Patents

Literature

96results about How to "Easily conveyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

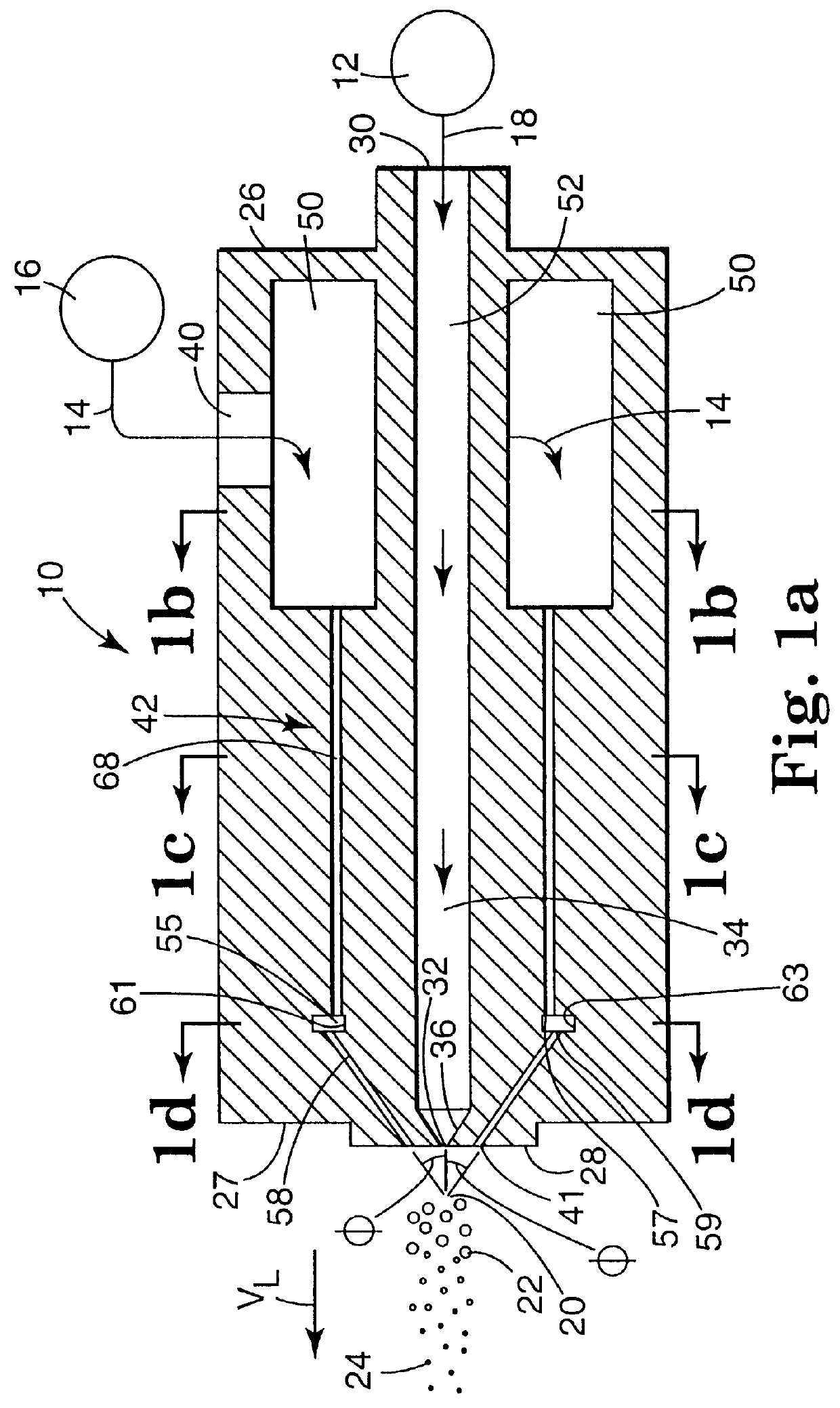

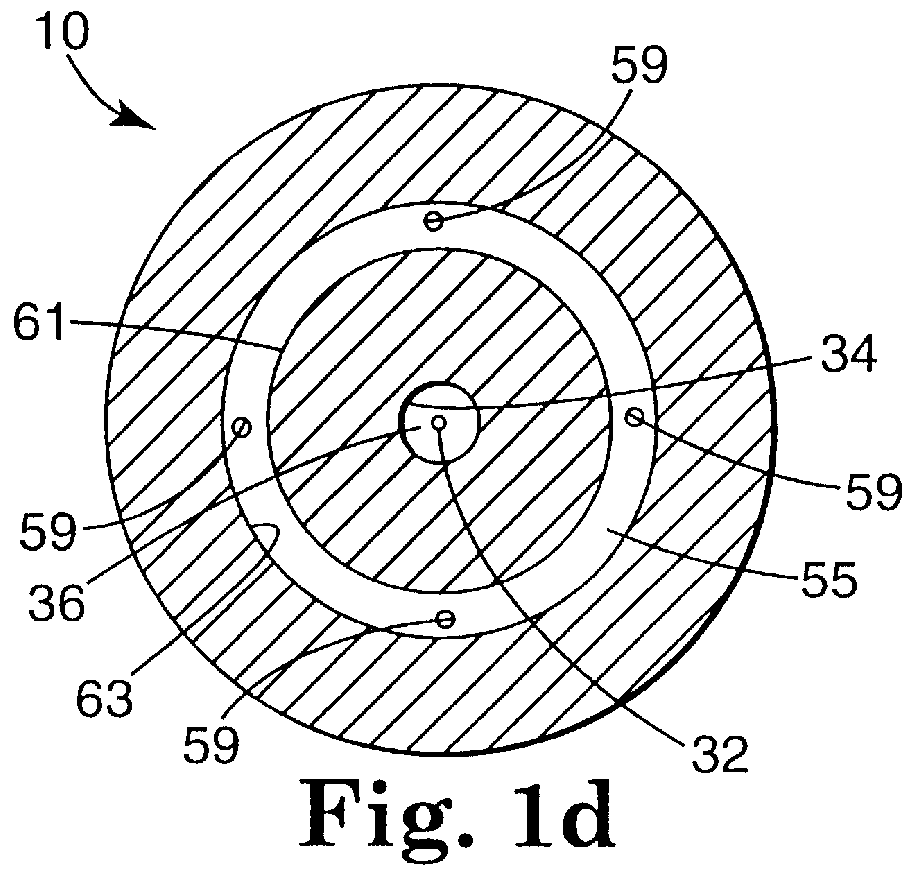

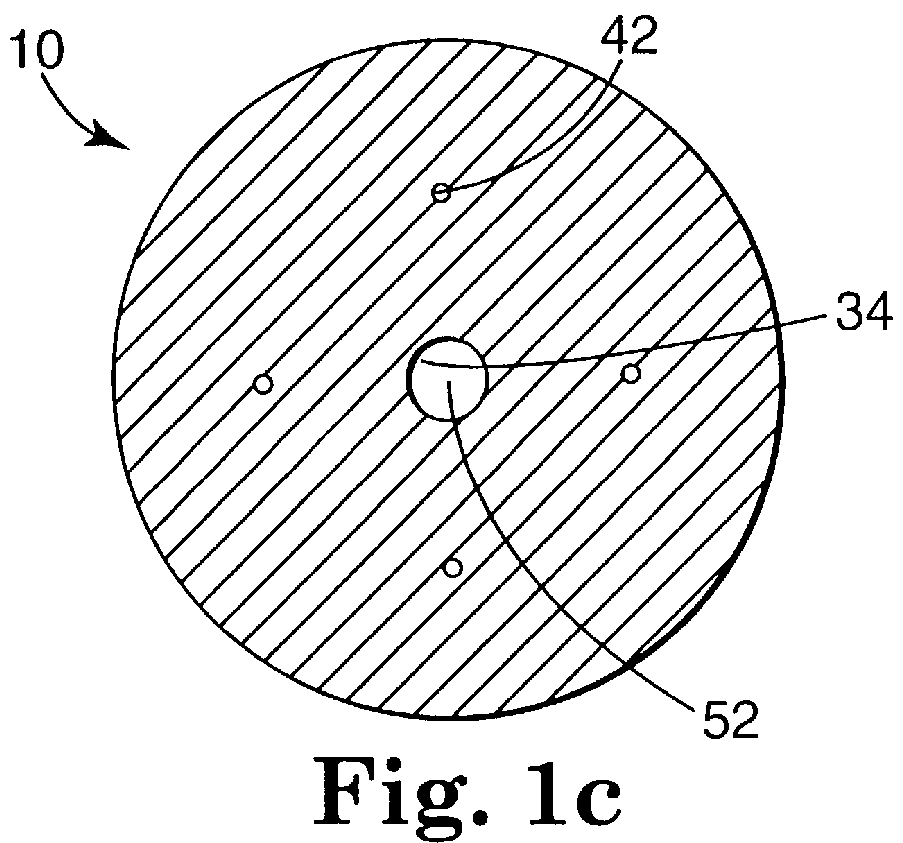

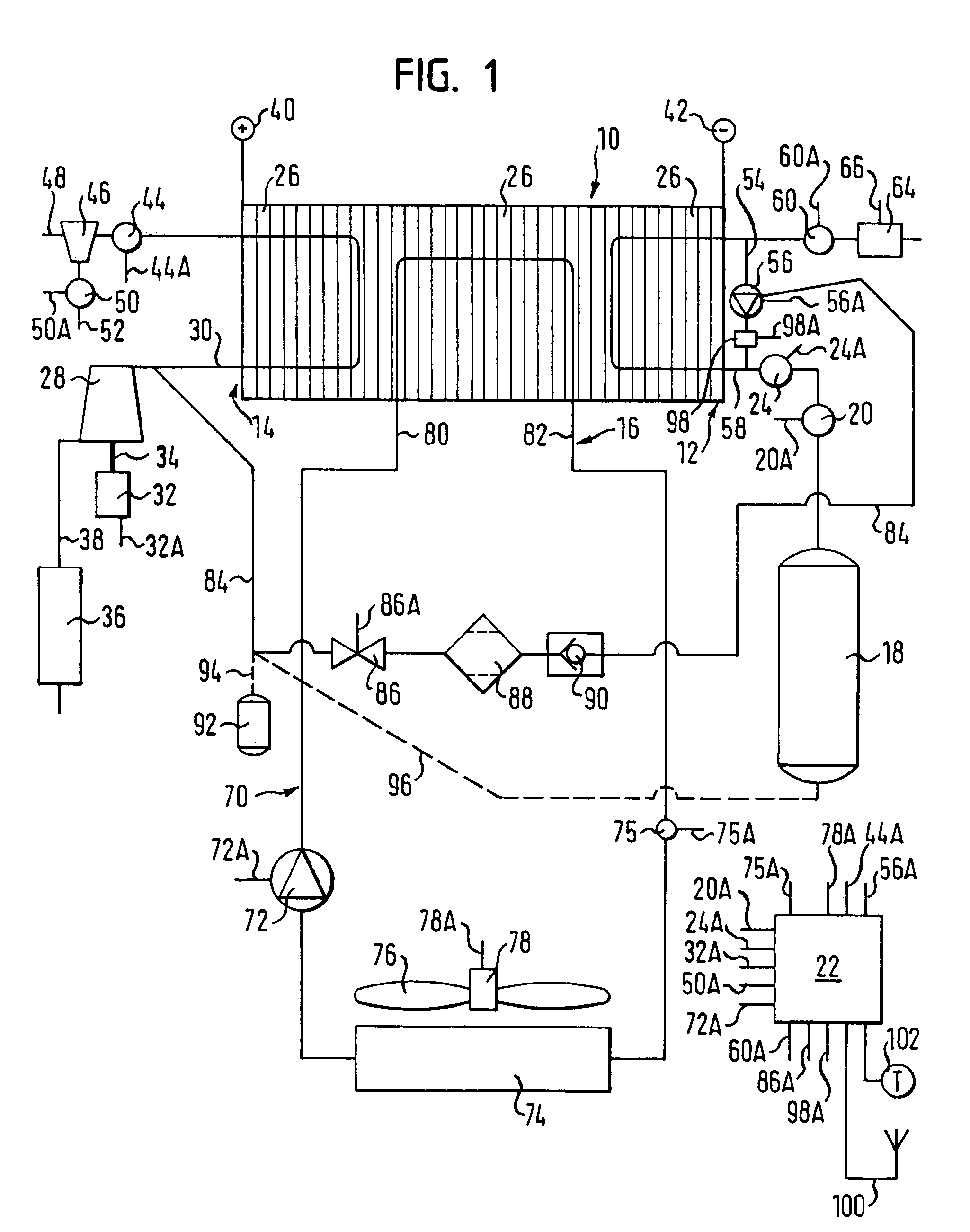

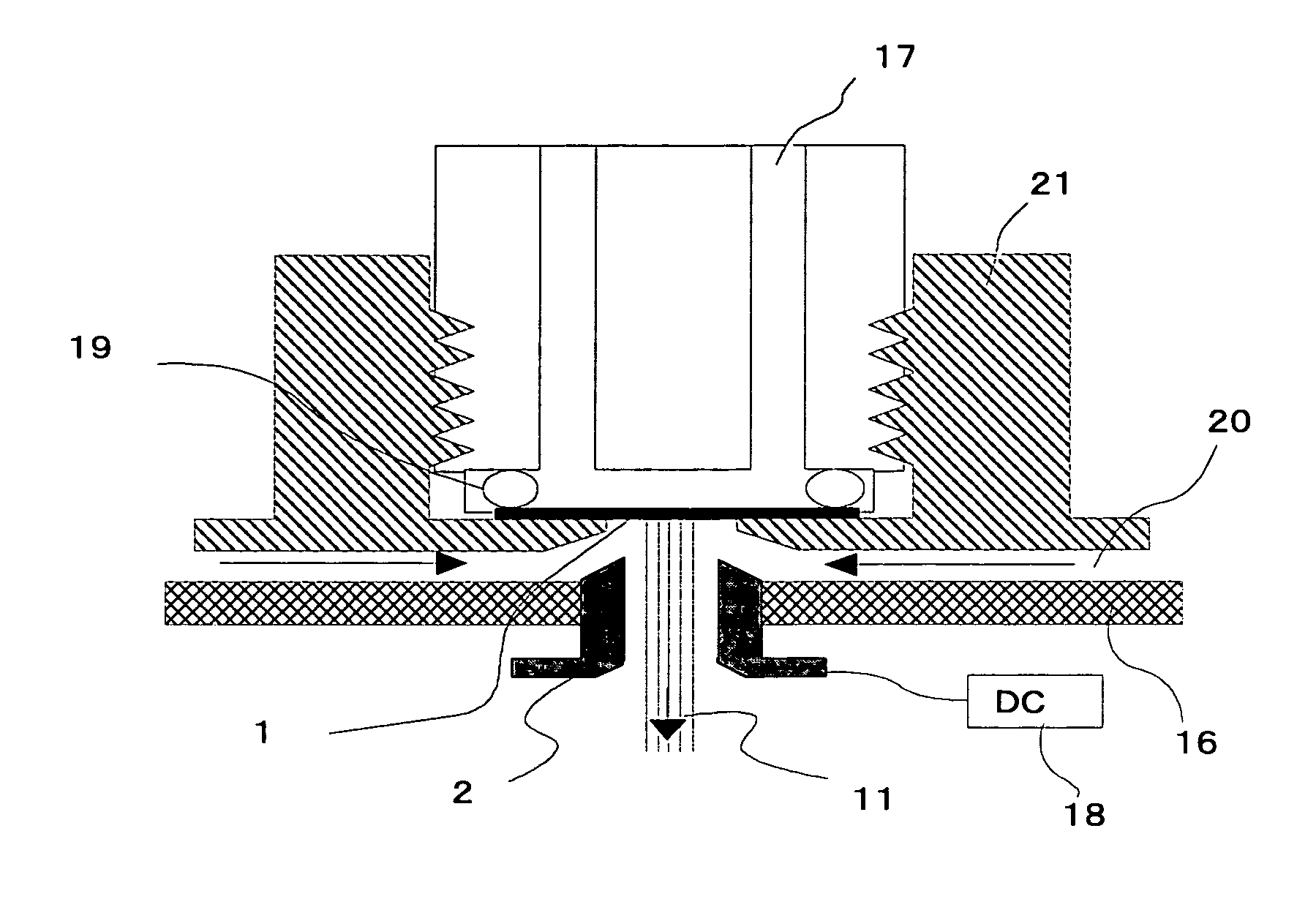

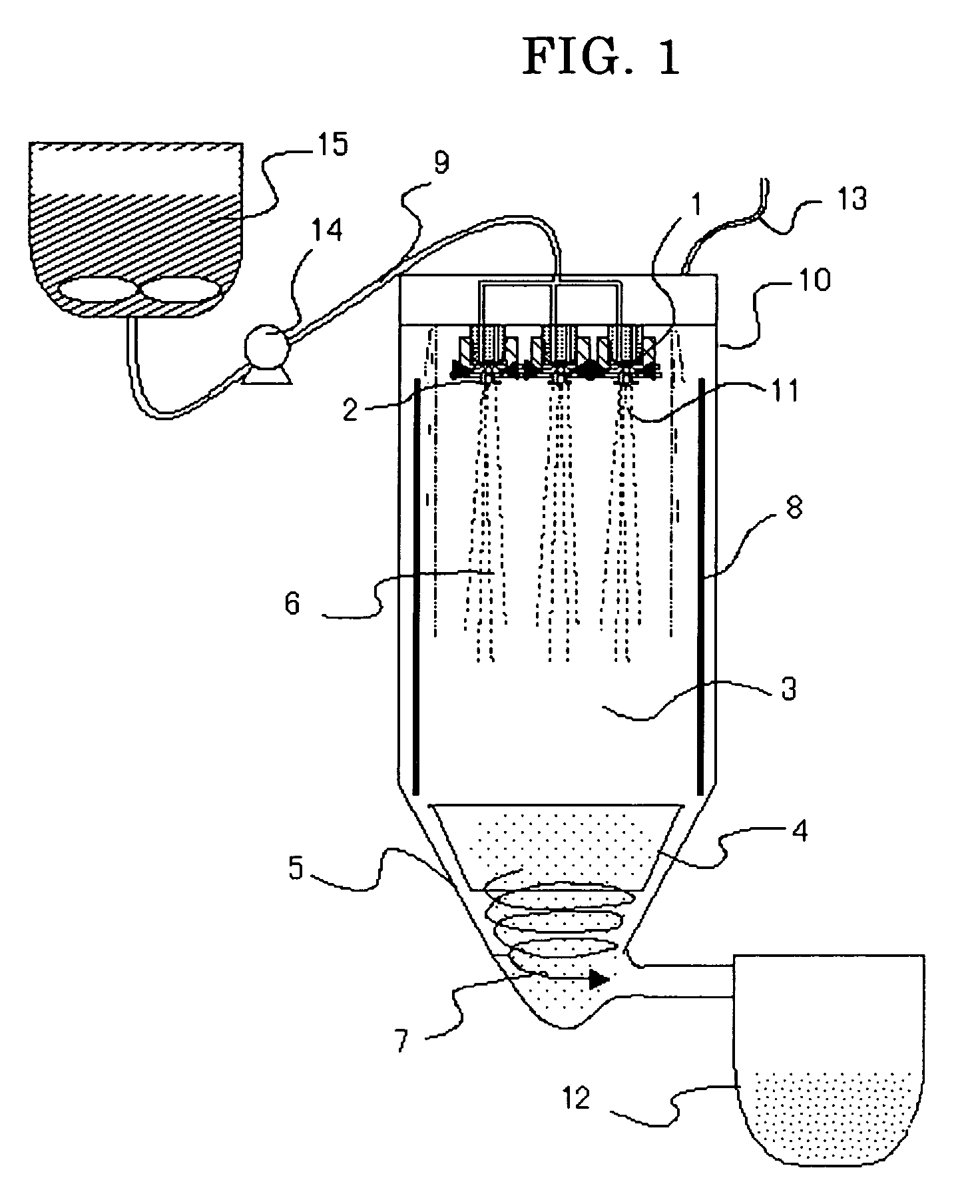

Apparatus and method of atomizing and vaporizing

InactiveUS6012647AMinimal slippageVaporization fastBurnersSpray nozzlesGas passingProcess engineering

Apparatus suitable for atomizing and vaporizing at least a first liquid by colliding at least one gas with the first liquid. The apparatus includes a gas inlet through which the gas enters the apparatus and a first liquid inlet through which the first liquid enters the apparatus. A discharge end of the apparatus includes at least one first liquid discharge outlet through which at least one stream of the first liquid is discharged from the apparatus. The discharge end also includes at least one gas discharge outlet through which at least one stream of gas is discharged from the apparatus to collide with and thereby atomize the discharged stream of the first liquid. A first liquid passageway interconnects the first liquid inlet with the first liquid discharge outlet. A gas passageway interconnects the gas inlet with the at least one gas discharge outlet. In one embodiment, the gas passageway comprises at least one gas chamber in thermal contact with an initial portion of the first liquid passageway such that a heated quantity of the gas in the chamber preheats the first liquid in the initial portion of the first liquid passageway. In alternative embodiments, the gas passageway includes a pressure dampening chamber allowing gas to be continuously discharged without pulsating.

