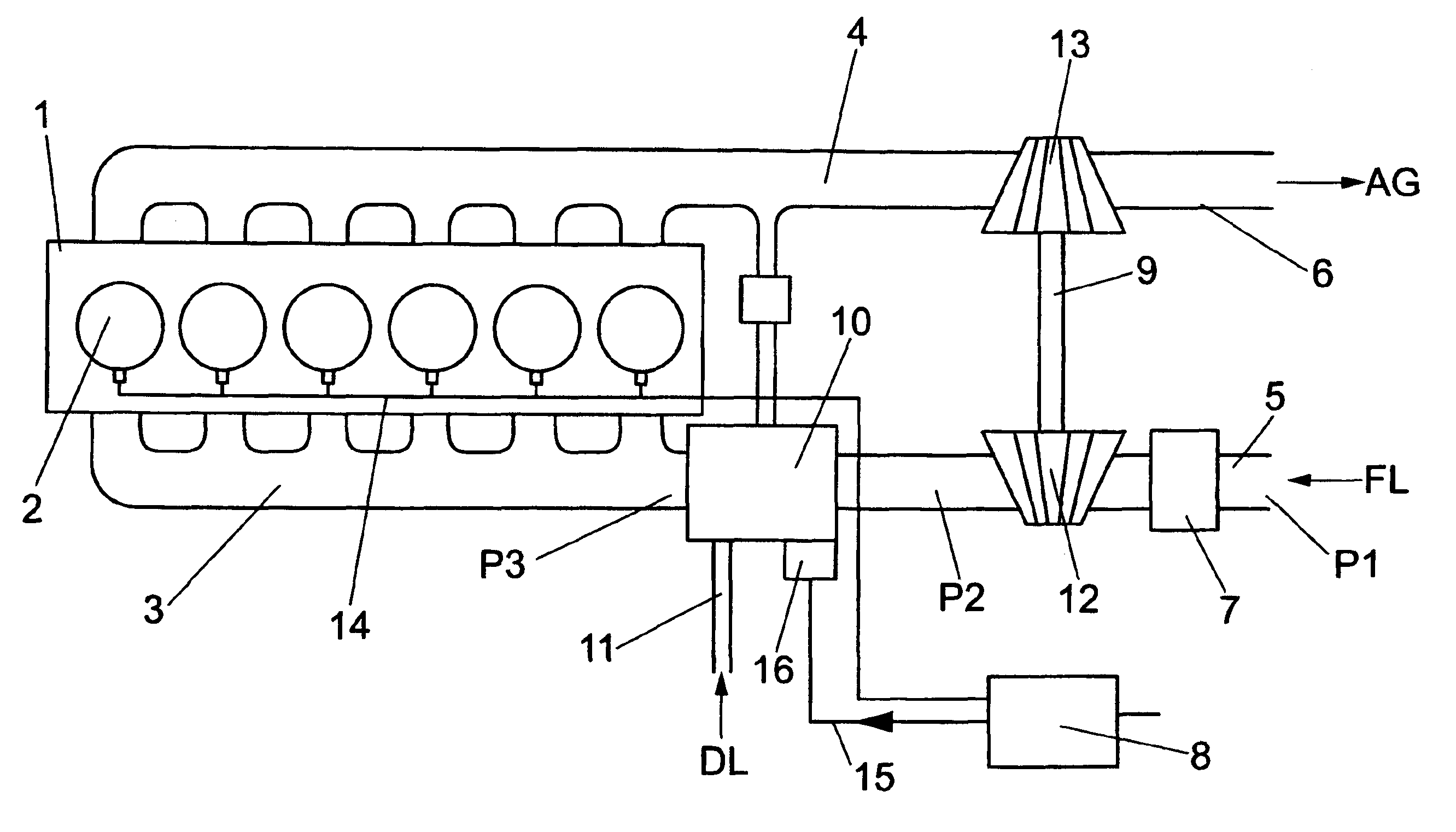

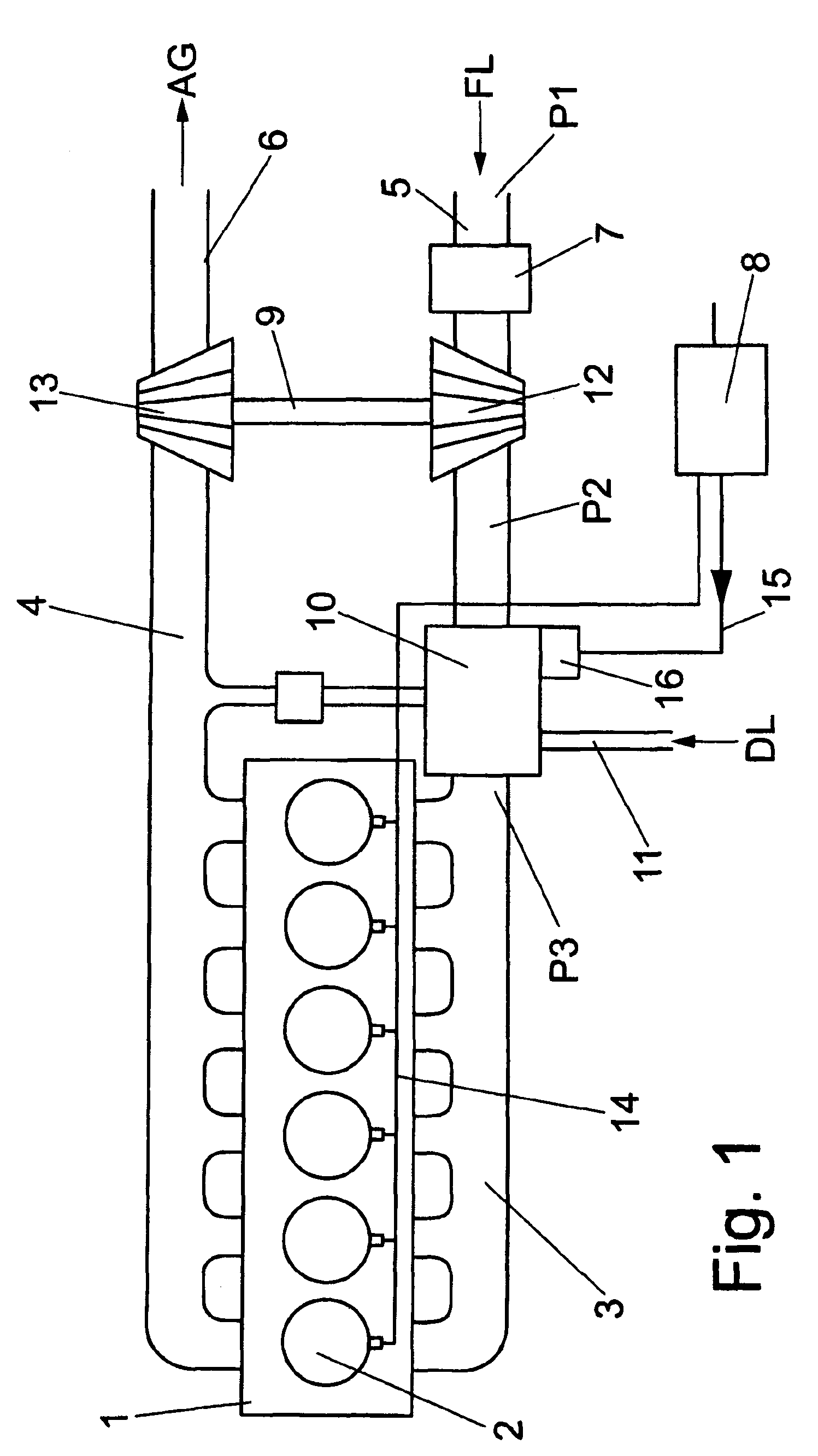

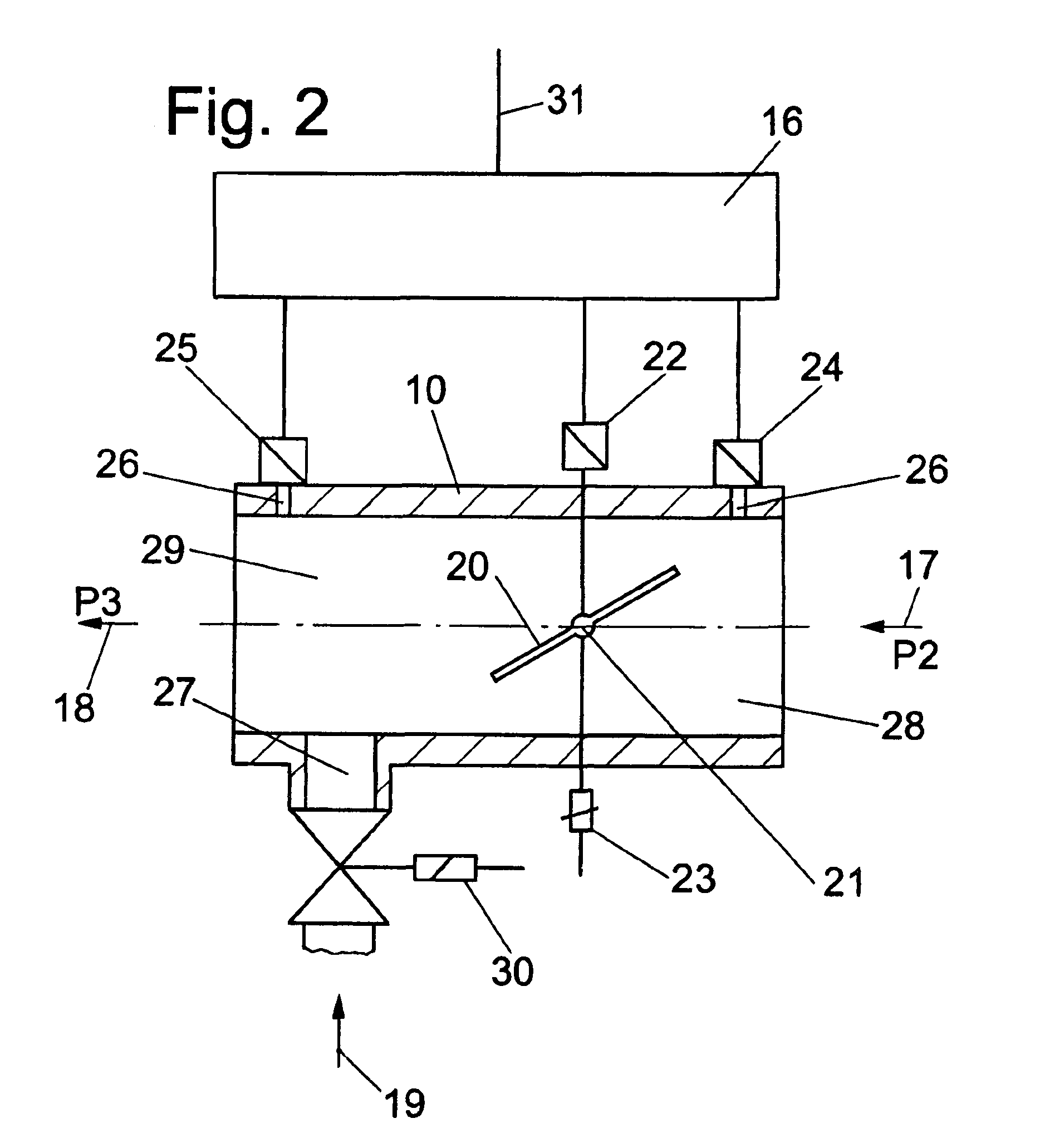

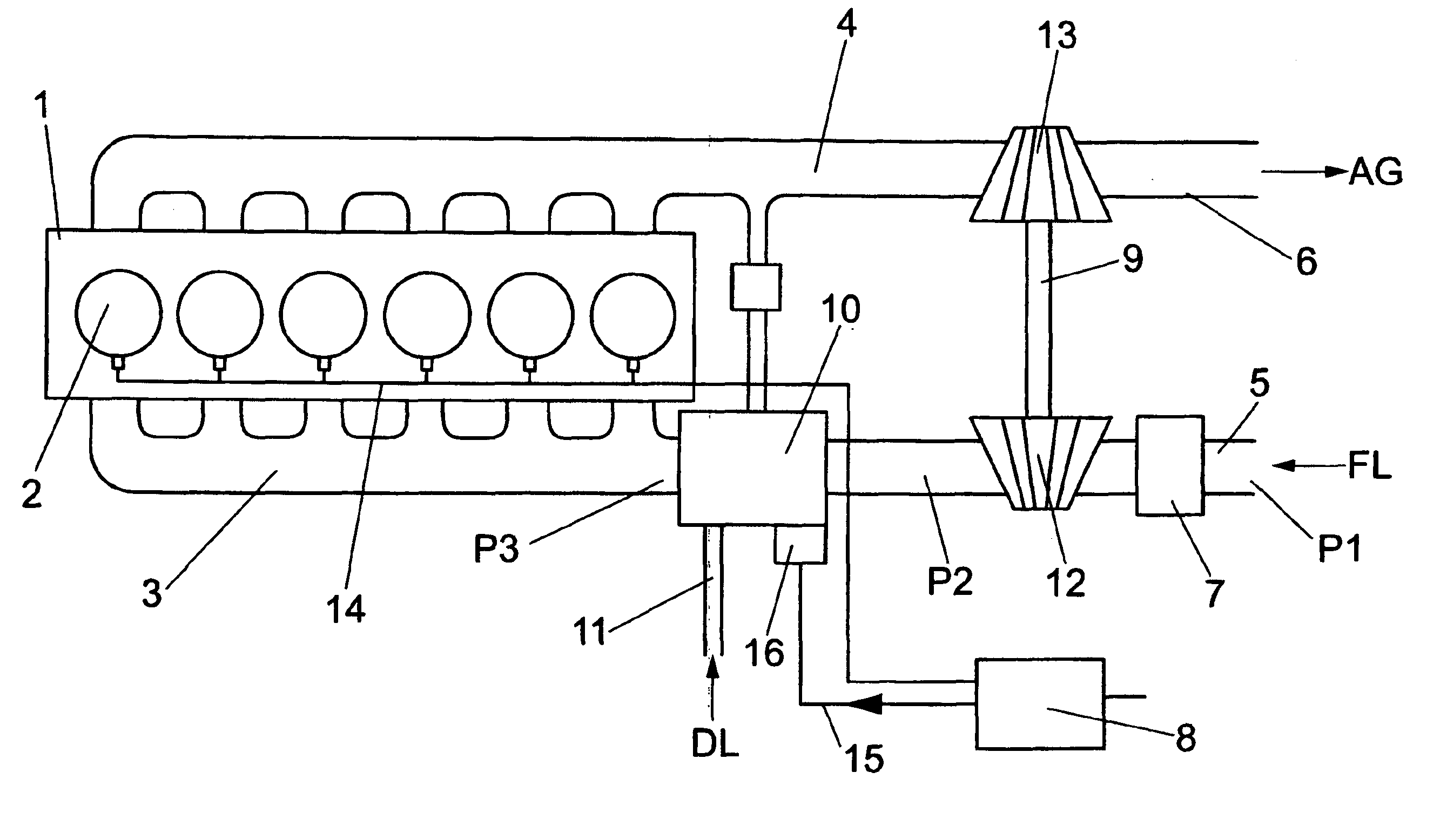

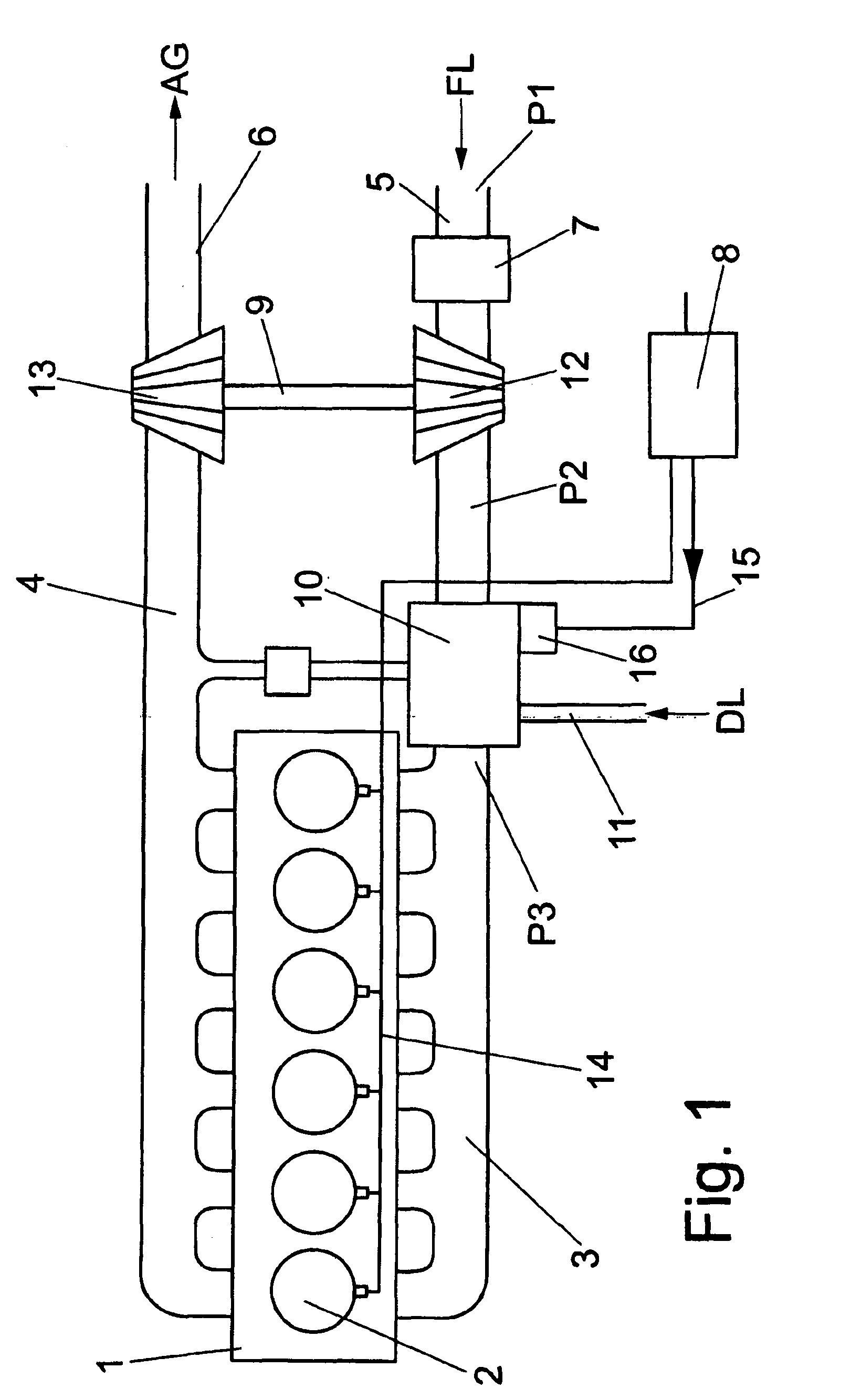

Method and device for controlling a suction pressure of an internal combustion engine

ActiveUS8037866B2Reduce energy consumptionIncrease intake pressureElectrical controlInternal combustion piston enginesExternal combustion engineTurbocharger

A method device for controlling a suction pressure of an internal combustion engine, particularly a diesel engine having an exhaust gas turbocharger. The compressor is connected to a suction line of the internal combustion engine via an actuating section having an actuating element for changing a cross-section of the actuating section. In the first step, the current suction pressure in the suction line of the internal combustion engine is determined. A compressor pressure of the compressor is determined by pressure sensors and compared to the suction pressure. Values corresponding to current operating data of the internal combustion engine are identified and an actuation signal is generated using a controller, based on the comparison; and changing the cross-section of the actuating section is adjusted by adjusting the actuating element using the actuating signals.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

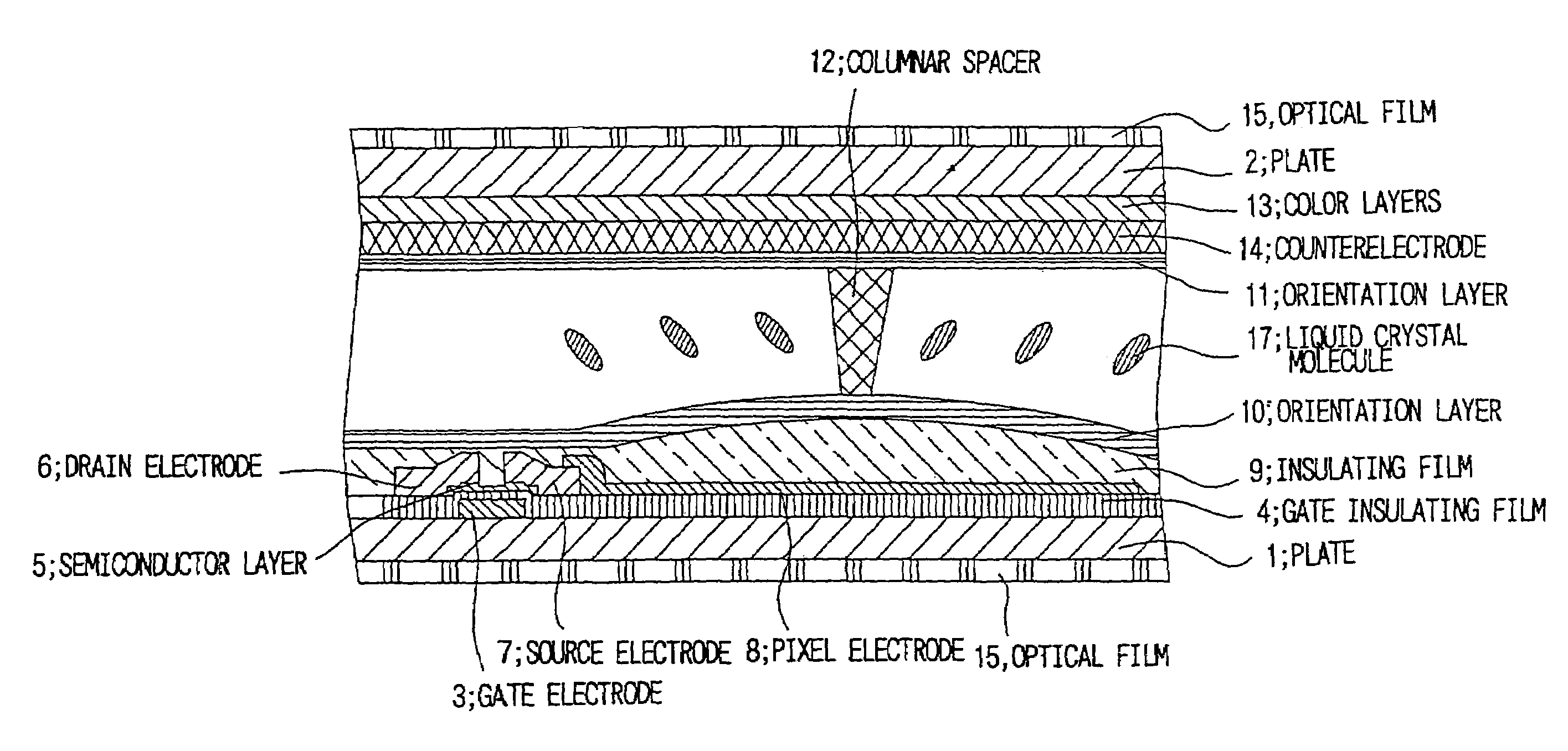

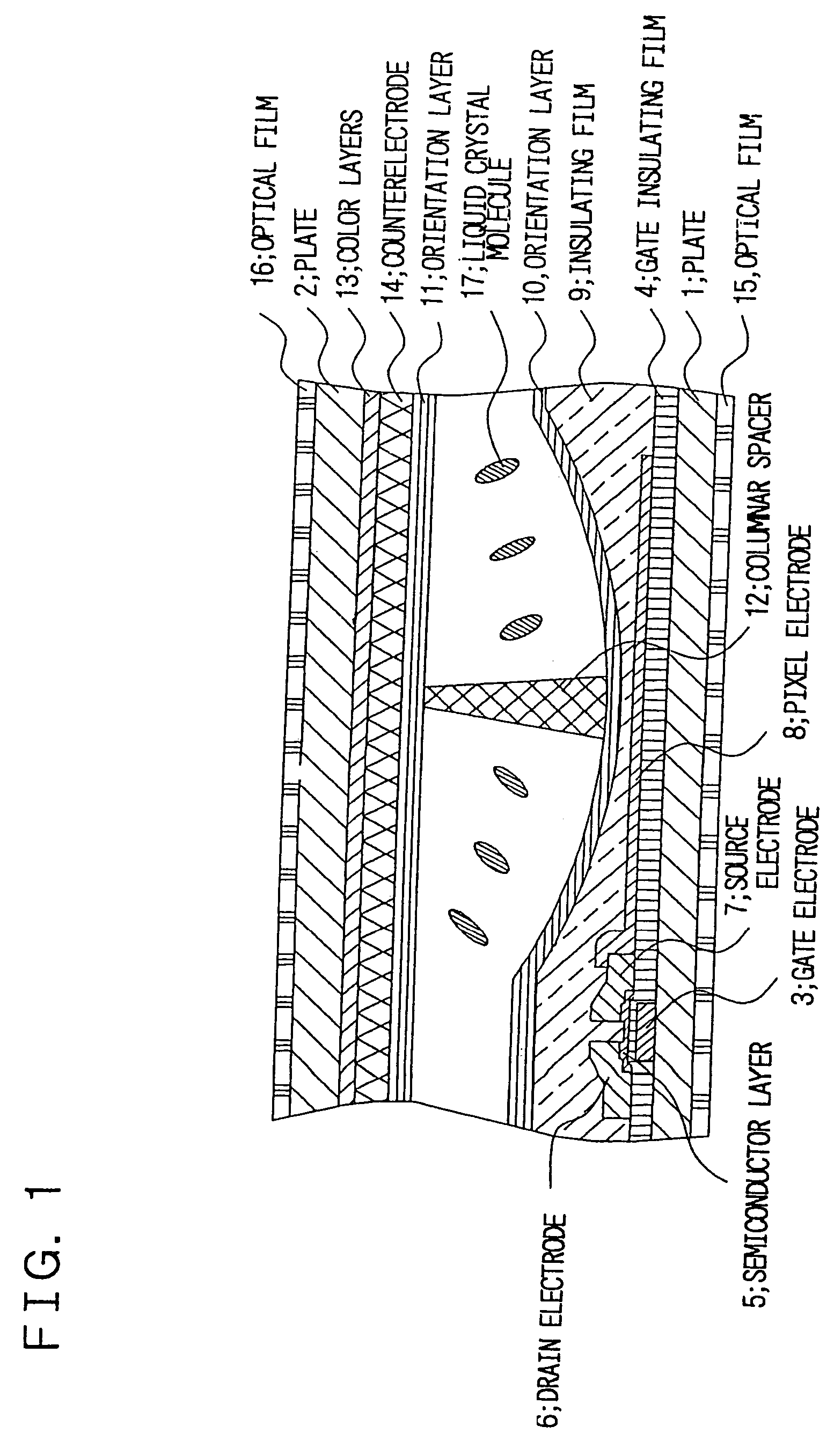

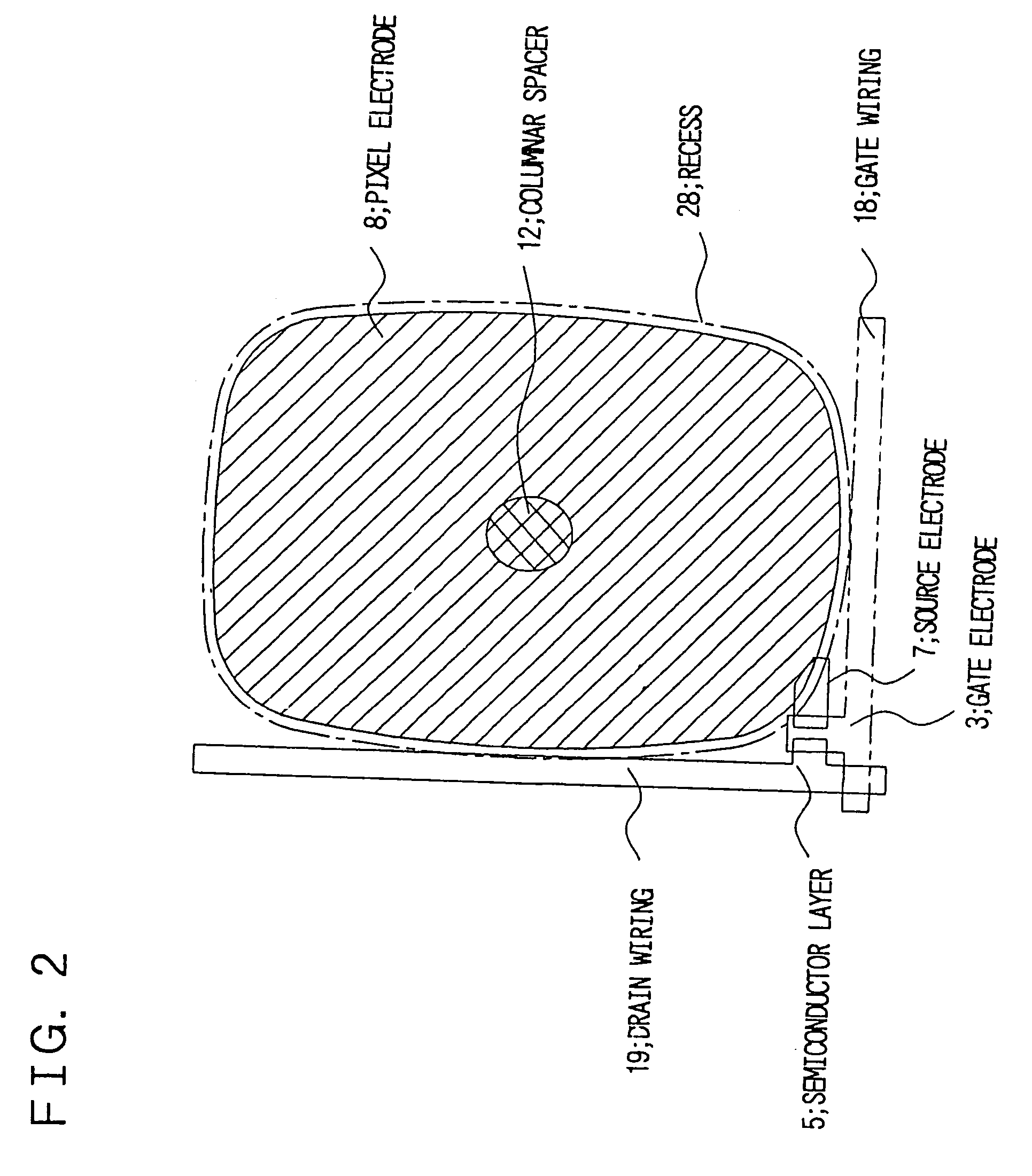

Liquid crystal display device with curved alignment surface

A multi-domain alignment liquid crystal display device in which liquid crystal molecules are aligned through a simple process and panel gap is maintained in stable fashion includes a first plate having a thin-film transistor provided at each point of intersection of a scanning line and signal line, a pixel electrode connected to the thin-film transistor and a first orientation layer formed on the pixel electrode and defining a curved surface, and a second plate having RGB color layers, an counterelectrode provided so as to oppose the pixel electrode, and a second orientation layer. A columnar spacer for regulating the panel gap is provided between the two opposing plates, and liquid crystal is sandwiched between the two plates and subjected to multi-domain alignment by the first orientation layer having the curved surface and the columnar spacer.

Owner:GOLD CHARM LTD

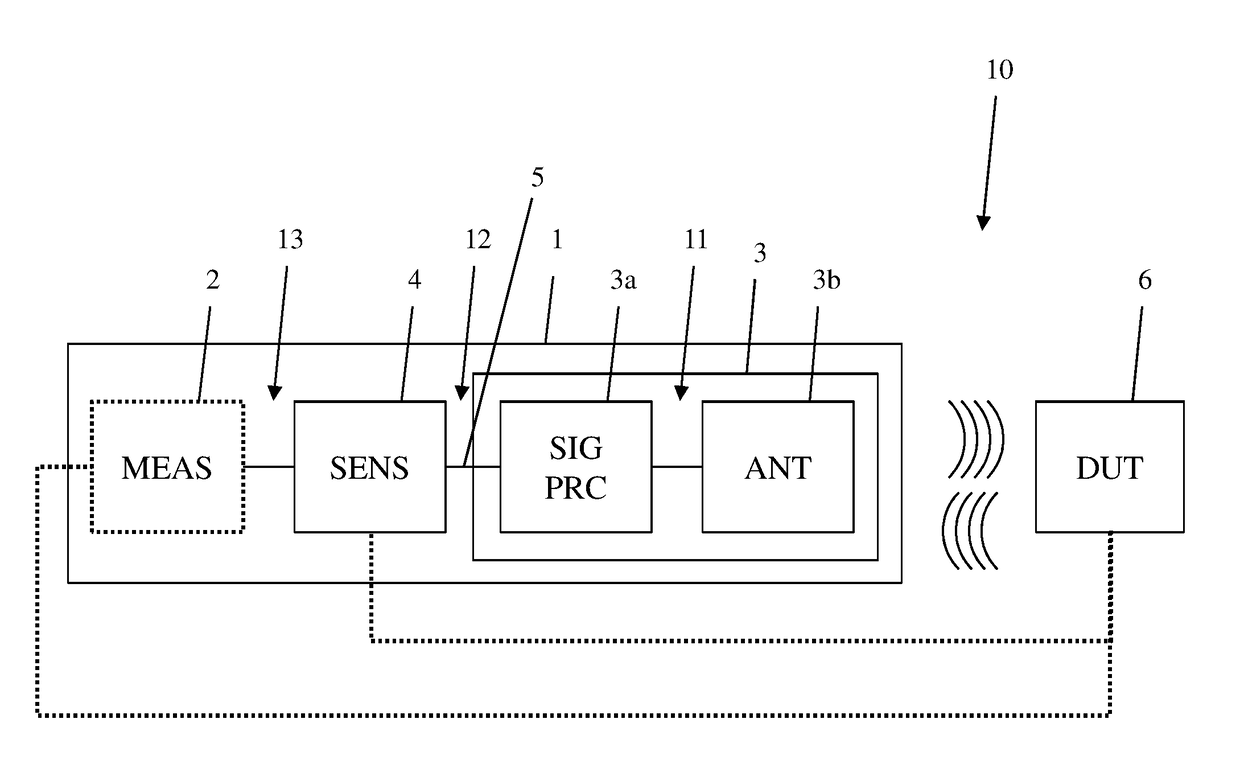

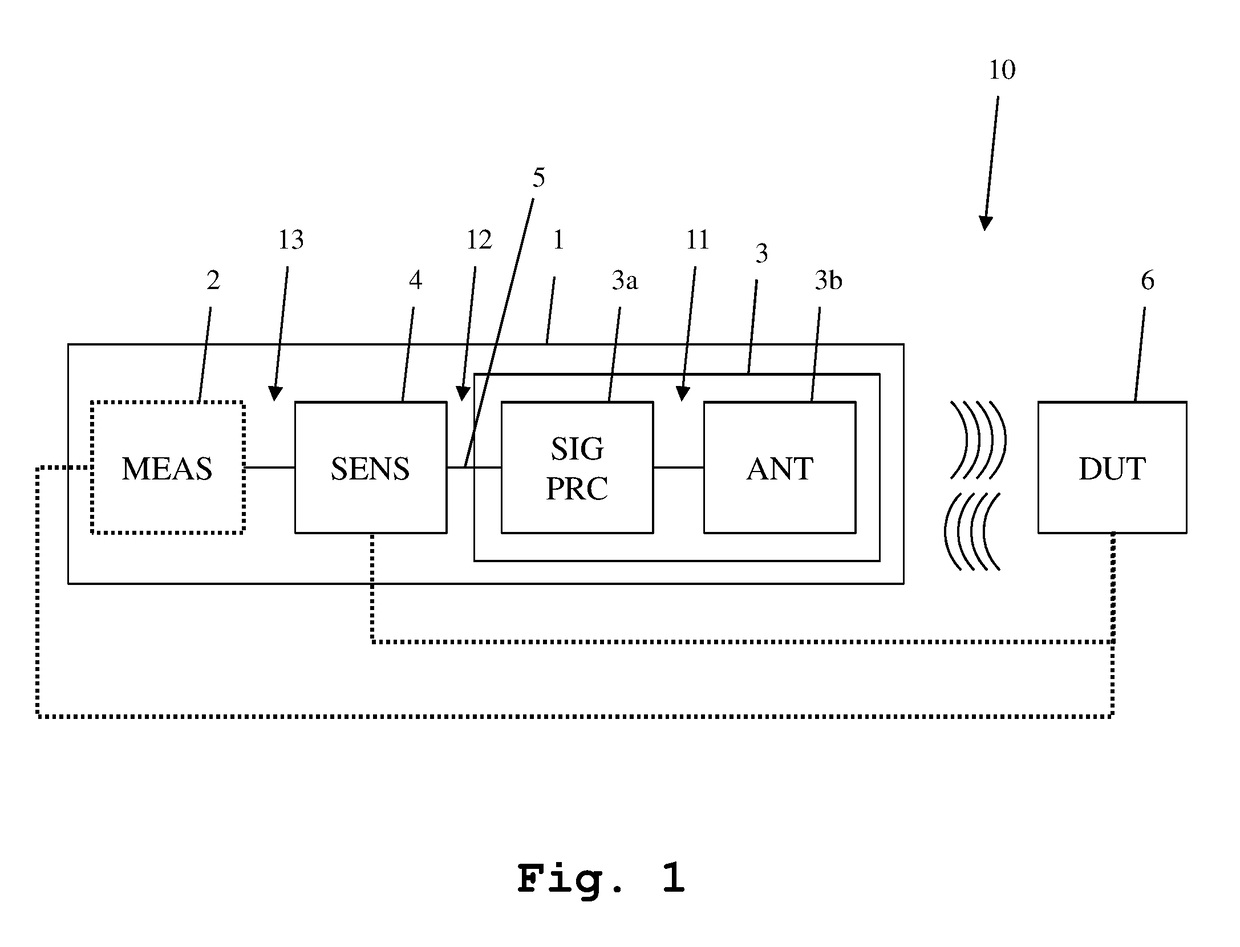

Measuring system for over-the-air power measurements with active transmission

ActiveUS20170244499A1Simple regulationEasy constructionTransmitters monitoringAc/pulses peak value measurementsTransmitter power outputComputer module

A measuring system for performing over the air power measurements is provided. The measuring system comprises, within a single housing, a detector module, comprising a detector input, a transmitter module, comprising a transmitter output, and an antenna. The detector input and the transmitter output are at least temporarily connected. At least the transmitter output or the detector input are at least temporarily connected to the antenna.