Owner:3M INNOVATIVE PROPERTIES CO

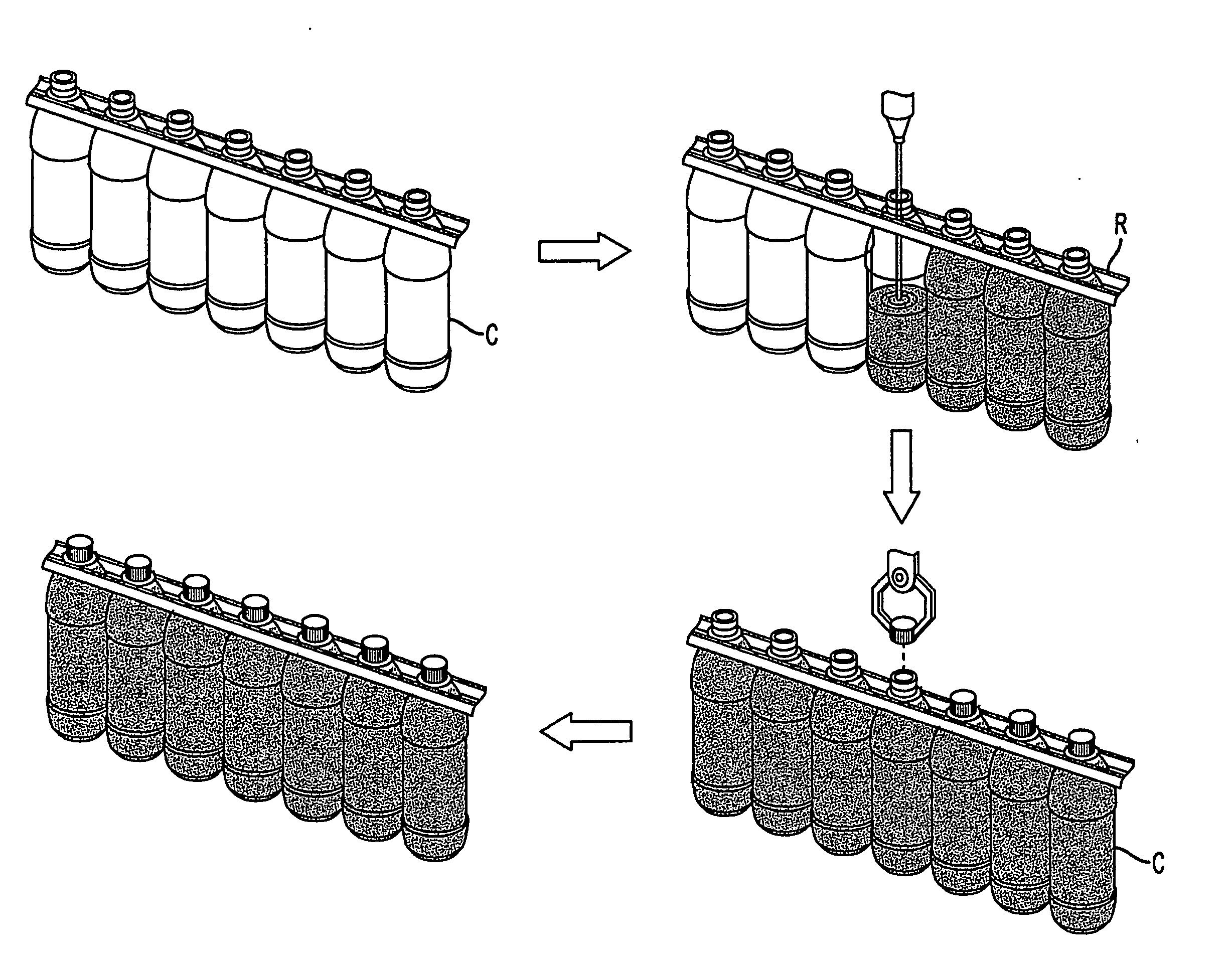

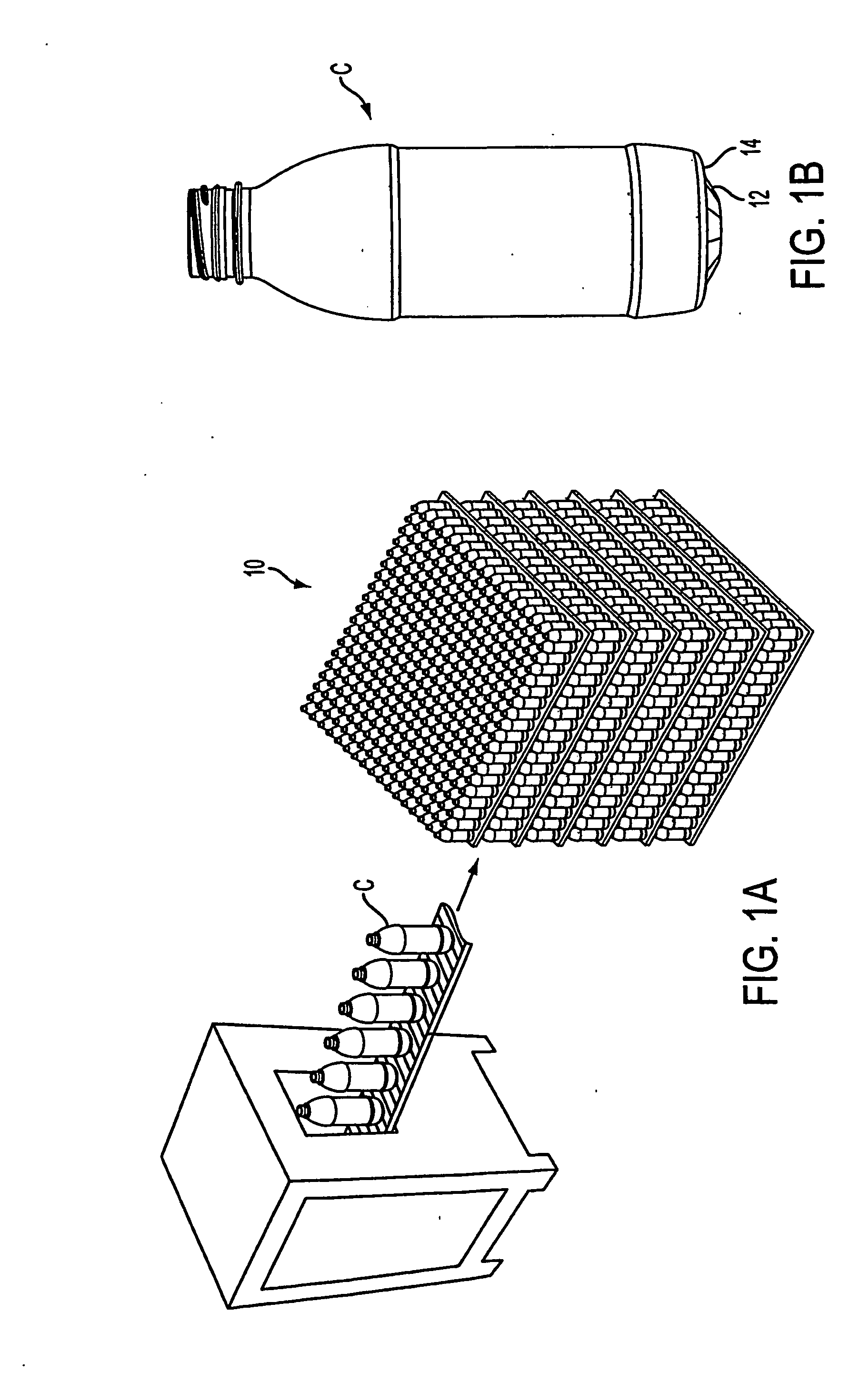

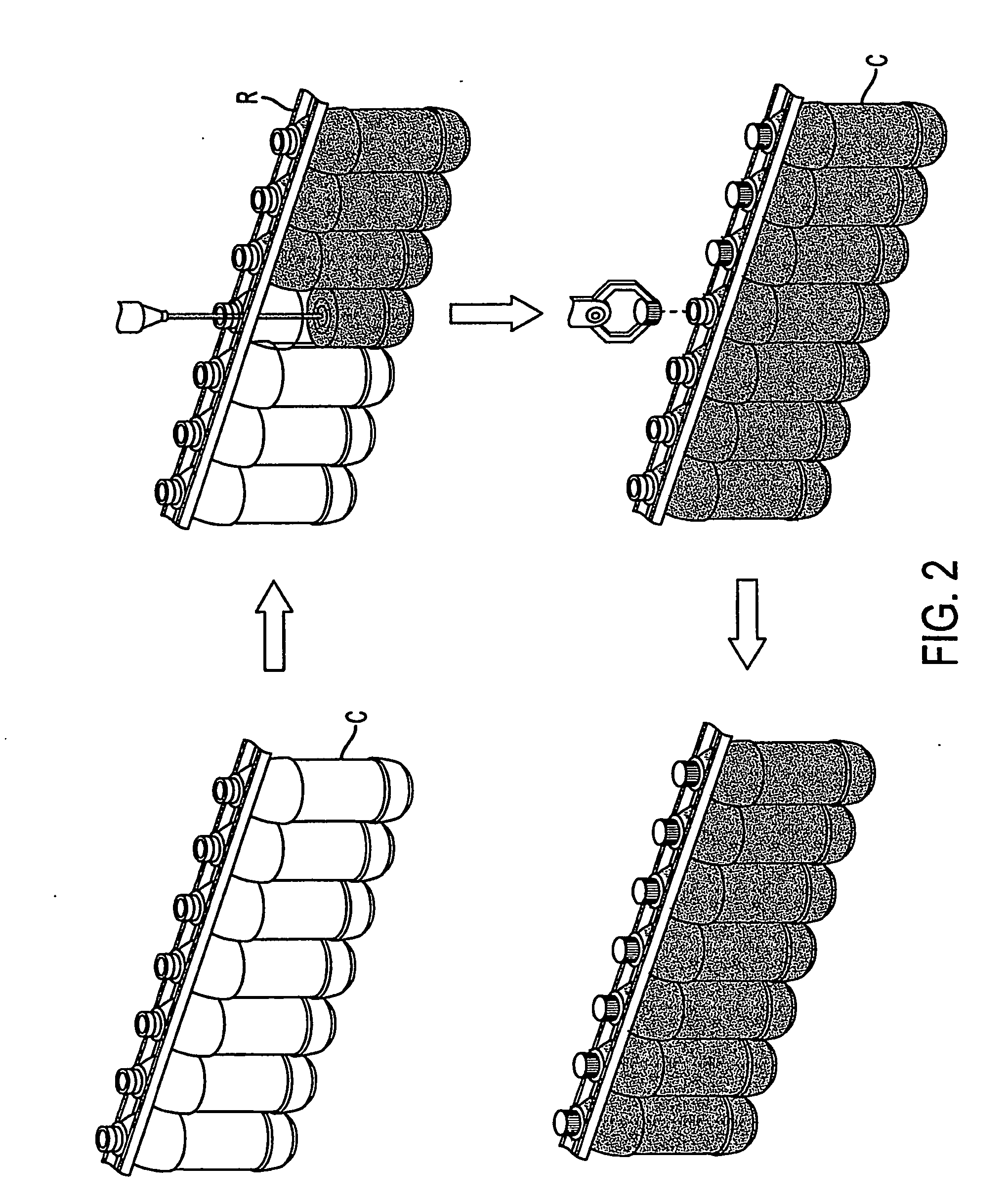

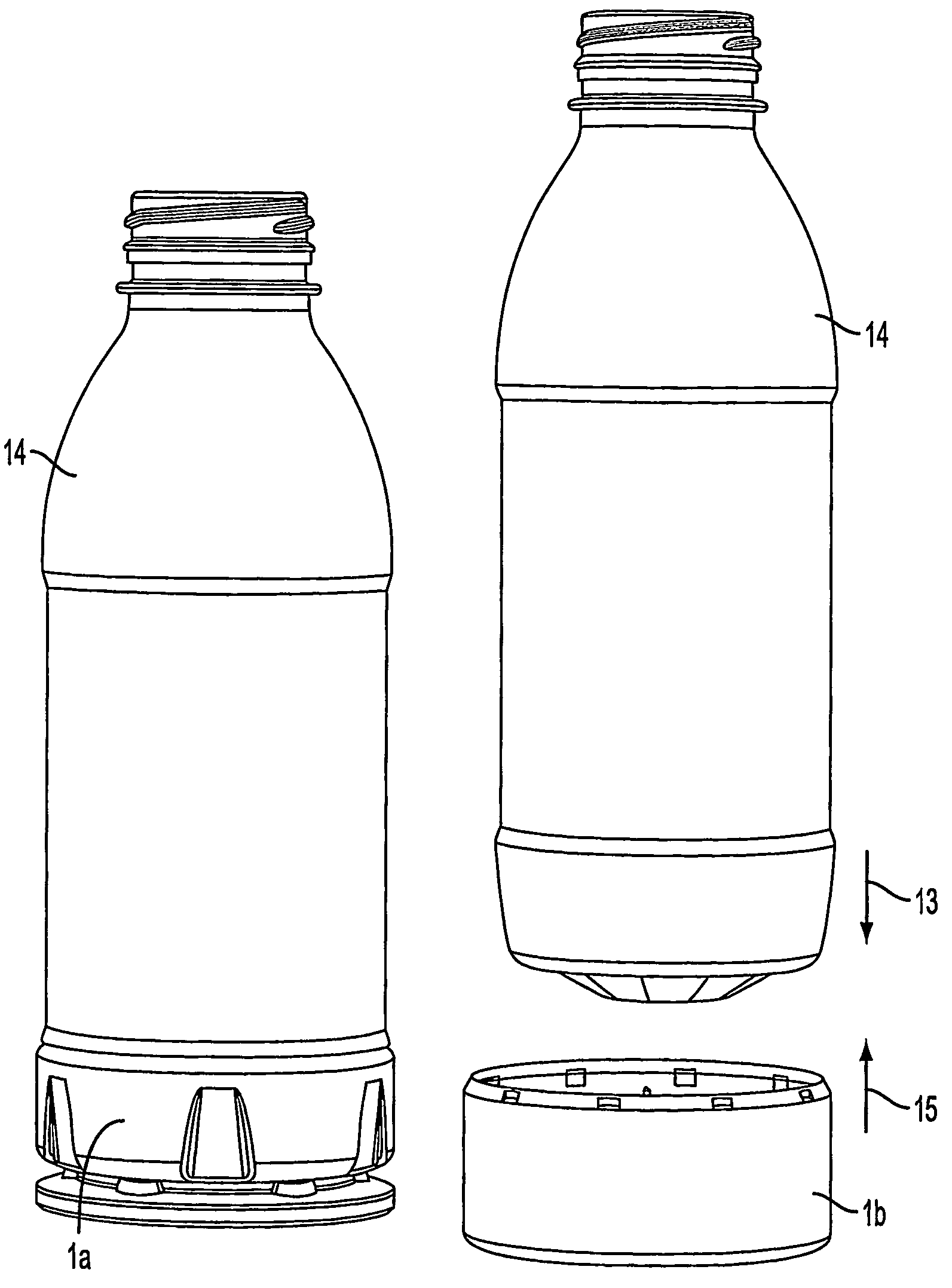

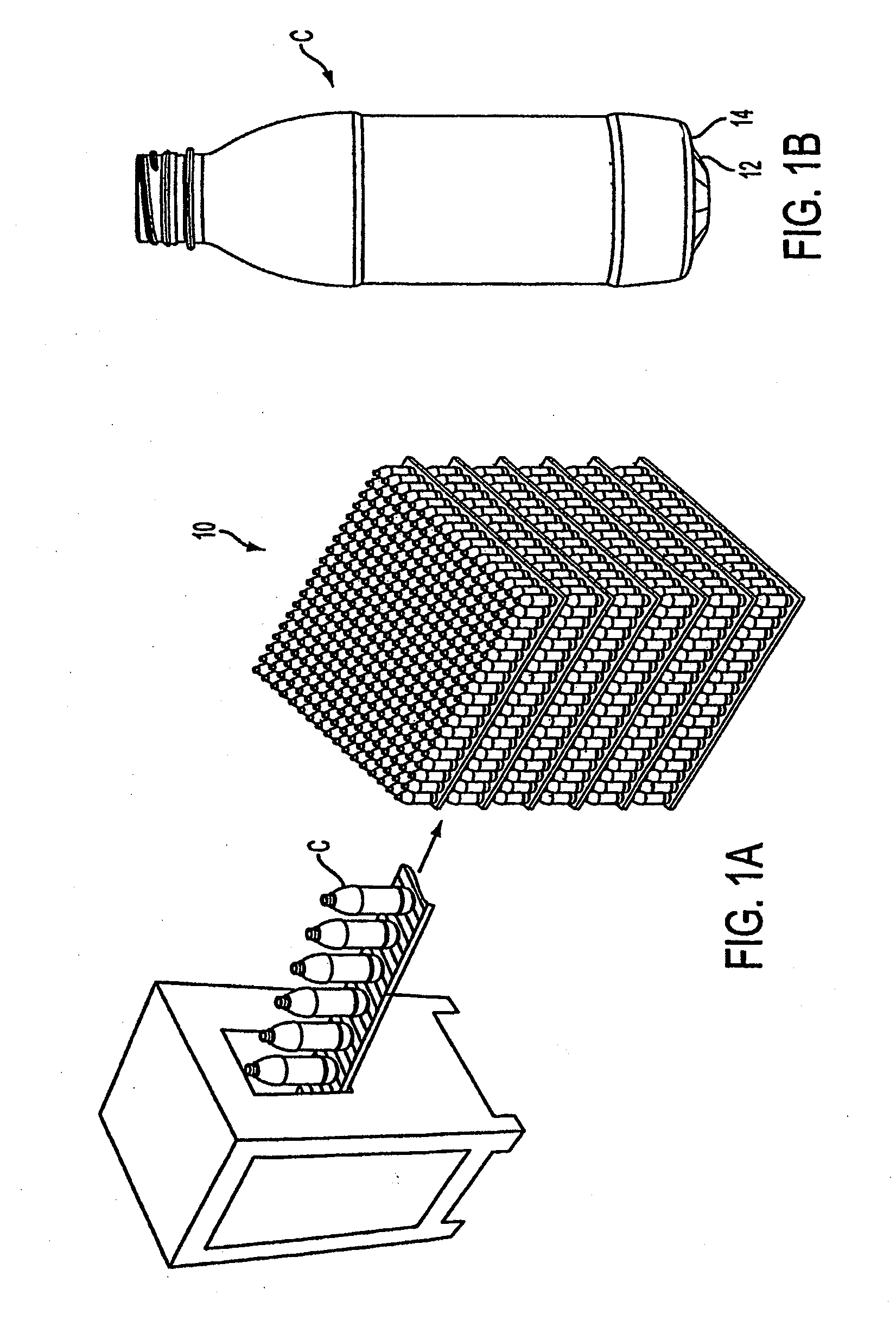

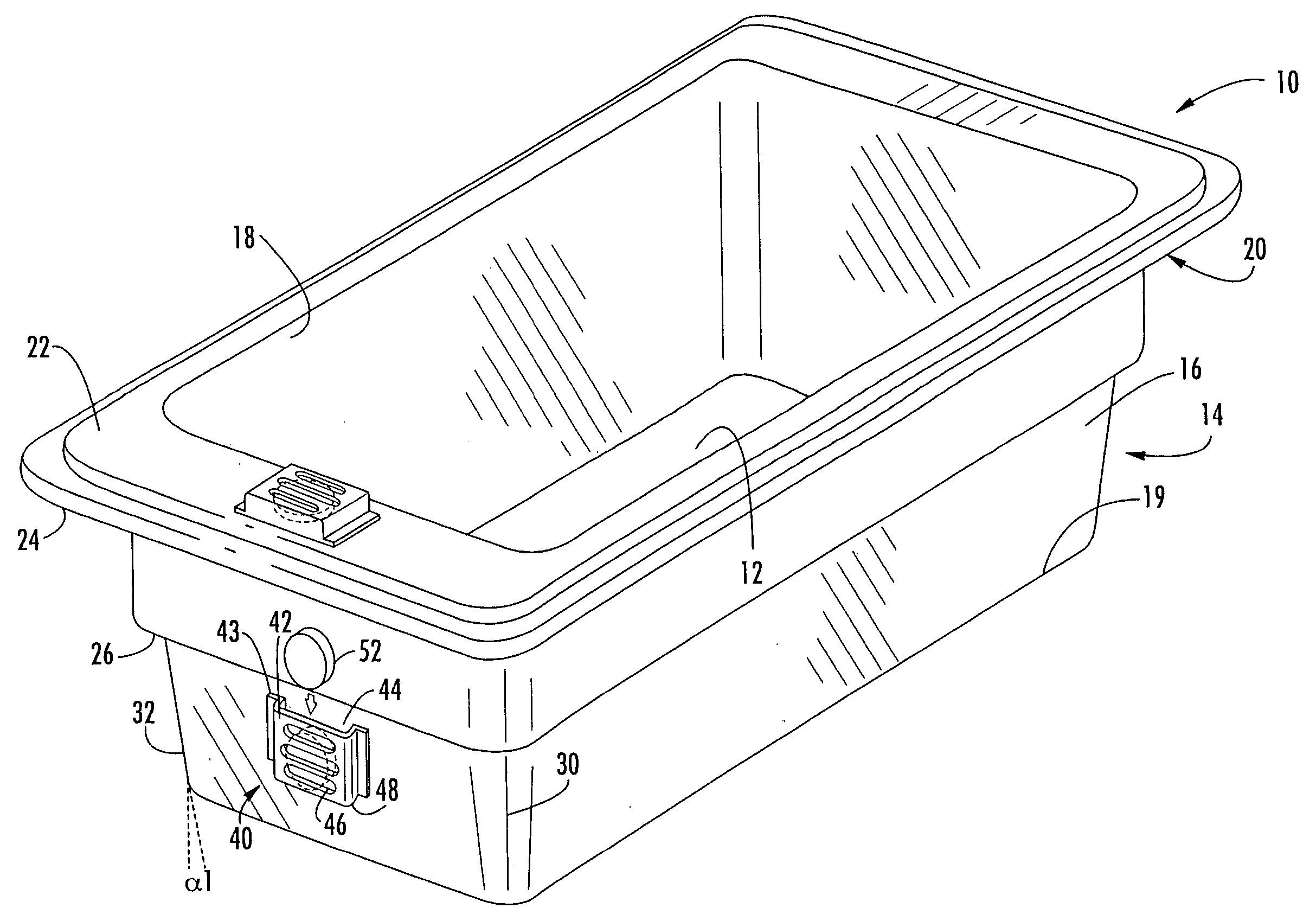

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

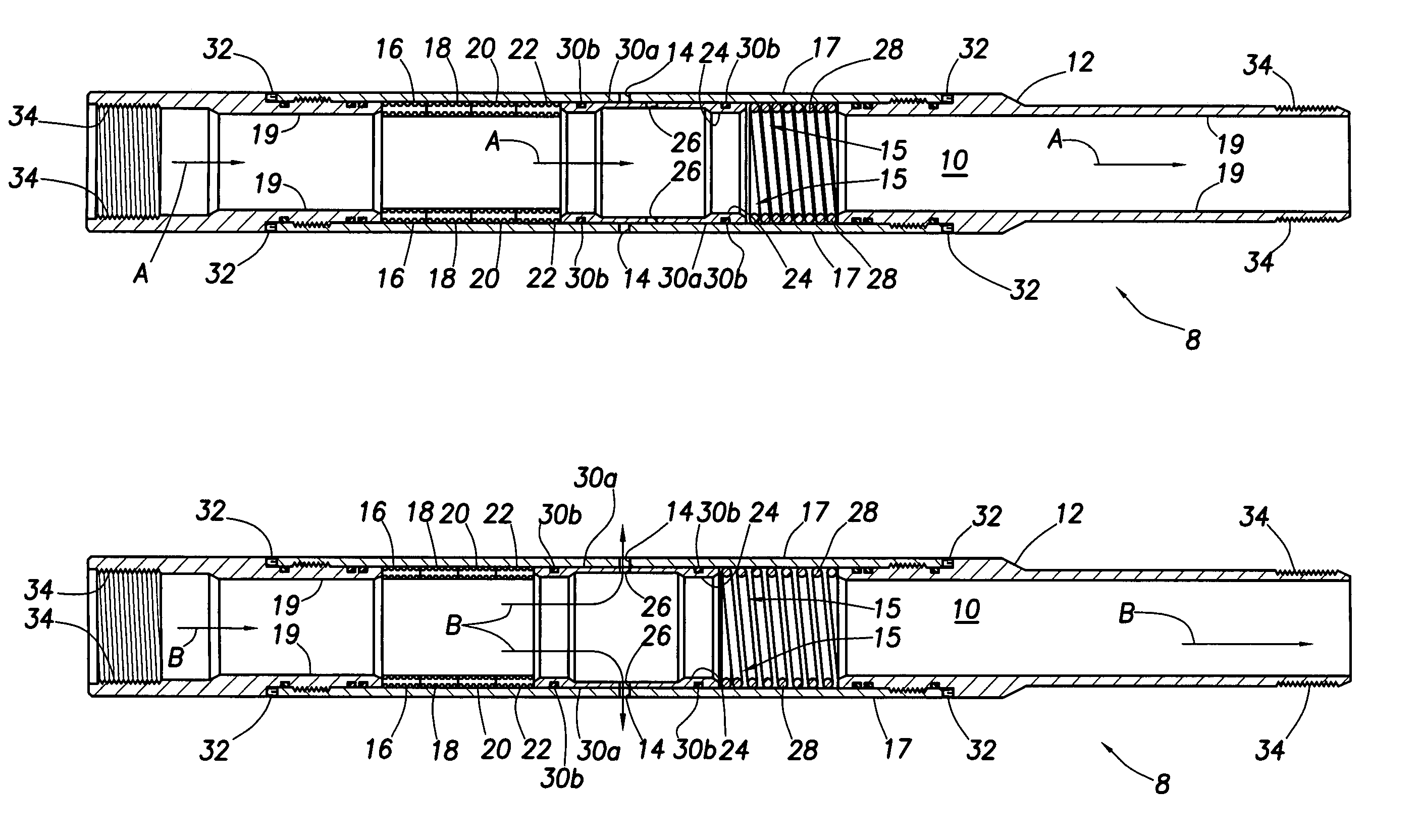

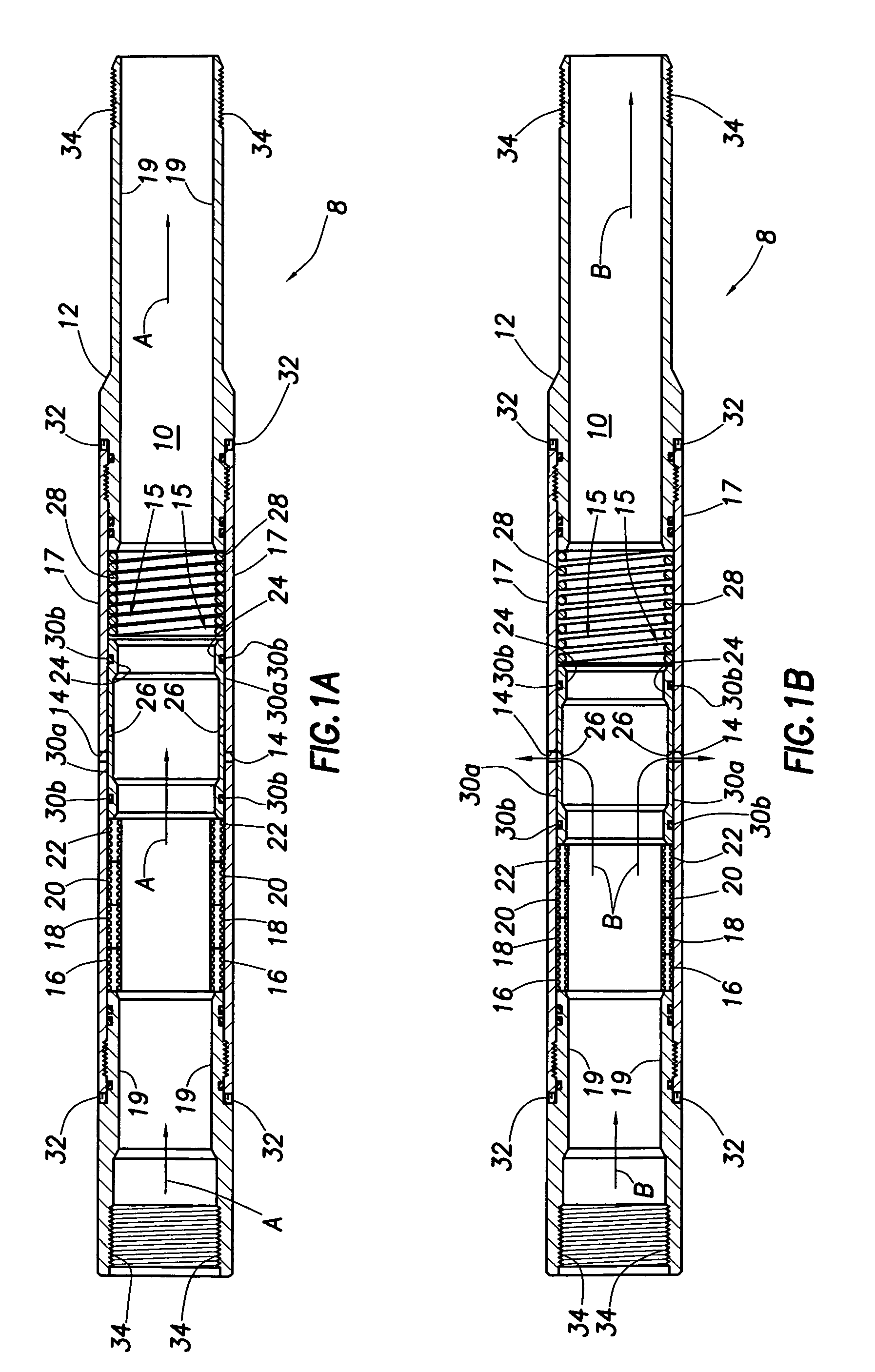

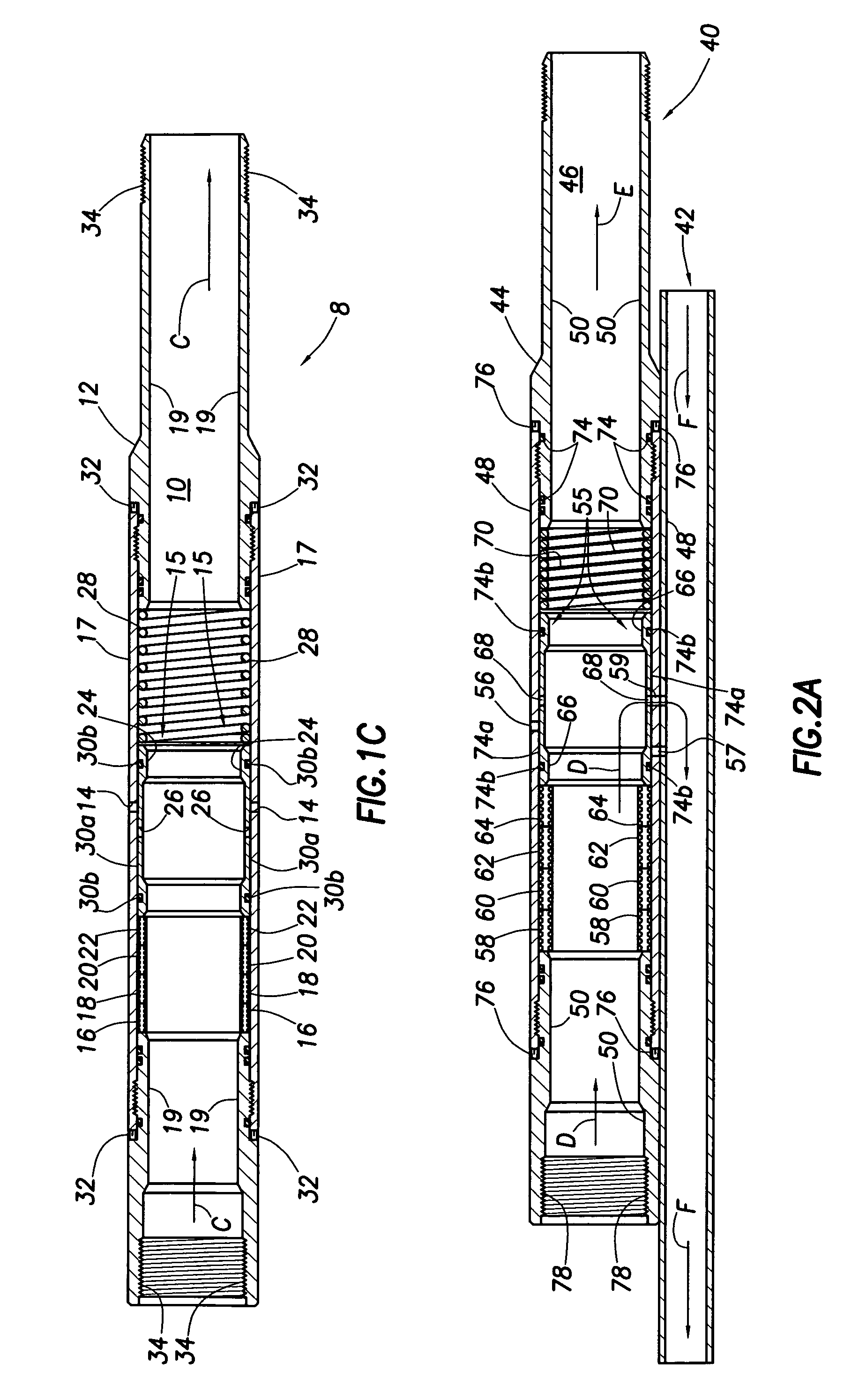

Thermally-controlled valves and methods of using the same in a wellbore

InactiveUS7032675B2Low viscosityEasily conveyedTemperature control without auxillary powerInsulationControl flowTemperature control

Methods of operating a downhole tool comprise thermally-controlling the tool by sensing a temperature and controlling the tool in response to the sensed temperature. Thermally-controlled downhole tools comprise a control element responsive to a change in temperature that control flow into, out of, or through a wellbore. Methods and systems for servicing a wellbore comprise using a thermally-controlled tool comprising a thermally-controlled valve (TCV) in a wellbore. The TCV includes a valve body comprising an injection port for allowing material to flow into or out of the wellbore and an opening / closing mechanism for regulating flow of the material through the injection port in response to a change in temperature. The valve body may be coupled to a downhole conduit. A plurality of TCV's may be arranged in the wellbore to control the injection of steam into the wellbore or the recovery of oil from the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

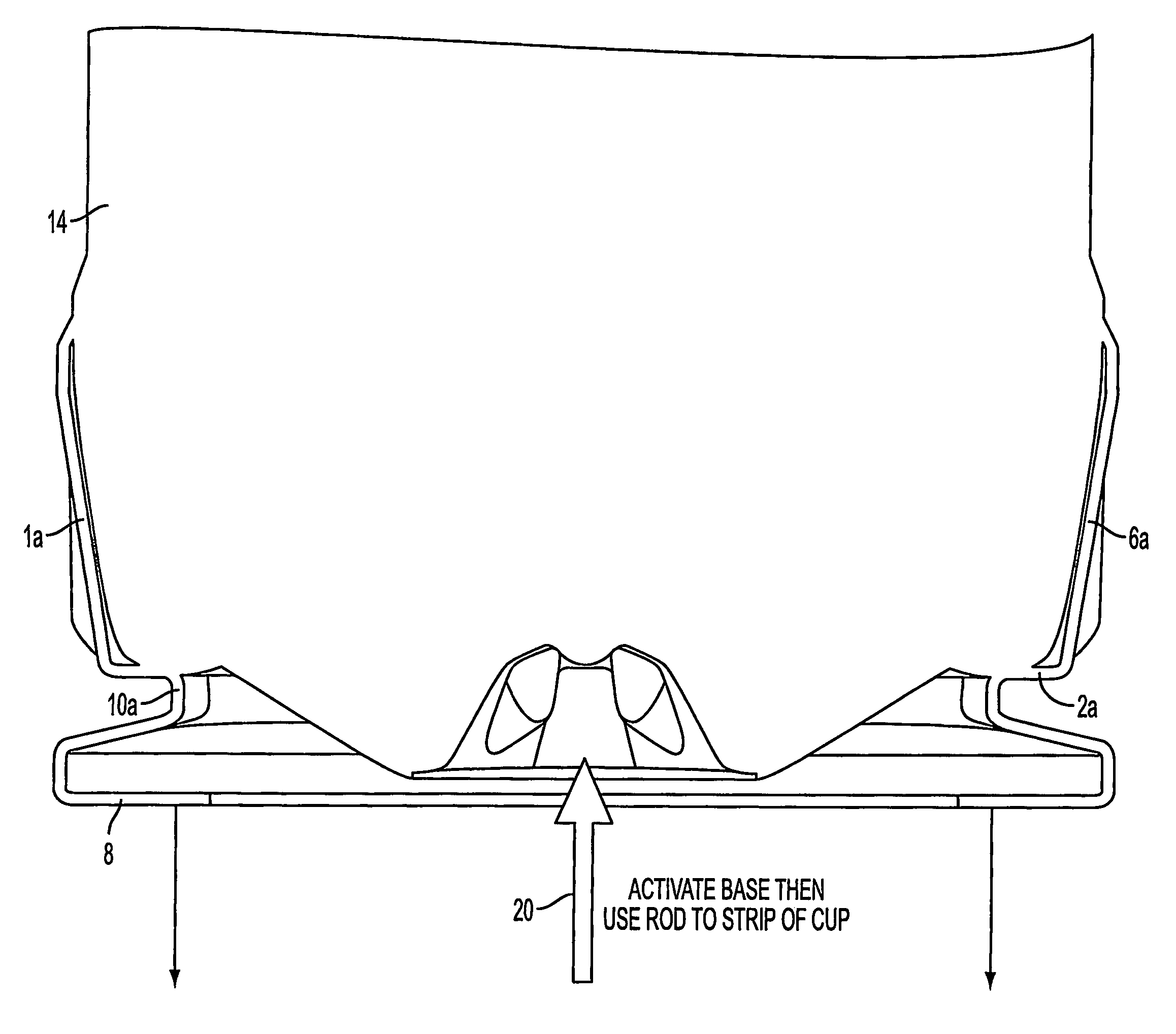

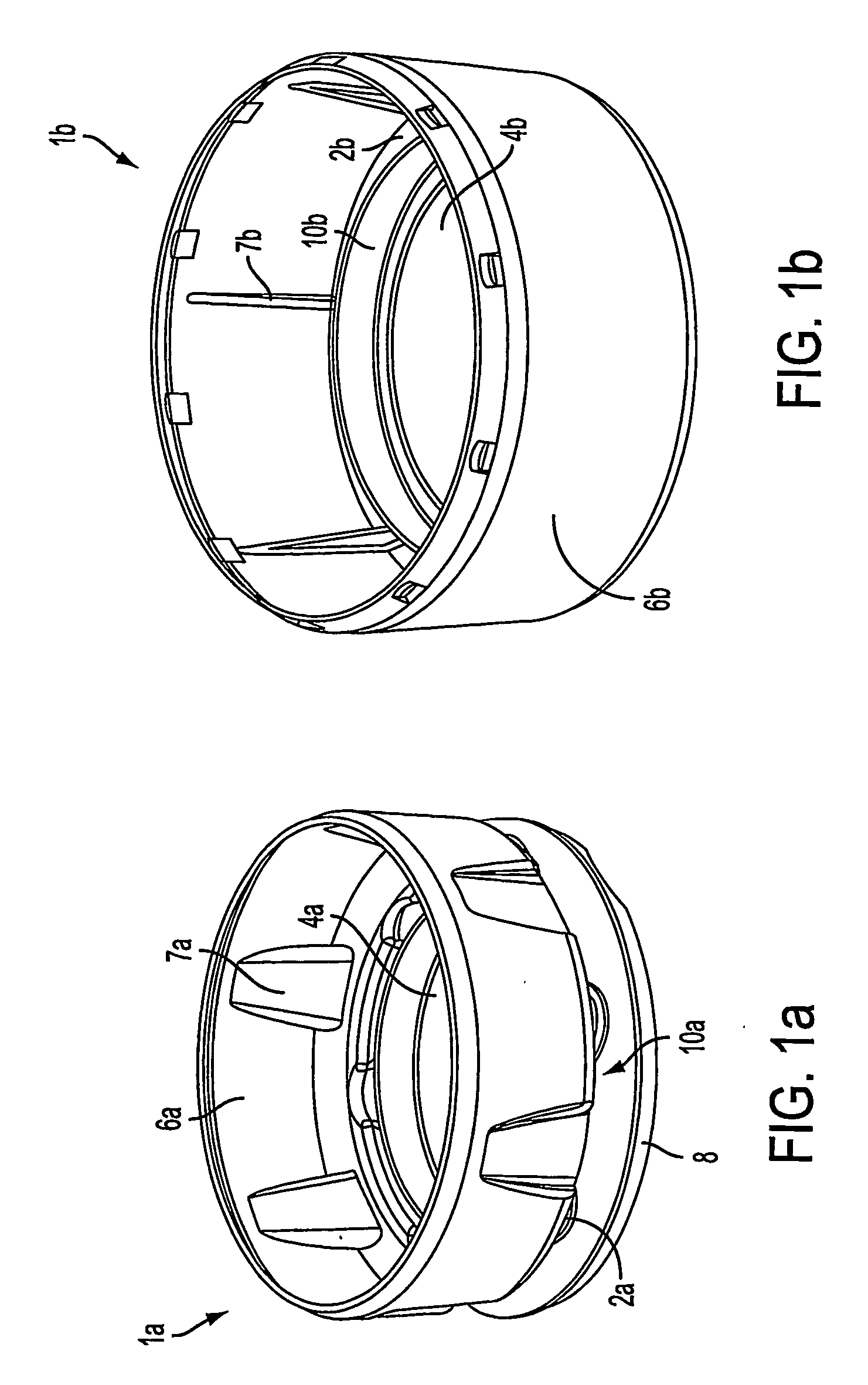

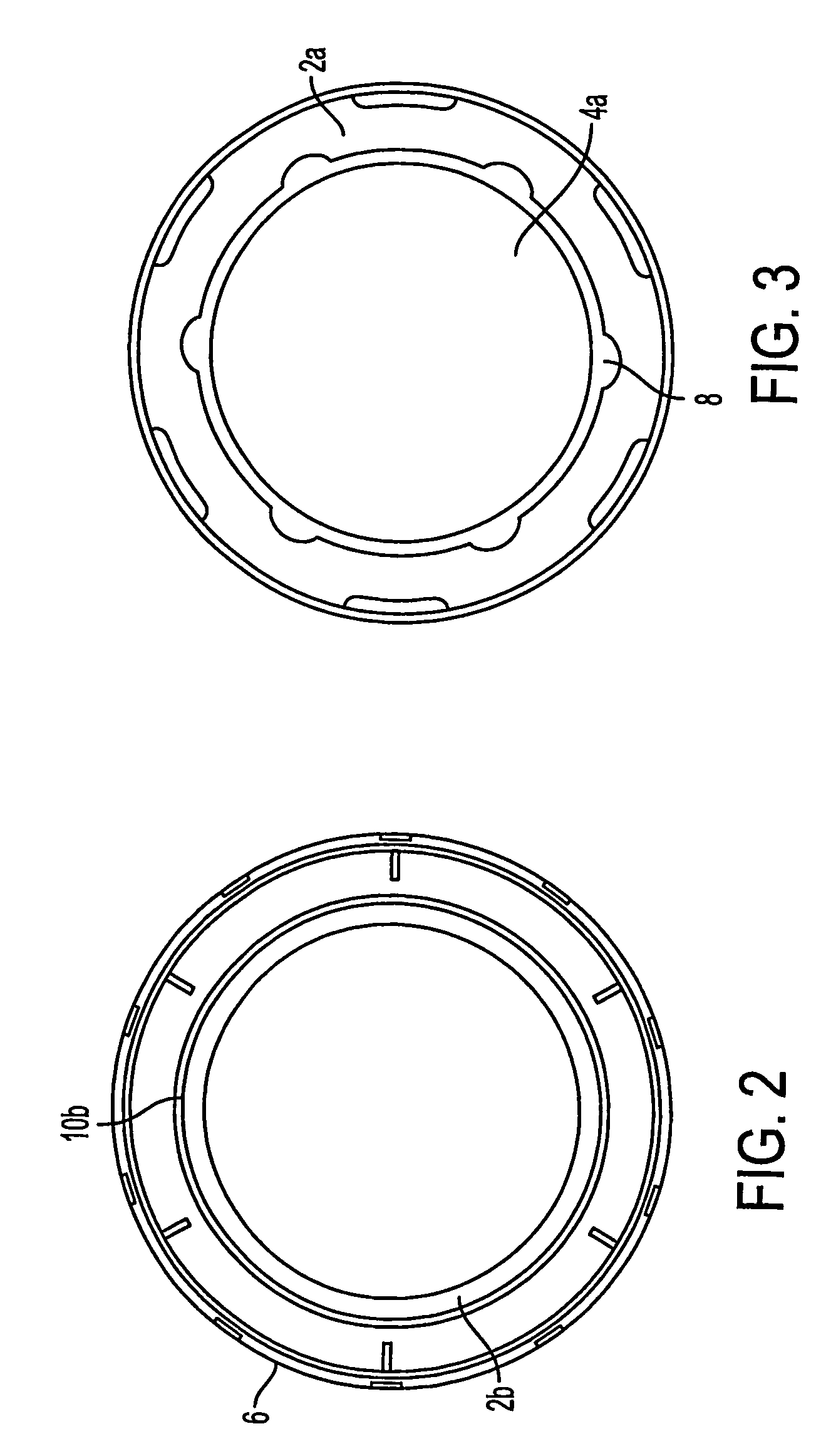

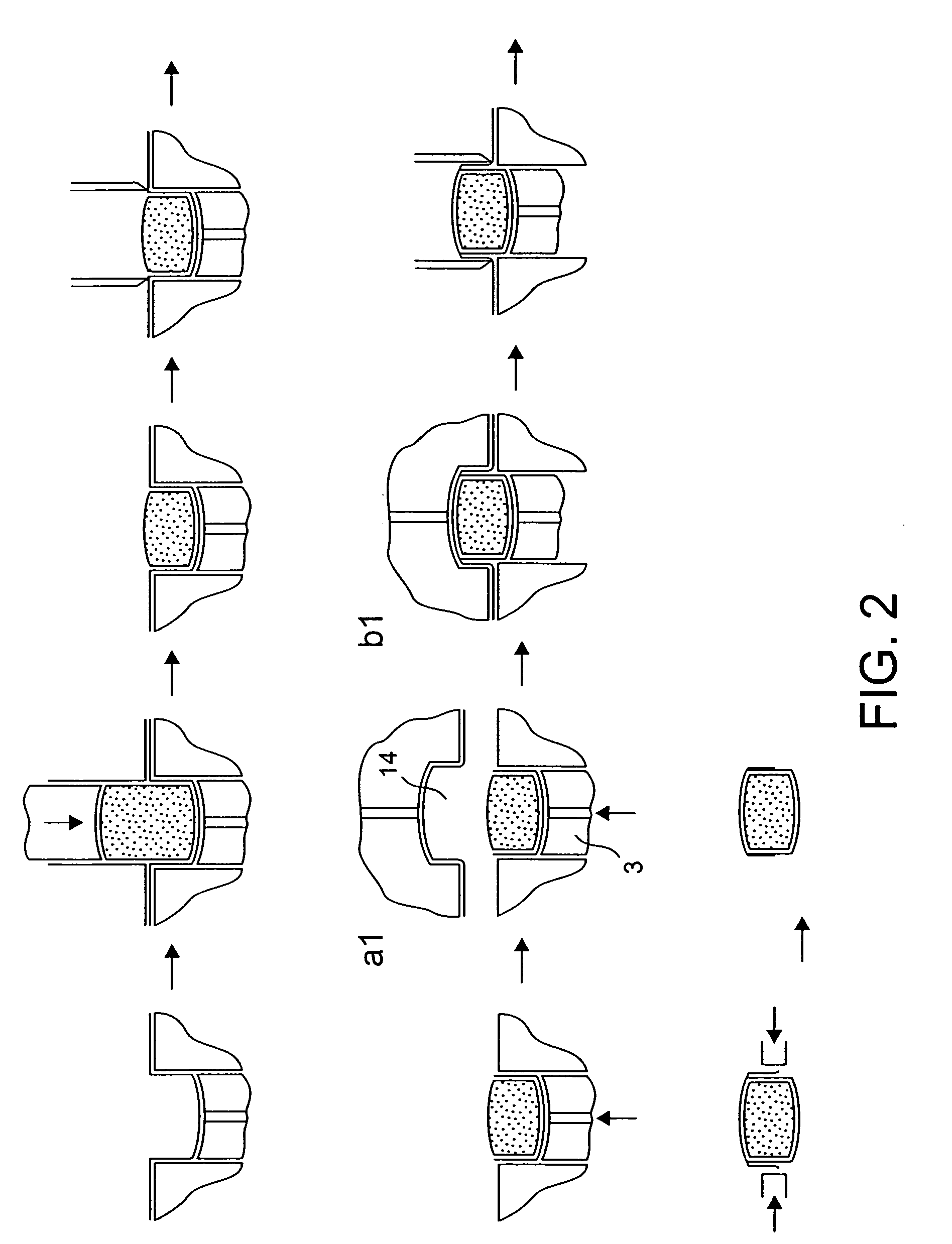

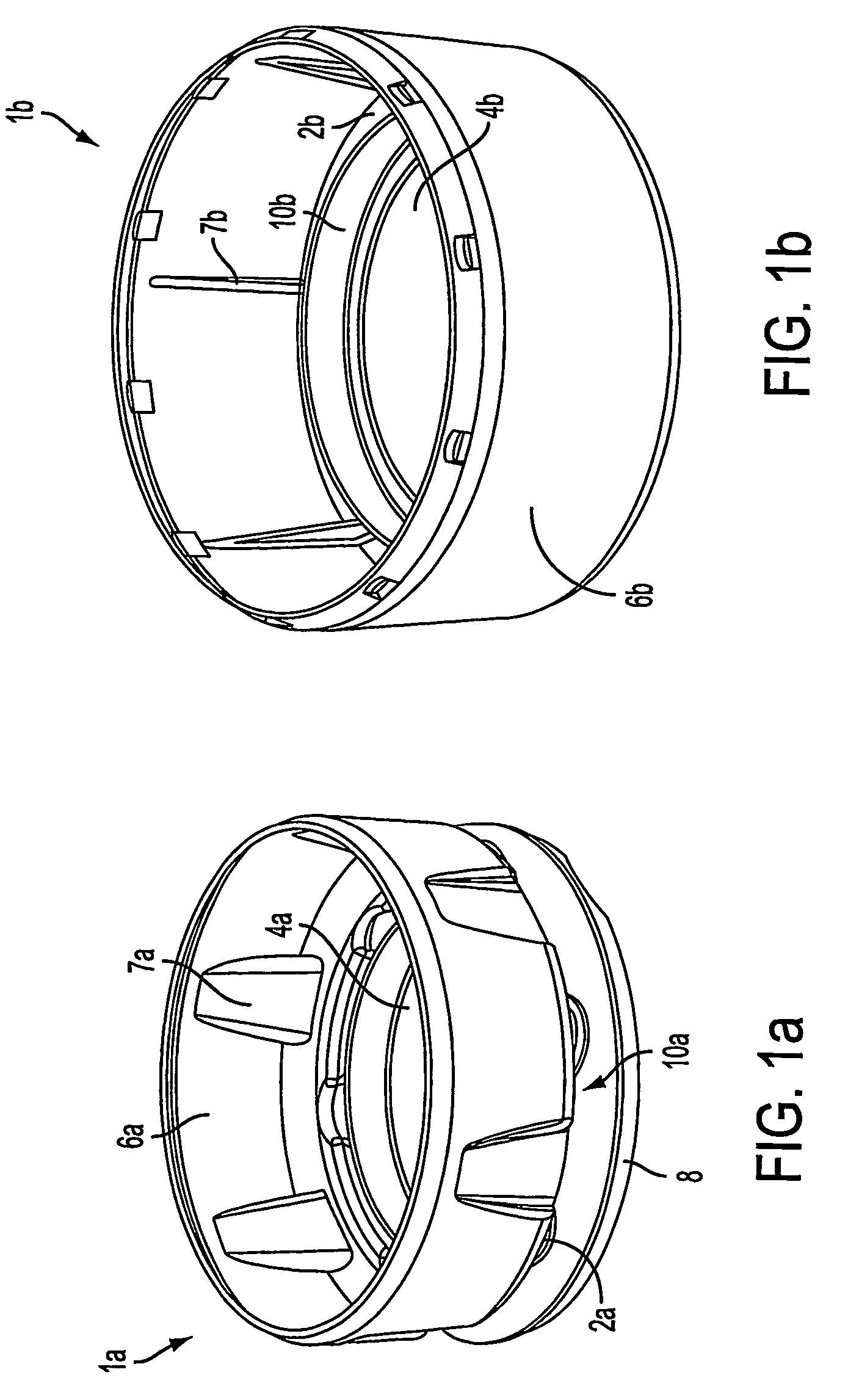

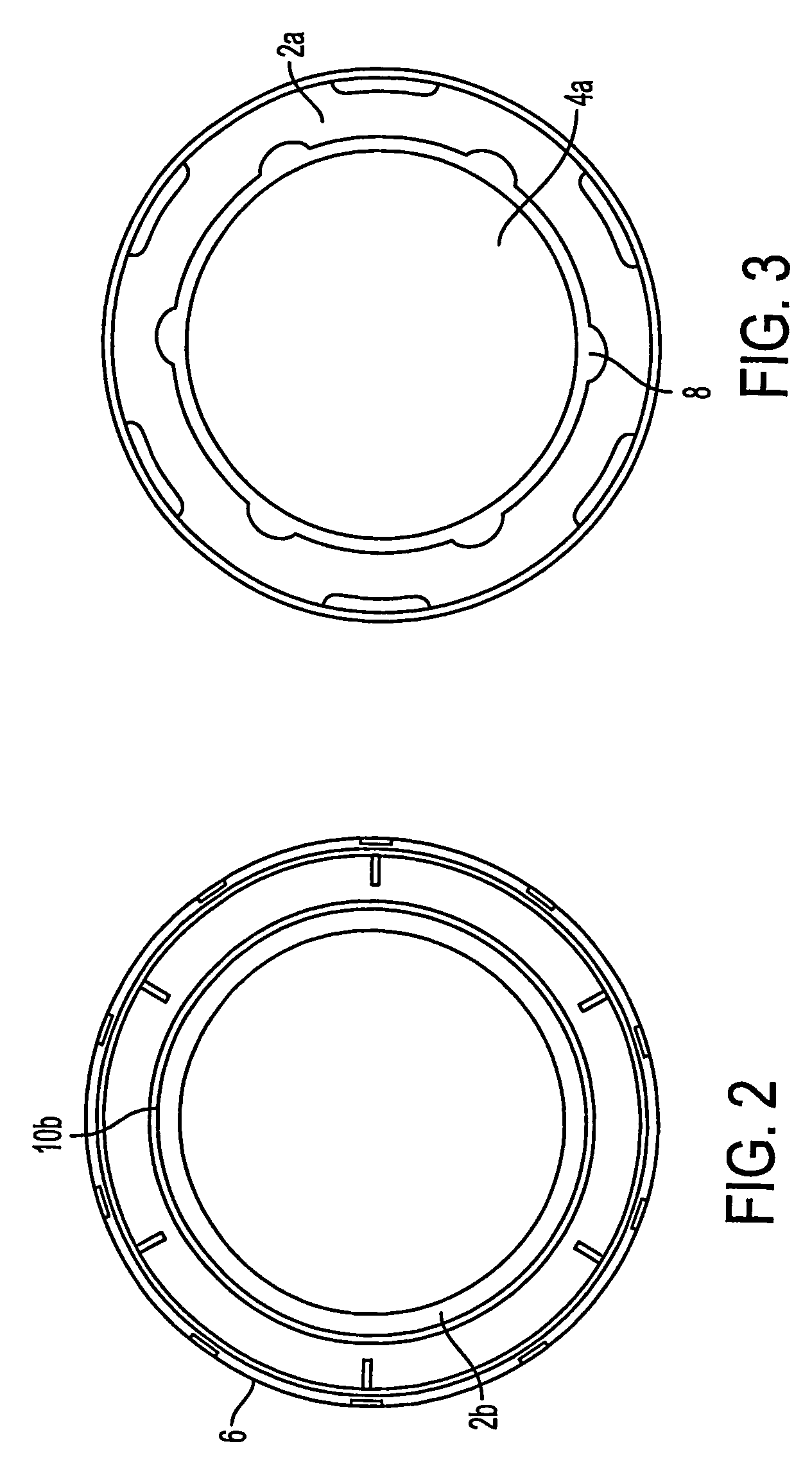

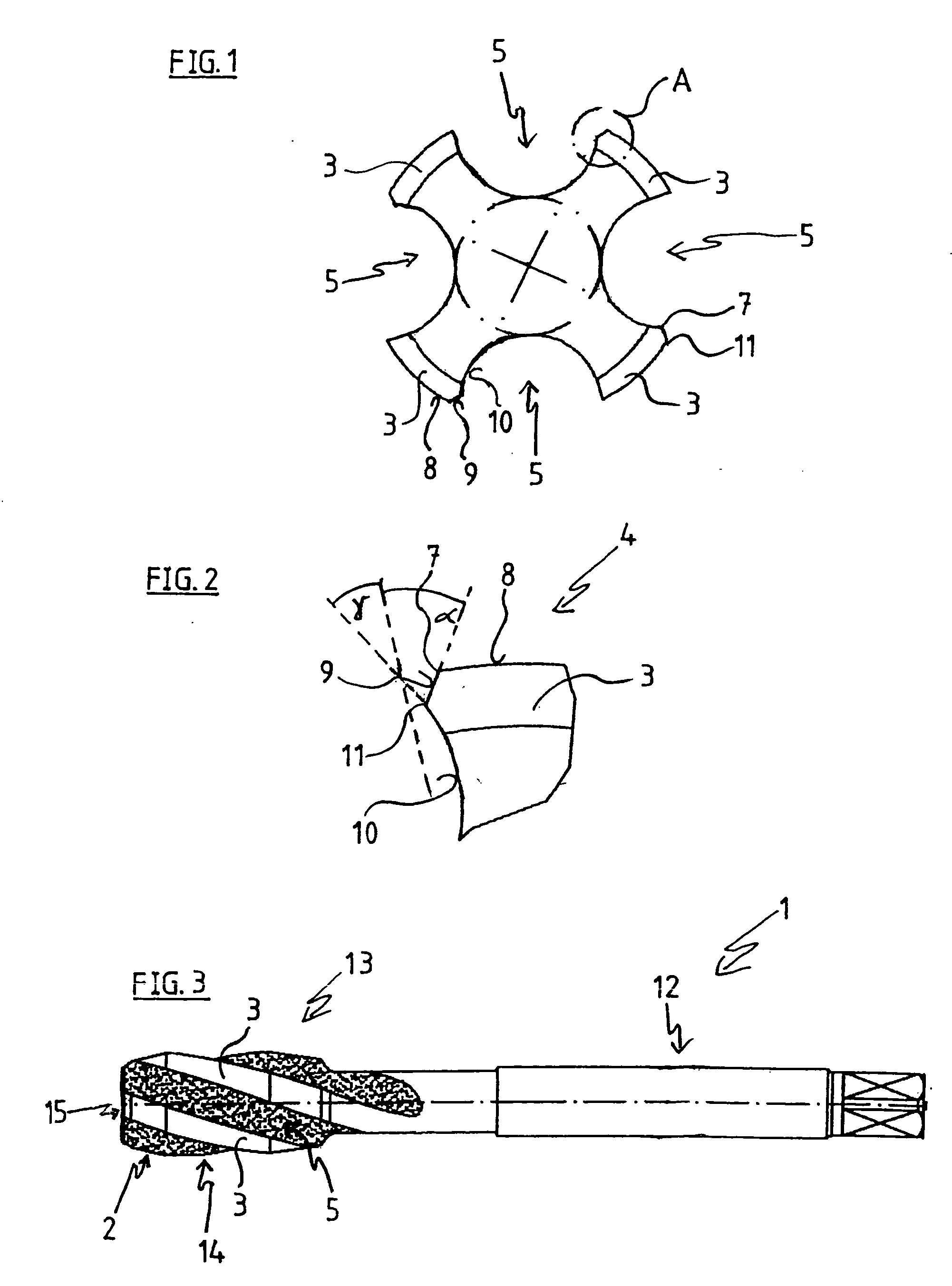

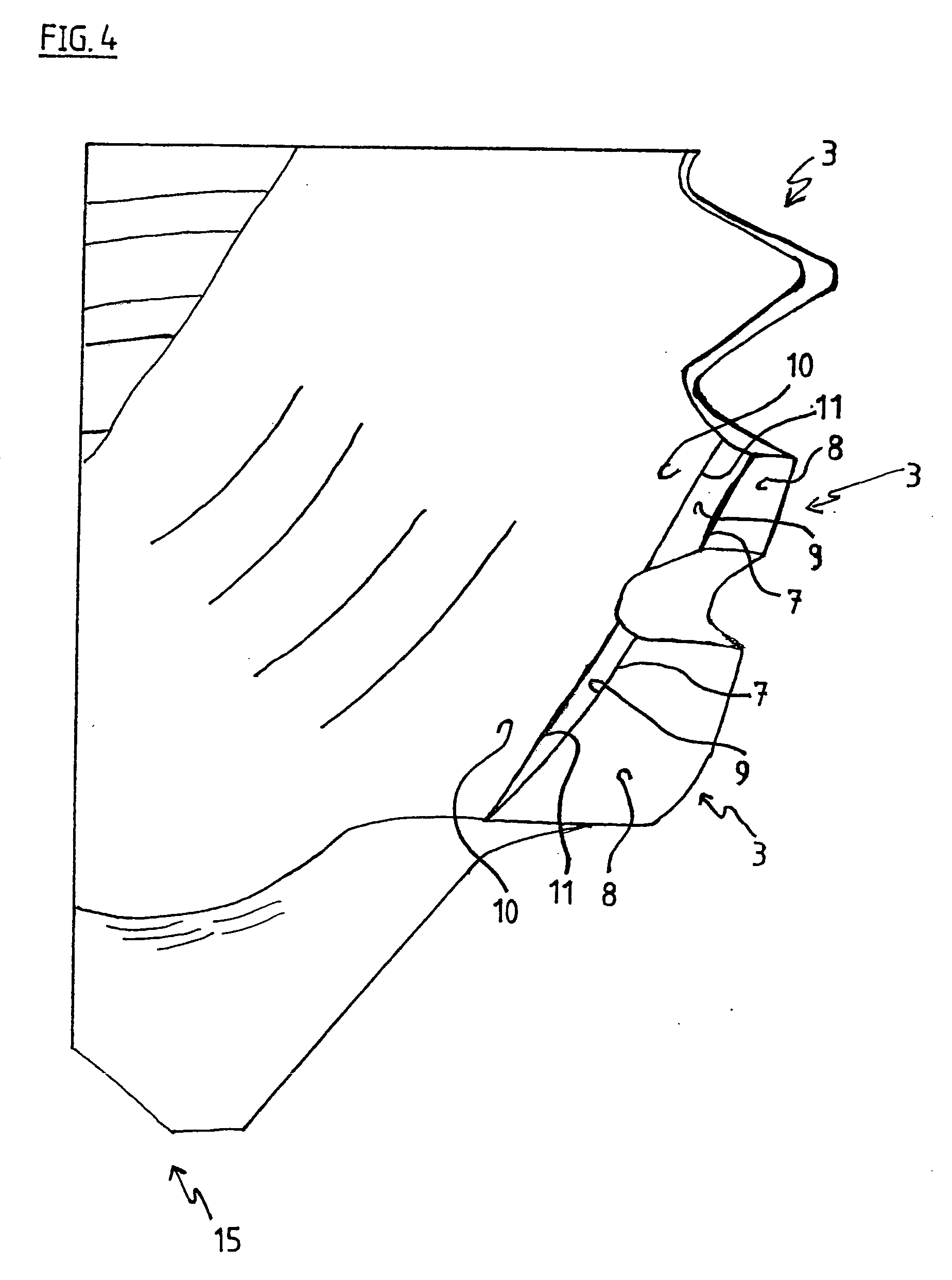

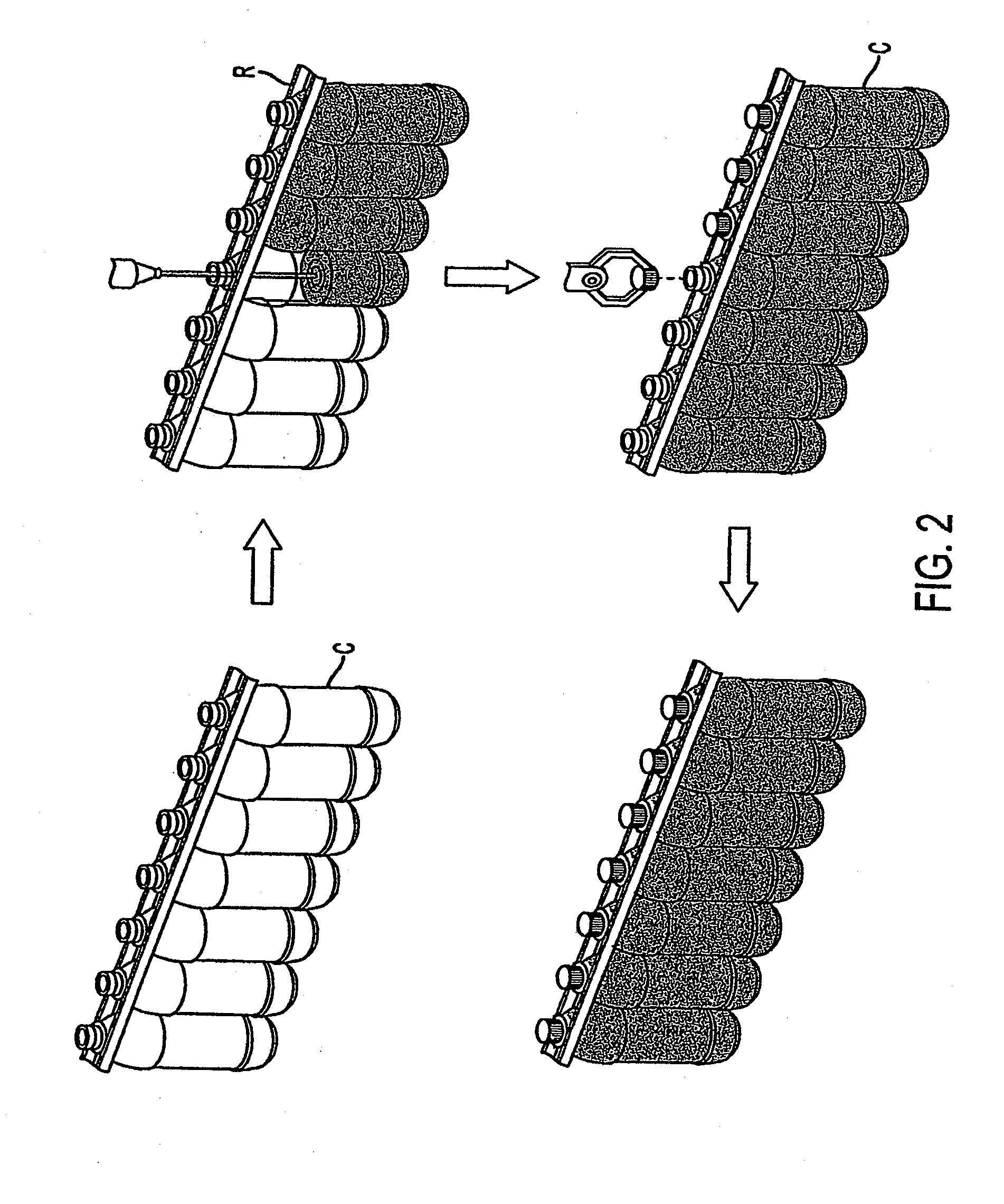

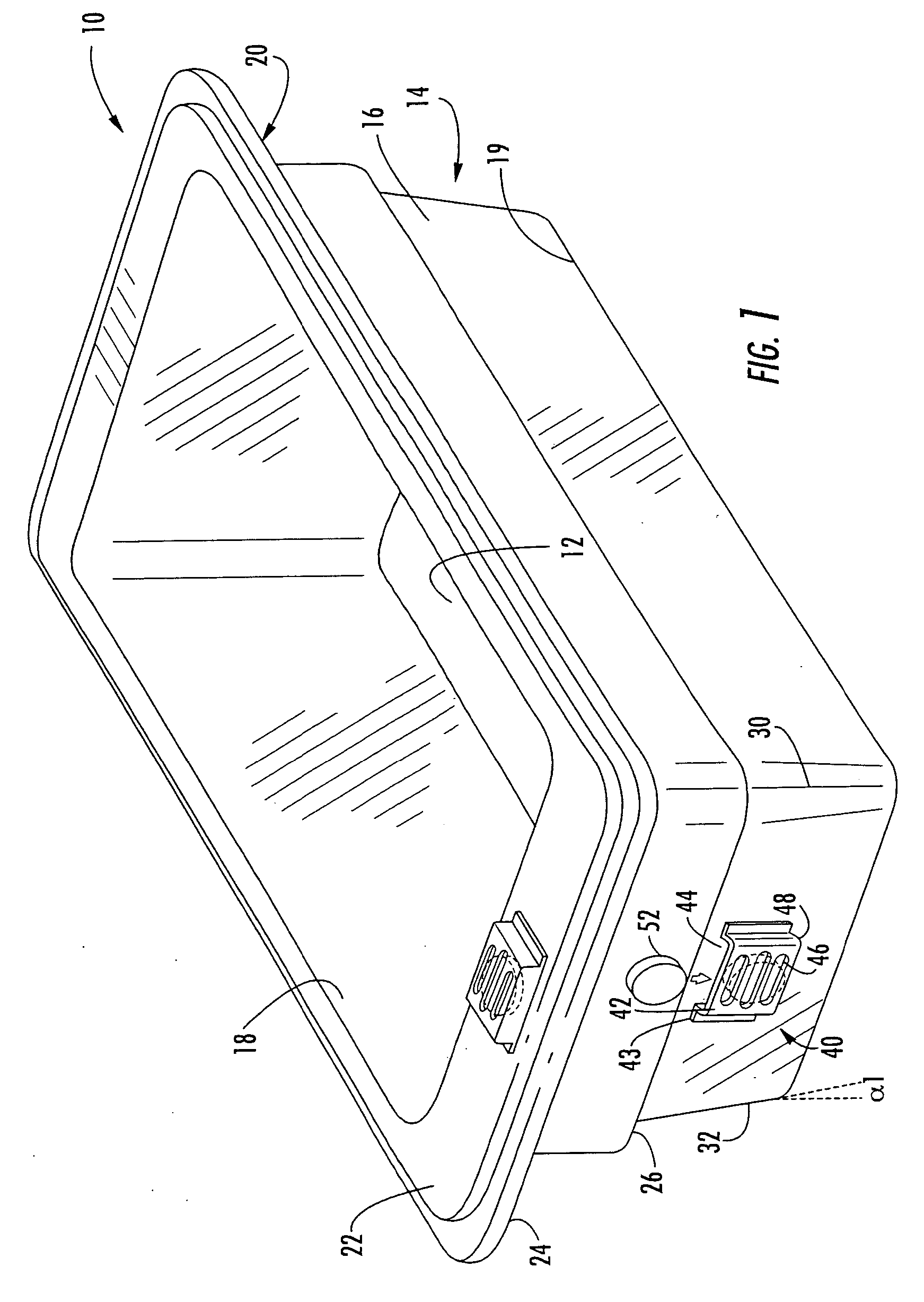

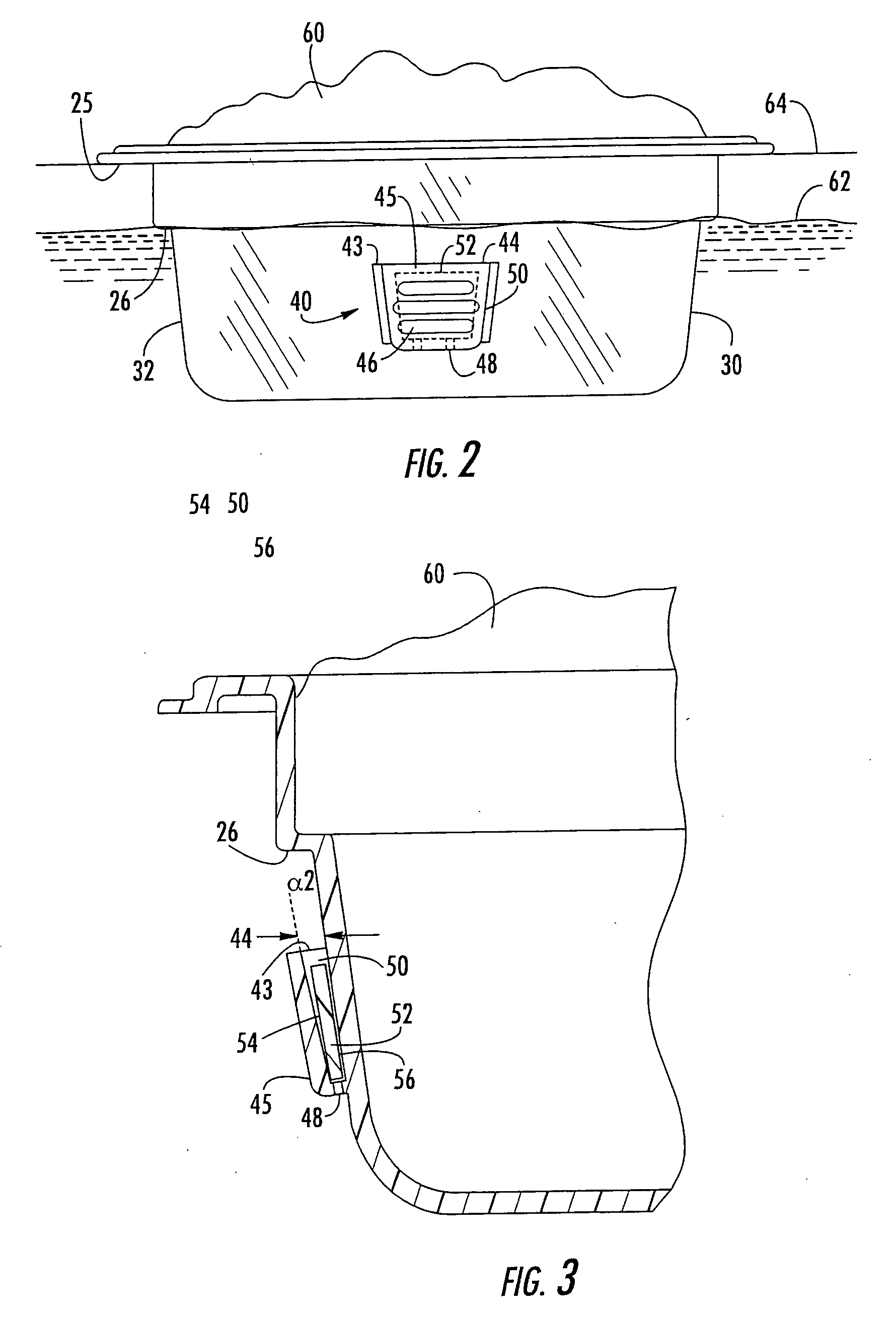

Process and device for conveying odd-shaped containers

A process for efficiently conveying containers along a table-top conveying system includes the steps of temporarily securing a transfer stabilizing support (1a, 1b) to a bottom end of a formed container (14) so that the container can freely move along a production line using the table-top conveying system where the transfer stabilizing support has a bottom surface (2a, 2b) with an opening (4a, 4b), a sidewall (6a, 6b) extending substantially perpendicular to the bottom surface, and a ridge area (10b) surrounding the opening and inside the sidewall of the support; and after the container has gone through operations of the production line, the transfer stabilizing support is removed so that aesthetic qualities of the formed container shape are revealed.

Owner:CO2 PAC

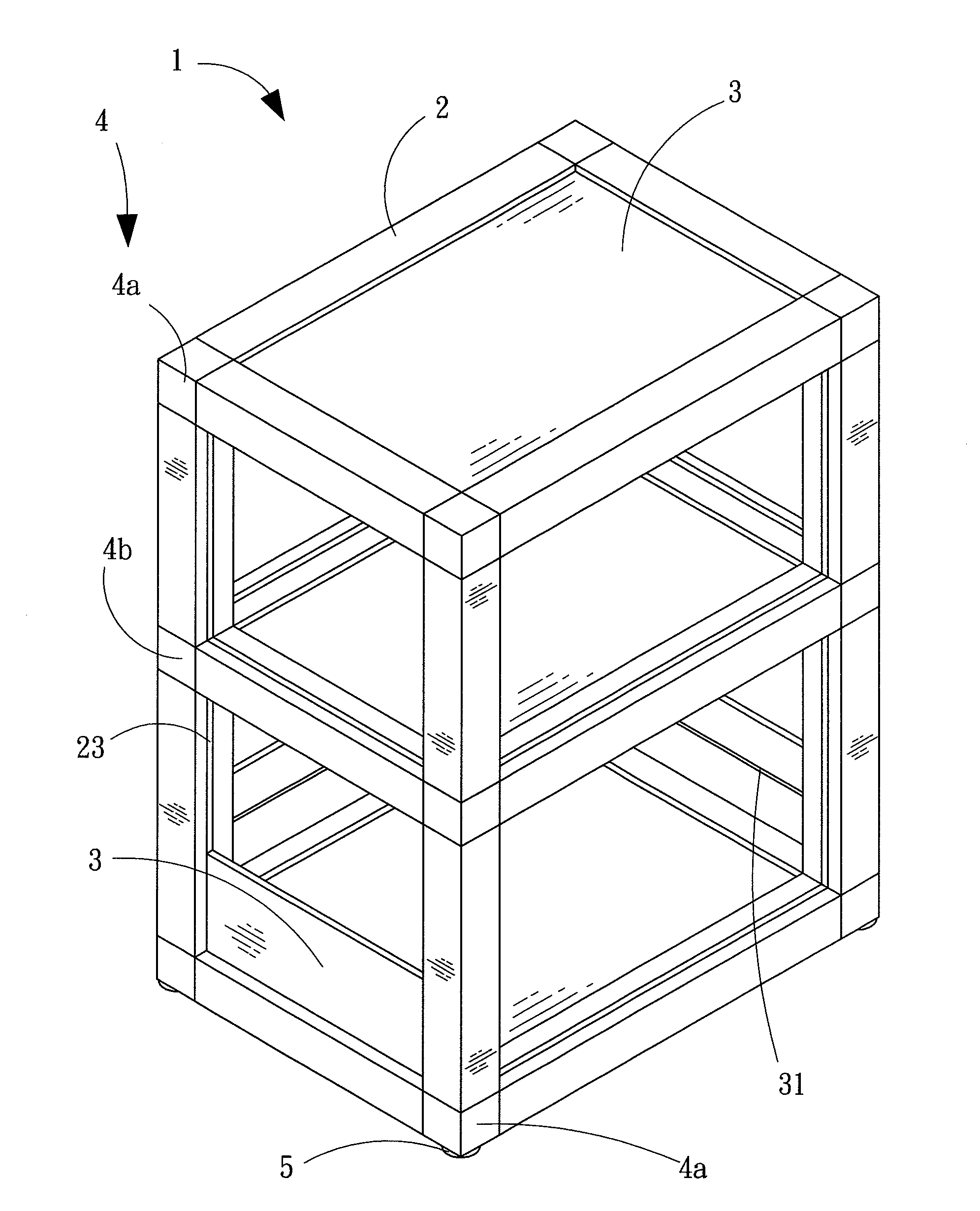

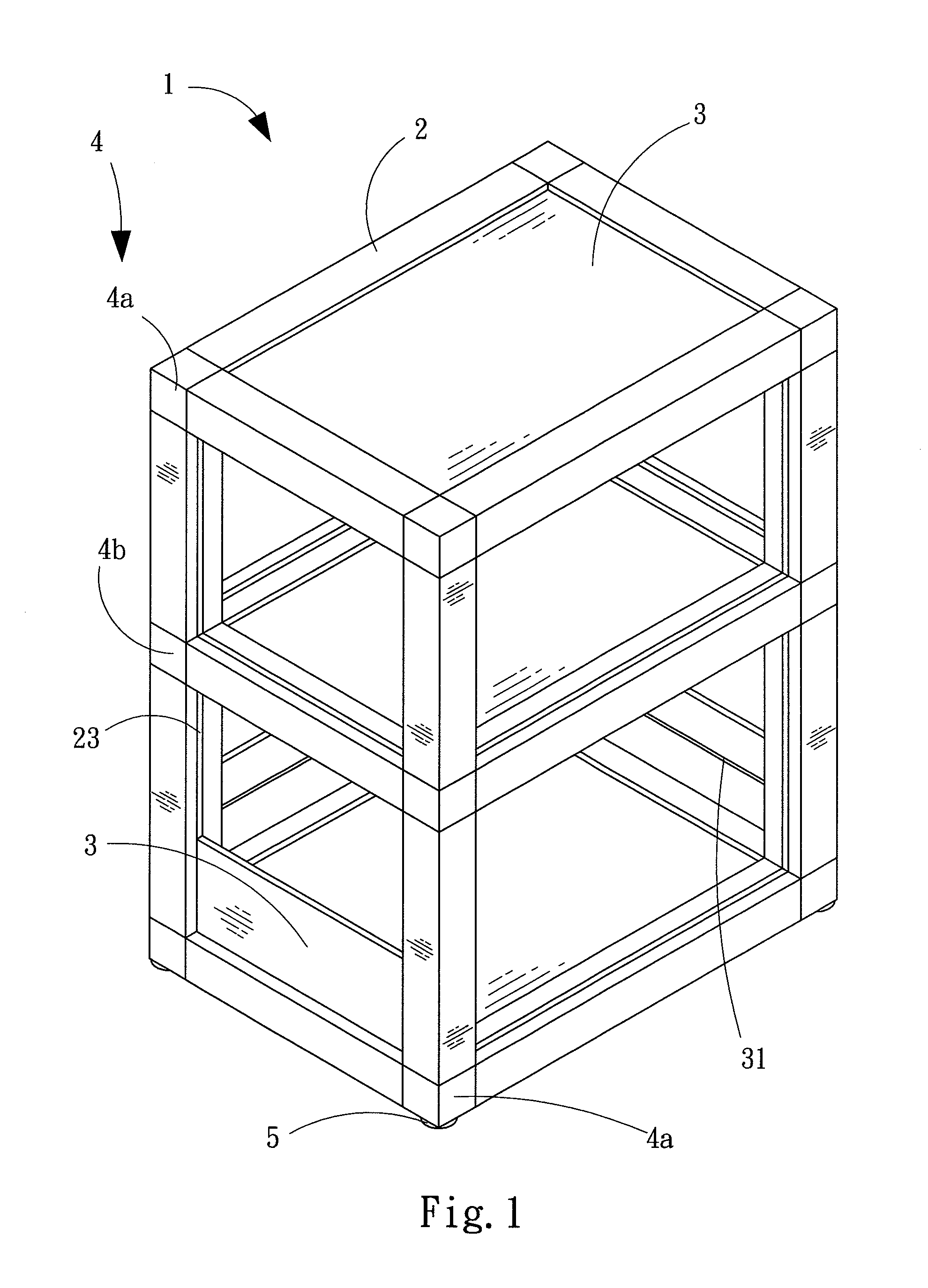

Environmental protection shelving combination

InactiveUS20110017691A1Easy constructionEasy to processFurniture partsFolding cabinetsEnvironmental resistanceMetal framework

The environmental protection shelving combination of the present invention includes sleeves and panels made of corner protection paper for support and plastic connector sets used for coupling the sleeves. Therefore, in accordance with different requirements, the assembly thereof can be altered as desired. Furthermore, since the corner protection paper is formed by pressing Kraft paper and the sand tube paper into a supporting structure, it can provide bearing and pressure capability, so that can replace the conventional wood, plastic or metal framework. Accordingly, not only the costs of material, conveying and assembly can be reduced, the pollution to the environment also can be minimized.