Owner:ROHDE & SCHWARZ GMBH & CO KG

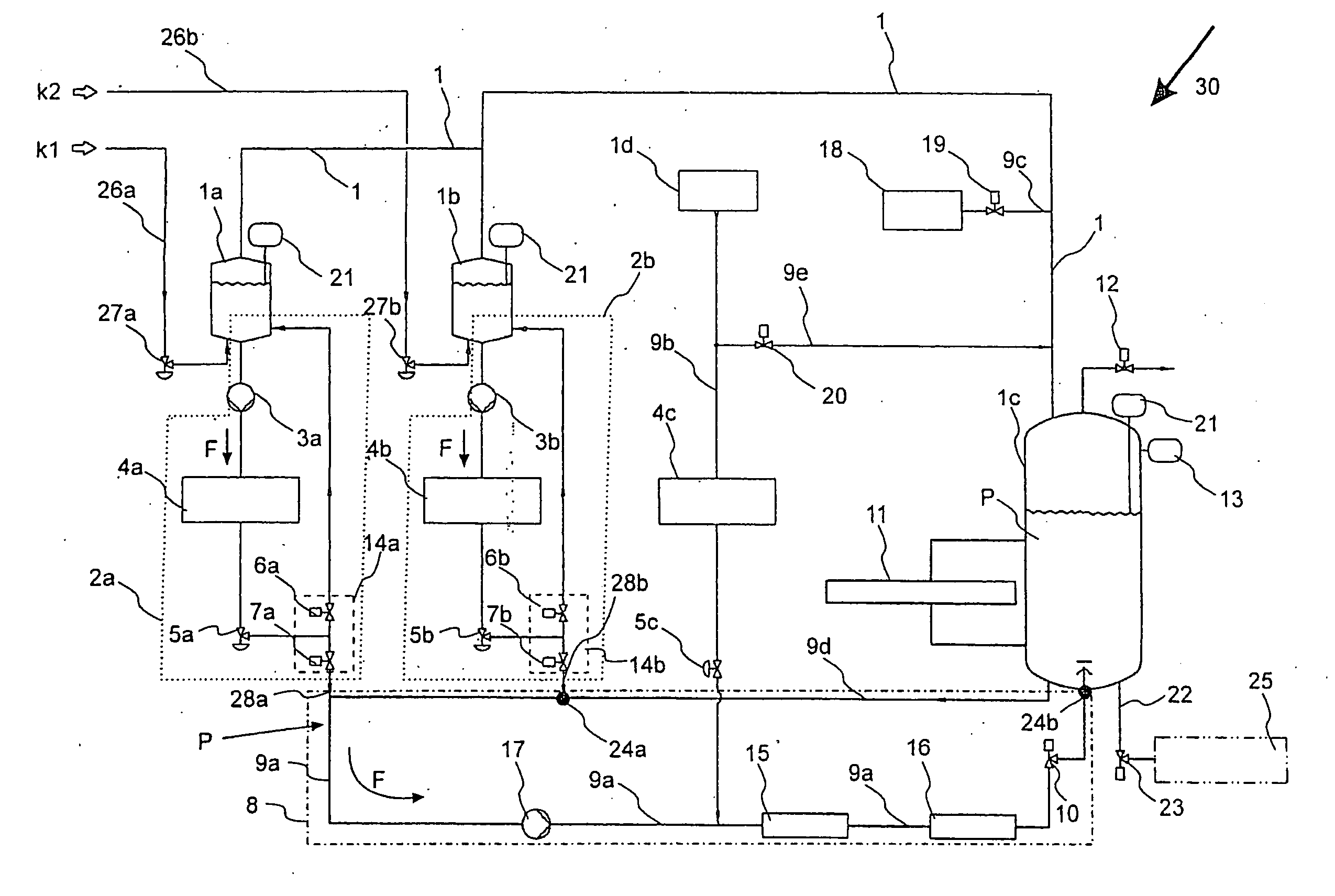

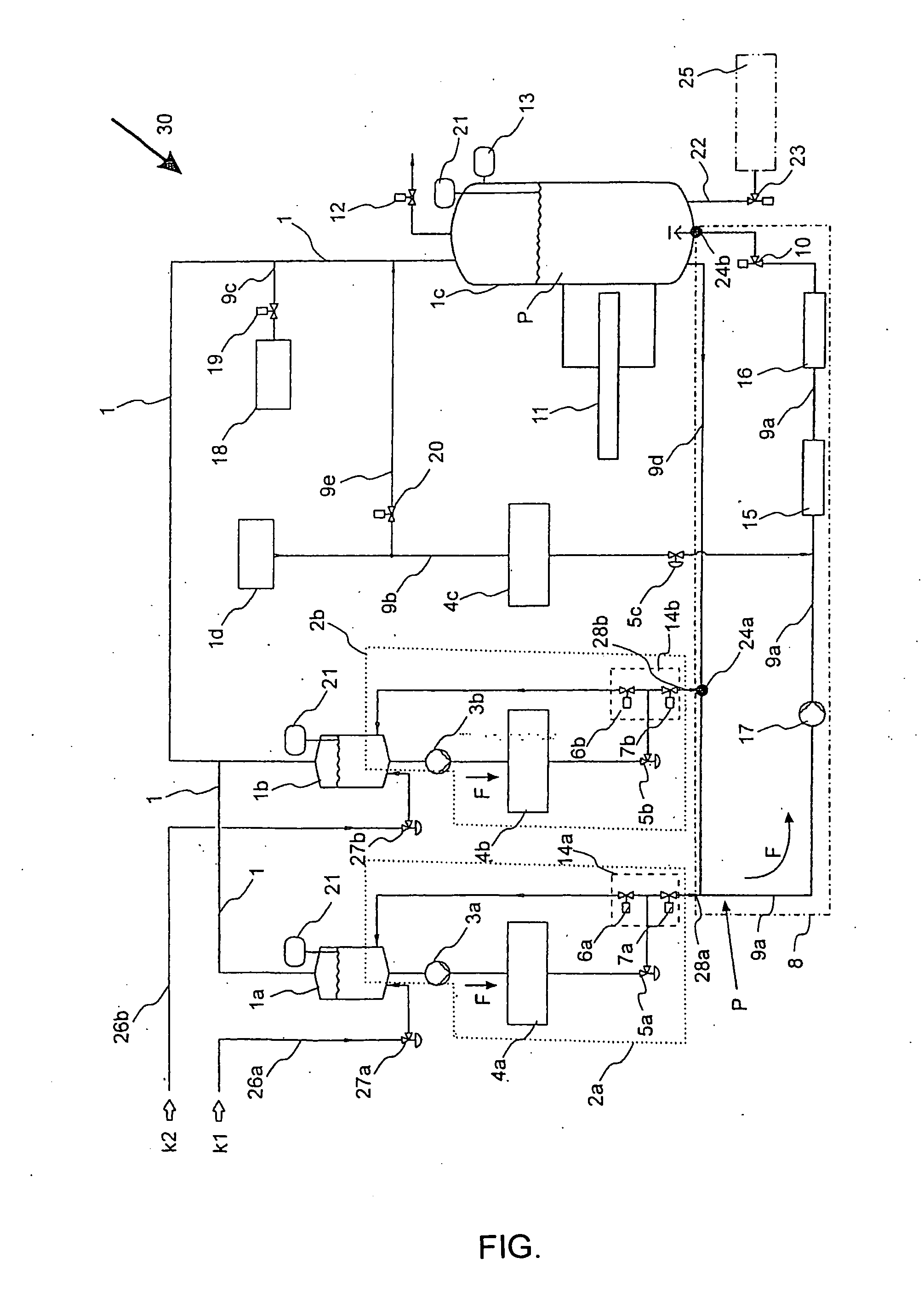

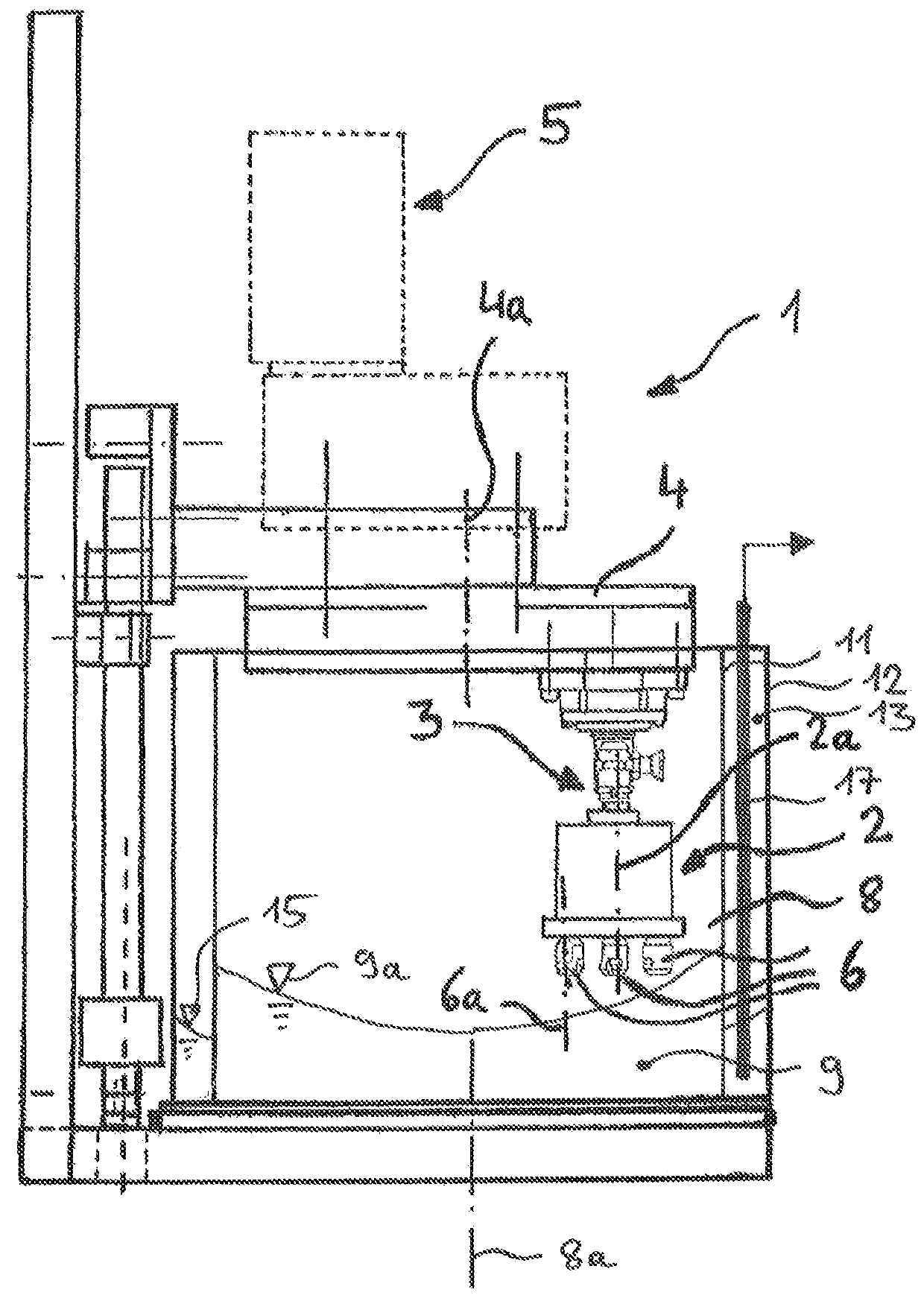

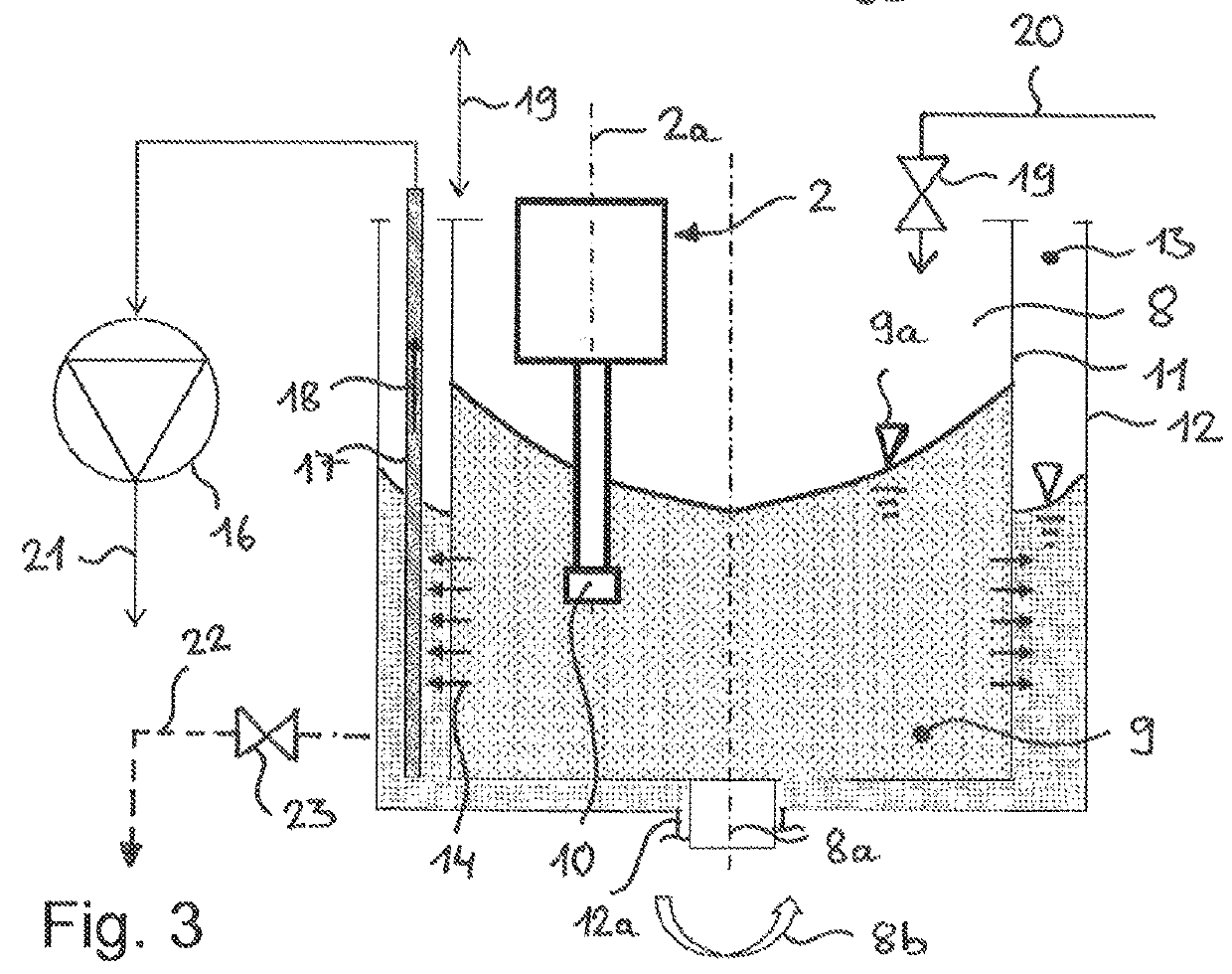

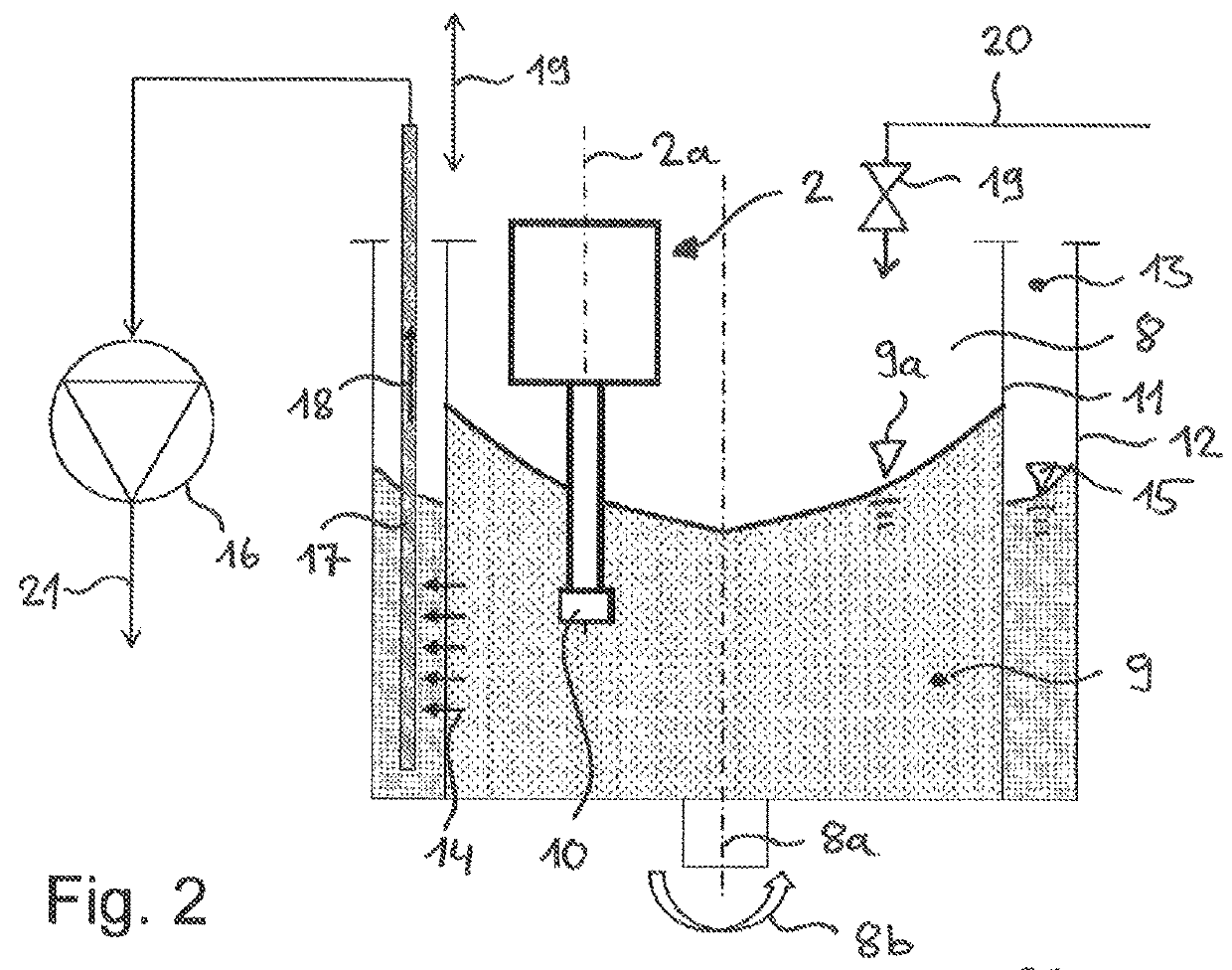

System and method for continuously producing a liquid mixture

ActiveUS20120160330A1Regulation stabilityLow costValve members for heating/coolingPipe heating/coolingLiquid productProcess engineering

The invention relates to a system (30) for continuously producing a liquid product (P) comprising at least two liquid components (k1, k2) that can be pumped, wherein the system comprises two storage tanks (1a, 1b) for each component (k1, k2), two mass-flow control circuits (2a, 2b) for the storage tanks (1a, 1b) for establishing a target mass flow of the component (k1, k2), a first line (9a) into which the components of the liquid product (P) are fed, a second line (9b) for feeding in carbon dioxide, and a filling tank (1c), wherein the first line (9a) feeds the liquid product (P) mixed with carbon dioxide into the filling tank (1c), wherein the storage tanks (1a, 1b) and the filling tank (1c) are designed as pressure vessels and are interconnected by means of at least one pressure equalization line (1) for establishing a pressure equalization between the storage tanks (1a, 1b) and the filling tank (1c).