Owner:WU CHUAN CHING

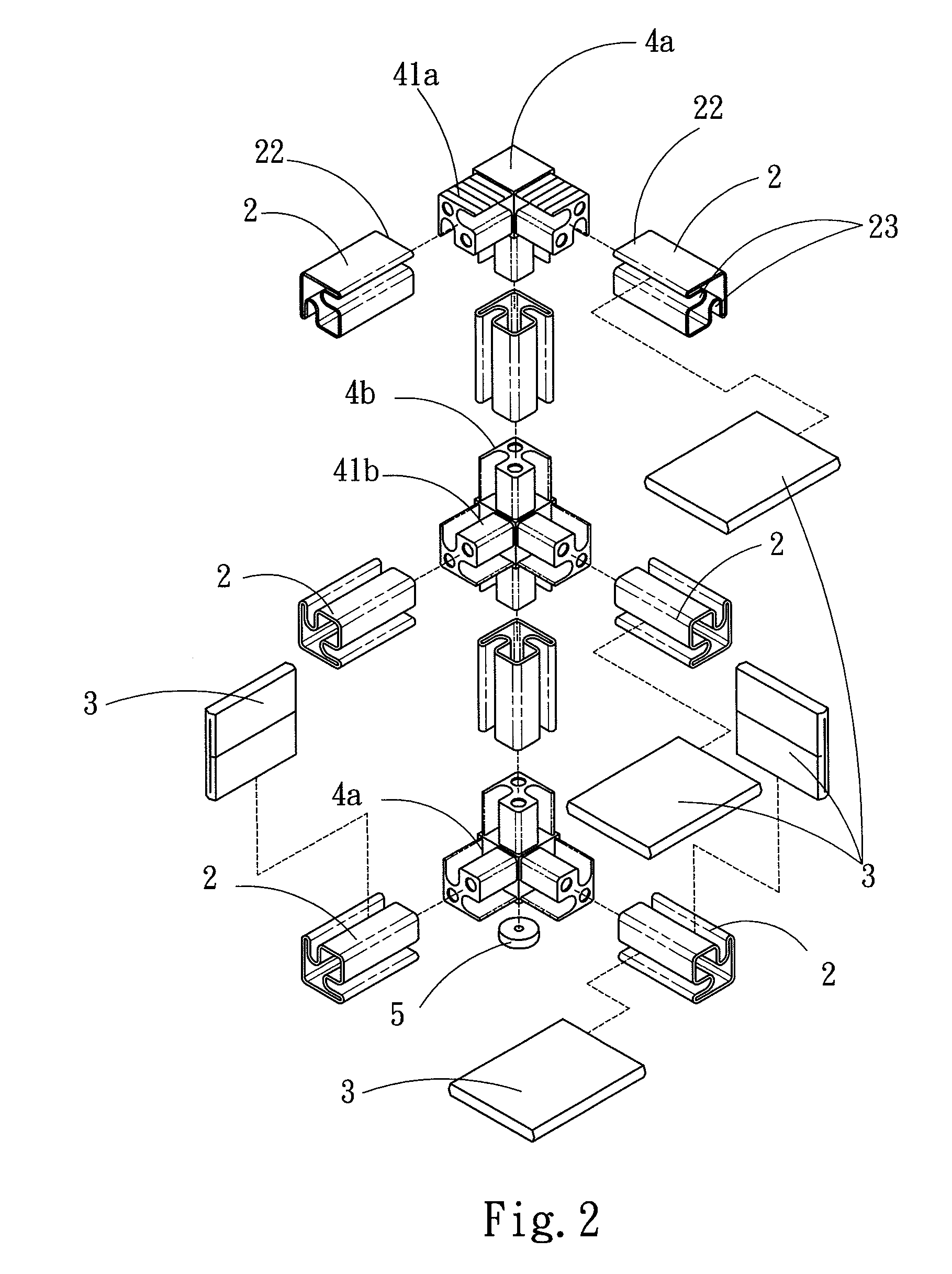

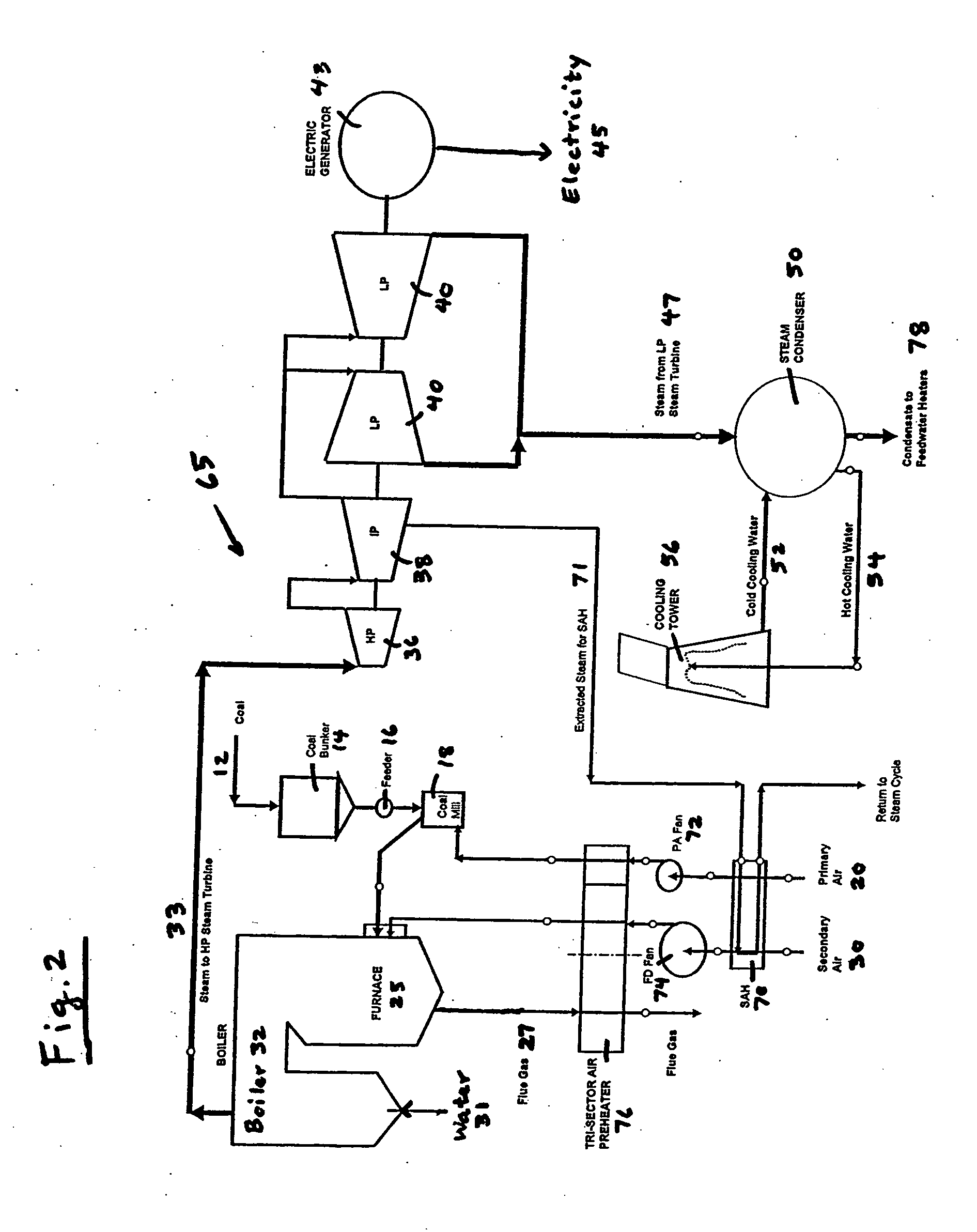

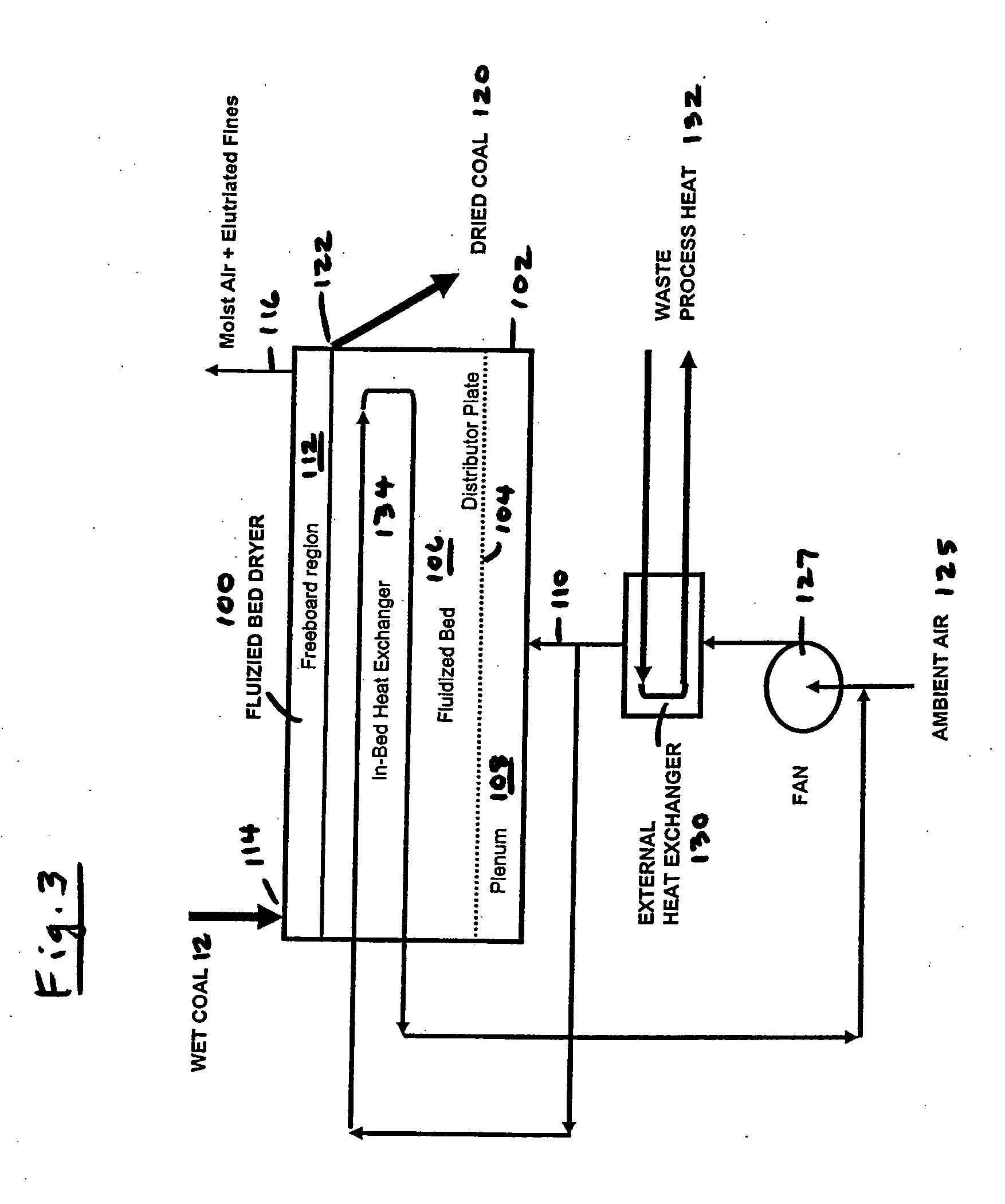

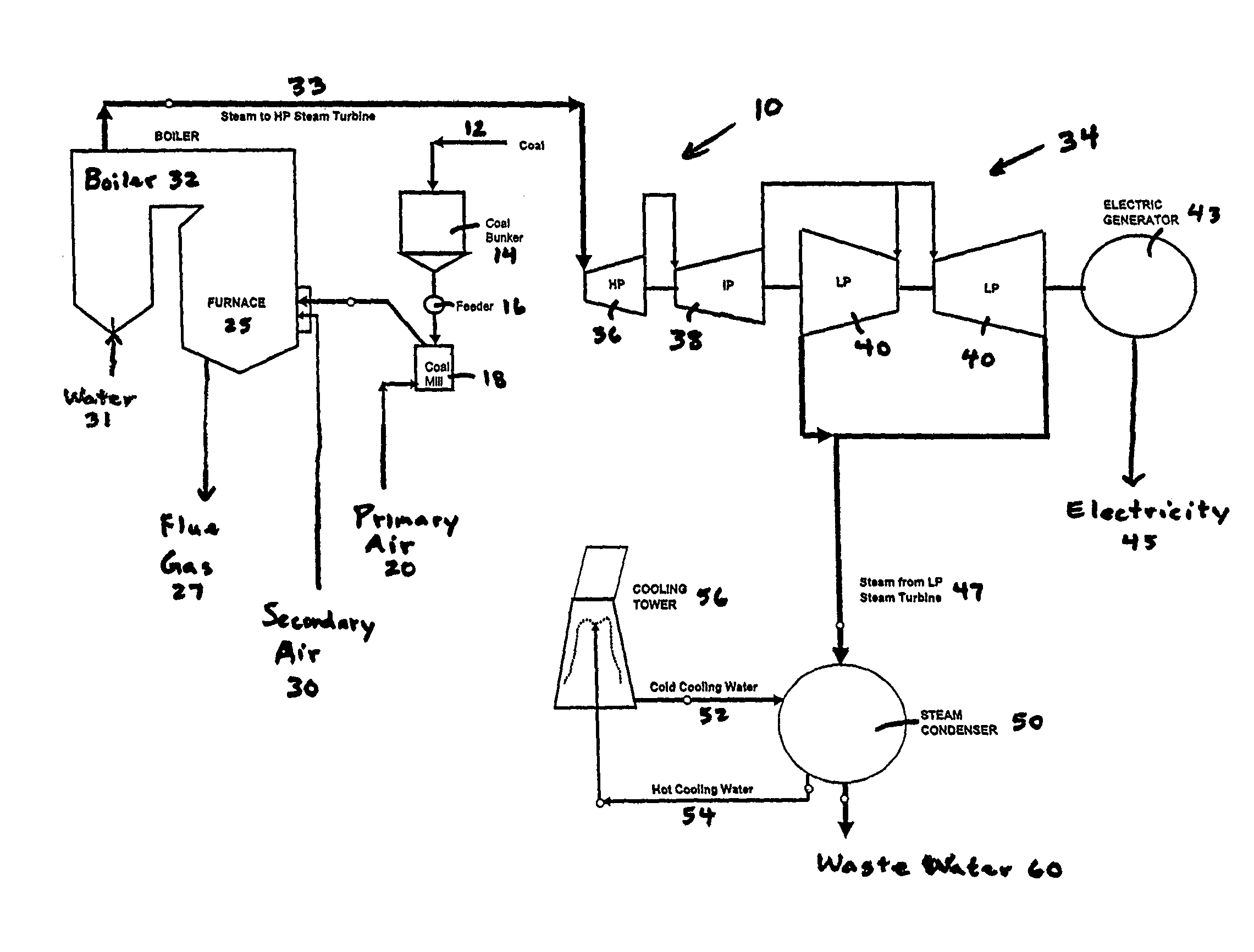

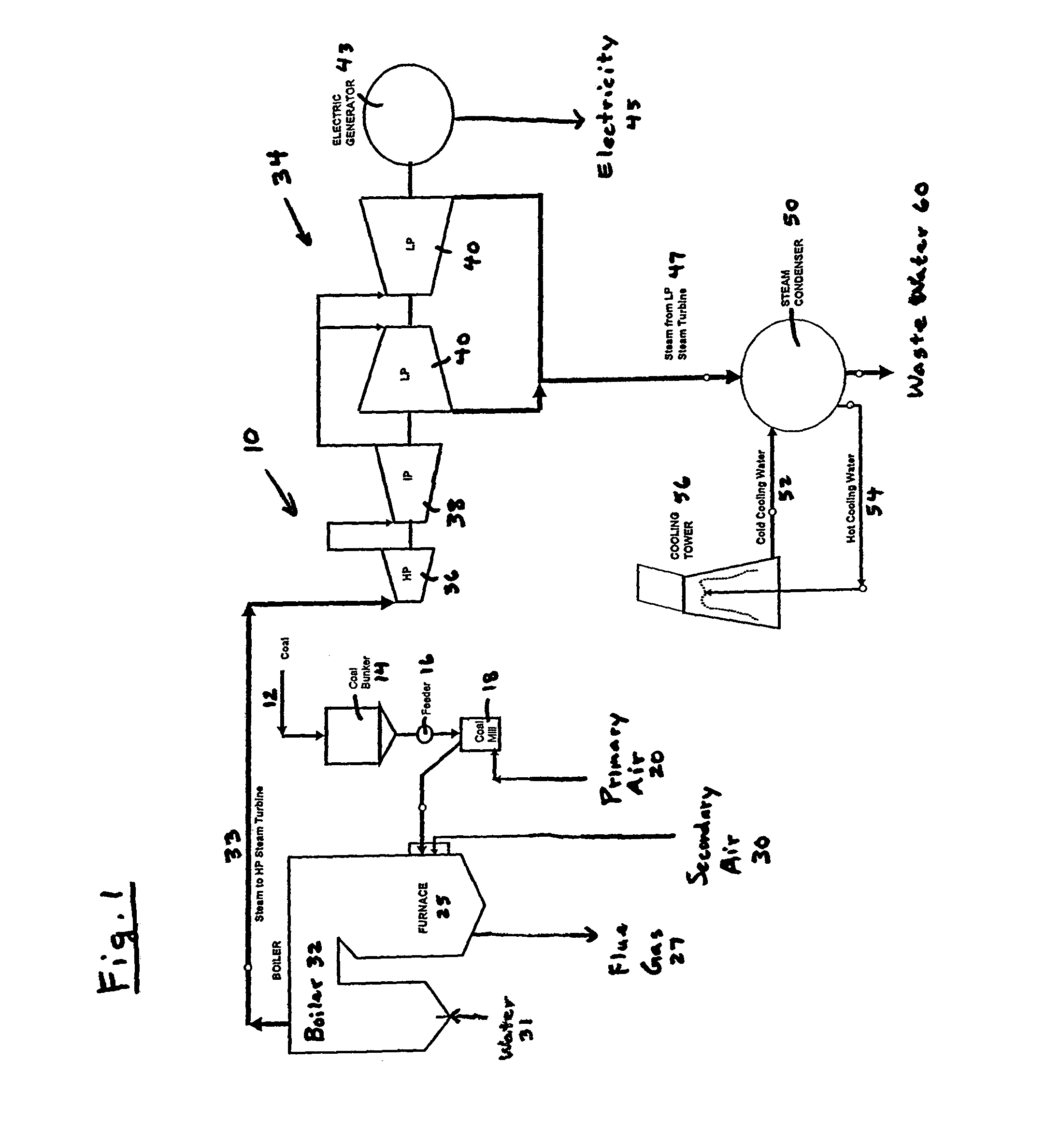

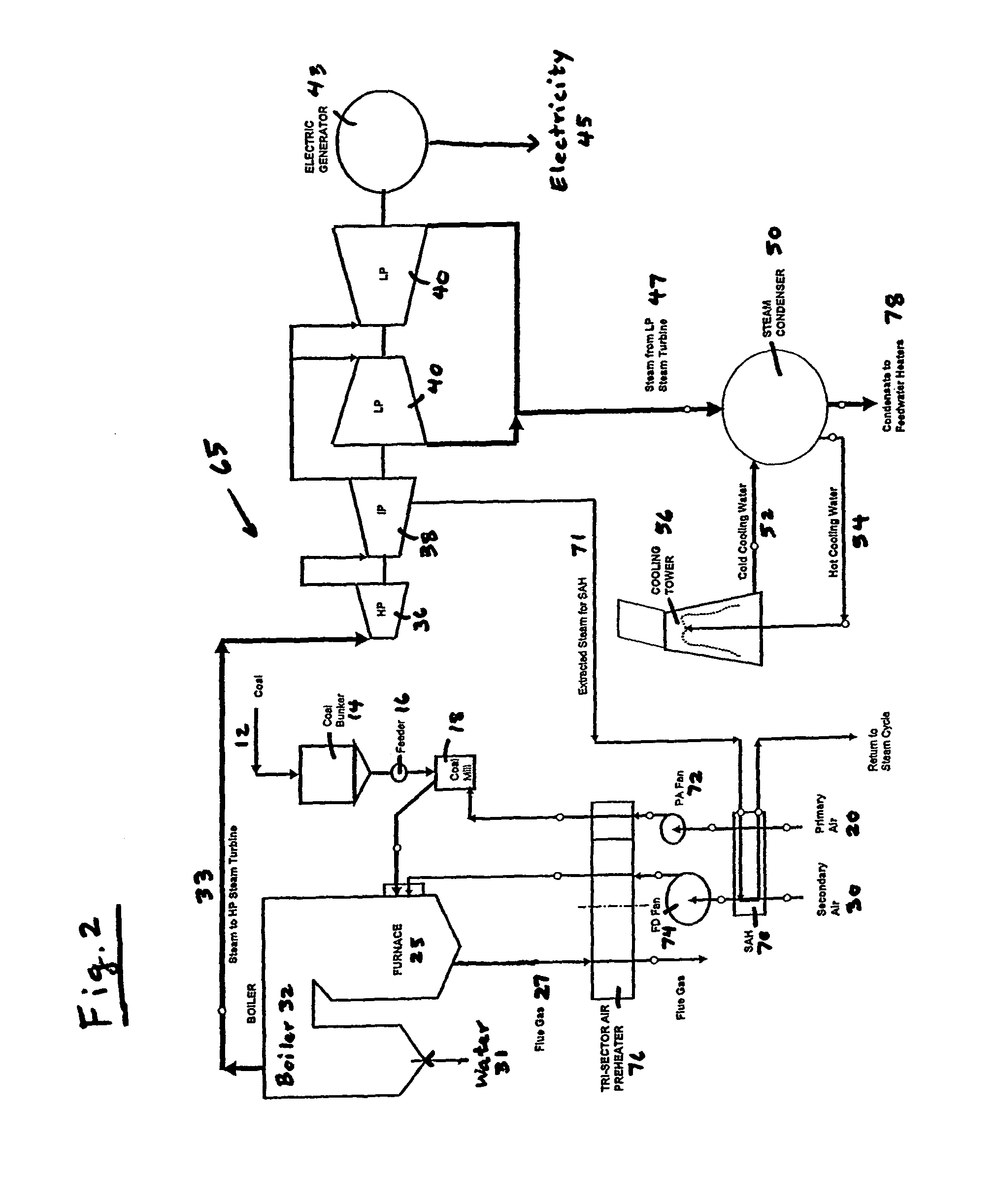

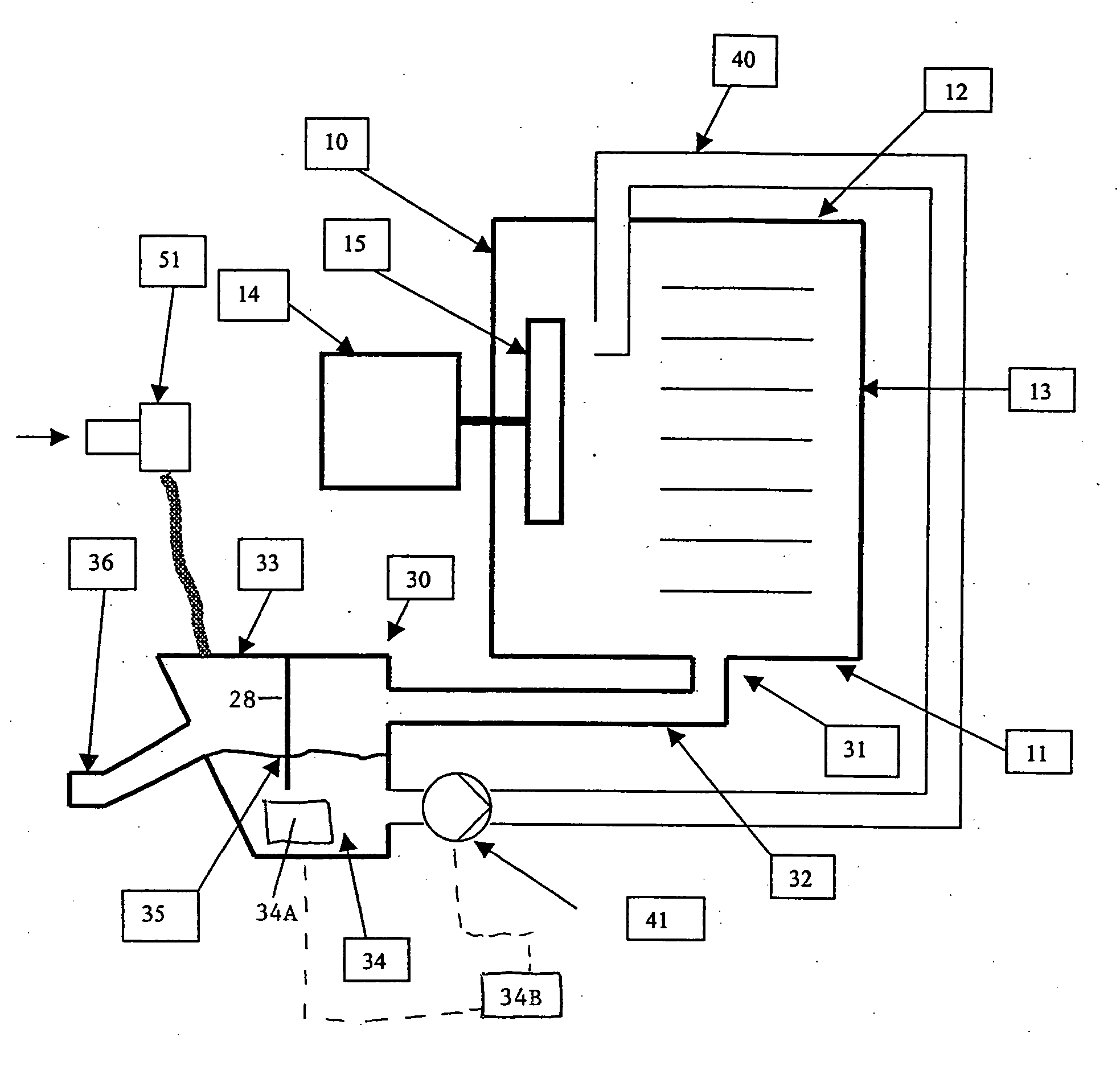

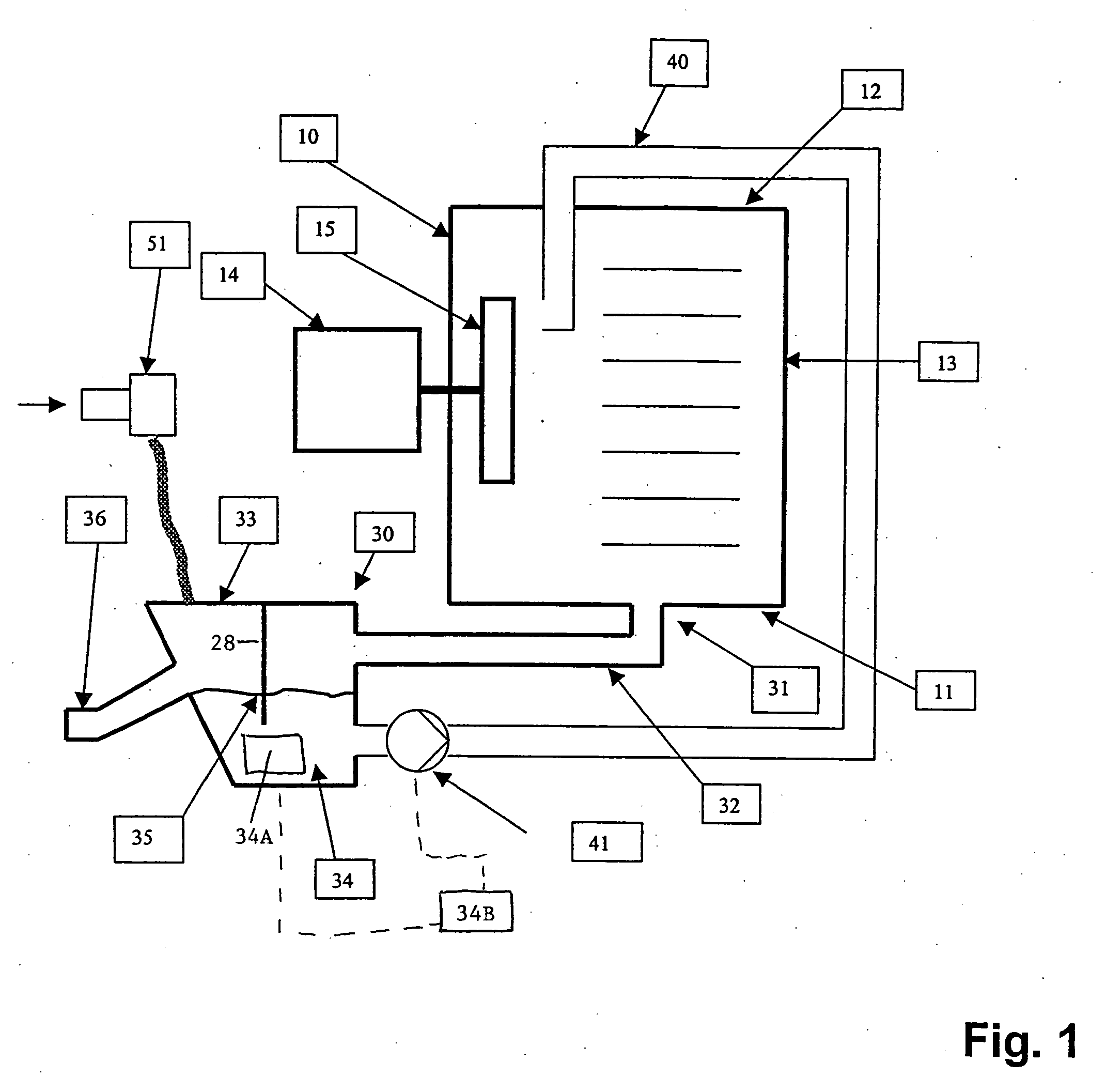

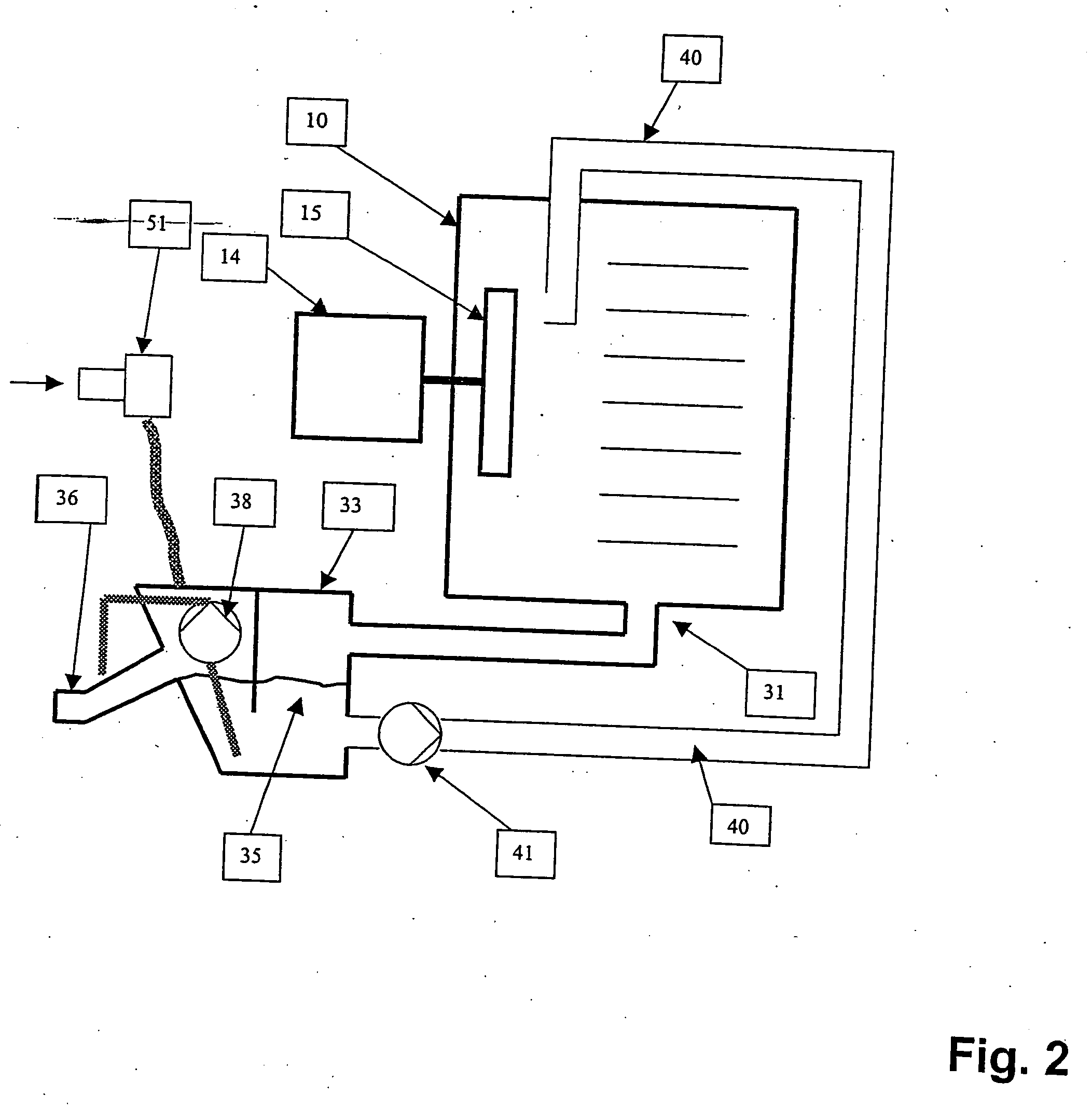

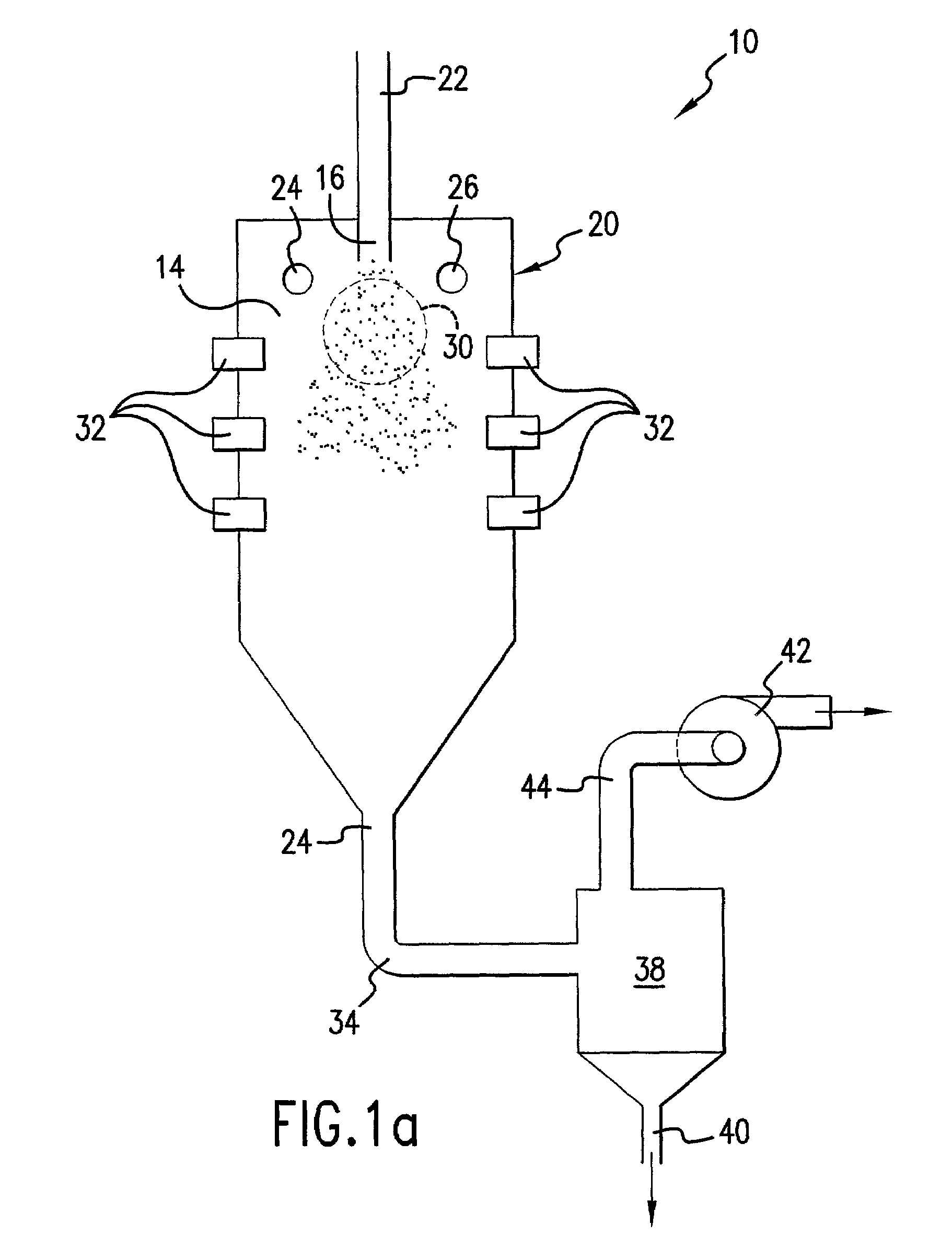

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

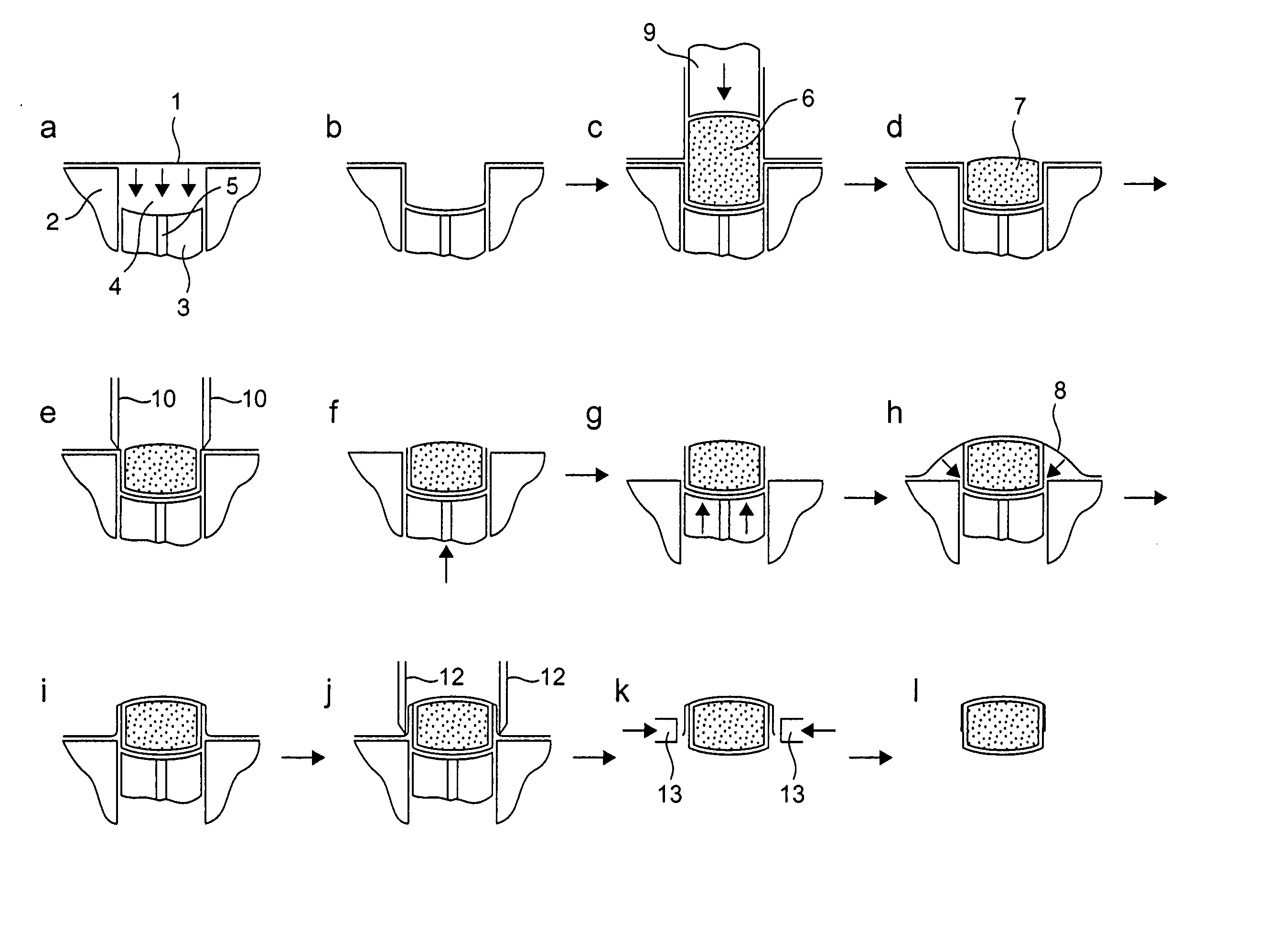

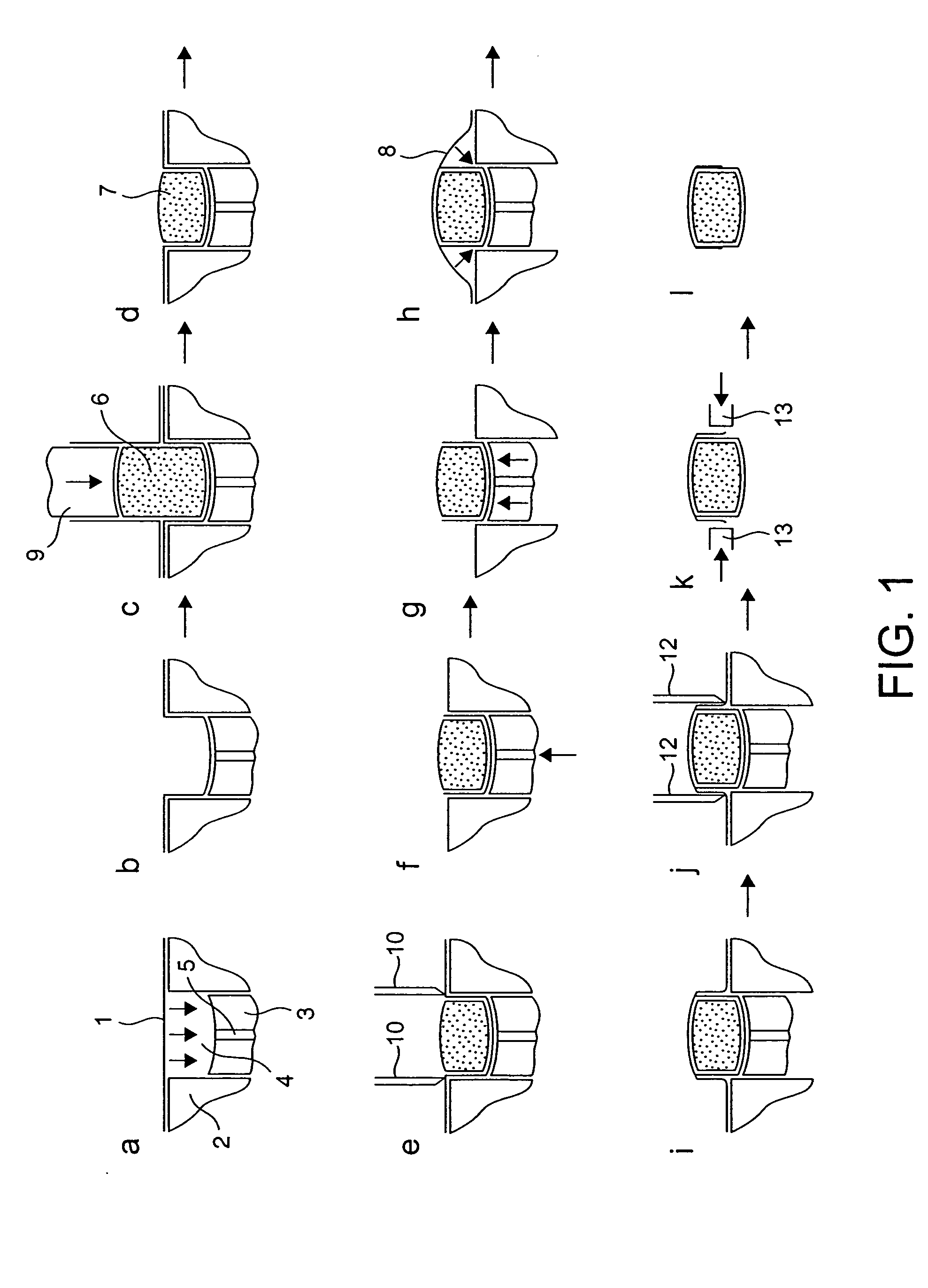

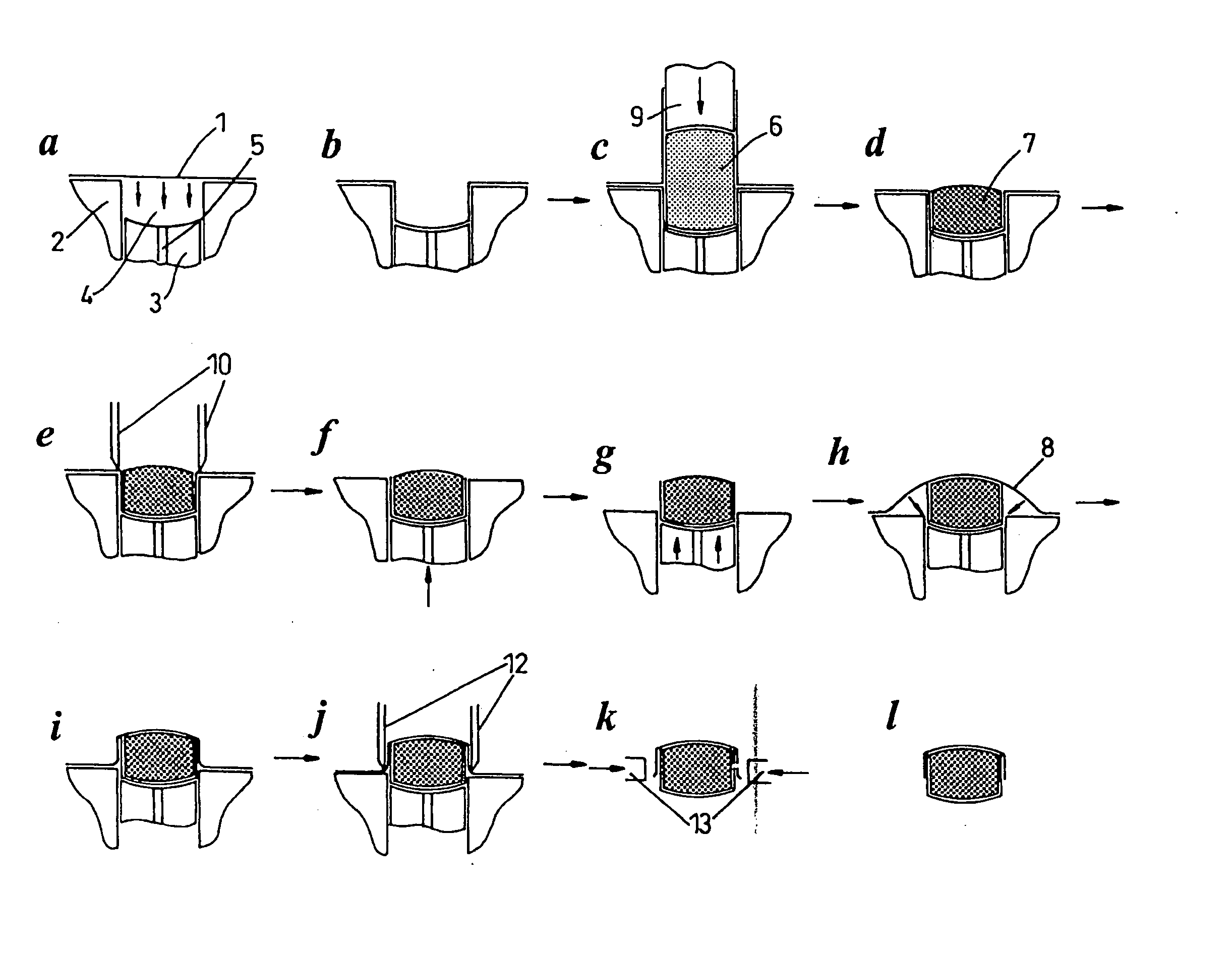

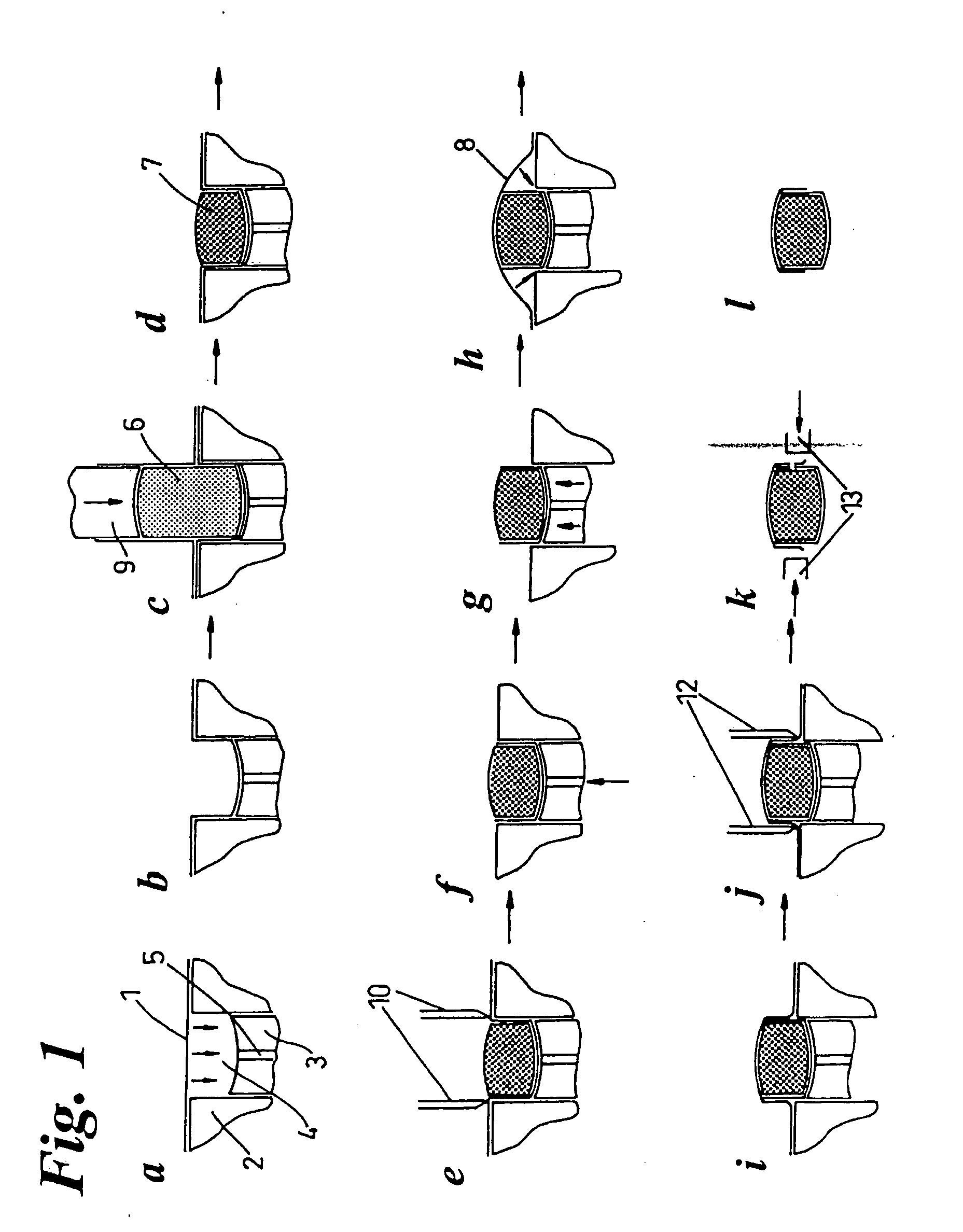

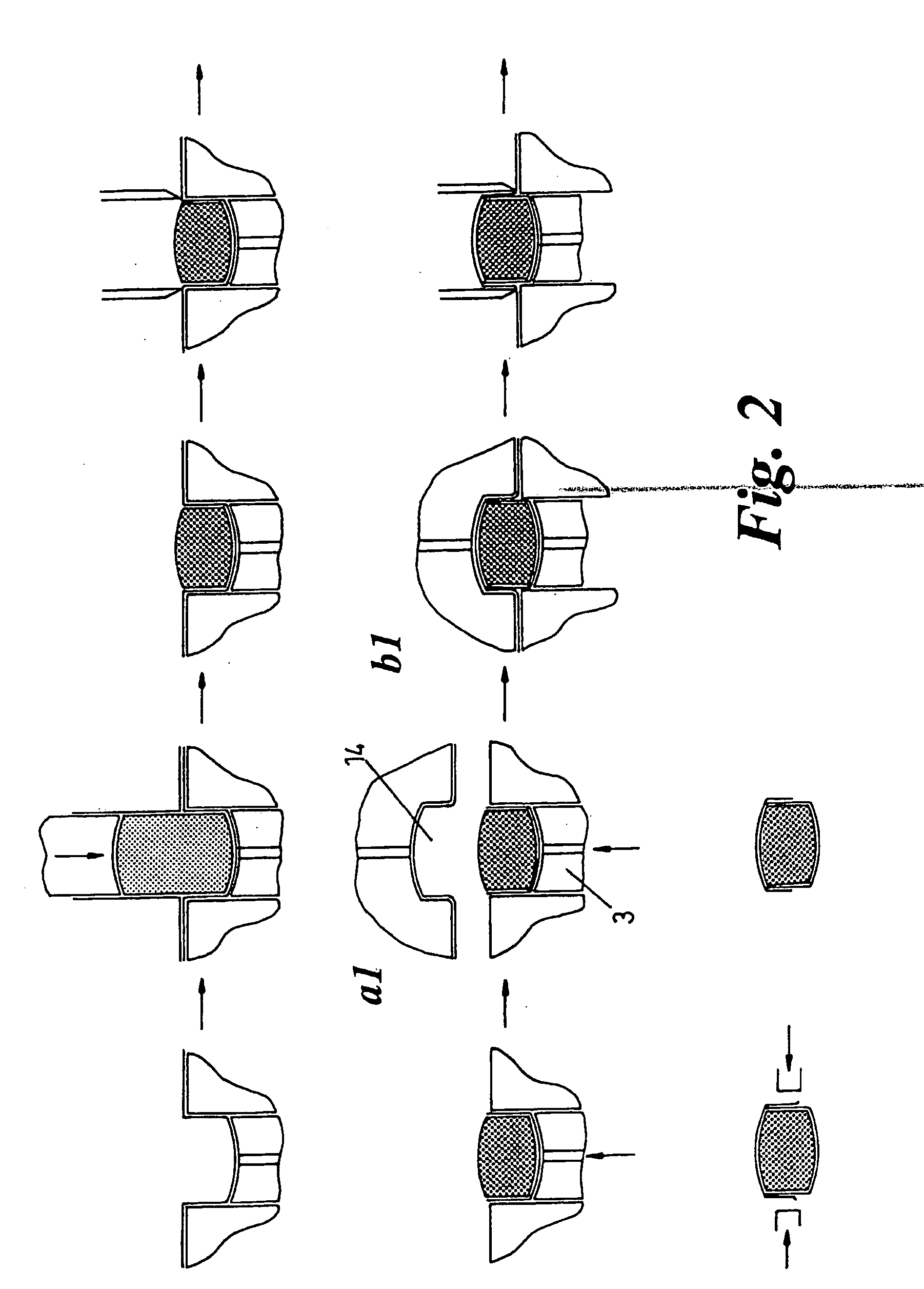

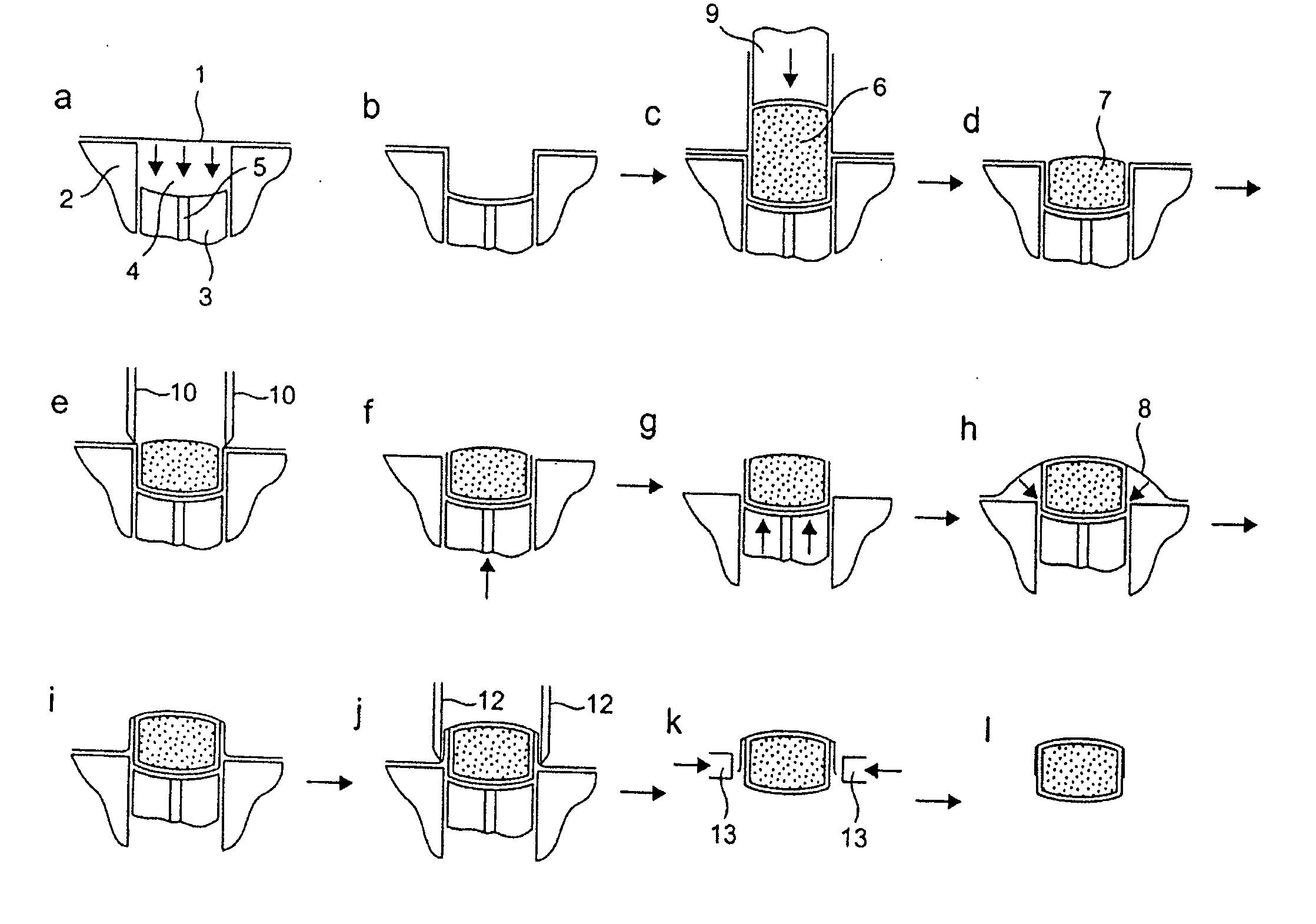

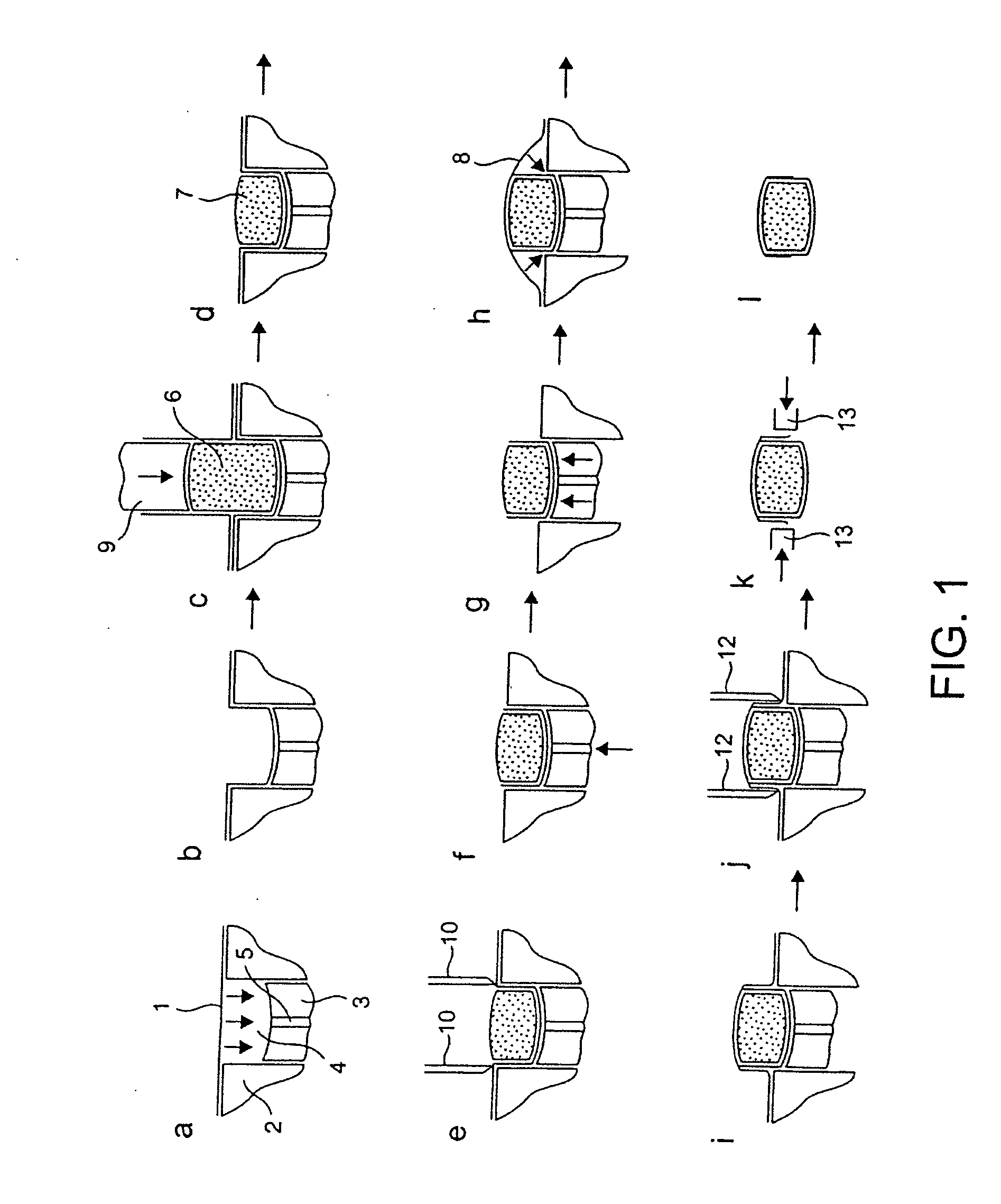

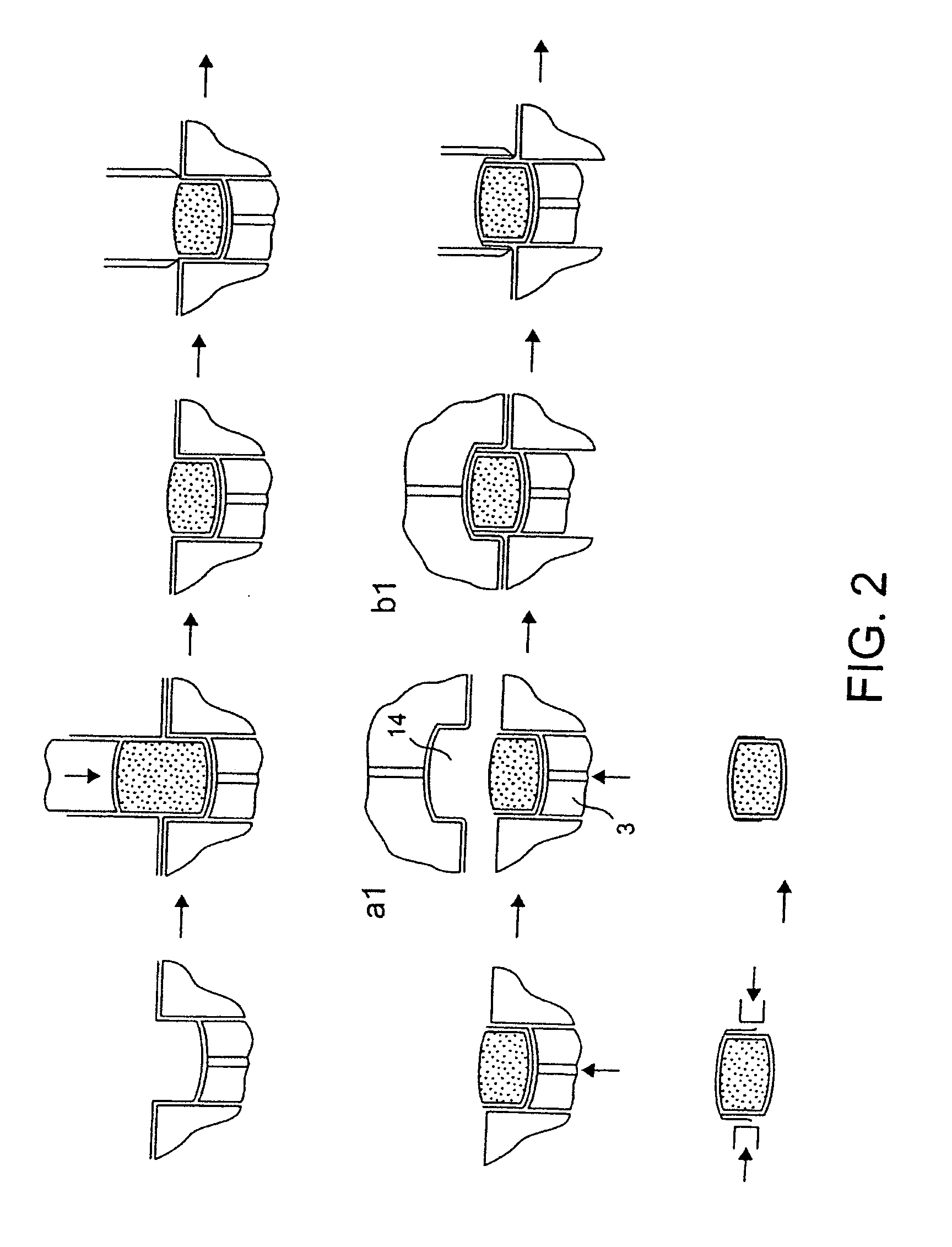

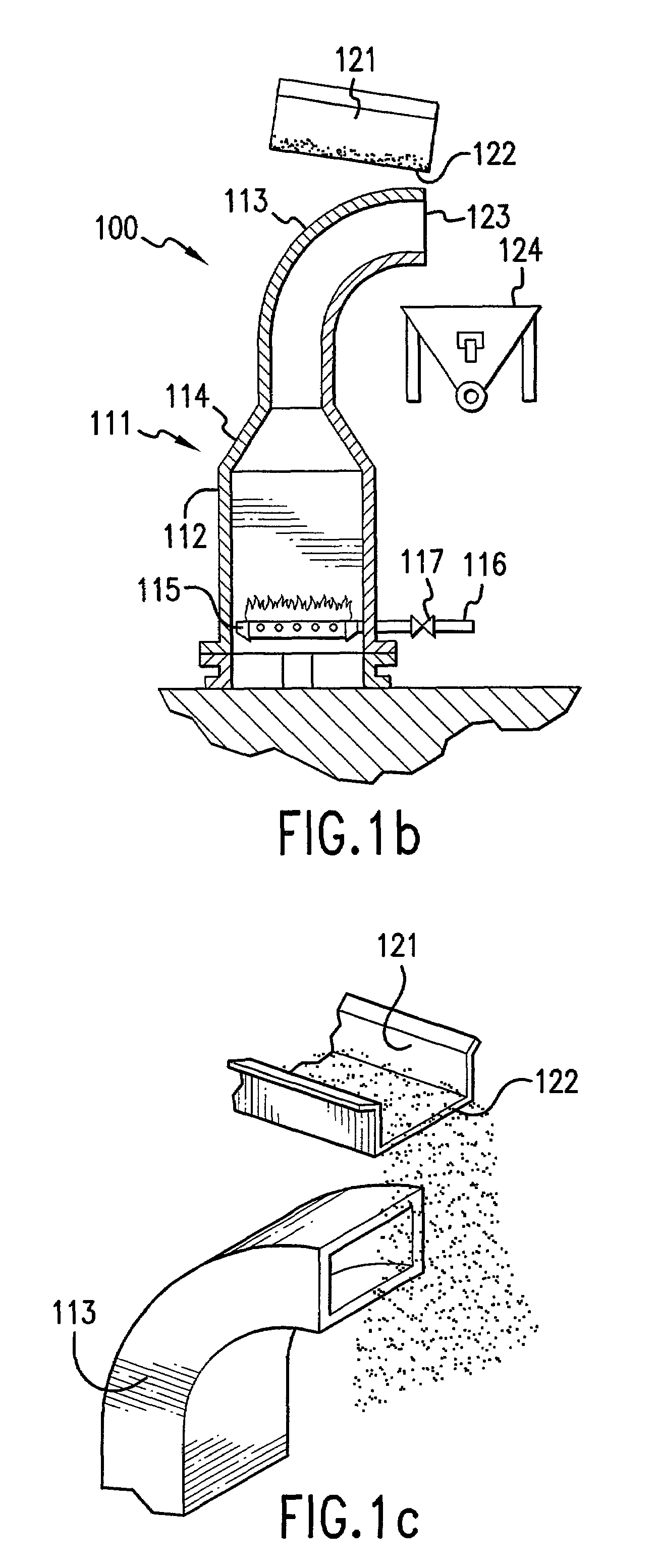

Powder compaction and enrobing

InactiveUS20050147710A1RobustQuicker release characteristicLayered productsConfectioneryMetallurgyMethyl cellulose

An apparatus and method is disclosed for forming a compacted powder slug coated with a film. The powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of a material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH

Process and device for conveying odd-shaped containers