Owner:MITECO

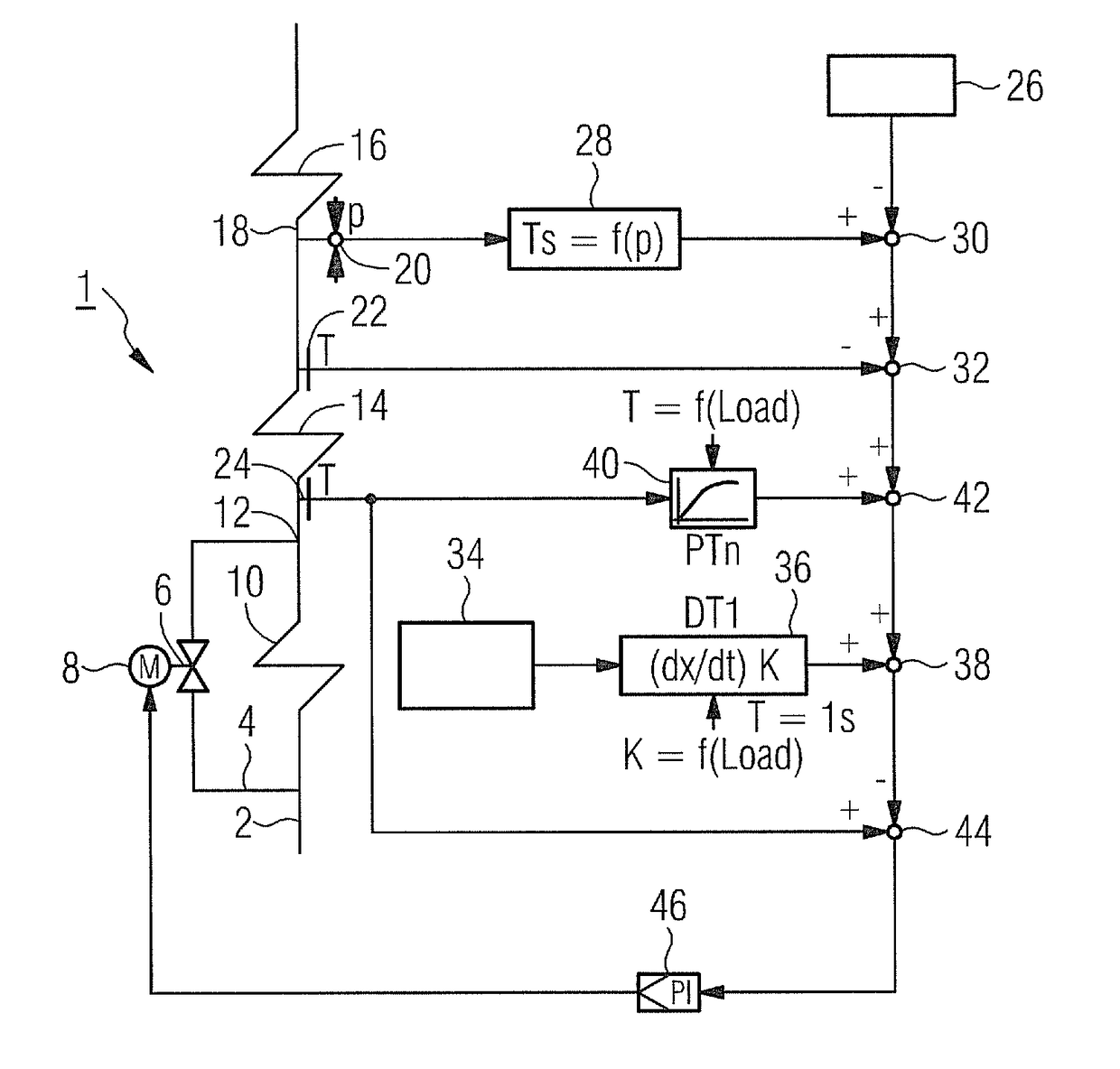

Method for operating a waste heat steam generator

ActiveUS9593844B2High level of operational safety and reliabilityReduce flow rateBoiler controlSteam engine plantsThermal energyEngineering

A method for operating a waste heat steam generator including an evaporator, an economizer having a number of economizer heating surfaces, and a bypass line connected on the flow medium side in parallel with a number of economizer heating surfaces is provided. The method makes possible higher operational safety and reliability in the control of the waste heat steam generator. For this purpose, a parameter that is characteristic of the thermal energy fed to the waste heat steam generator is used to control or regulate the flow rate of the by-pass line.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

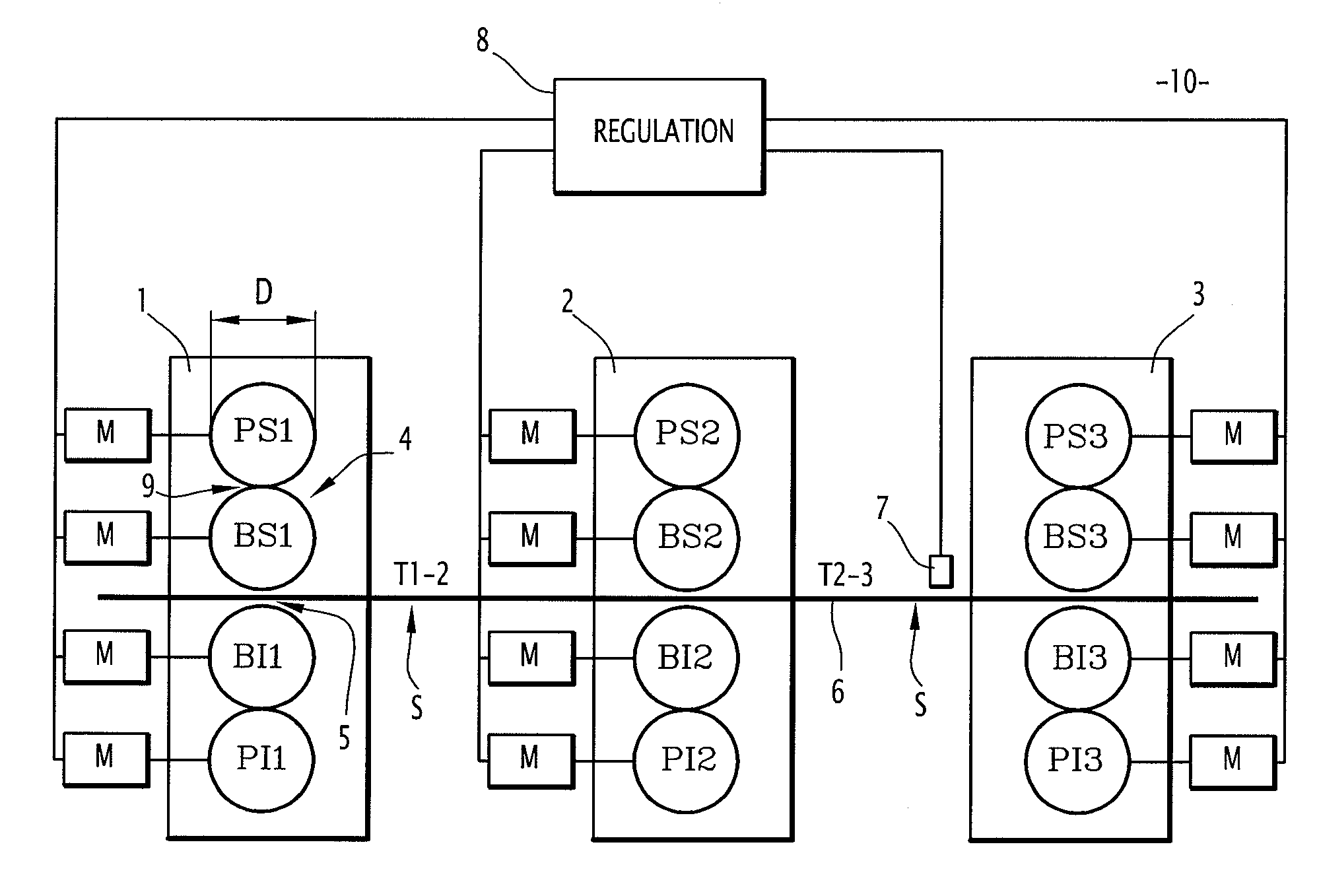

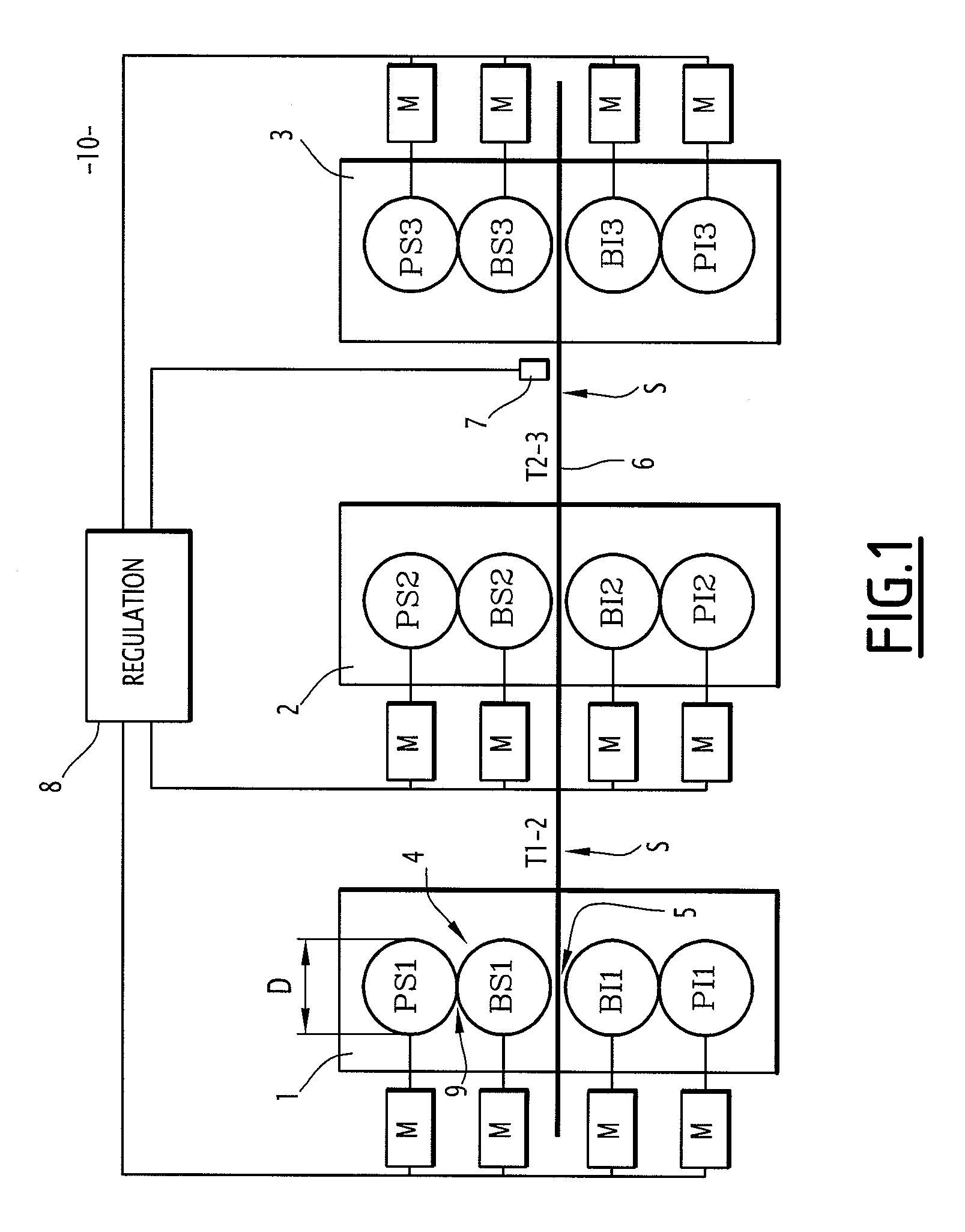

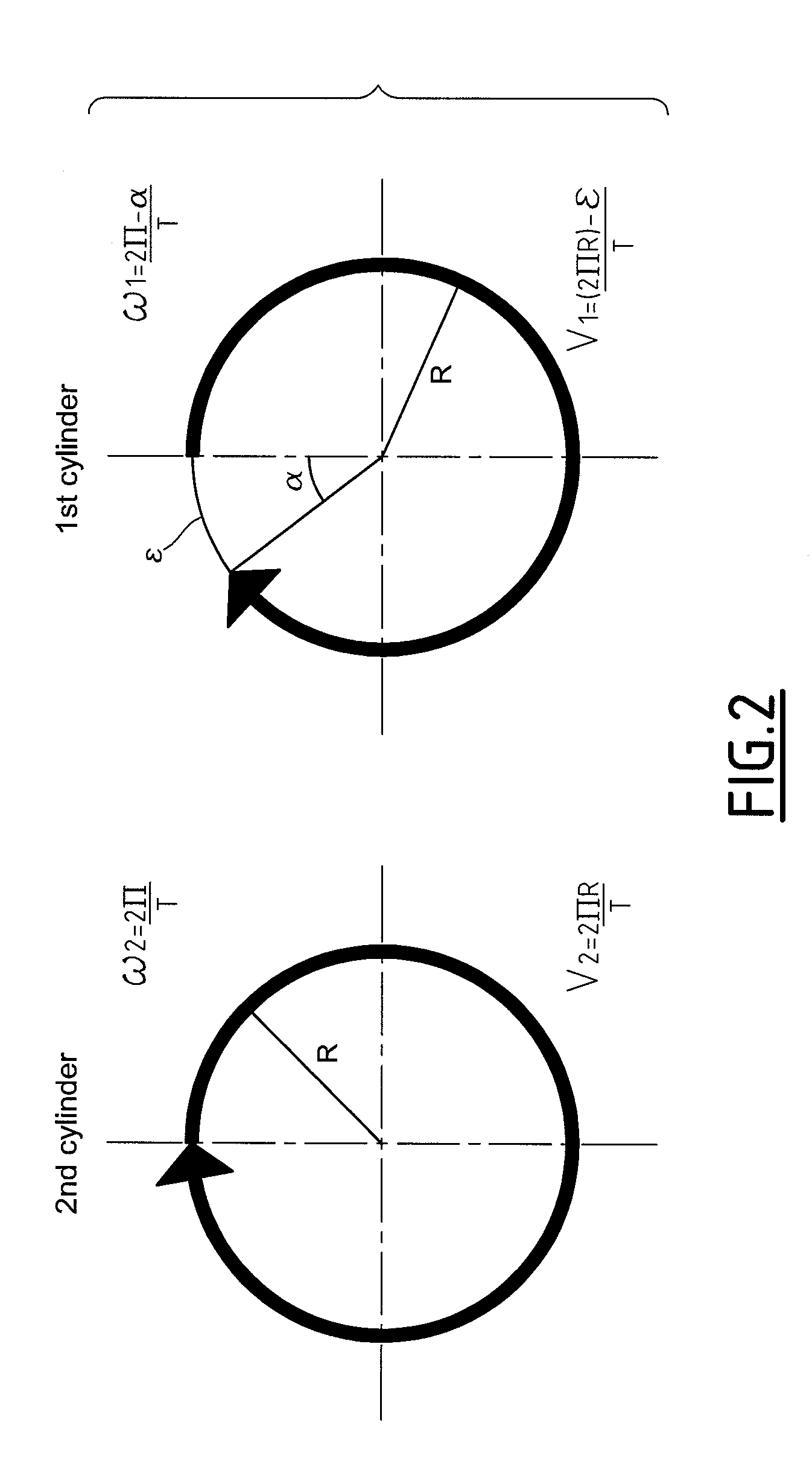

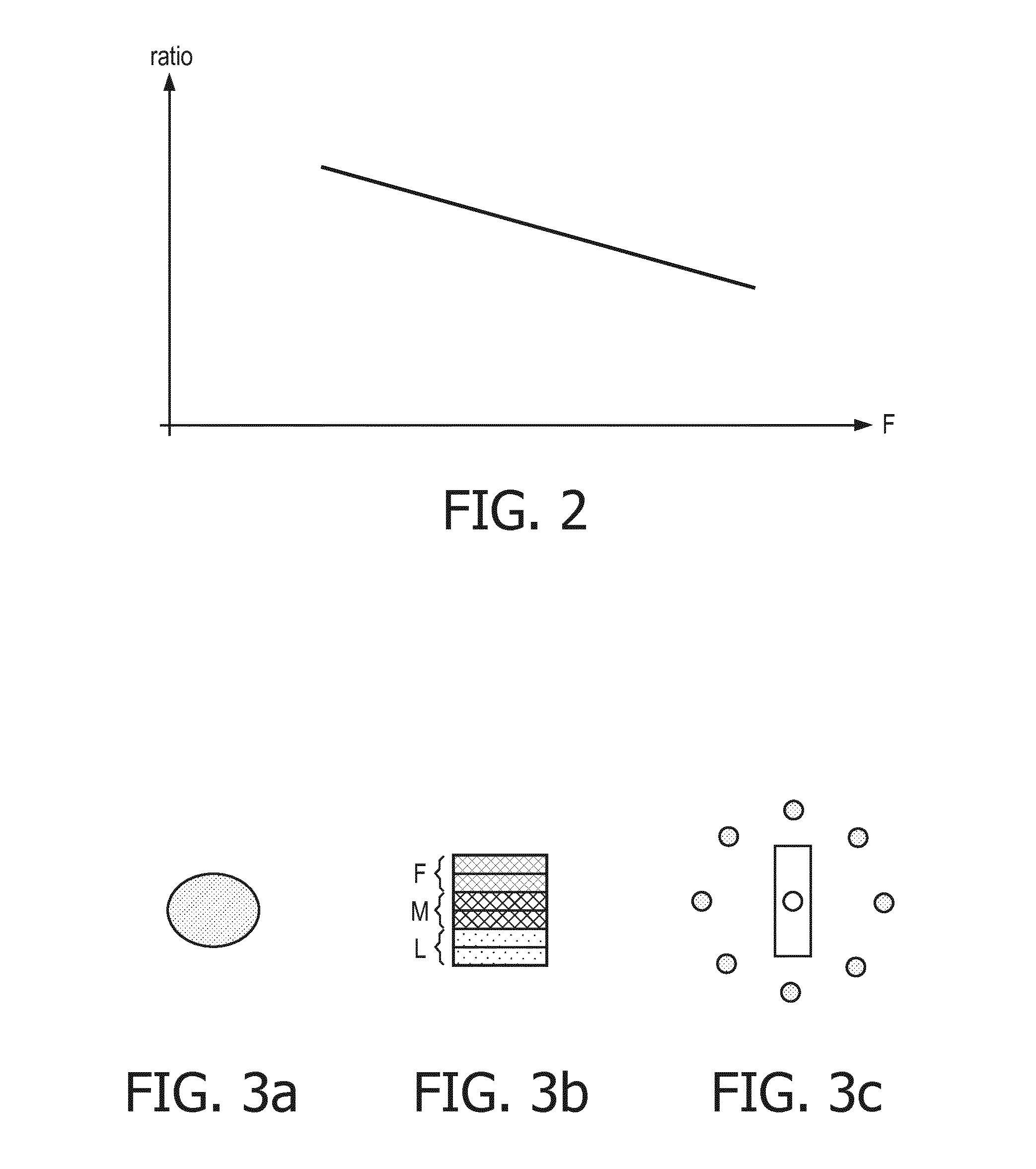

Method for Regulating the Angular Velocity of Printing Cylinders

InactiveUS20110018471A1Reliable and simple and flexible mannerLess-powerful motorMultiple dynamo-motor startersDynamo-electric converter controlCounter pressureAngular velocity

A method for regulating a first printing unit is provided. The first printing unit includes a plate cylinder, a first blanket cylinder carrying a tubular blanket and an impression cylinder. The first blanket cylinder defines a region of contact with the plate cylinder. The impression cylinder defines a region of counter-pressure with the first blanket cylinder. The method includes when the first printing unit is printing, a regulating step of a duration greater than or equal to six minutes in respect of the angular printing velocity ω1 of the first blanket cylinder relative to the angular printing velocity ω2 of the plate cylinder so that, for at least part of the duration of the regulating step, the ratio ω1 / ω2 of the angular velocities is different from the ratio D2 / D 1 between the diameter D2 of the plate cylinder and the diameter D1 of the first blanket cylinder in order to define a difference in velocity Δω=ω1−ω2×D2 / D1, any difference in velocity Δωbeing of the same sign throughout the entire duration of the regulating step.