ActiveUS7574846B2Aesthetic qualities of the formed container shape are revealedImprove stabilityCapsDecorative coversProduction lineEngineering

A process for efficiently conveying containers along a table-top conveying system includes the steps of temporarily securing a transfer stabilizing support (1a, 1b) to a bottom end of a formed container (14) so that the container can freely move along a production line using the table-top conveying system where the transfer stabilizing support has a bottom surface (2a, 2b) with an opening (4a, 4b), a sidewall (6a, 6b) extending substantially perpendicular to the bottom surface, and a ridge area (10b) surrounding the opening and inside the sidewall of the support; and after the container has gone through operations of the production line, the transfer stabilizing support is removed so that aesthetic qualities of the formed container shape are revealed.

Owner:CO2 PAC

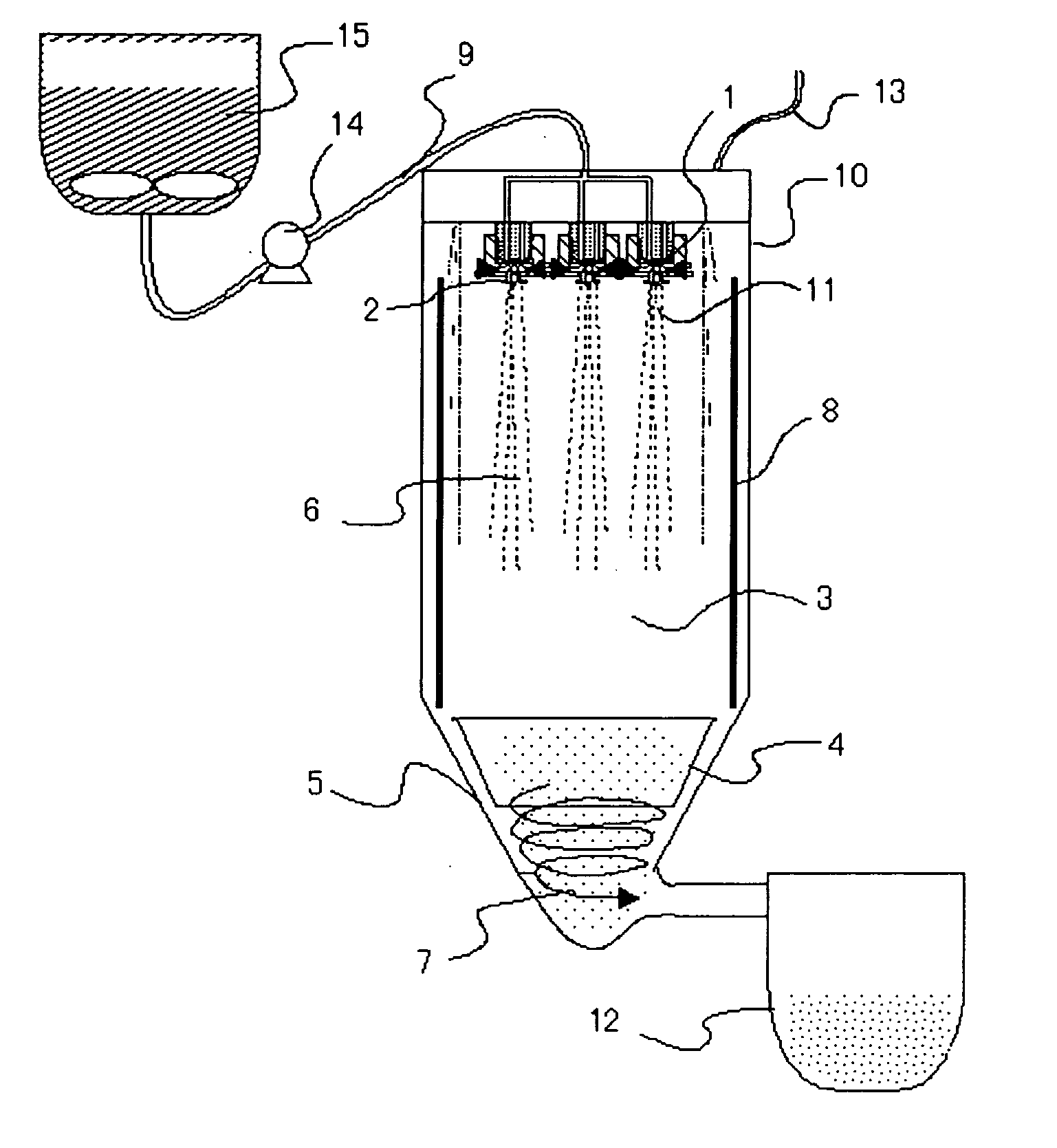

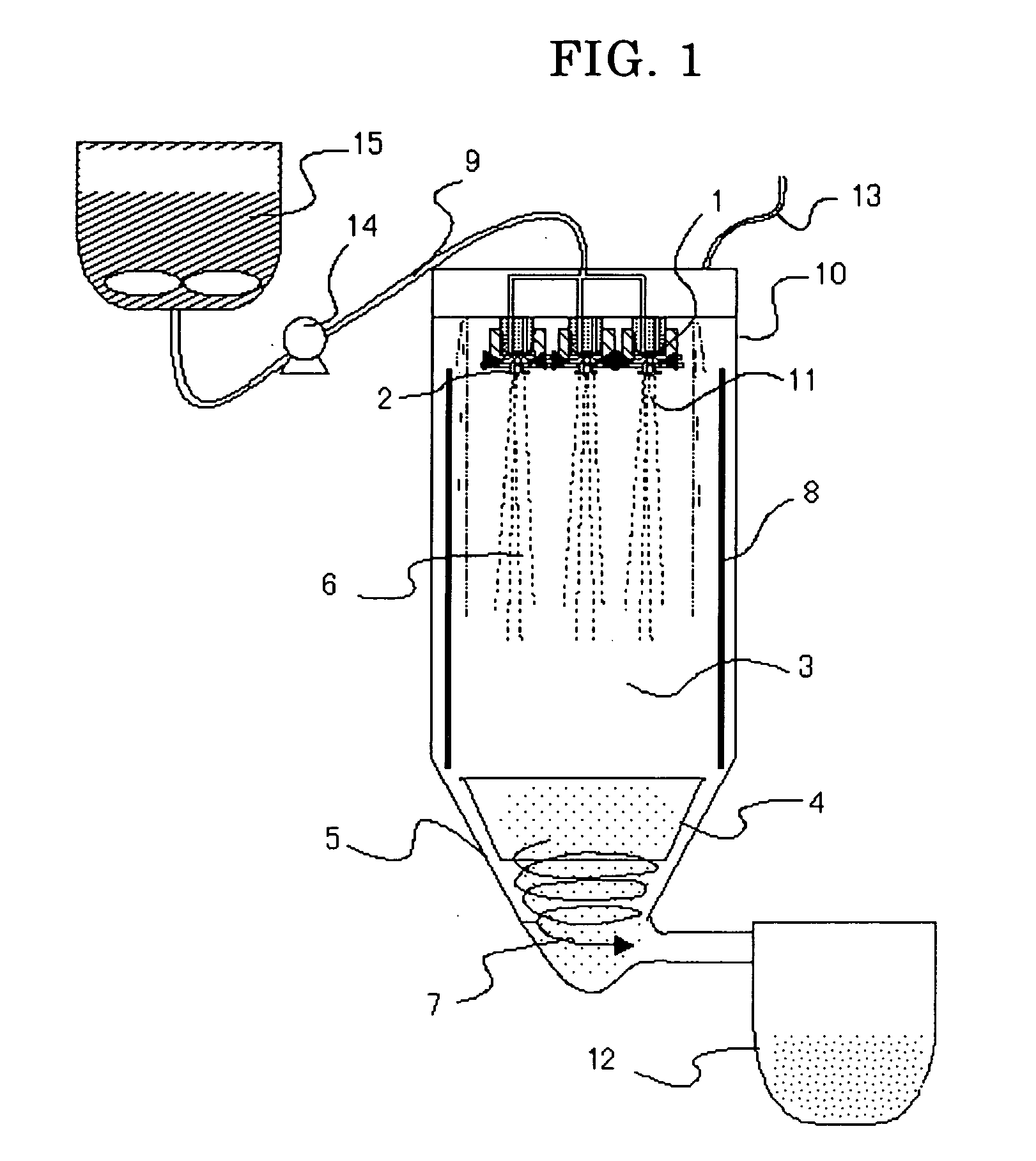

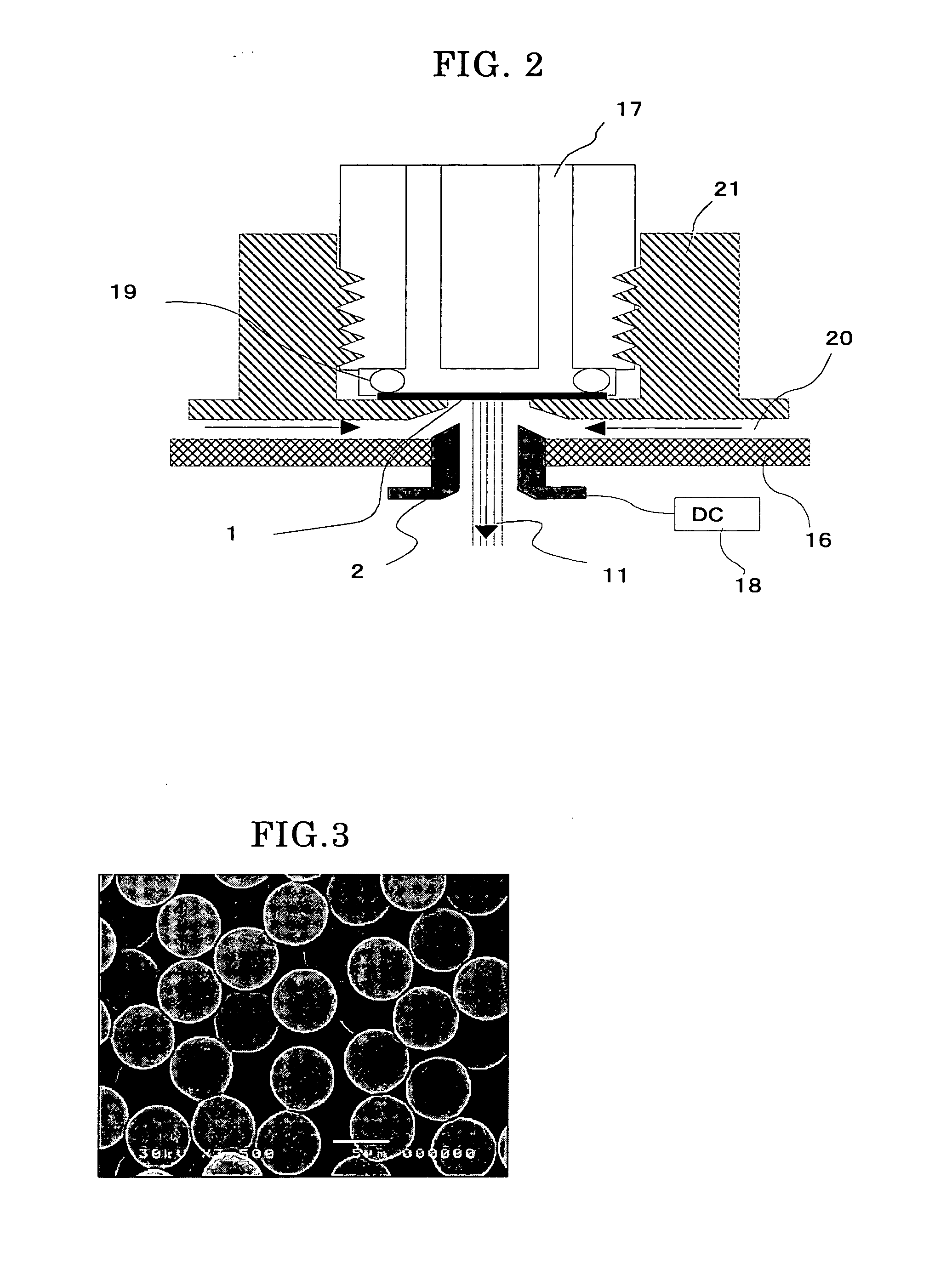

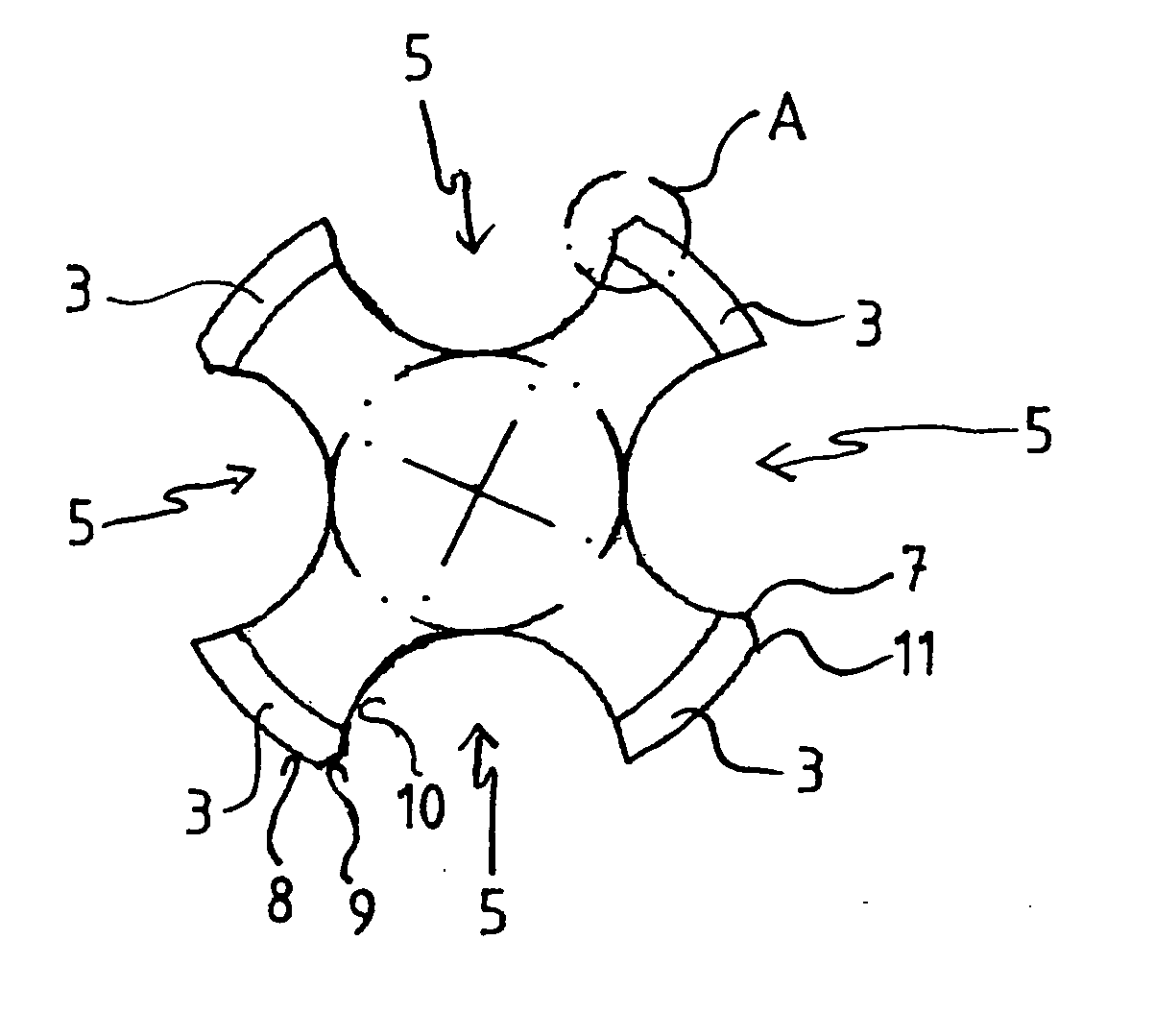

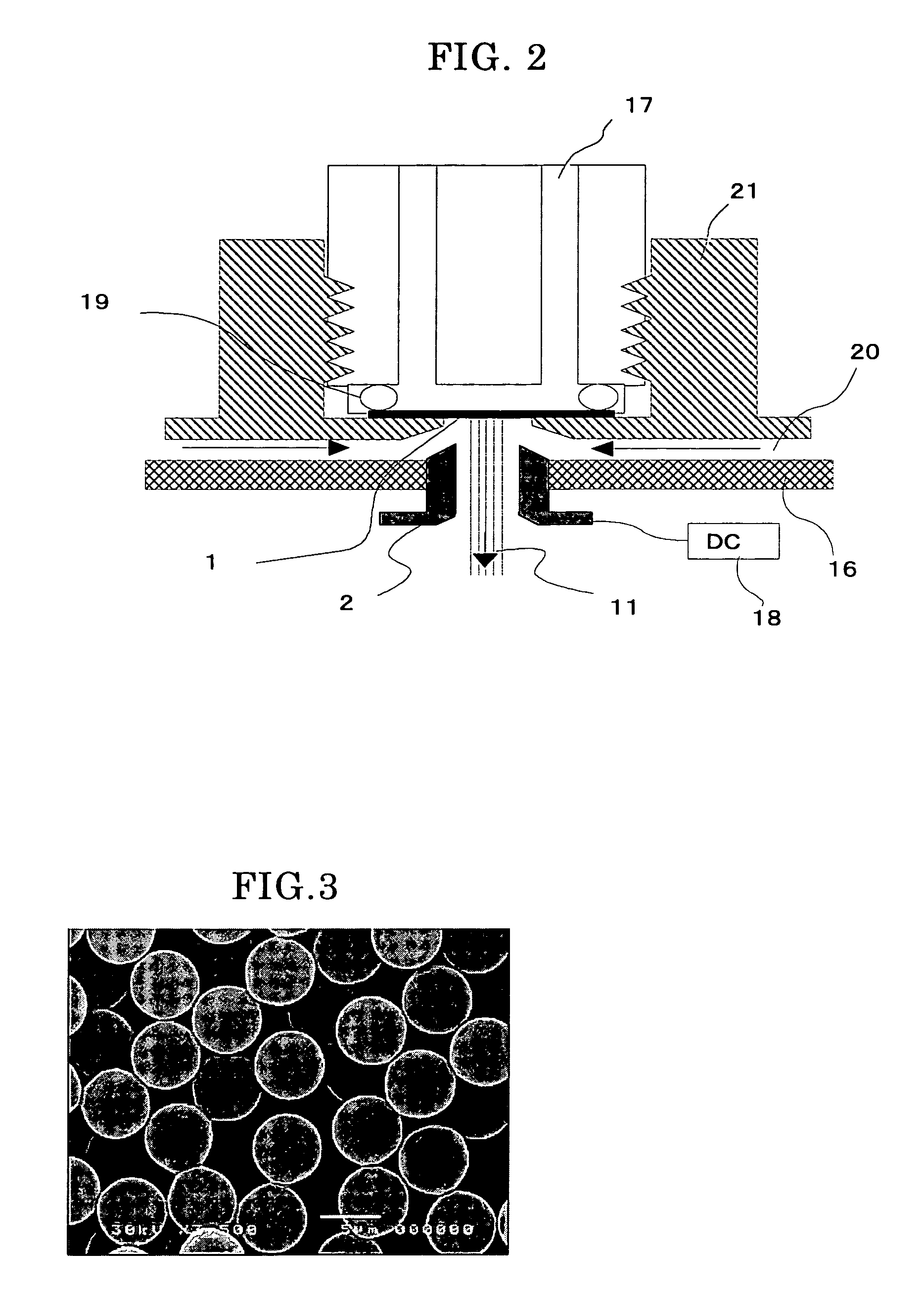

Method for producing a toner, and toner

InactiveUS20060210909A1Increase in numberSufficient productivityGranule coatingGranulation by liquid drop formationConstant frequencyColoring agents