Owner:GOSS INT MONTATAIRE

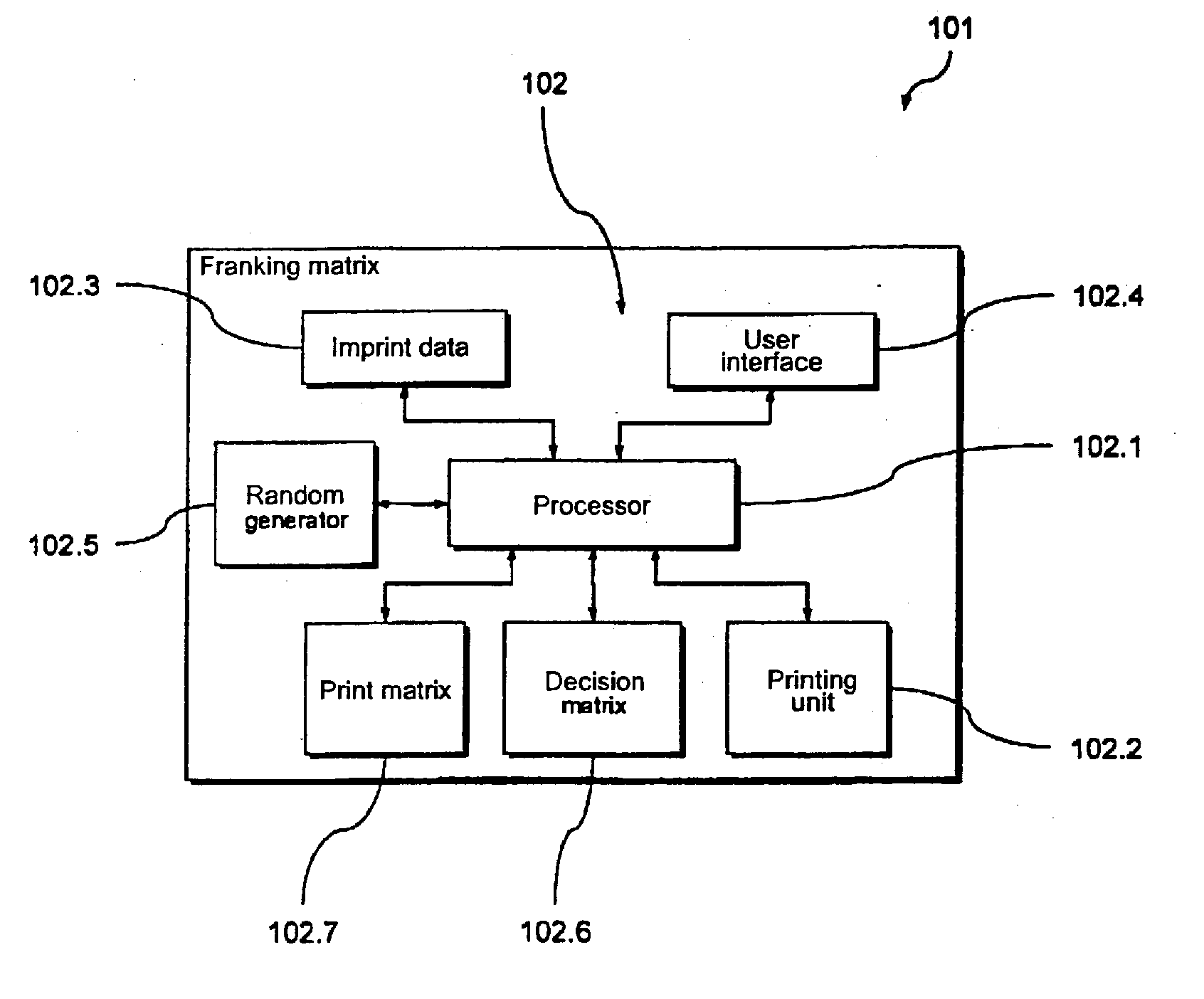

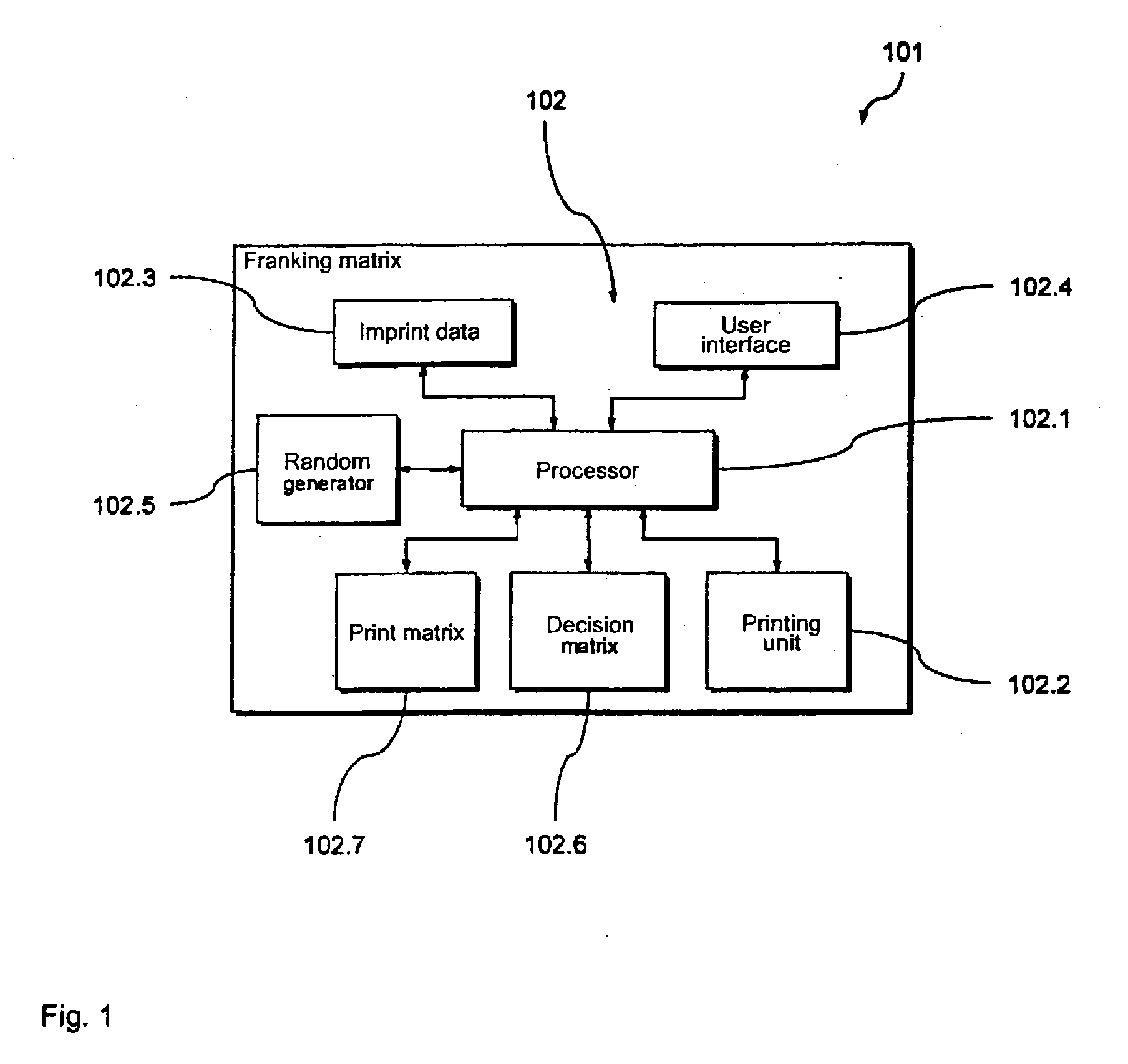

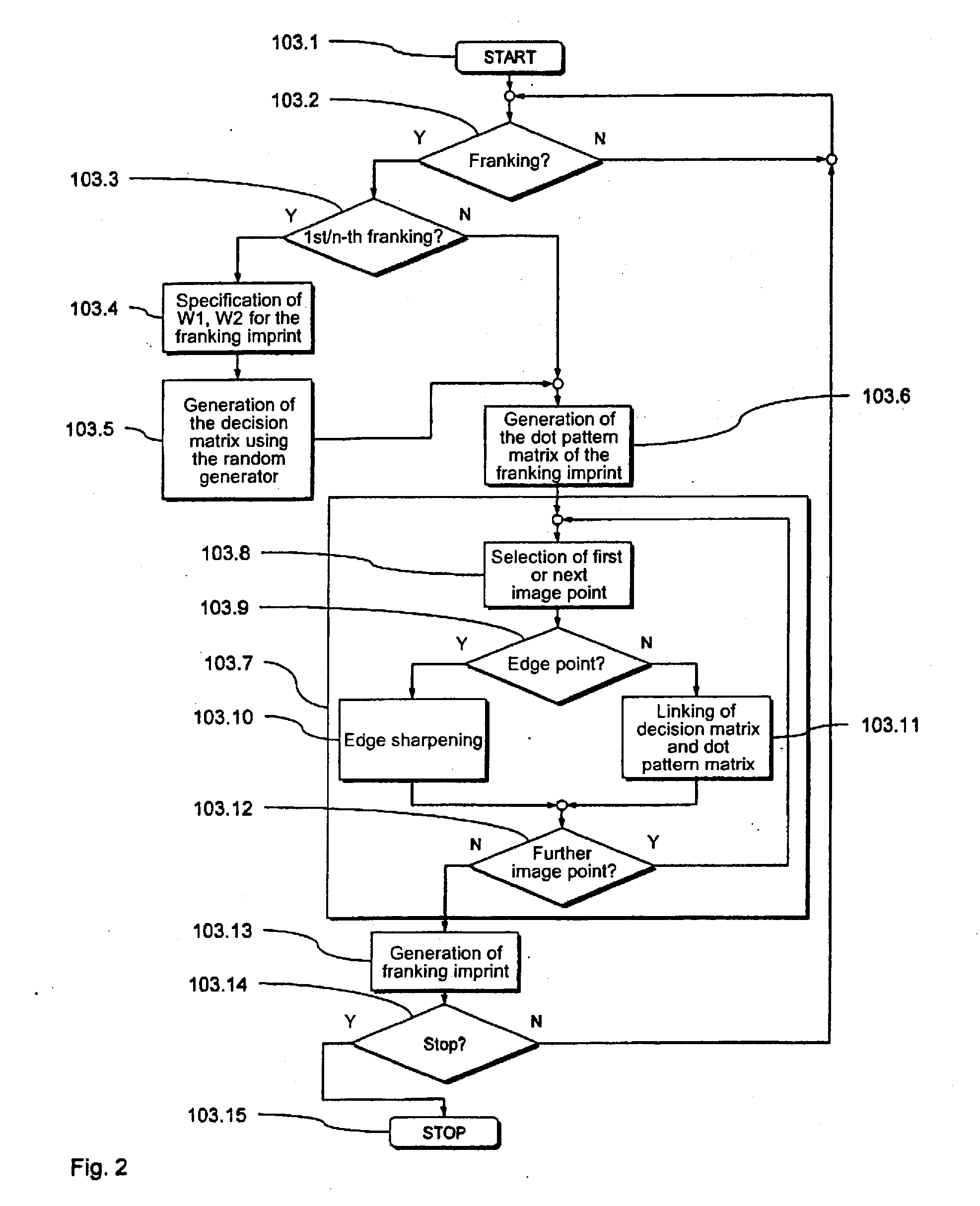

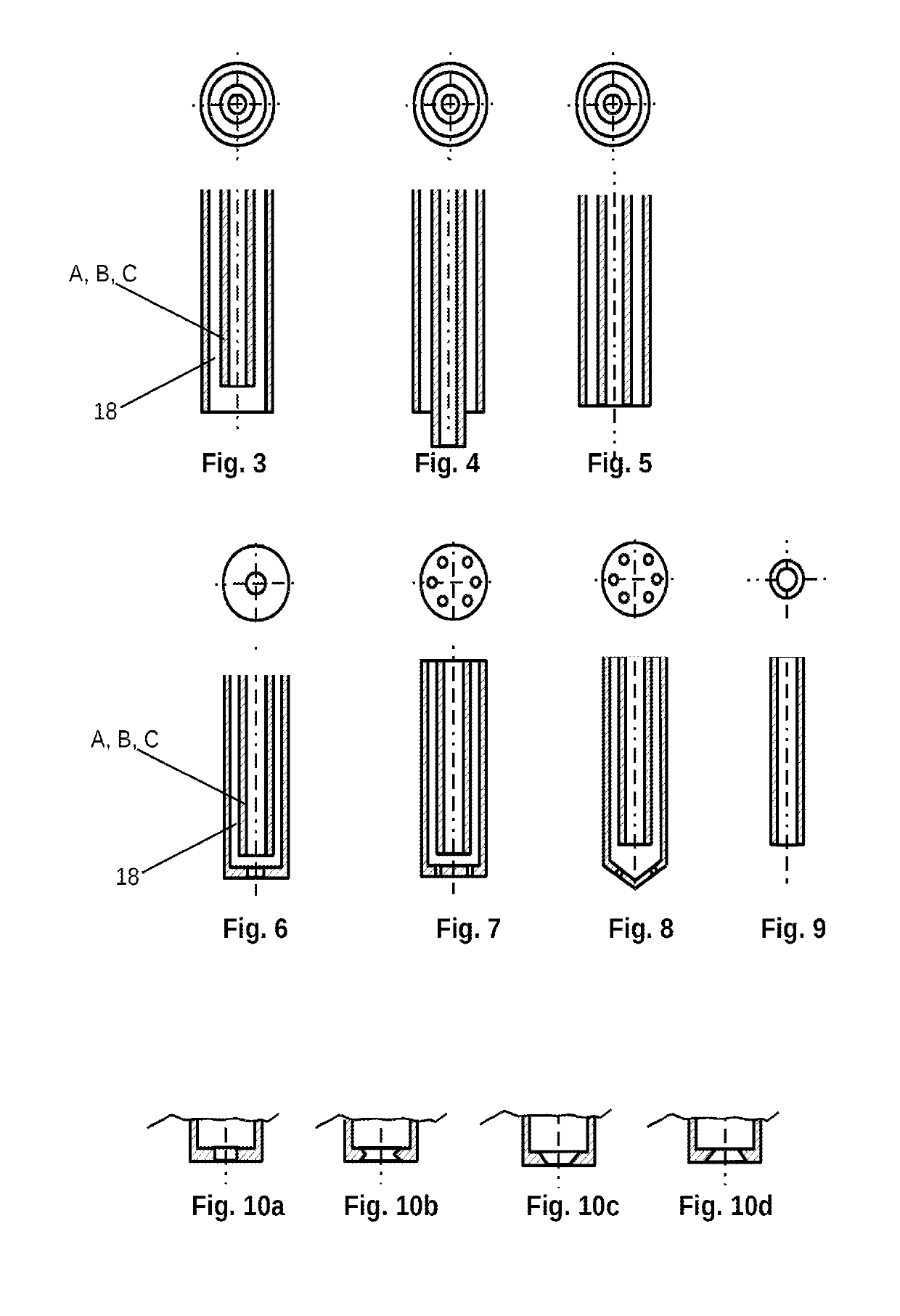

Method and arrangement for generating a dot matrix imprint

InactiveUS20080024800A1Reduce in quantityAvoiding interfering regular patternImage enhancementDigitally marking record carriersDot matrixArtificial intelligence

In a method and arrangement for generation of an imprint with a printing device operating according to a dot matrix principle (in particular an inkjet principle), a dot pattern is provided for the imprint, with which the printing device image points corresponding to the provided dot pattern on a substrate. For at least one first image point a probability with which the image point is generated is provided. Whether this image point is actually generated on the substrate is determined in a decision step using a random generator and the probability. The image point is generated (or not) in a subsequent step dependent on the result of the decision step.

Owner:FRANCOTYP POSTALIA

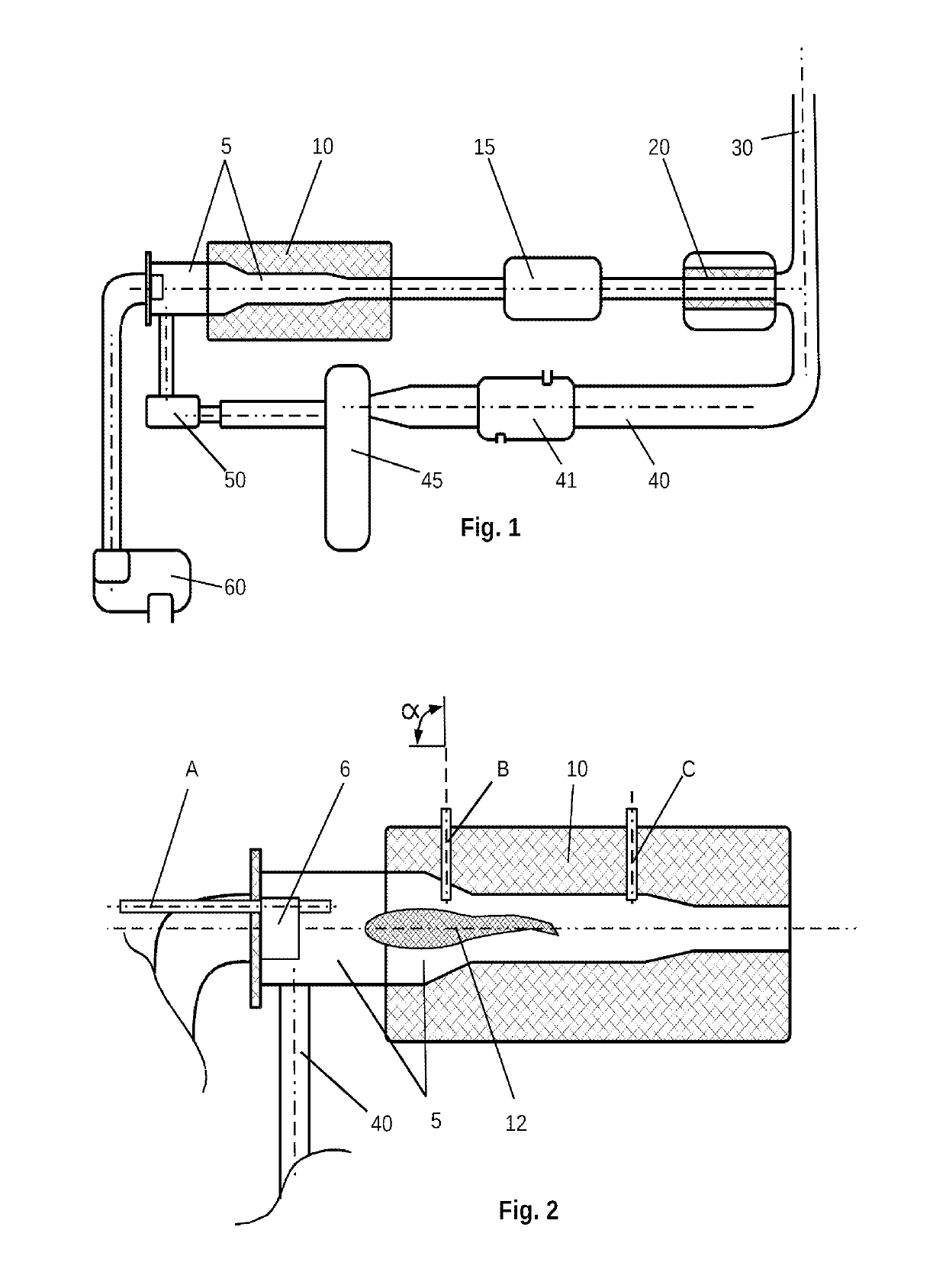

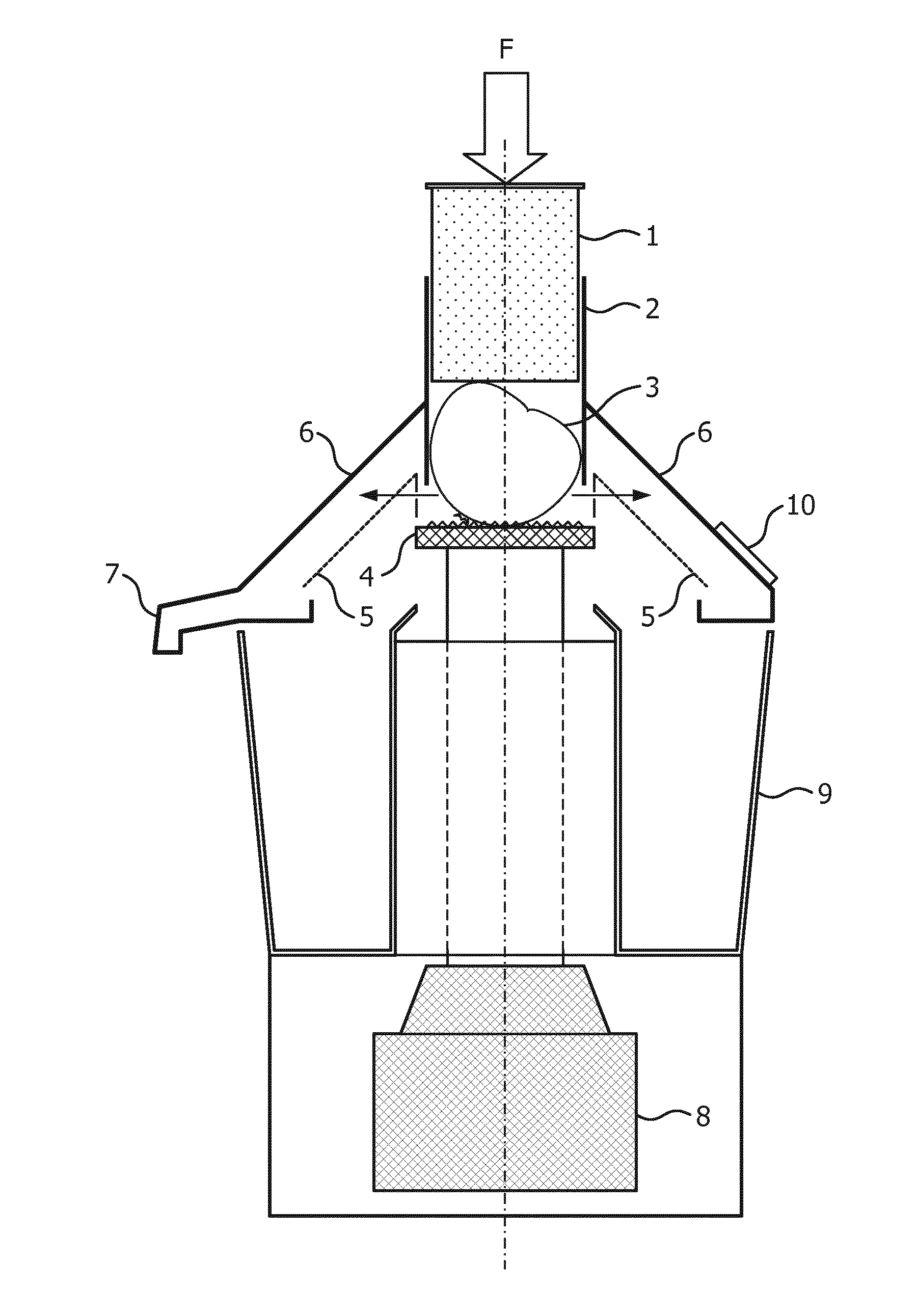

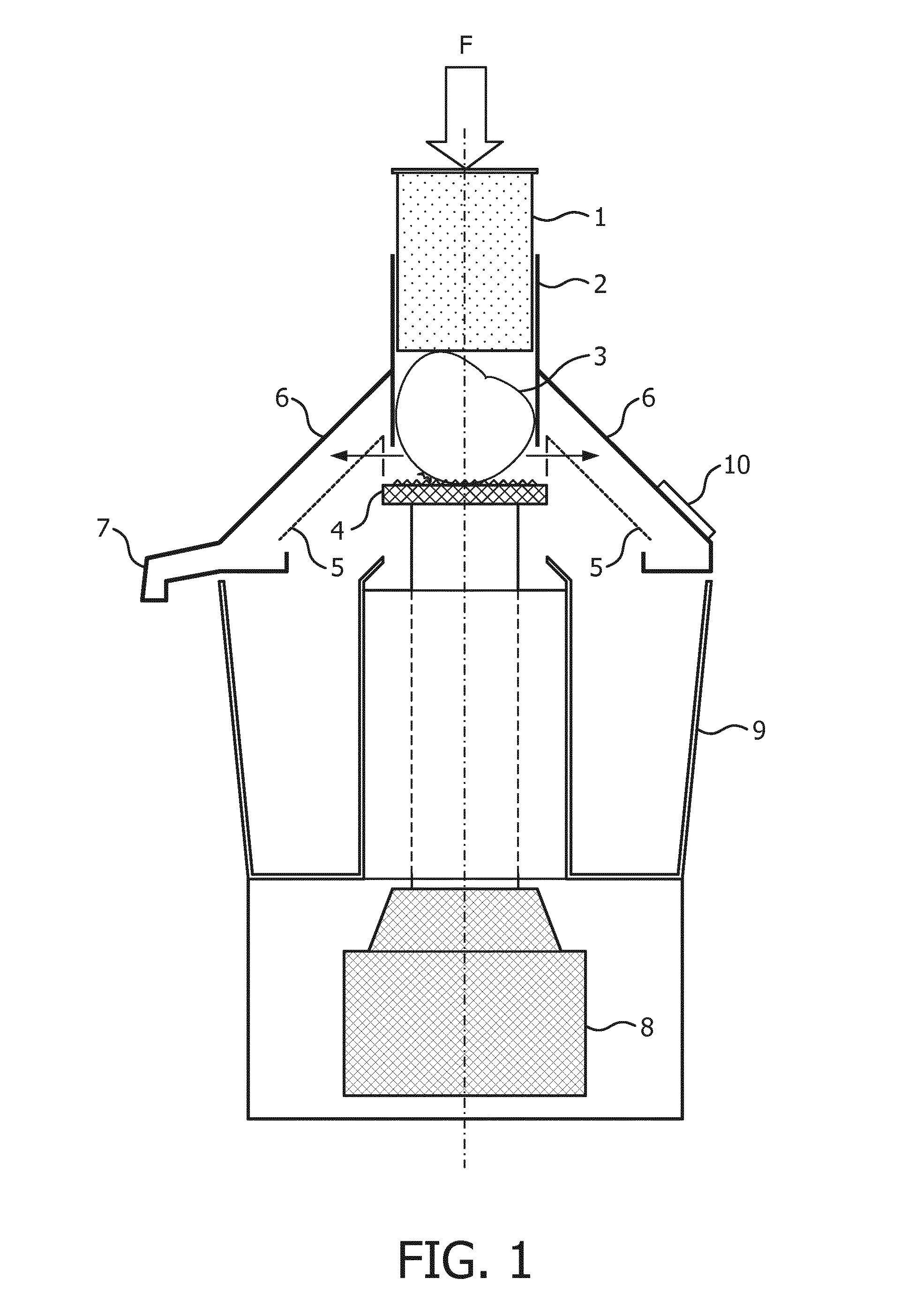

Method and device for melting the ends of rods

ActiveUS20100122557A1Easily conveyedConvenient ArrangementGlass transportation apparatusGlass reforming apparatusCombustorEngineering

The invention relates to a method for treating the ends of glass rods in which glass rods are inserted into receptacles in a carrier and with the carrier are carried past a burner and at least one rail in an advancing direction, the flame of the burner melting at least one end of the glass rods and the glass rods being lifted by the rail in the receptacles and rolling on the rail so that the glass rods are made to rotate during the melting process.

Owner:SCHOTT AG

Method for controlling the filling of at least one cavity

PendingUS20160303787A1Simple regulationSufficient openingInjection molding machineMechanical engineering

A method for controlling the filling of at least one cavity in a device for producing an object, in particular in an injection molding machine, wherein a melt is inserted into the cavity through an opening, and the width thereof is altered, wherein the width of the opening is also to be changed and adjusted, that is, fixed, in a position between a closed position and a maximal open position.

Owner:PRIAMUS SYST TECH AG

Method and Device for Controlling a Suction Pressure of an Internal Combustion Engine

ActiveUS20100228464A1Cutting costsReliable transmissionElectrical controlInternal combustion piston enginesExternal combustion engineTurbocharger

A method device for controlling a suction pressure of an internal combustion engine, particularly a diesel engine having an exhaust gas turbocharger. The compressor is connected to a suction line of the internal combustion engine via an actuating section having an actuating element for changing a cross-section of the actuating section. In the first step, the current suction pressure in the suction line of the internal combustion engine is determined. A compressor pressure of the compressor is determined by pressure sensors and compared to the suction pressure. Values corresponding to current operating data of the internal combustion engine are identified and an actuation signal is generated using a controller, based on the comparison; and changing the cross-section of the actuating section is adjusted by adjusting the actuating element using the actuating signals.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

Testing facility for ageing exhaust gas systems

ActiveUS20190234279A1Increase in significanceSimple regulationInternal-combustion engine testingInternal combustion piston enginesParticulatesCombustor

Testing facility for ageing exhaust gas systems, with a burner (5), a receiving area for receiving at least one catalytic converter (15) and / or a particulate filter (20). An ash-forming component is supplied here to the burner flame.