The object of the present invention is to provide a method for producing a toner which includes ejecting a toner composition fluid containing a toner composition which contains a toner and a colorant, from a nozzle vibrated at a constant frequency to make the toner composition fluid into droplets, and solidifying the droplets to be made into particles, in which the toner composition fluid comprises a toner composition, and the toner composition contains a resin, and a colorant.

Owner:RICOH KK

Screw-tap for cutting female threads

InactiveUS20050042049A1Adequate process reliabilityMore compactThread cutting toolsWood turning toolsScrew threadRake angle

A screw-tap includes at least two cutting lands with respective cutting edges. The cutting edges have, at least in a starting taper region thereof, a chamfer with a negative angle that reduces a rake angle of the cutting edges. An angle of the chamfer to a plane oriented perpendicular to a surface produced in a workpiece has a value in a range of −10° and −60°. A width of the chamfer is between 0.05 and 0.75 times a depth of profile.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

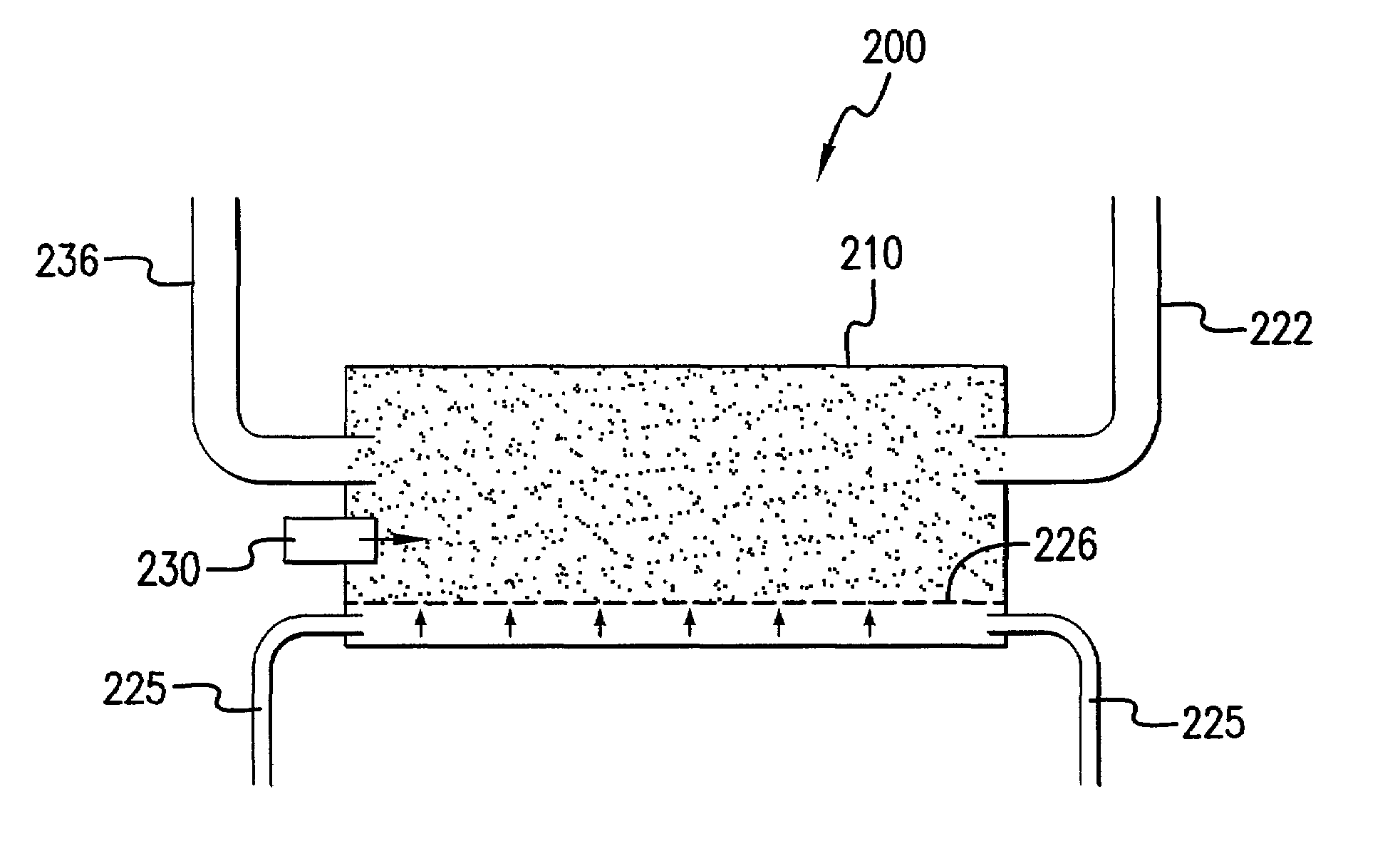

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS8579999B2Improve efficiencyIncrease heatDrying solid materials with heatSolid fuelsFluidized bed dryingMoisture

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

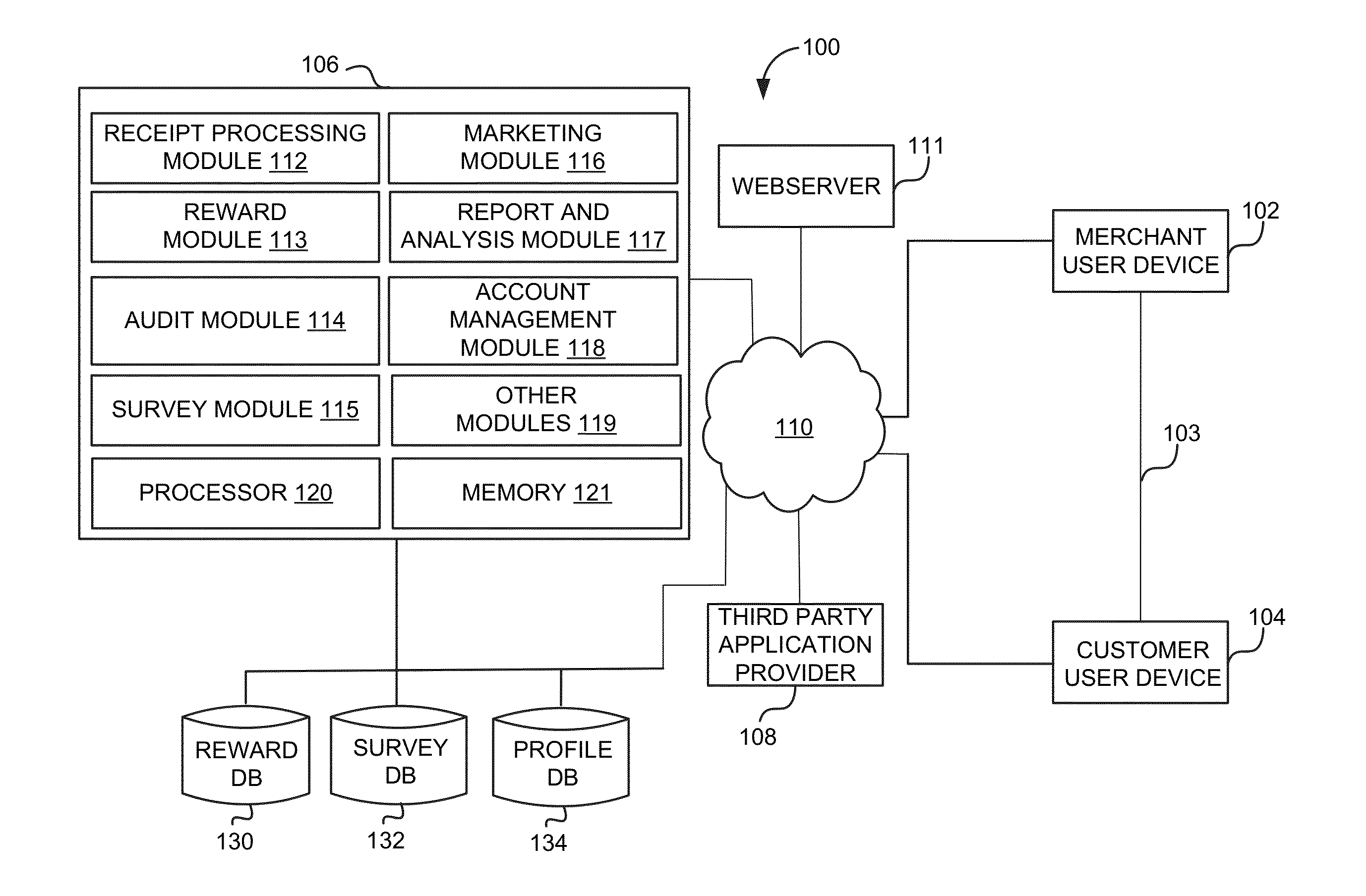

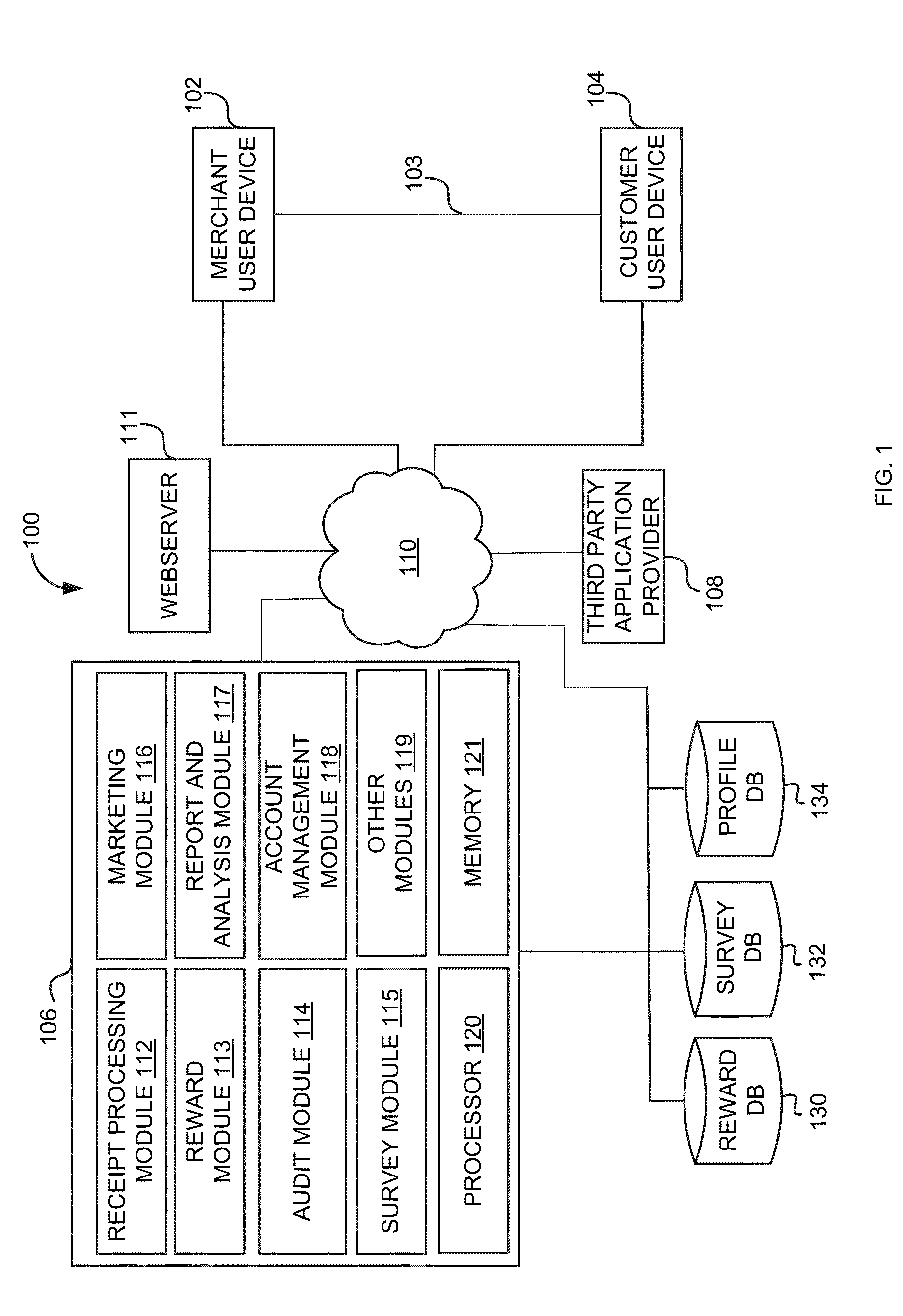

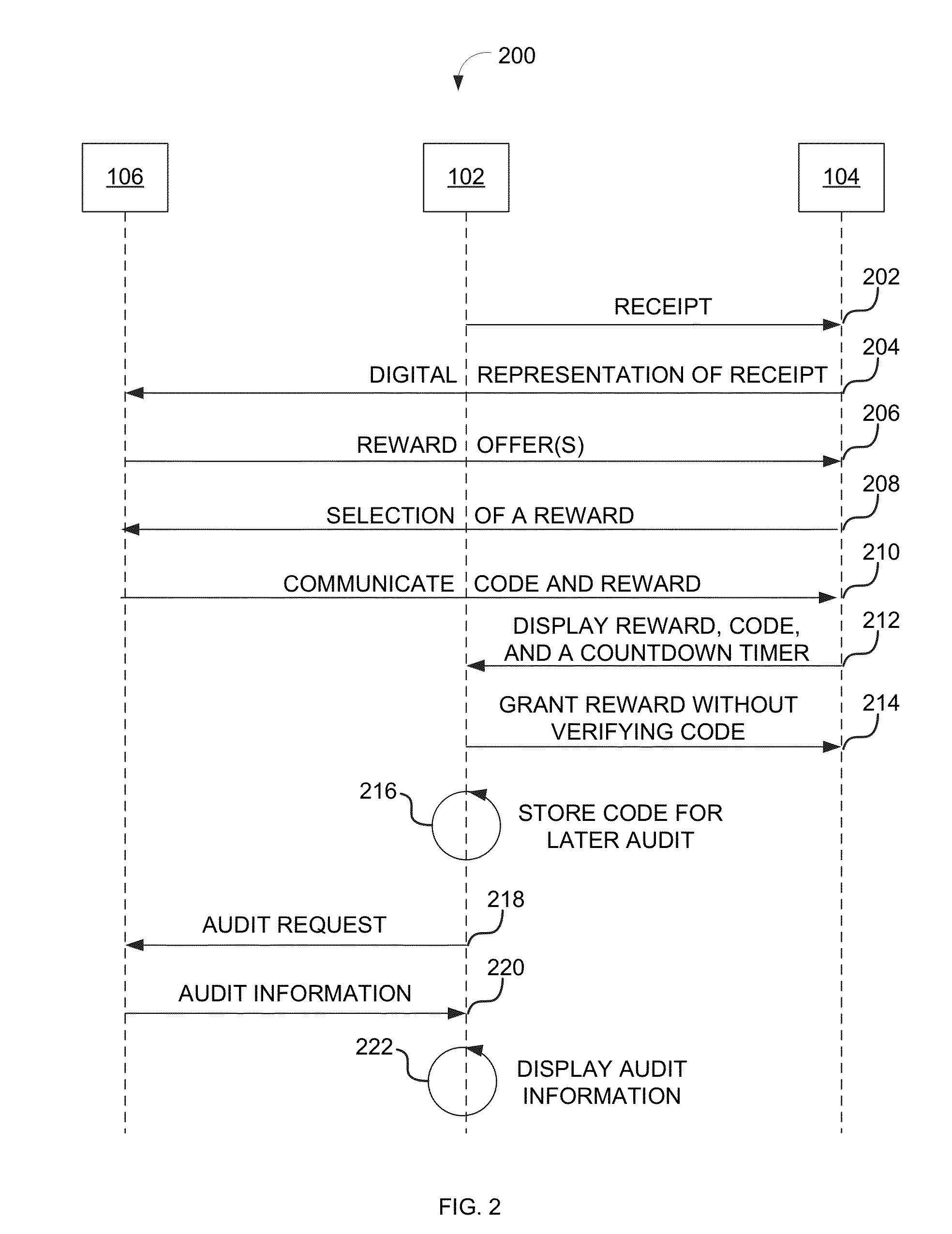

System and method for providing imaging and other digital representations of receipts to impart incentives on users

The disclosure relates to systems and methods for providing a card-less reward program that awards rewards based on purchase data determined from digital representations of sales receipts, and facilitating analytics related to the reward program, feedback from customers, and detection of fraudulent reward redemptions. A reward server may receive a digital representation of a sales receipt, determine purchase data based on the digital representation, and determine one or more rewards to be awarded based on the determined purchase data. The reward server may generate a code in association with the one or more rewards that can be used for auditing purposes to determine whether a reward was fraudulently obtained. The reward server may provide analytics and customer surveys to determine the effectiveness of reward programs and / or other merchant efforts to build and enhance customer loyalty.

Owner:DAILYGOBBLE

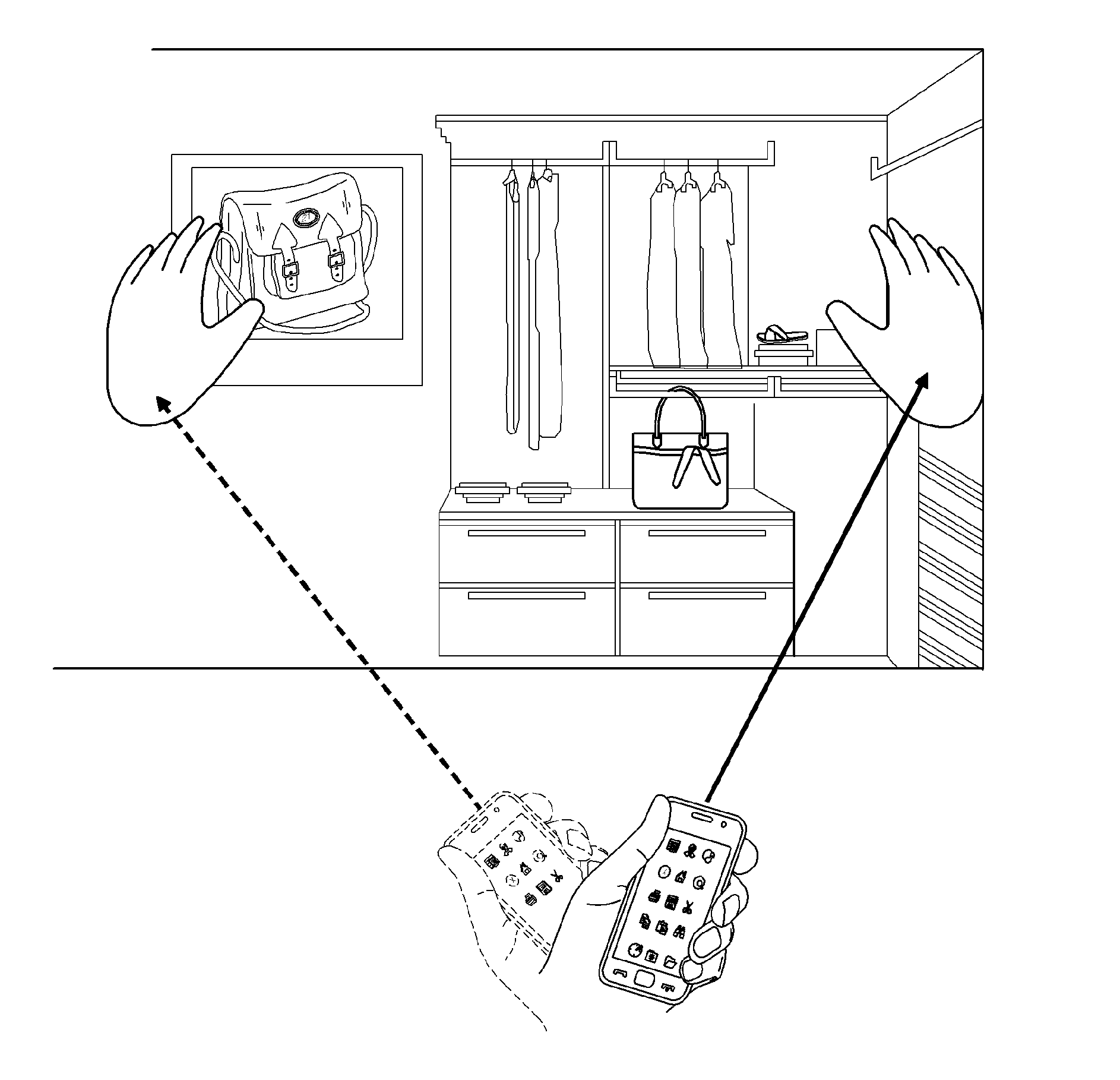

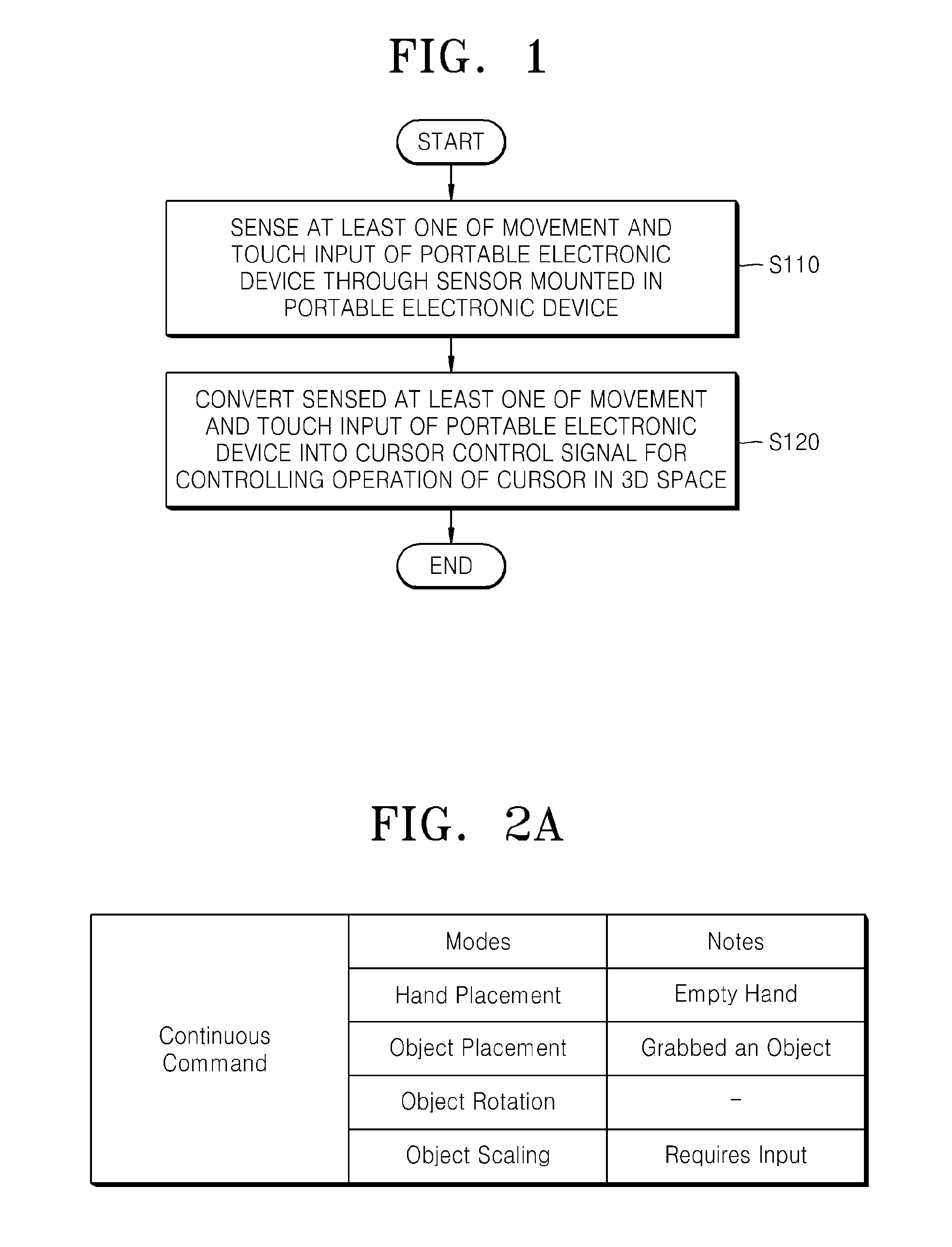

Method of controlling three-dimensional virtual cursor by using portable electronic device

InactiveUS20130314320A1Easy to controlEasily conveyedDigital data processing detailsCathode-ray tube indicatorsControl signalTime limit

A method of controlling a three-dimensional virtual cursor (3D) by using a portable electronic device, the method including: sensing at least one of a movement and a touch input of a portable electronic device through a sensor mounted in the portable electronic device; and converting the sensed at least one of the movement and the touch input of the portable electronic device into a cursor control signal for controlling an operation of a cursor in a 3D space to output the cursor control signal. According to the method, a 3D virtual cursor may be conveniently controlled without a location or time limit by using a portable electronic device which a user carries.