Owner:FEV EURO GMBH

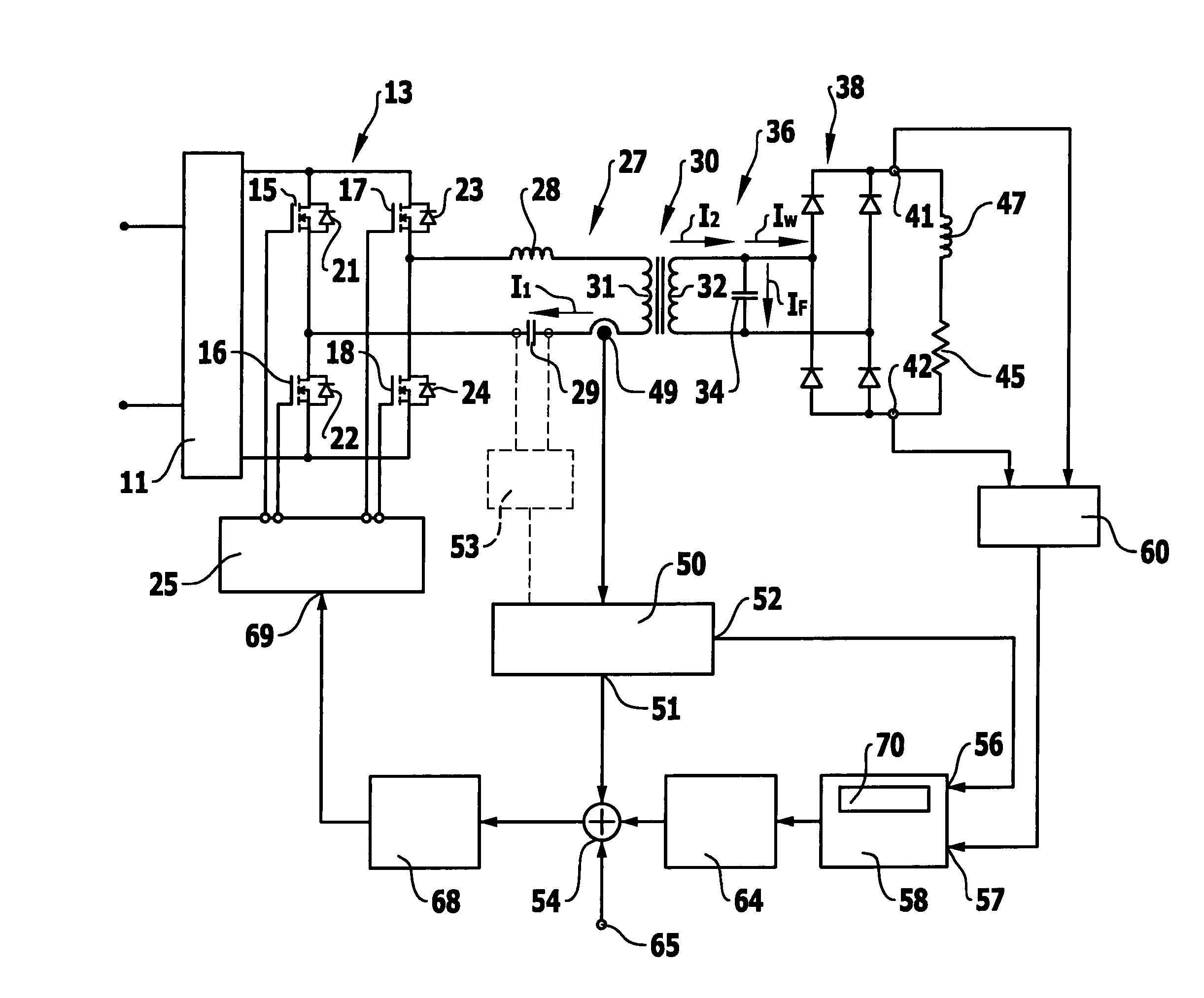

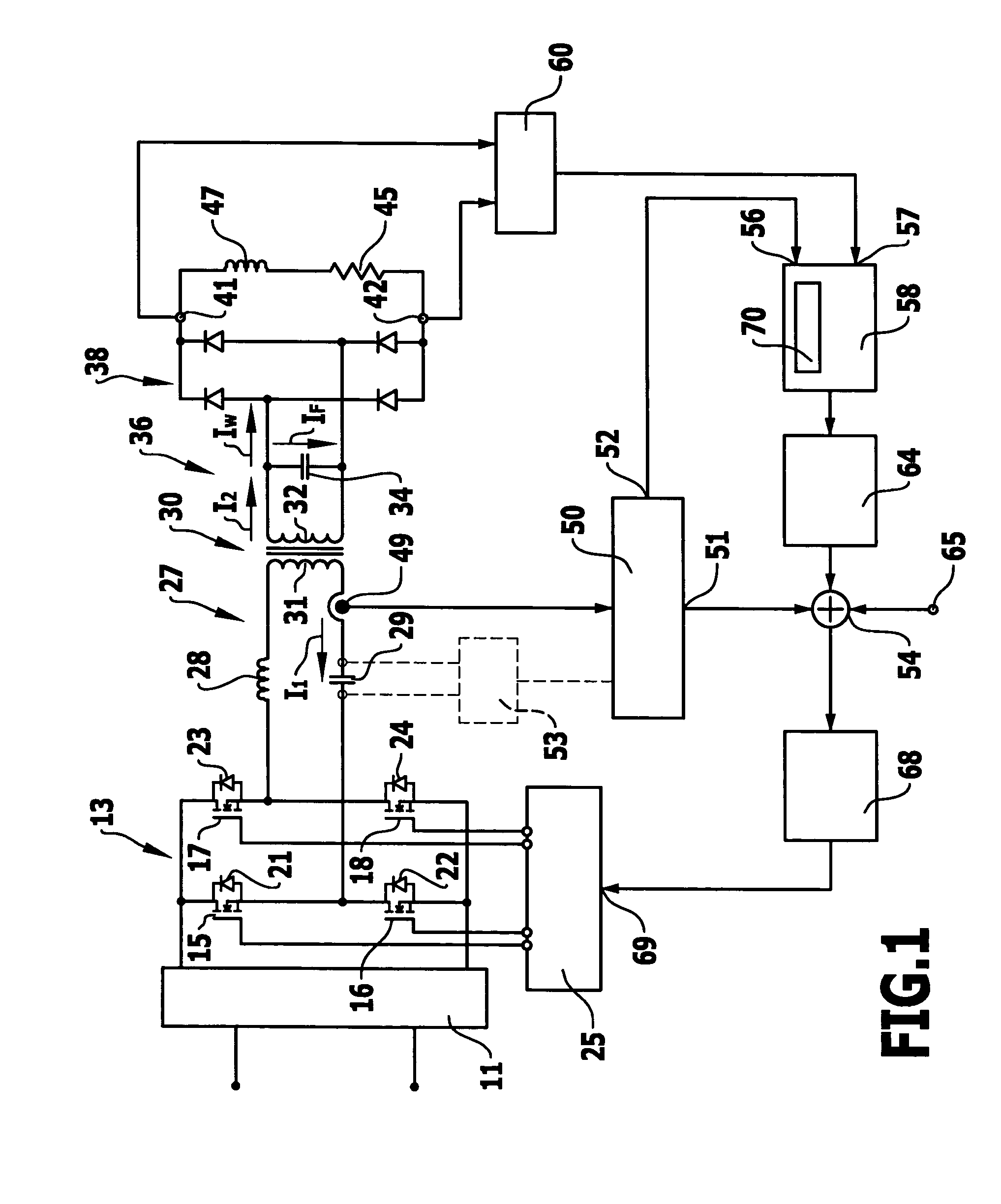

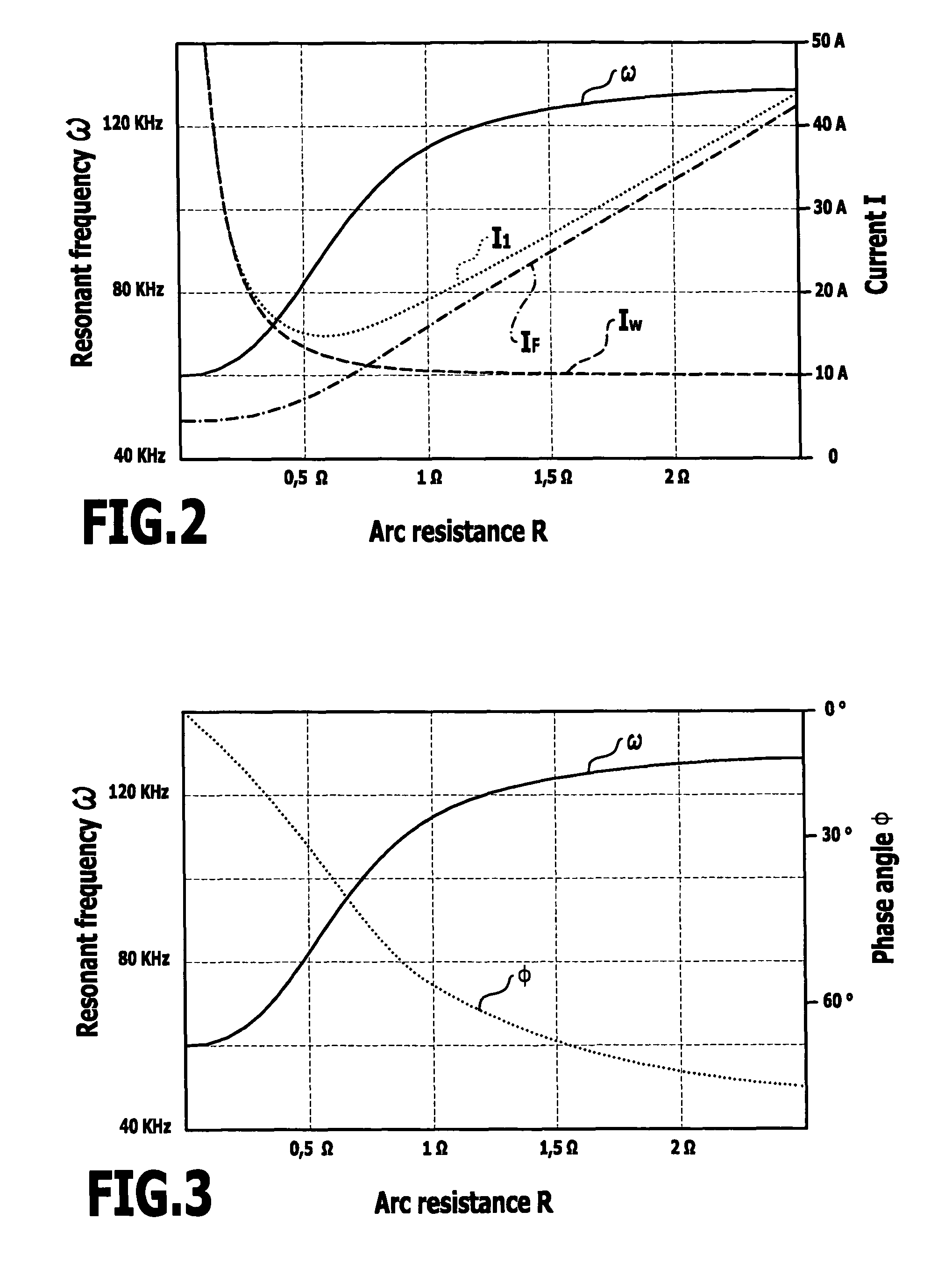

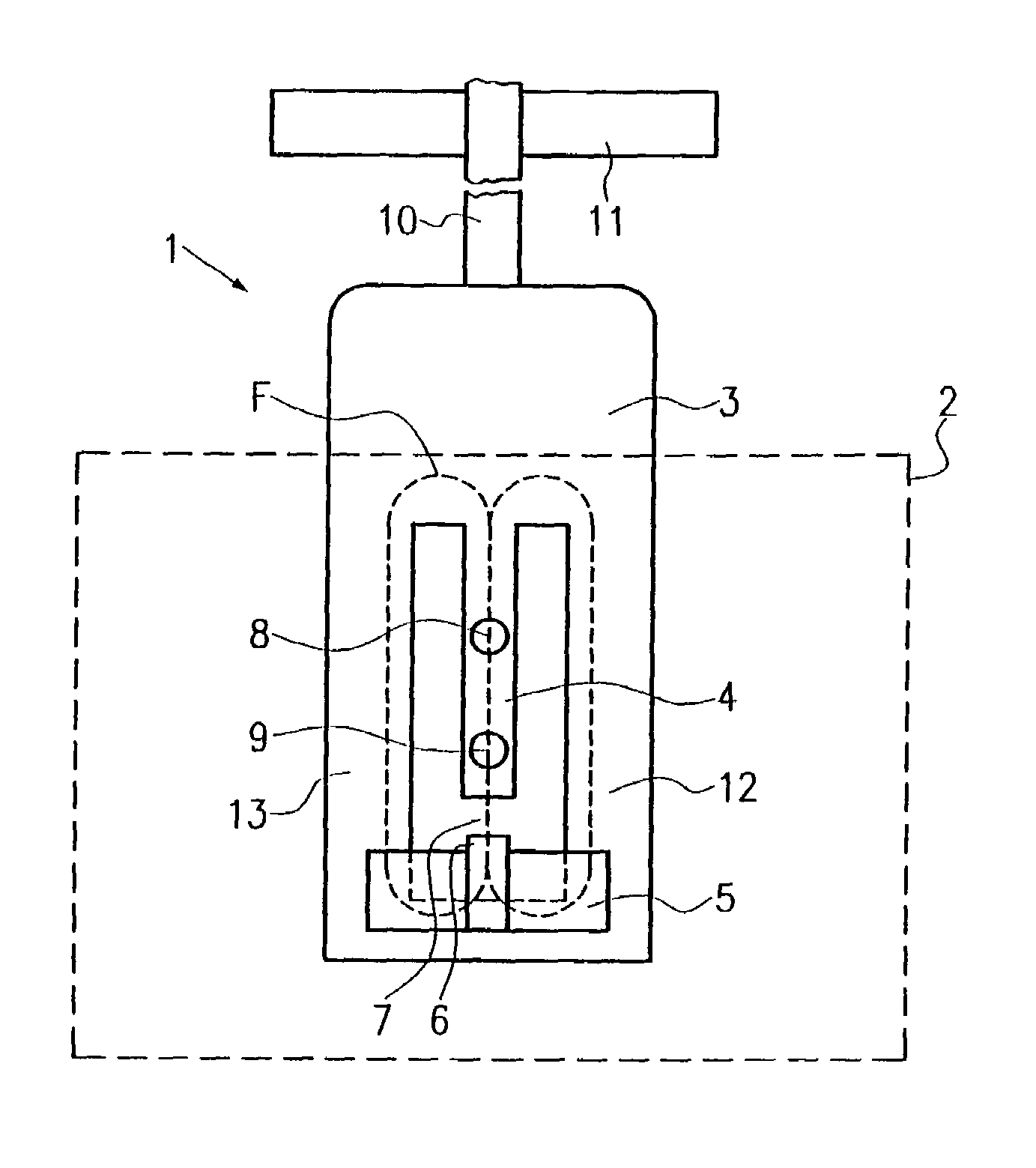

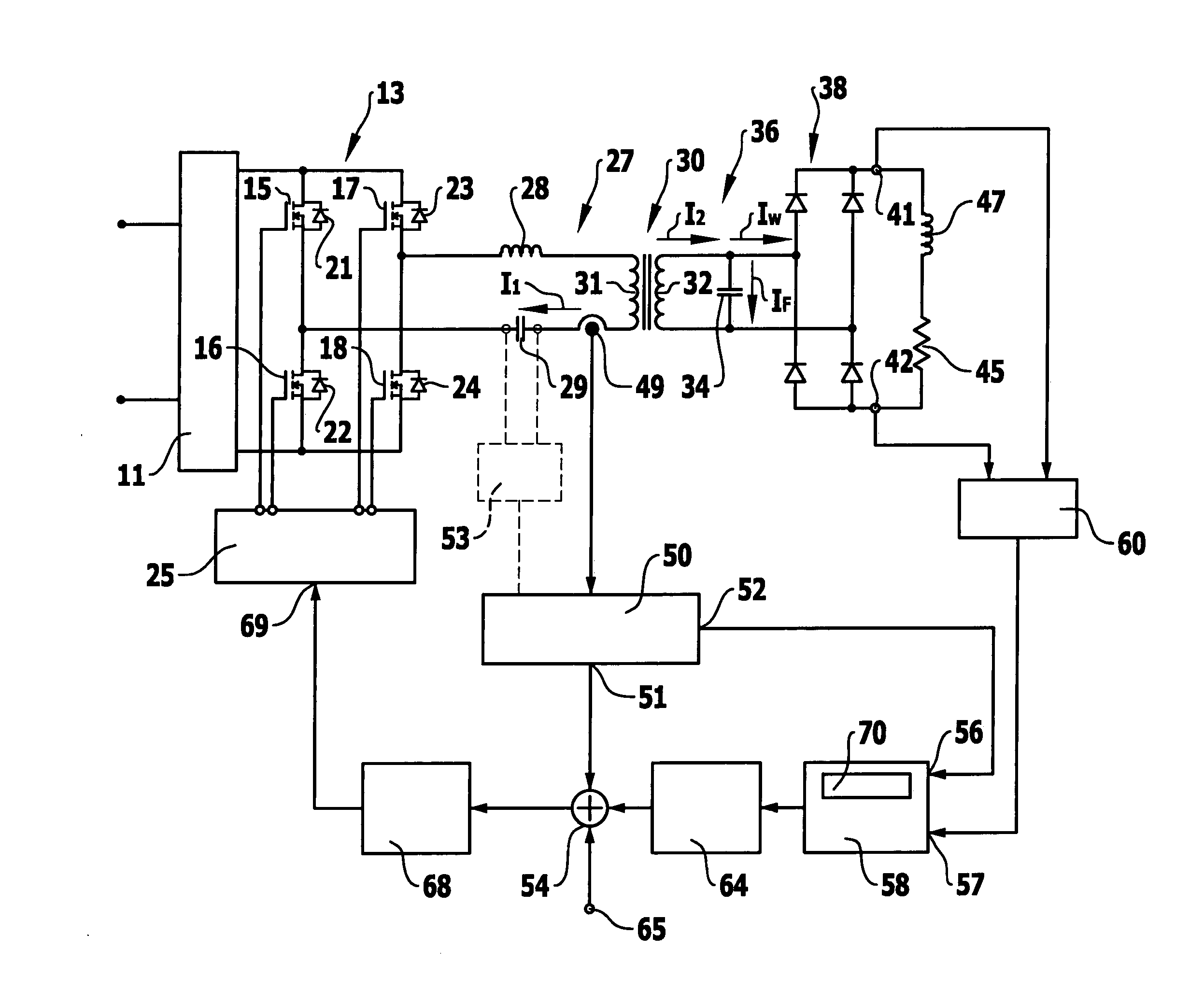

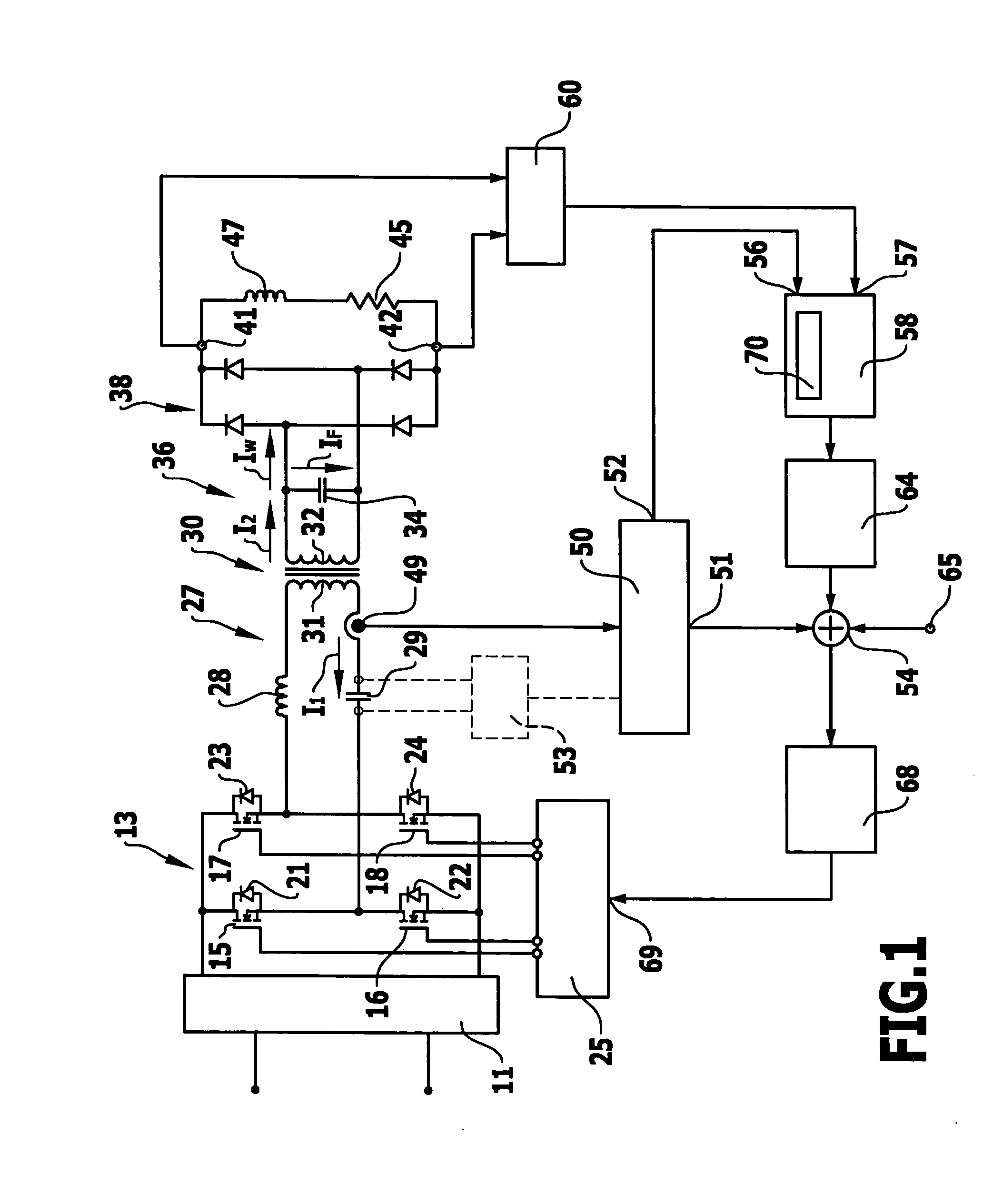

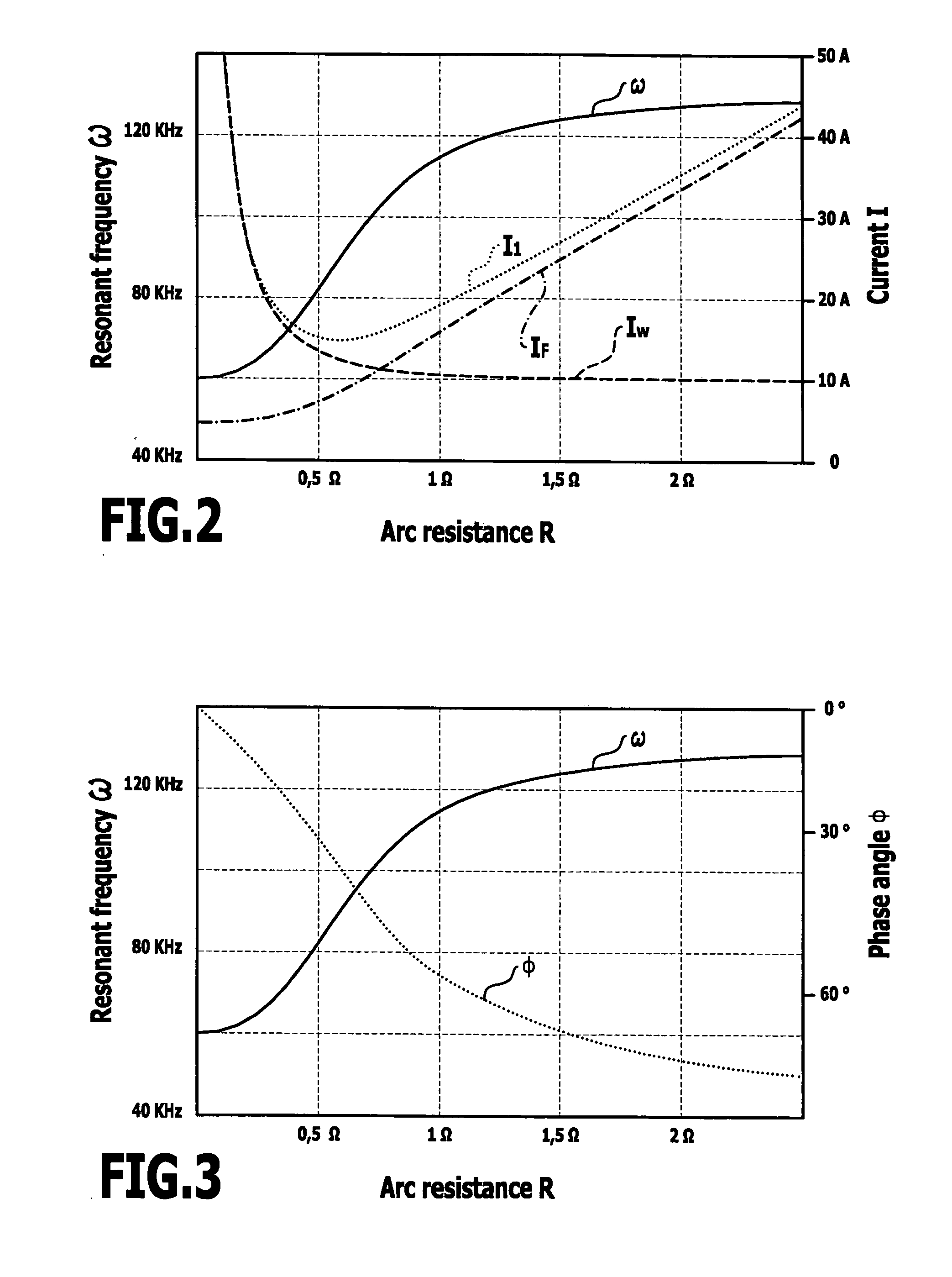

Method for regulating a welding current source and welding current source for carrying out the method

The invention relates to a method for regulating a welding current source with a current transformer, which has a series resonant circuit on the primary side and a parallel resonant circuit on the secondary side, the series resonant circuit being supplied with a variable alternating voltage by a bridge circuit and the parallel resonant circuit providing energy to a welding process by way of a rectifier, and a control unit controlling the bridge circuit in dependence on at least one state variable of the welding current source. In order to develop the method in such a way as to make regulation possible at low cost and with as little power loss as possible, it is proposed according to the invention that only the primary current or a state variable on the primary side corresponding to the primary current is recorded as the electrical-current state variable of the welding current source and a control signal dependent on the primary current or on the state variable corresponding thereto is fed to the control unit. A welding current source for carrying out the method is also proposed.