Owner:KOREA INST OF SCI & TECH

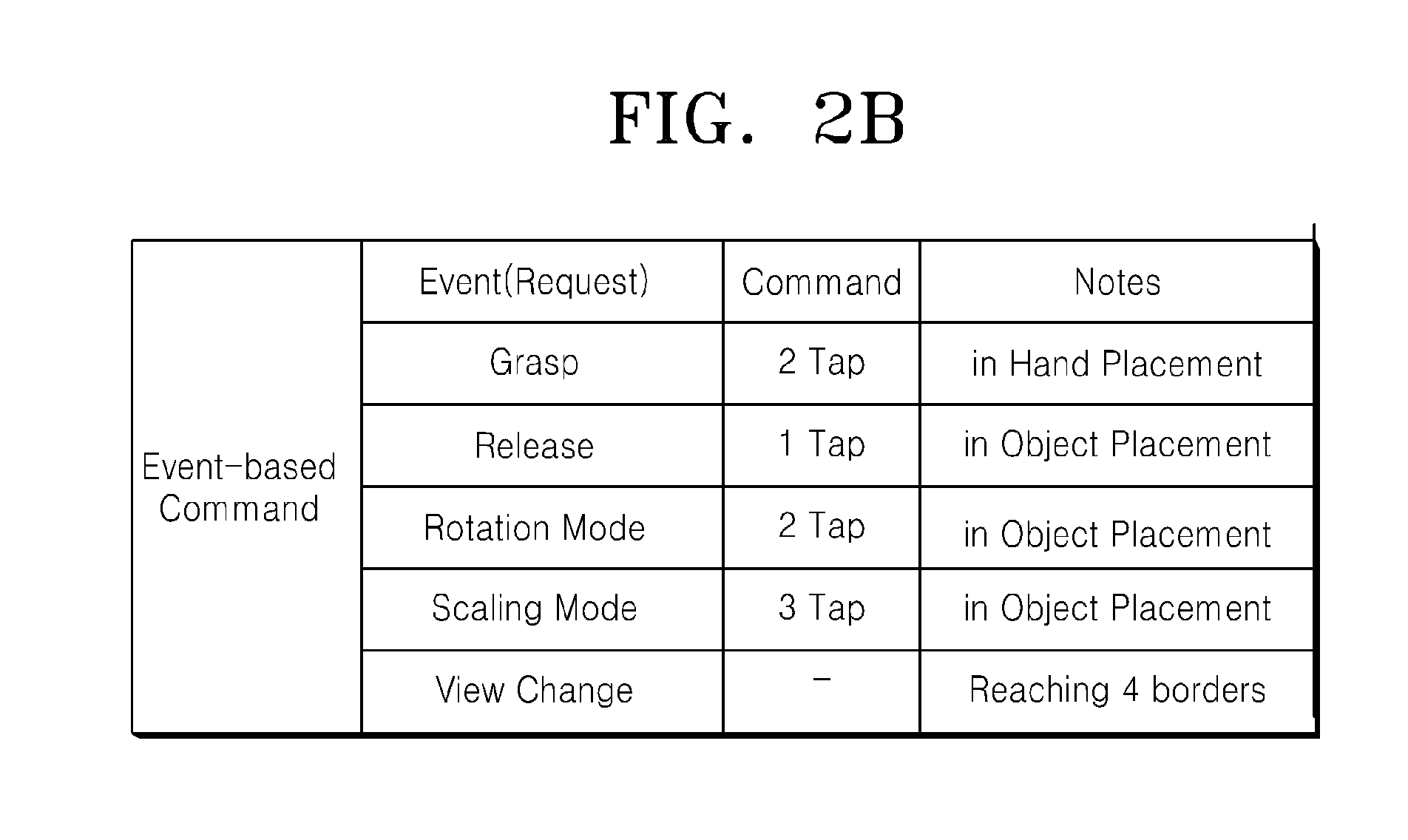

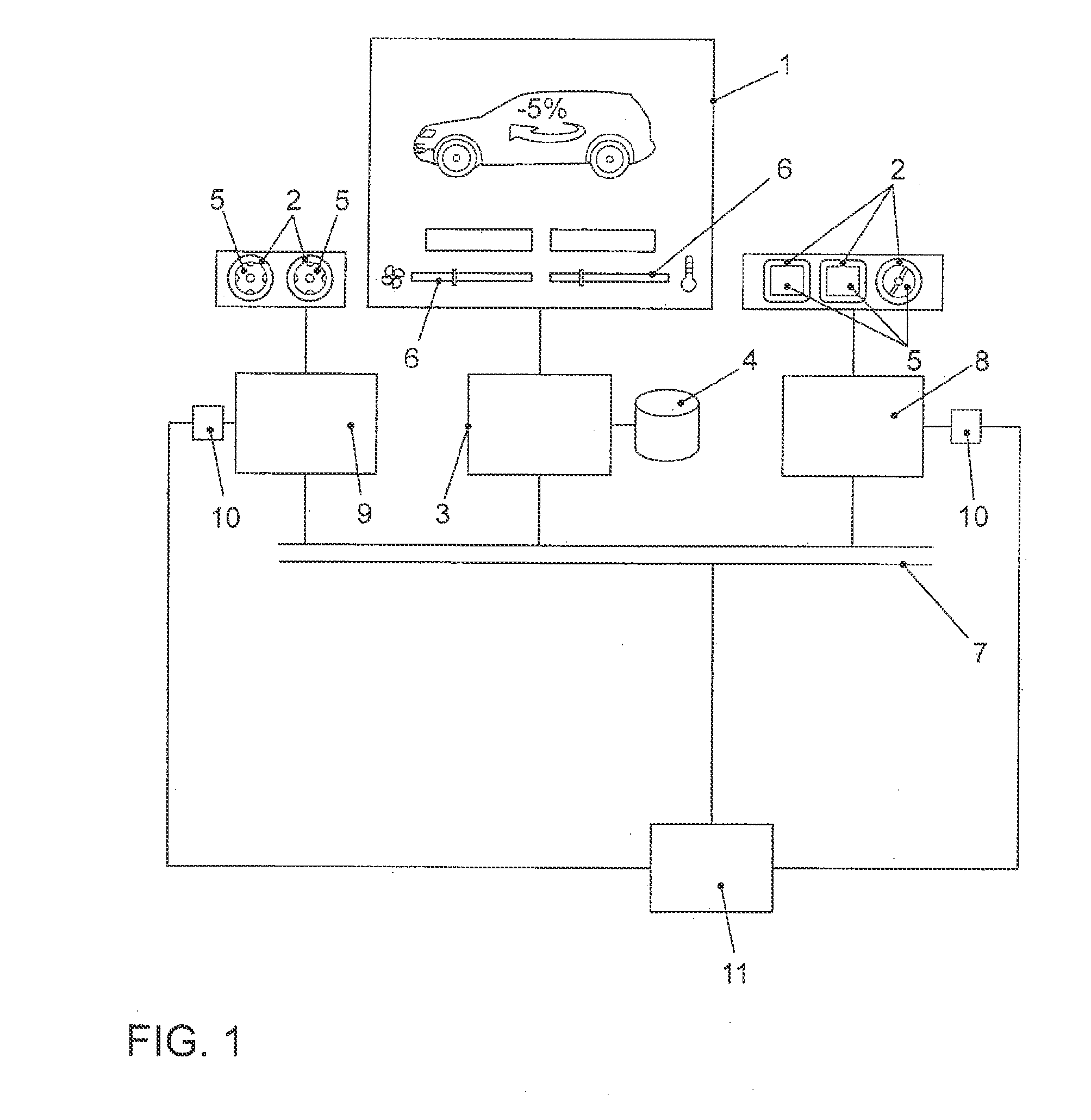

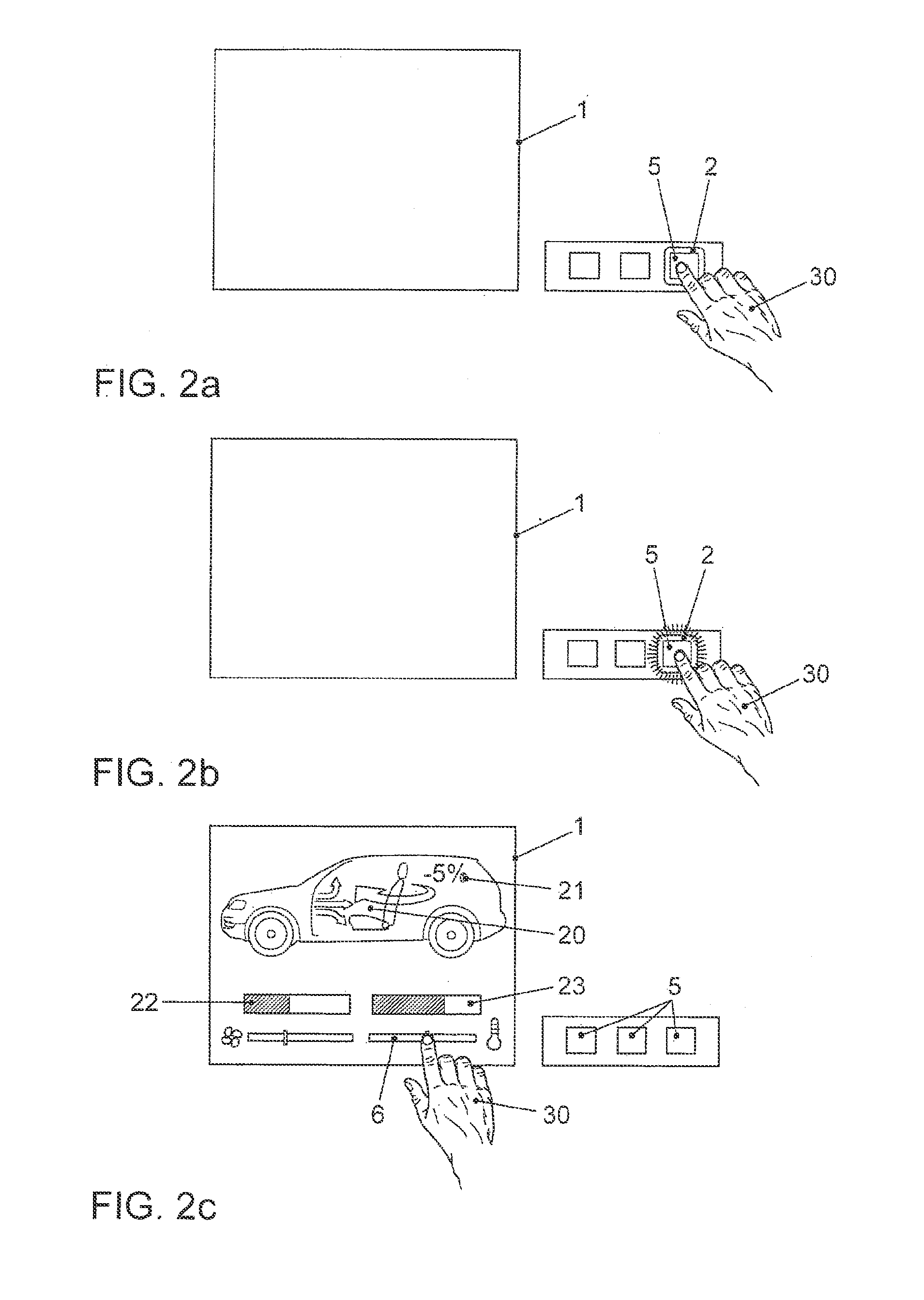

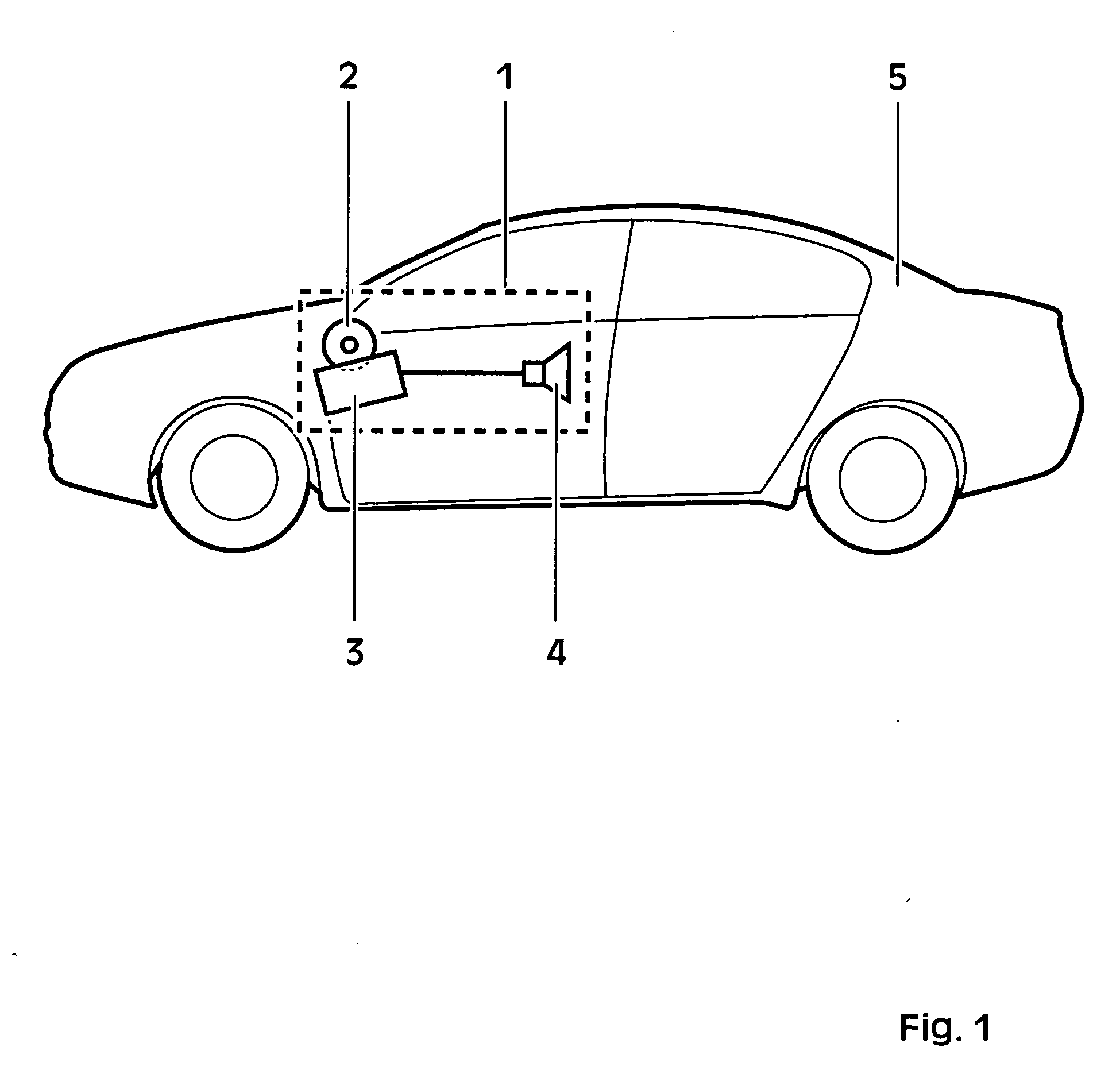

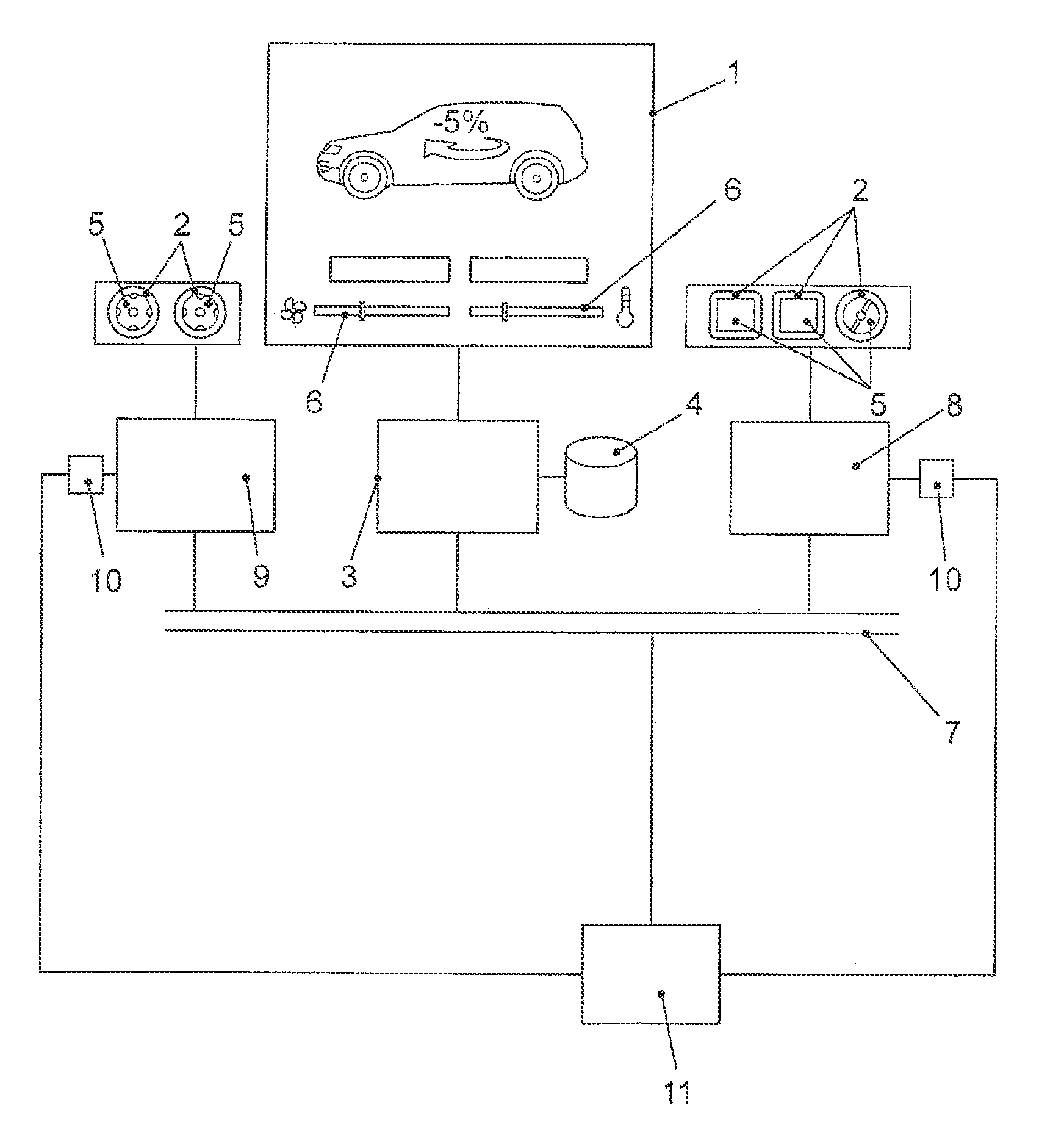

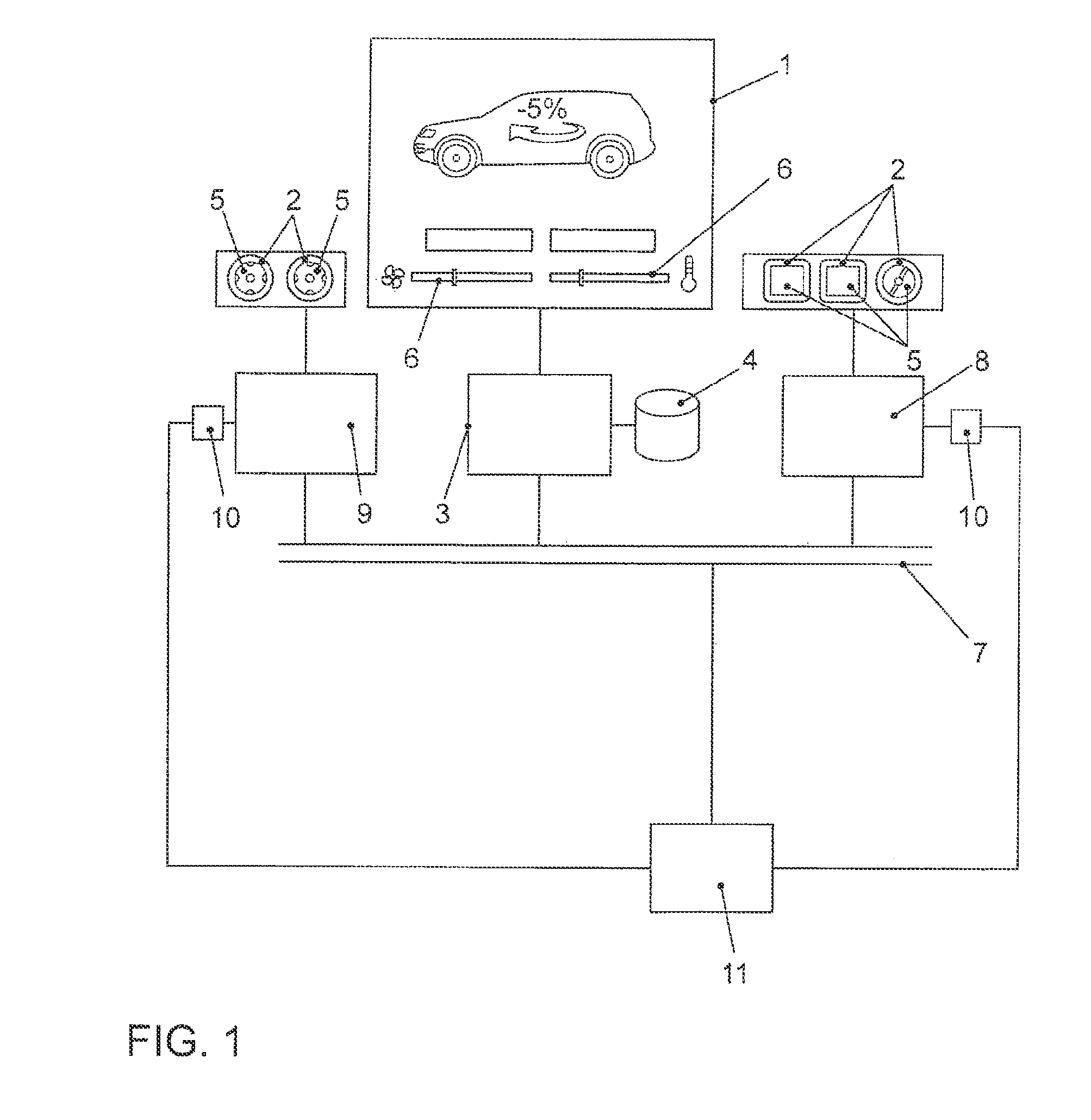

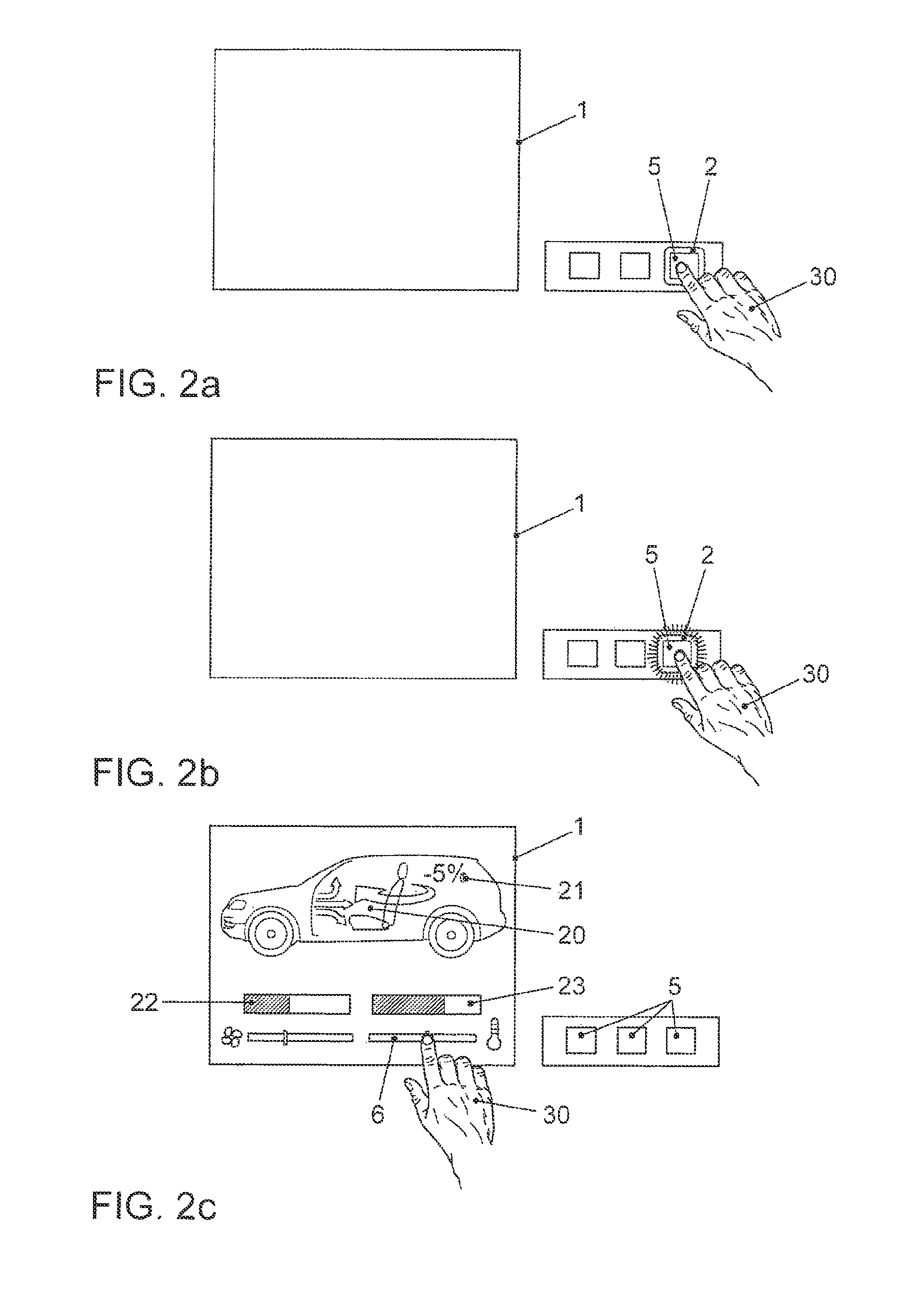

Method and Device for Operating a User Interface for Displaying the Travel Range of a Vehicle

ActiveUS20120209465A1Increase the itineraryLow costAnalogue computers for vehiclesAnalogue computers for trafficSimulationEnergy expenditure

In a method and a device for operating a user interface in a vehicle, in particular for determining and displaying information in connection with electrical consumers, an operator action is detected, by which the operation of an electrical consumer disposed in the vehicle is modified, and a change in the energy consumption of the electrical consumer caused by the operator action is determined. Using the determined energy consumption, a change in the travel range of the vehicle caused by the modified operation of the electrical consumer is calculated, and the calculated change in travel range is displayed directly. The method and the device are especially suitable for a vehicle driven by an electric motor.

Owner:VOLKSWAGEN AG

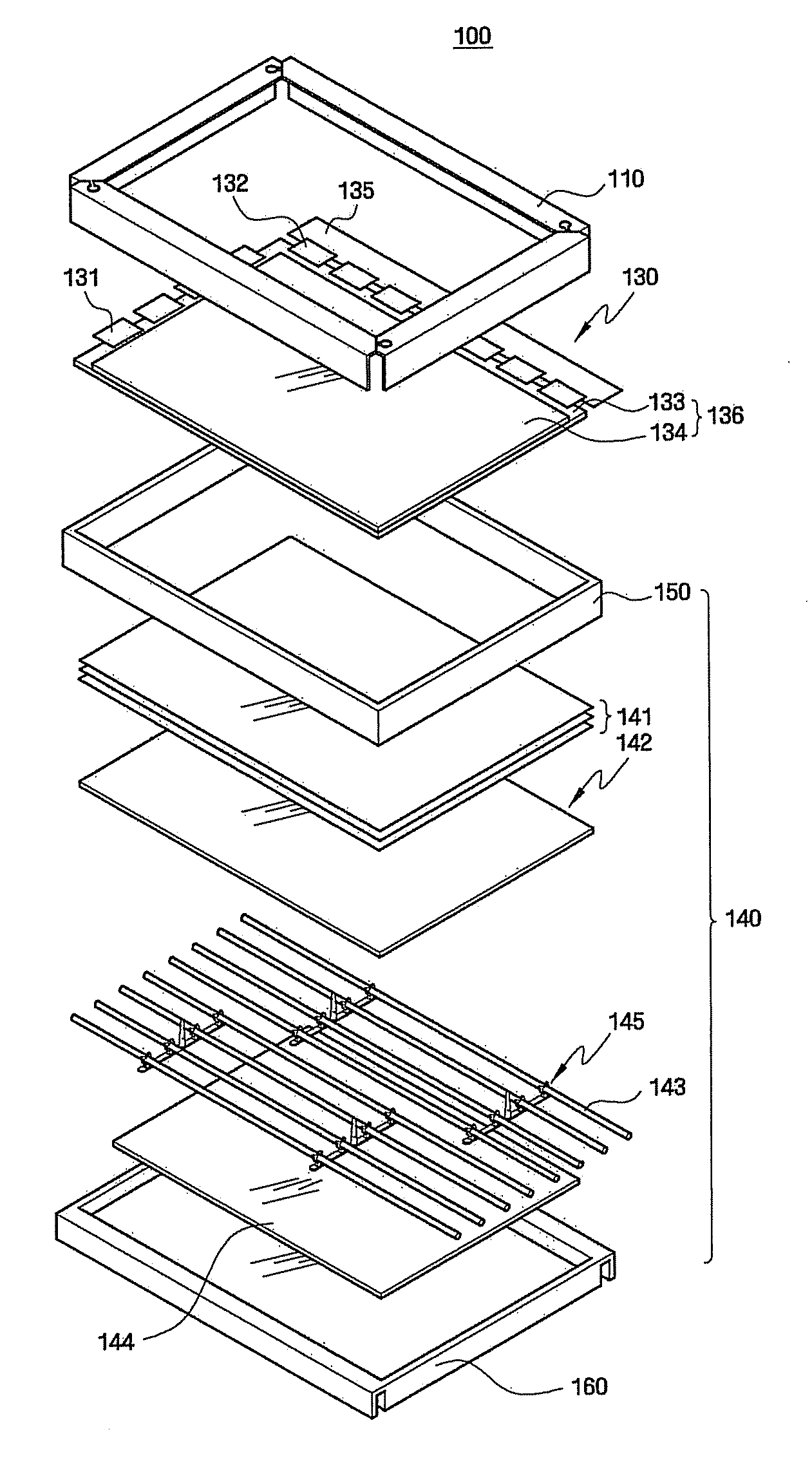

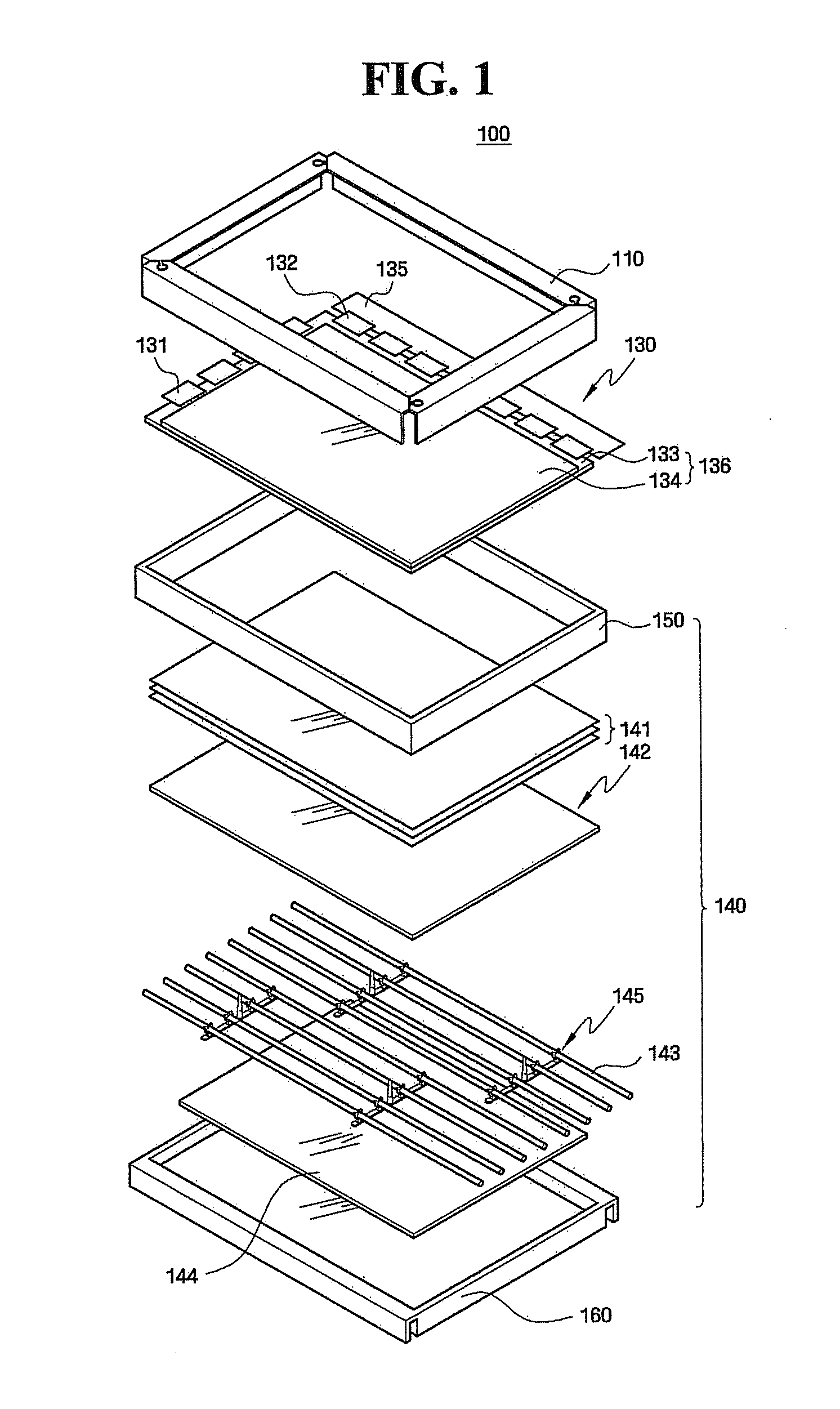

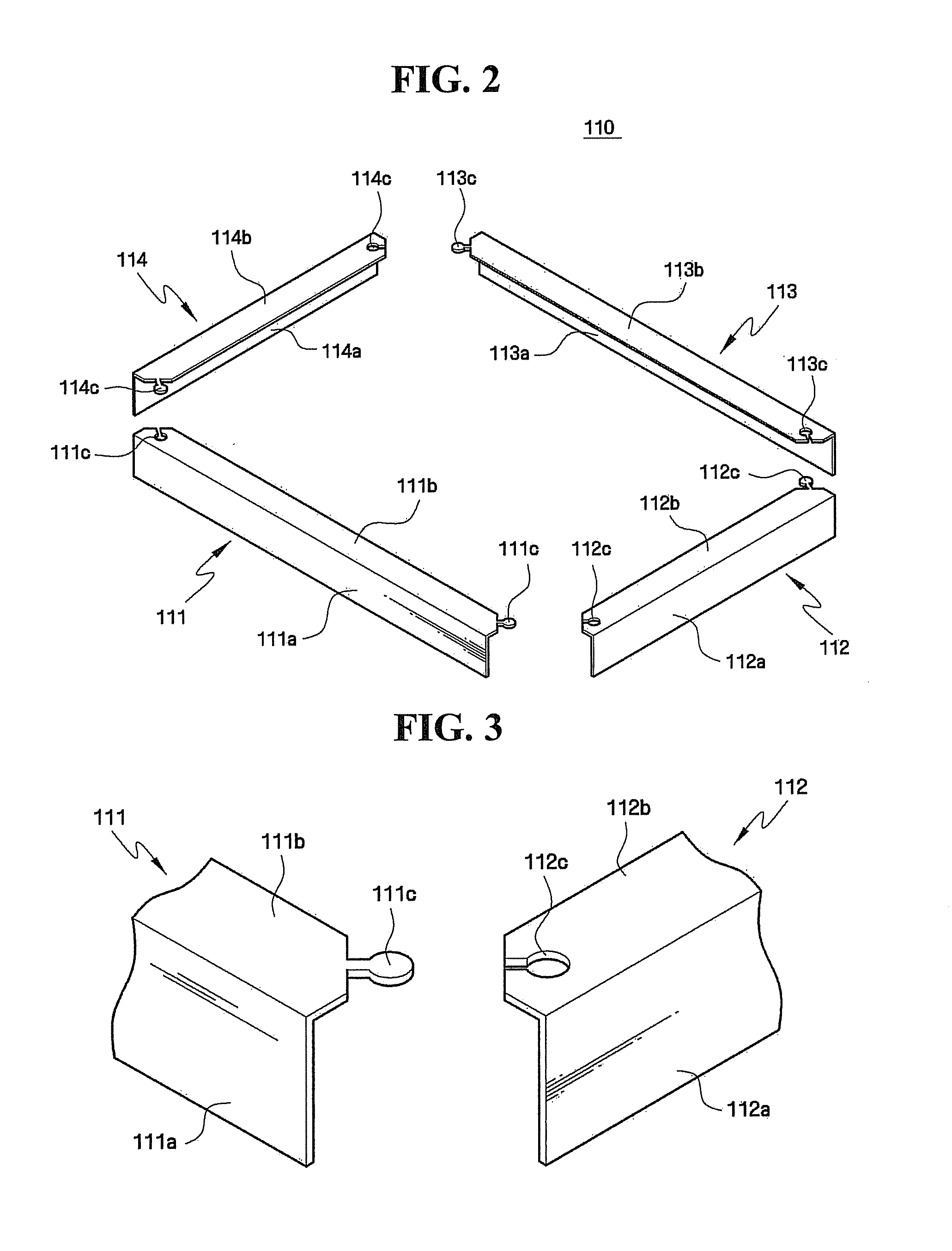

Container, display apparatus including the same, and method of manufacturing display apparatus

ActiveUS20080100768A1Easy to assembleEasily conveyedNon-linear opticsEngineeringMechanical engineering

Owner:SAMSUNG DISPLAY CO LTD

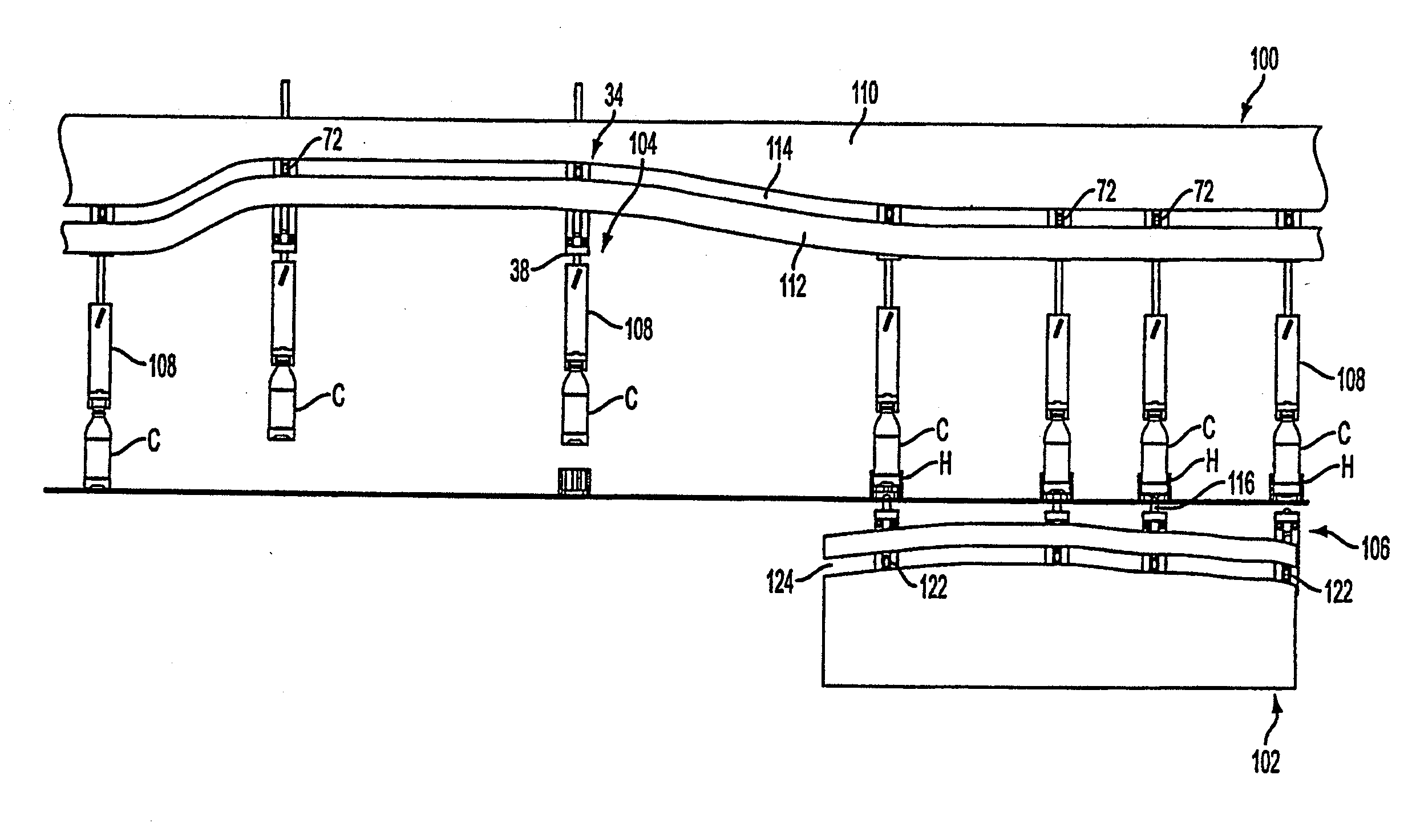

Container Handling System

ActiveUS20090120530A1Smooth for label placementThorough removalSynchronising machinesFilling using counterpressureBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

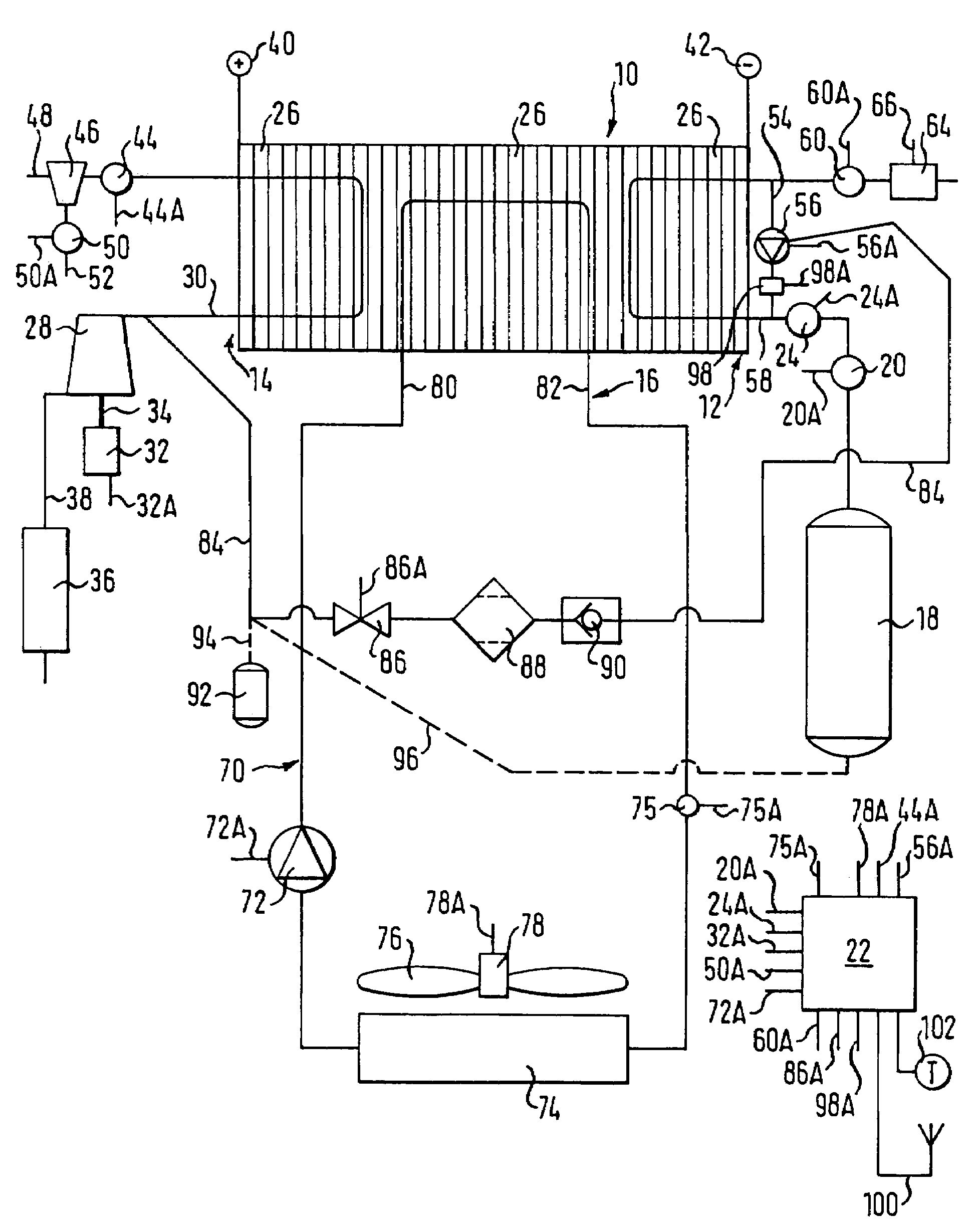

Operation method and purging system for a hydrogen demand/delivery unit in a fuel cell system

InactiveUS7354669B2Prevent operation of and damageAvoid harmful effectsFuel cells groupingPump componentsHydrogenFuel cells

The invention pertains to a process for preventing the freezing of water in a structural component containing at least one moving part in the anode cycle of a fuel cell system, characterized by the fact that at the time of a switching-off process the structural component is scavenged by a dry scavenging gas in order to remove a quantity of water present there.