Owner:LORCH SCHWEISSTECHNIK GMBH

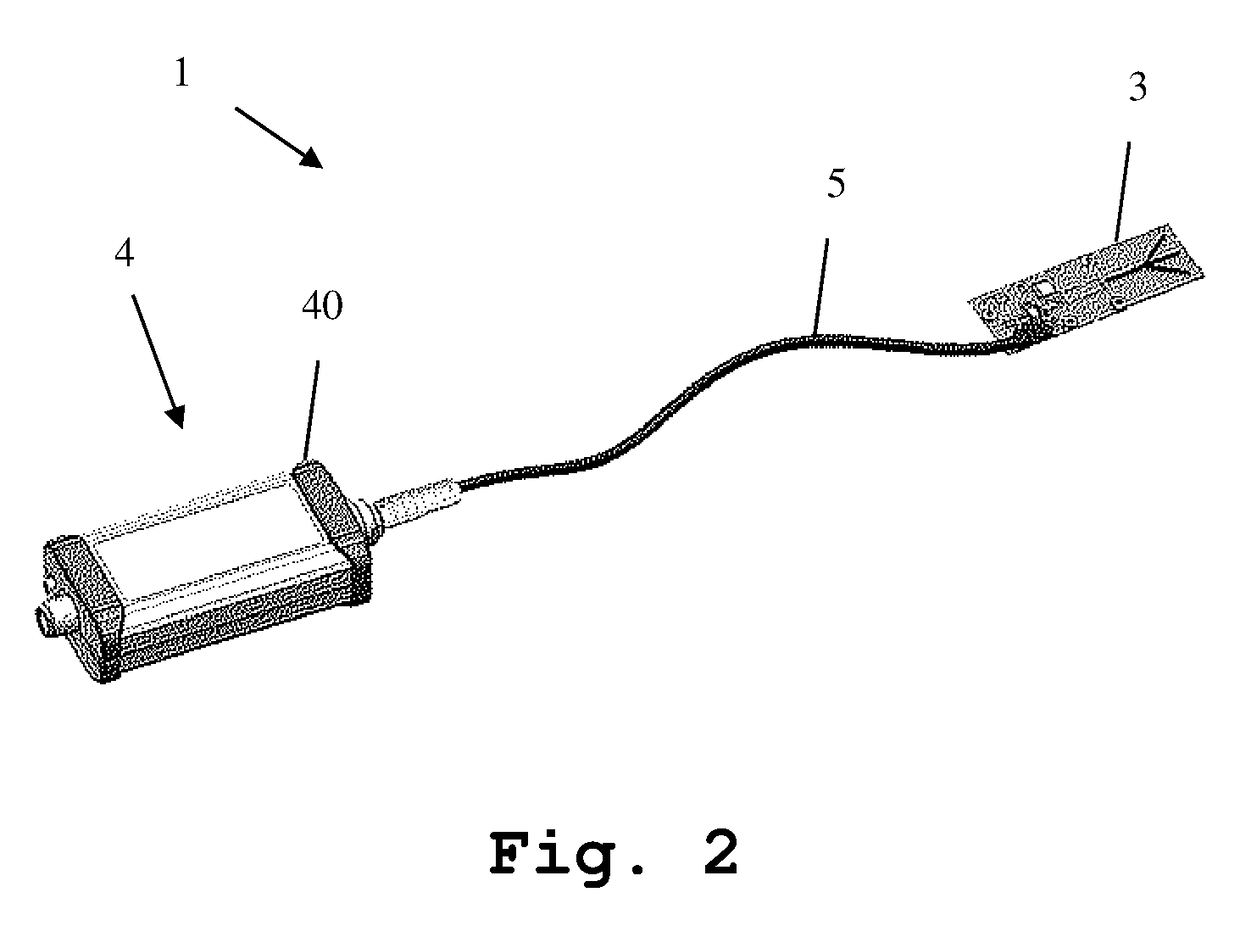

Measuring instrument and method for detecting a force

InactiveUS7543505B2Simple regulationIncrease dynamicsControlling membersFoot actuated initiationsMeasuring instrumentRelative motion

The present invention relates to a force measuring instrument, having a carrier plate (3), at least one magnet (5), and at least one magnetically sensitive element (6). A tongue element (4) protrudes at least partly from the carrier plate (3) and is joined to a plate element (2). Between the tongue element (4) and the carrier plate (3), an air gap (7) is formed, in which the magnetically sensitive element (6) is positioned. The force to be measured, delivered via the plate element (2), leads to a relative motion between the end, toward the air gap, of the tongue element (4) and the carrier plate (3). This causes a change in the magnetic field geometry in the air gap (7). The present invention also relates to a method for detecting a force.

Owner:ROBERT BOSCH GMBH

Method for regulating a welding current source and welding current source for carrying out the method

The invention relates to a method for regulating a welding current source with a current transformer, which has a series resonant circuit on the primary side and a parallel resonant circuit on the secondary side, the series resonant circuit being supplied with a variable alternating voltage by a bridge circuit and the parallel resonant circuit providing energy to a welding process by way of a rectifier, and a control unit controlling the bridge circuit in dependence on at least one state variable of the welding current source. In order to develop the method in such a way as to make regulation possible at low cost and with as little power loss as possible, it is proposed according to the invention that only the primary current or a state variable on the primary side corresponding to the primary current is recorded as the electrical-current state variable of the welding current source and a control signal dependent on the primary current or on the state variable corresponding thereto is fed to the control unit. A welding current source for carrying out the method is also proposed.

Owner:LORCH SCHWEISSTECHNIK GMBH

Electric food processing device

InactiveUS20170007063A1Reduced effectivenessEasy loadingGrain treatmentsStrainersEngineeringMechanical engineering

An electric food processor is of the type in which the user applies pressure to the food item against a rotary processing member (4) against during processing. A pressure indicator (10) is provided for displaying a signal at least representing the user-applied pressure.

Owner:KONINKLJIJKE PHILIPS NV

Electrically drivable valve for regulating volume flows in a heating and/or cooling system of a motor vehicle

InactiveUS20140326343A1Reliable reduction of pressure lossReduce total pressure lossCoolant flow controlMultiple way valvesMobile vehicleElectricity

An electrically drivable valve for regulating volume flows in a heating and / or cooling system of a motor vehicle with a housing, on which at least two connecting pieces are formed, whereby depending on the arrangement of the valve in a heating and / or cooling circuit one or more connecting pieces are formed as inflow connections and a connecting piece as an outflow connection or one or more connecting pieces as outflow connections and a connecting piece as an inflow connection, whereby a valve body rotatable around a rotation axis is arranged in the housing. In the case of an electrically controllable valve, in which pressure losses in the control circuit are reliably reduced, in the case of an axial inflow or outflow of the valve by a heating medium and / or coolant the axes of one or more outflow connections or of one or more inflow connections are oriented axially and radially relative to the rotation axis of the valve body.

Owner:BEHR THERMOT TRONIK

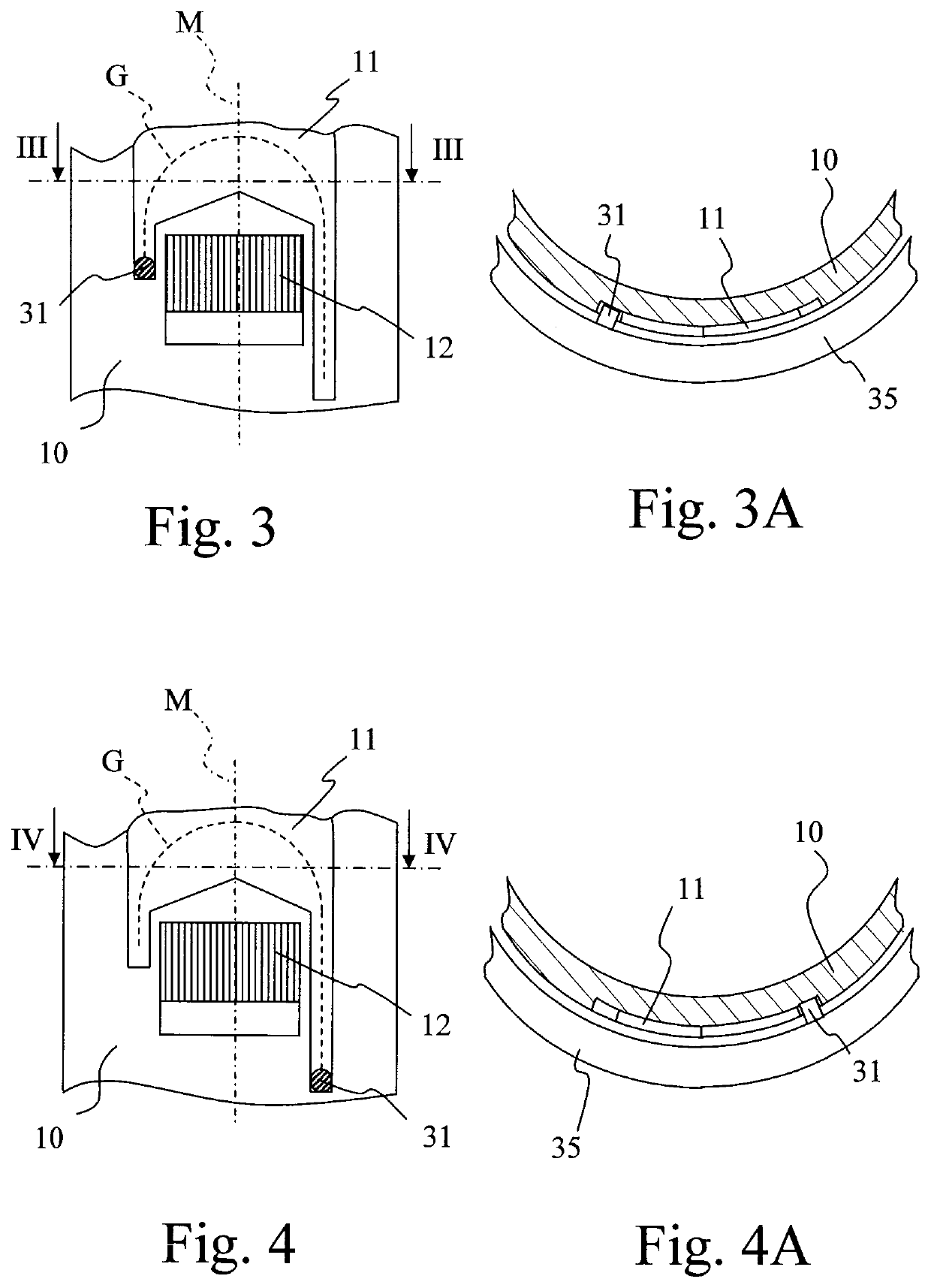

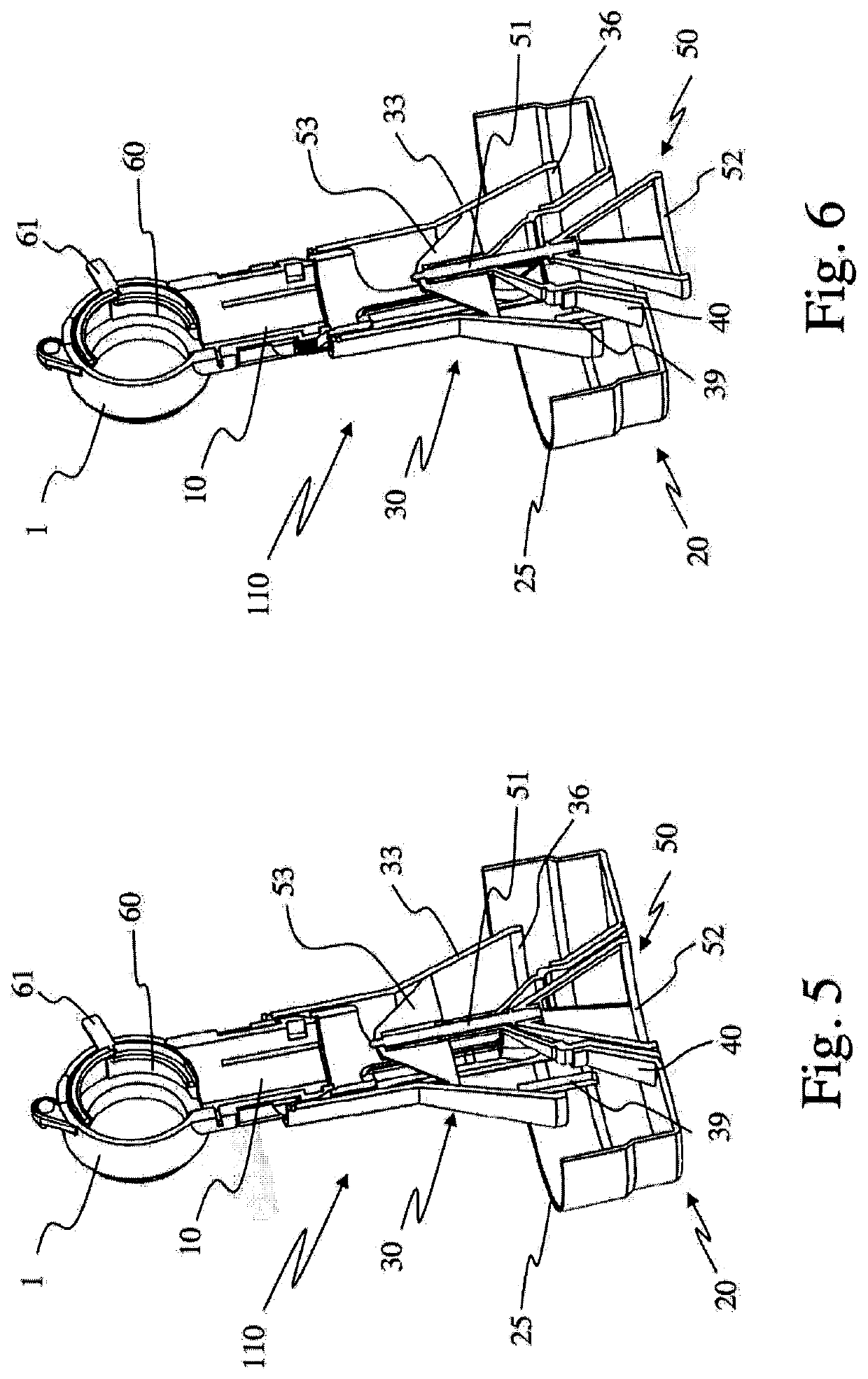

Feeding dispenser for animal breeding with improved adjustment of the feed level

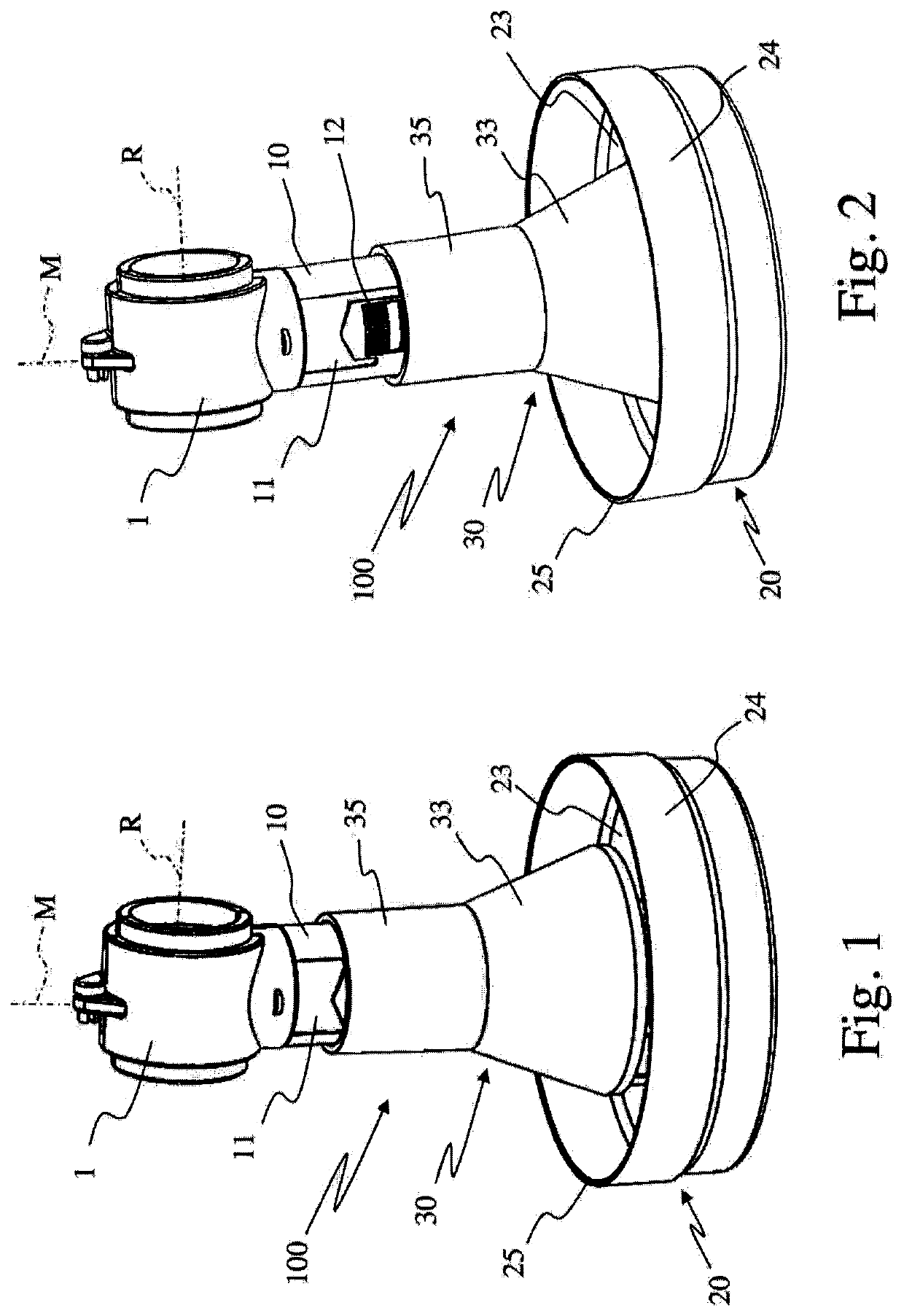

An automatic feeding dispenser (100) for poultry breeding is described, comprising in general a cylindrical feed supply conduit (10), an accumulation tray (20) to supply the feed to poultry and a shutter (30) having at least one cylindrical portion (35), outer sliding and rotatable with respect to the supply conduit (10). The cylindrical portion (35) of the shutter (30) and the cylindrical supply conduit (10) are coupled and free to slide between one another by means of a protuberance (231, 31) engaged in a groove (11, 211). The groove (11, 211) is shaped to provide two bearing seats at different heights, respectively an upper height and a lower height. The upper bearing seat of the two bearing seats is defined by a bump (215) that can be surmounted by the protuberance (231, 31) by elastic deformation of part of the cylindrical supply conduit (10) and / or part of the cylindrical portion (35) of the shutter (30) following an upward or downward thrust exerted on the shutter (30) with force sufficient to exceed the elastic reaction of part of the cylindrical supply conduit (10) and / or part of the cylindrical portion (35) of the shutter (30).

Owner:CORTI ZOOTECNICI

Drag and/or dip finishing machine for the surface machining of workpieces by means of grinding and/or polishing granules in the presence of a liquid machining agent

ActiveUS10040164B2Simple and cost-effective designEasy to optimizeEdge grinding machinesPolishing machinesEngineeringMachining

A drag and / or dip finishing machine has at least one workpiece holder for the releasable fastening of the workpieces to be machined and a container, disposed beneath the workpiece holder, for accommodating the grinding and / or polishing granules, wherein the workpiece holder and the container are movable relative to each other in that at least the container is rotationally driven. The container has a chamber, which extends around the whole of the periphery thereof and is fluidically connected to the inside, accommodating the grinding and / or polishing granules, of the container, at least on a lower portion thereof, the chamber being equipped with a liquid discharge unit in order to be able to discharge the machining agent from the chamber in the event of an excess of machining agent in the container.

Owner:OTEC PRAZISIONSFINISH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com