Owner:GM GLOBAL TECH OPERATIONS LLC

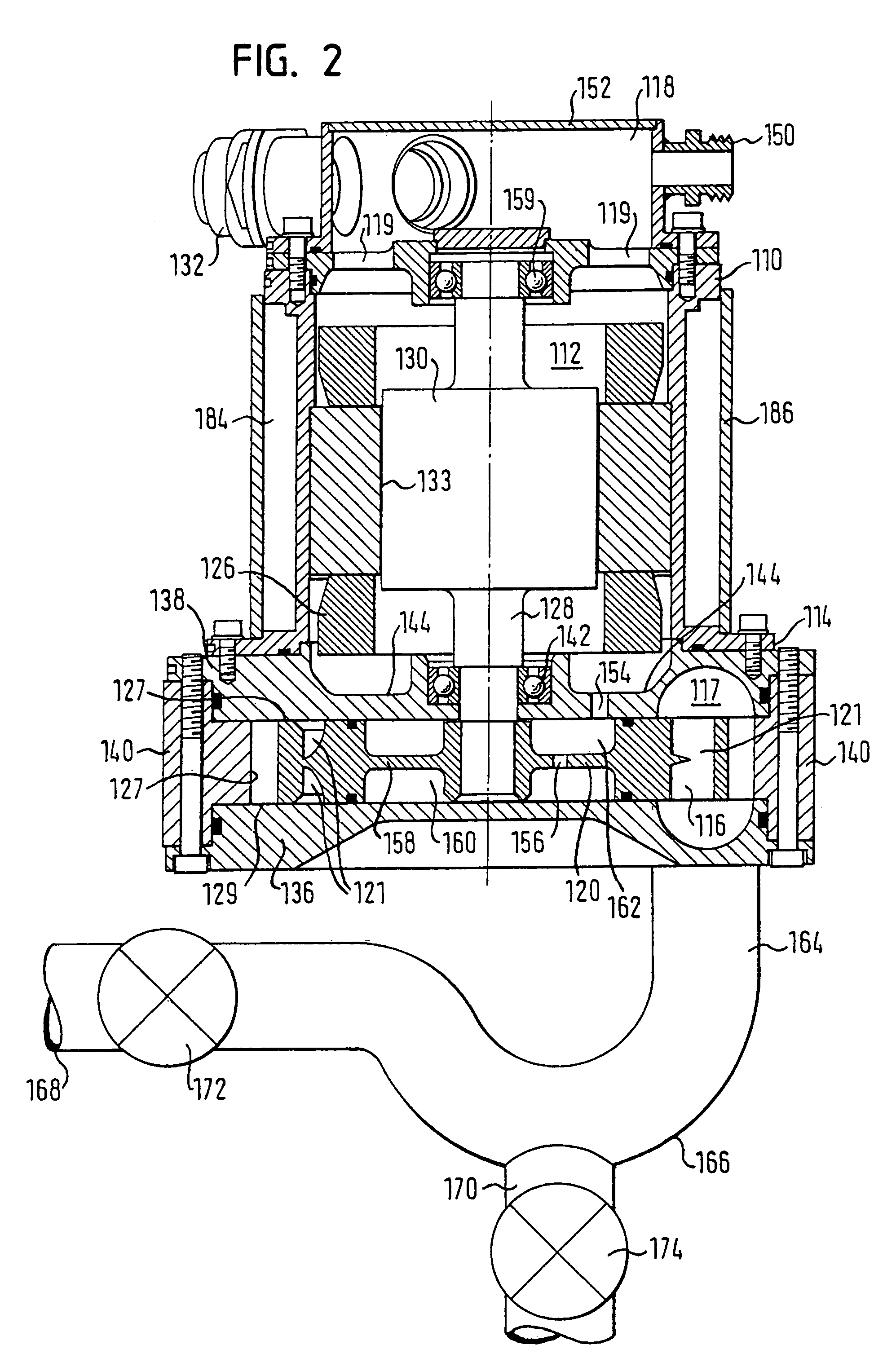

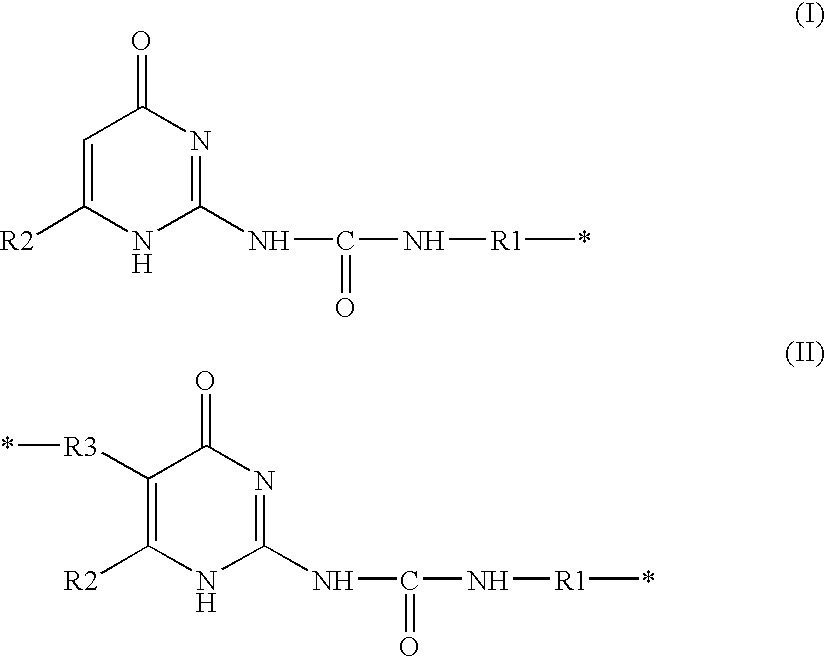

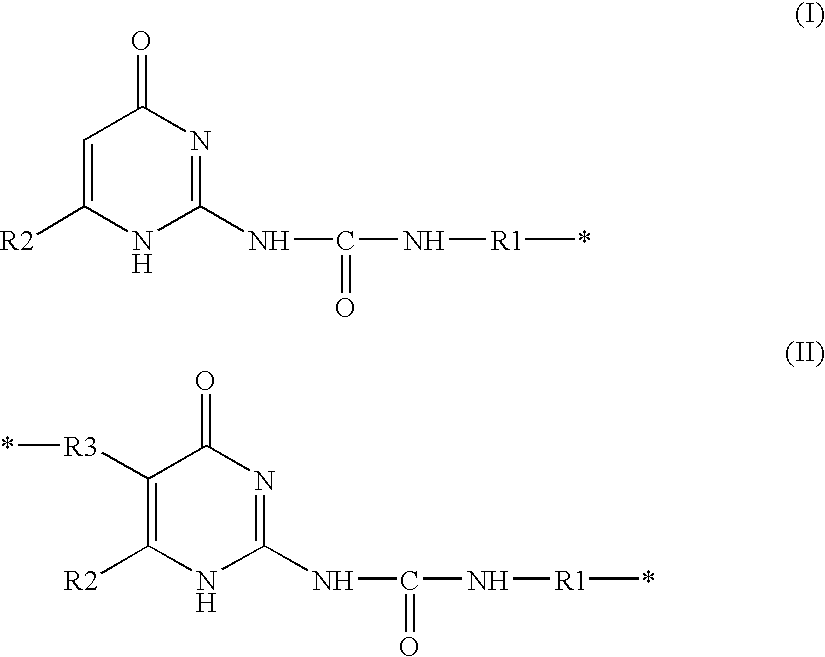

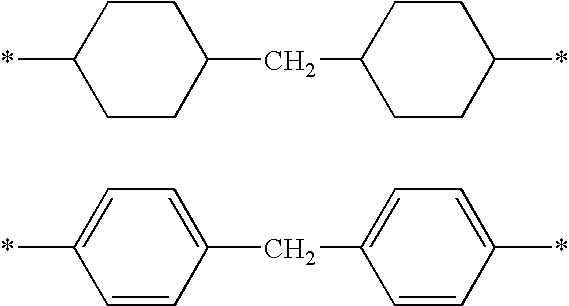

Composition containing a compound capable of establishing hydrogen bonds, and cosmetic treatment process

ActiveUS20100028277A1High strengthImprove staminaBiocideOrganic active ingredientsHydrogenChemical compound

Composition containing, in a cosmetically or dermatologically acceptable medium, a compound that may be obtained by reaction between:an oil bearing at least one nucleophilic and / or electrophilic reactive function, anda junction group capable of establishing hydrogen bonds with one or more partner junction groups, the junction group bearing at least one reactive function capable of reacting with the reactive function borne by the oil, and also comprising at least one unit of formula (I) or (II):

Owner:LOREAL SA

Powder compaction and enrobing

InactiveUS20050220824A1RobustSmall areaWrappers shrinkageWood working apparatusHydroxypropylmethyl celluloseMethyl cellulose

Powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH INT

Additional improvements in powder compaction and enrobing

InactiveUS20050266116A1Good effectEasy to swallowConfectioneryPharmaceutical product form changeMetallurgyMethyl cellulose

Owner:BIOPROGRESS TECH

Container storage system and method

A container system for storing food or other products is provided comprising a bottom wall and a peripheral wall defining a storage area for receiving the goods, and a display window extending from the outer surface of the peripheral wall. The display window defines a gap for receiving at least one display token. The display token corresponds to information relating to the goods or products stored in the container, and the display token is visible through the wall of the display window.

Owner:MORRIS DOUGLAS SEAN

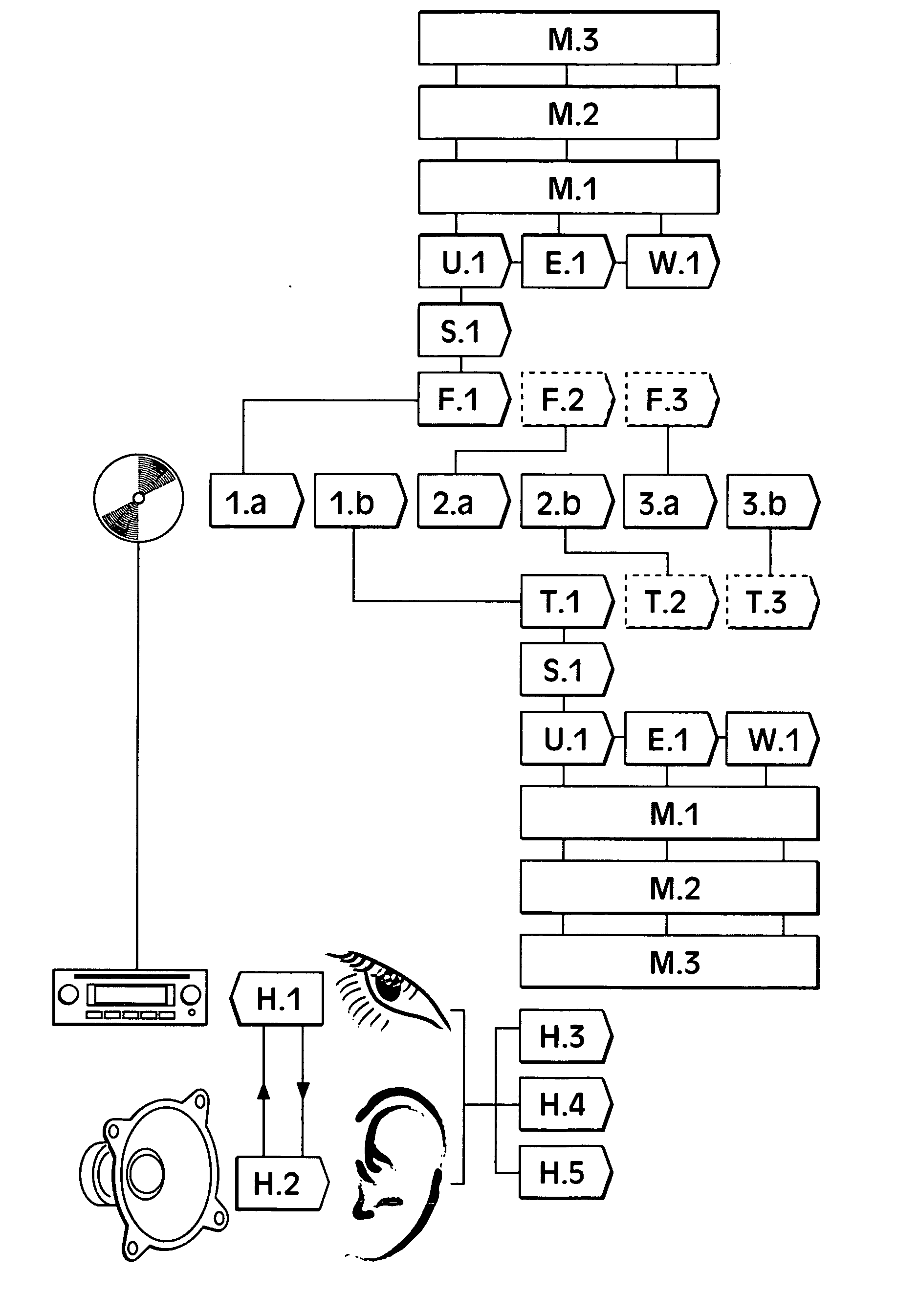

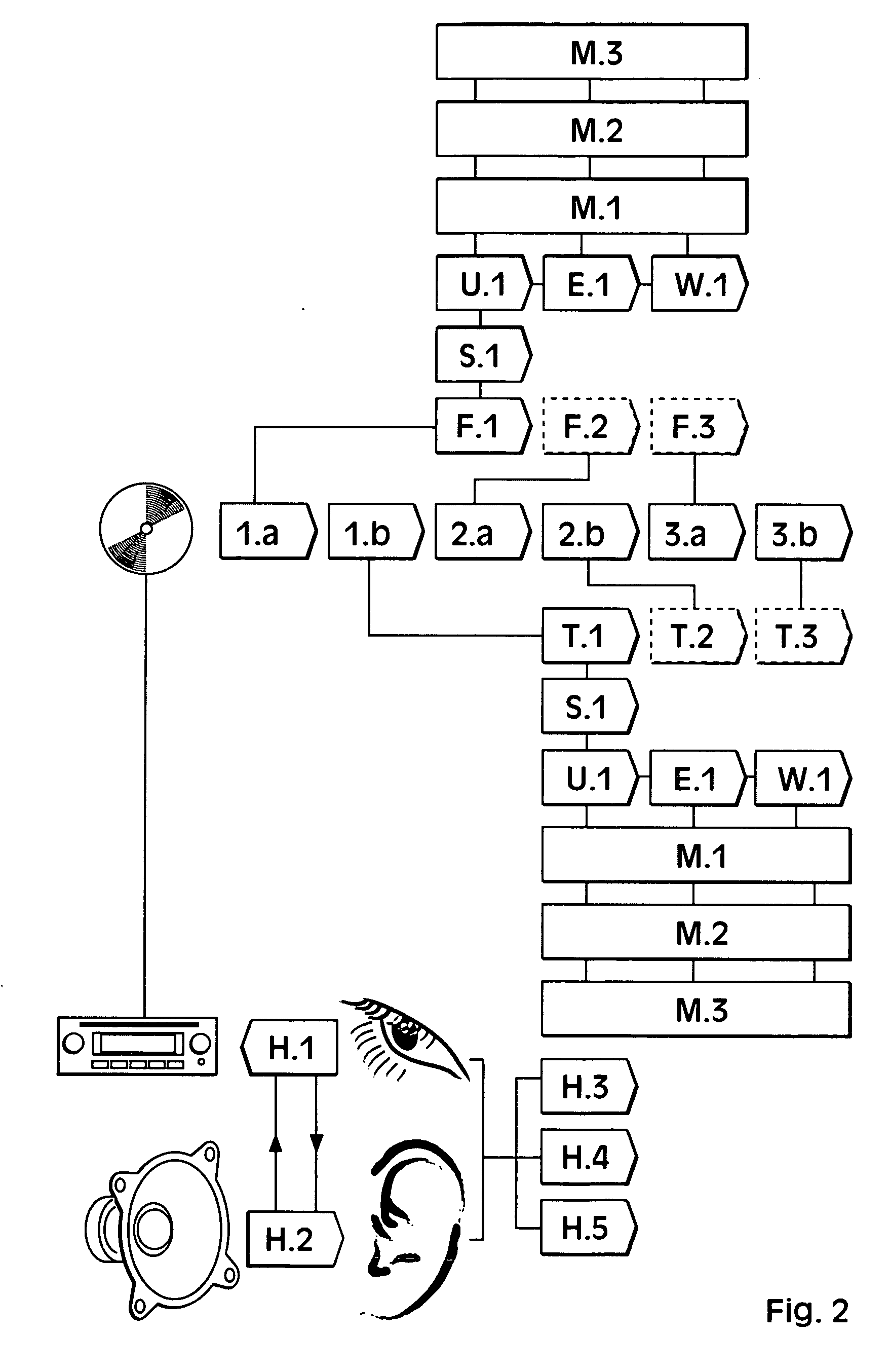

System and audio product for instructing user in operating functions of motor vehicle

InactiveUS20060024646A1Improve securityLearn about operating functions more quickly and more convenientlyCosmonautic condition simulationsElectrical appliancesMotorized vehicleComputer science

The invention relates to a system and an audio product for instructing a user in the operating functions of a motor vehicle. The invention features an audio file containing audio information for teaching the operating functions of a motor vehicle, and which may be brought into use on a player. By using the invention, a user of a motor vehicle may learn the operating functions of the motor vehicle simply and reliably by audio means.

Owner:PFRIEMER KATALOGE

Cooking device with a cooking chamber outlet

ActiveUS20060260476A1Reliable technologySimple designSelf-cleaning stoves/rangesAir-treating devicesWater reservoirWaste management

A cooking device has a cooking chamber as well as a cooking chamber outlet for a fluid. An air trap is provided downstream of the cooking chamber outlet. A device outlet is arranged in turn downstream of the air trap. A water reservoir is located in the air trap. A connection pipe leads from the water reservoir in the air trap into the cooking chamber. Associated with the connection pipe is a transport means, which permits a controllable supply of fluid from the water reservoir in the air trap into the cooking chamber.

Owner:MKN MASCHFAB KURT NEUBAUER

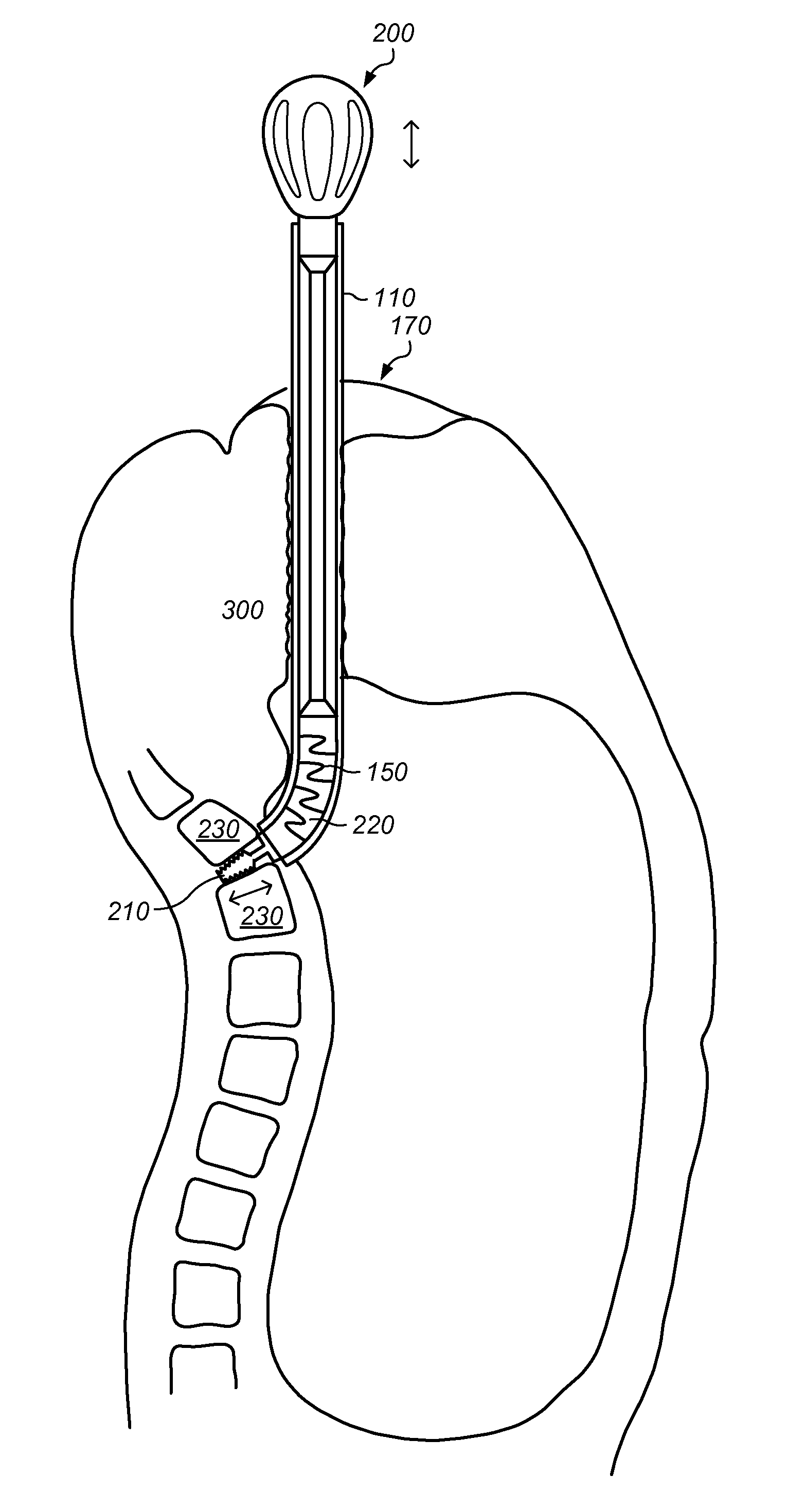

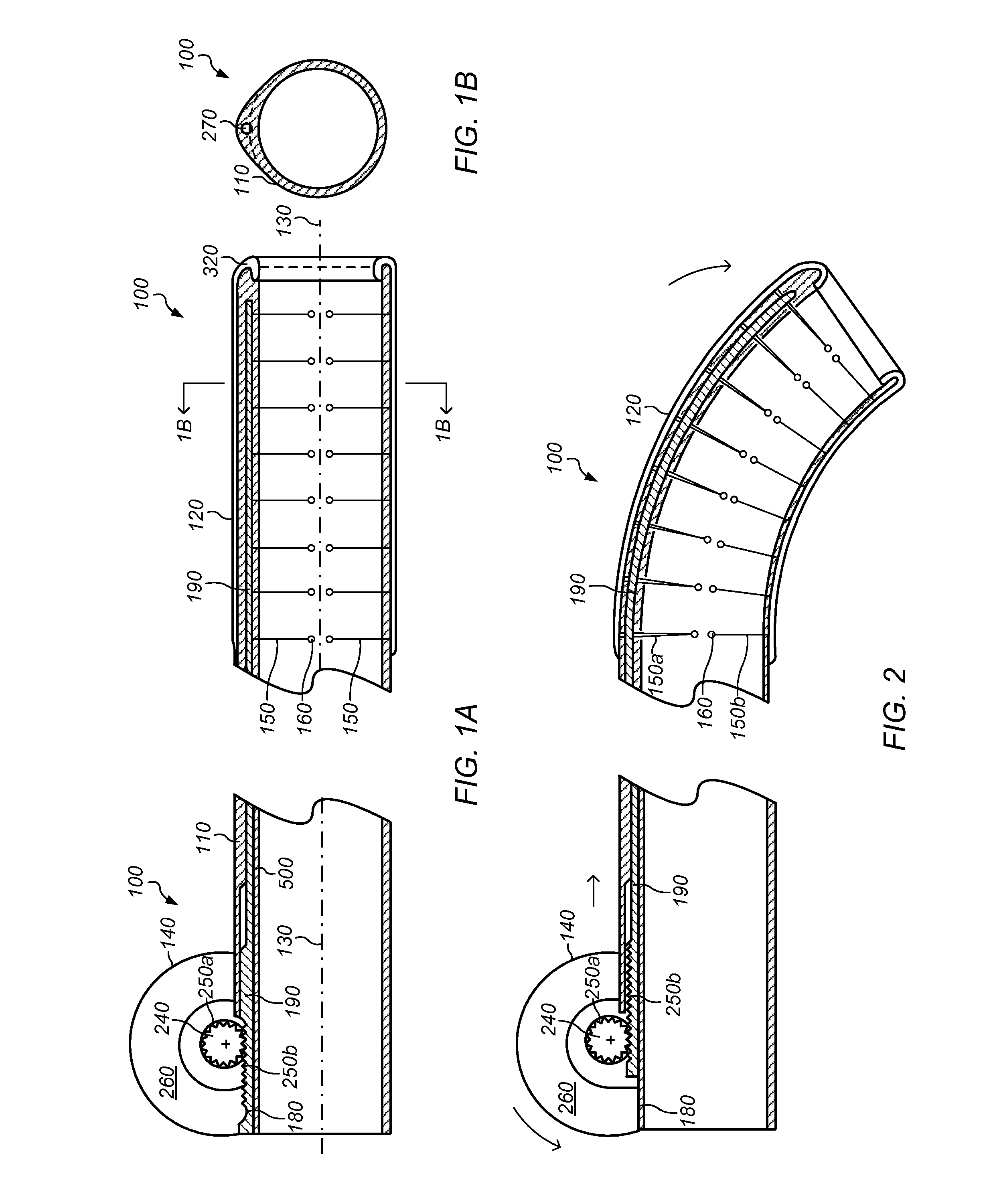

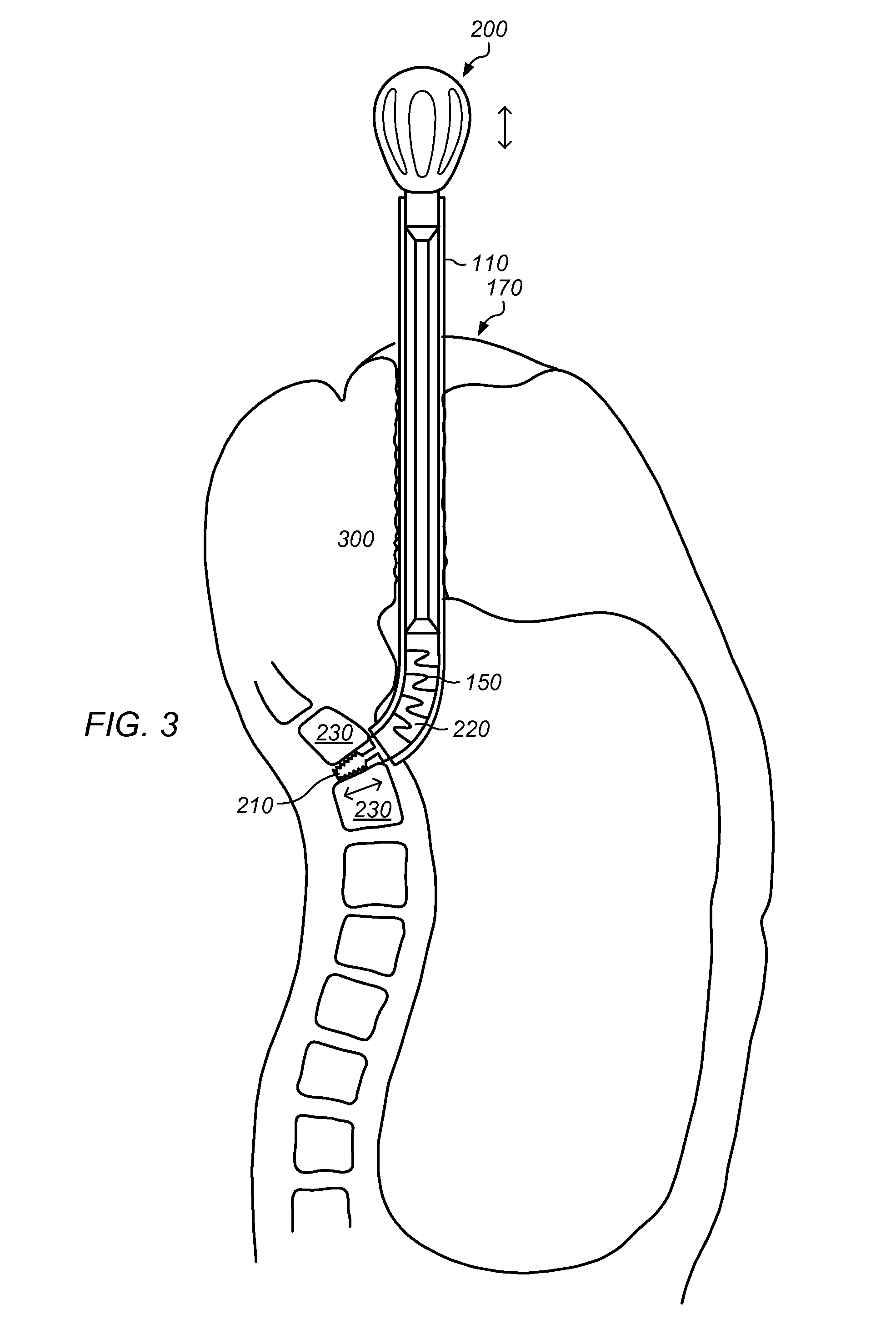

Method and system for performing spinal surgical procedures using natural orifices

ActiveUS20130197644A1Increase distanceEasily conveyedInternal osteosythesisCannulasInterior spaceHuman use

This disclosure describes devices and methods for performing spinal surgical procedures. In some embodiments, a method may include positioning at least a portion of at least one surgical instrument in at least one naturally occurring orifice of a human by a user. In some embodiments, a method may include accessing an interior space of the human using at least one of the surgical instruments. The method may include performing at least a portion of a spinal surgical procedure using at least one of the surgical instruments positioned in at least one of the naturally occurring orifices of the human. The method may include removing at least one of the surgical instruments from at least one of the naturally occurring orifices upon completion of at least a portion of the spinal surgical procedure.

Owner:NOVAPPROACH SPINE +2

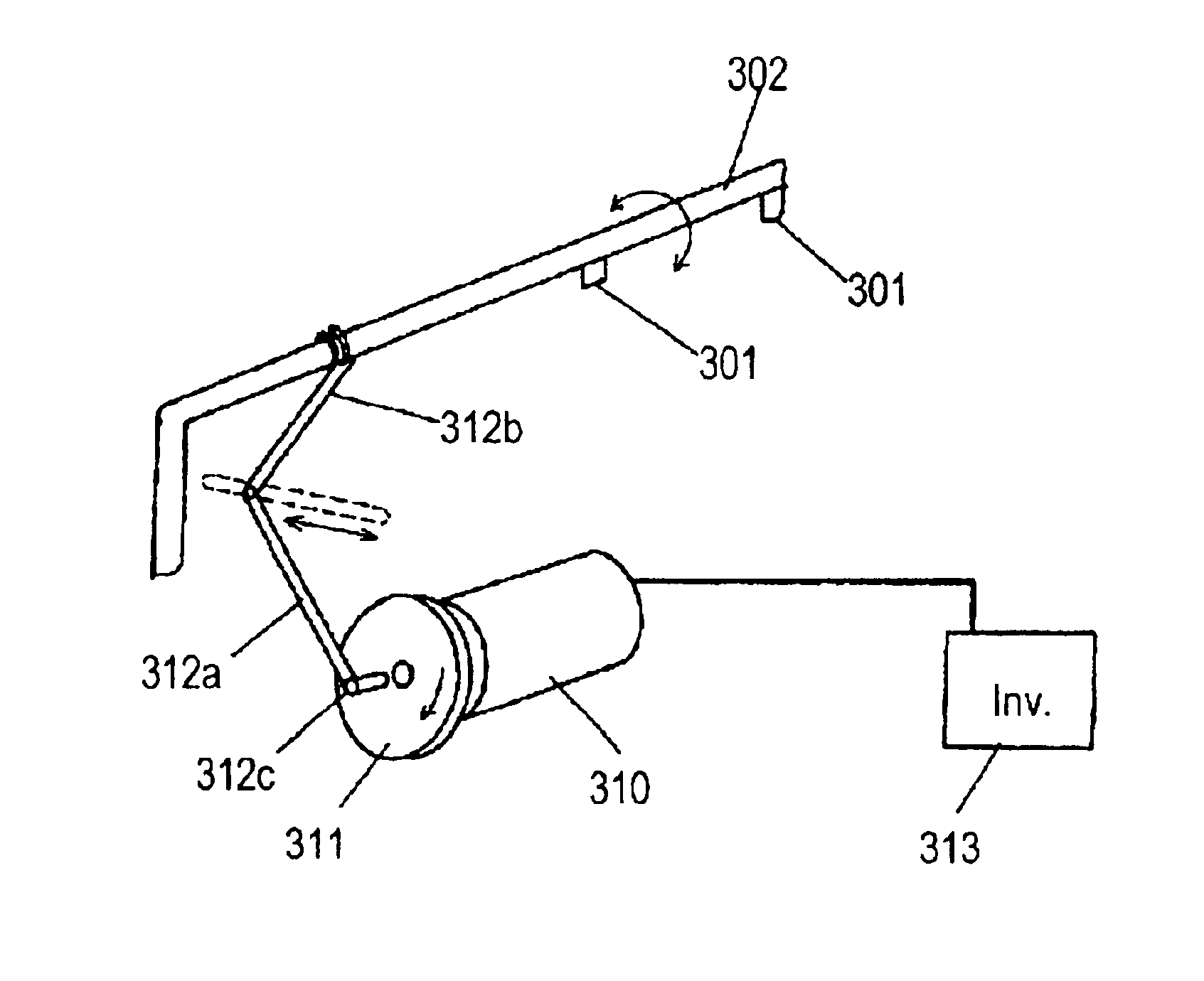

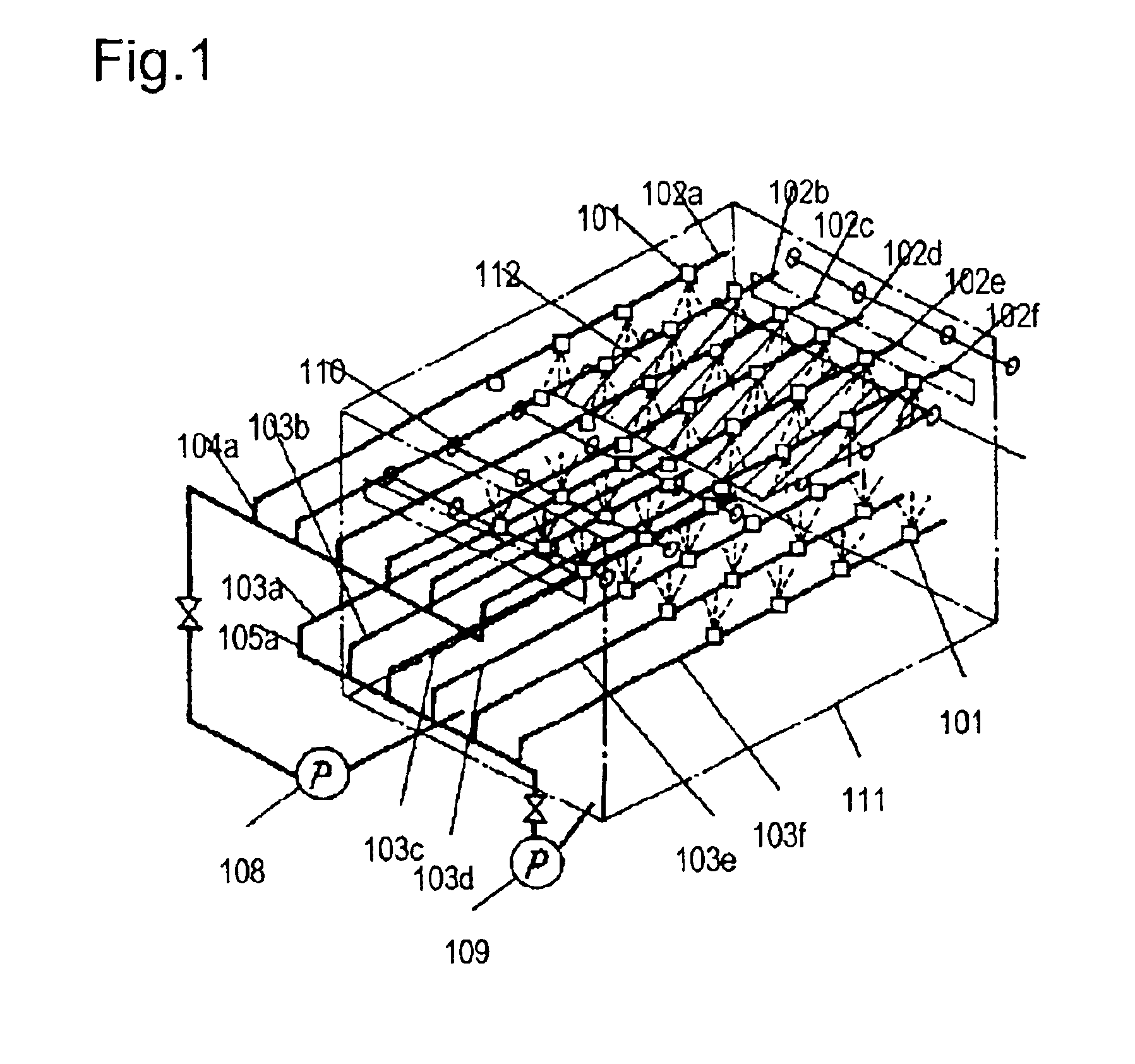

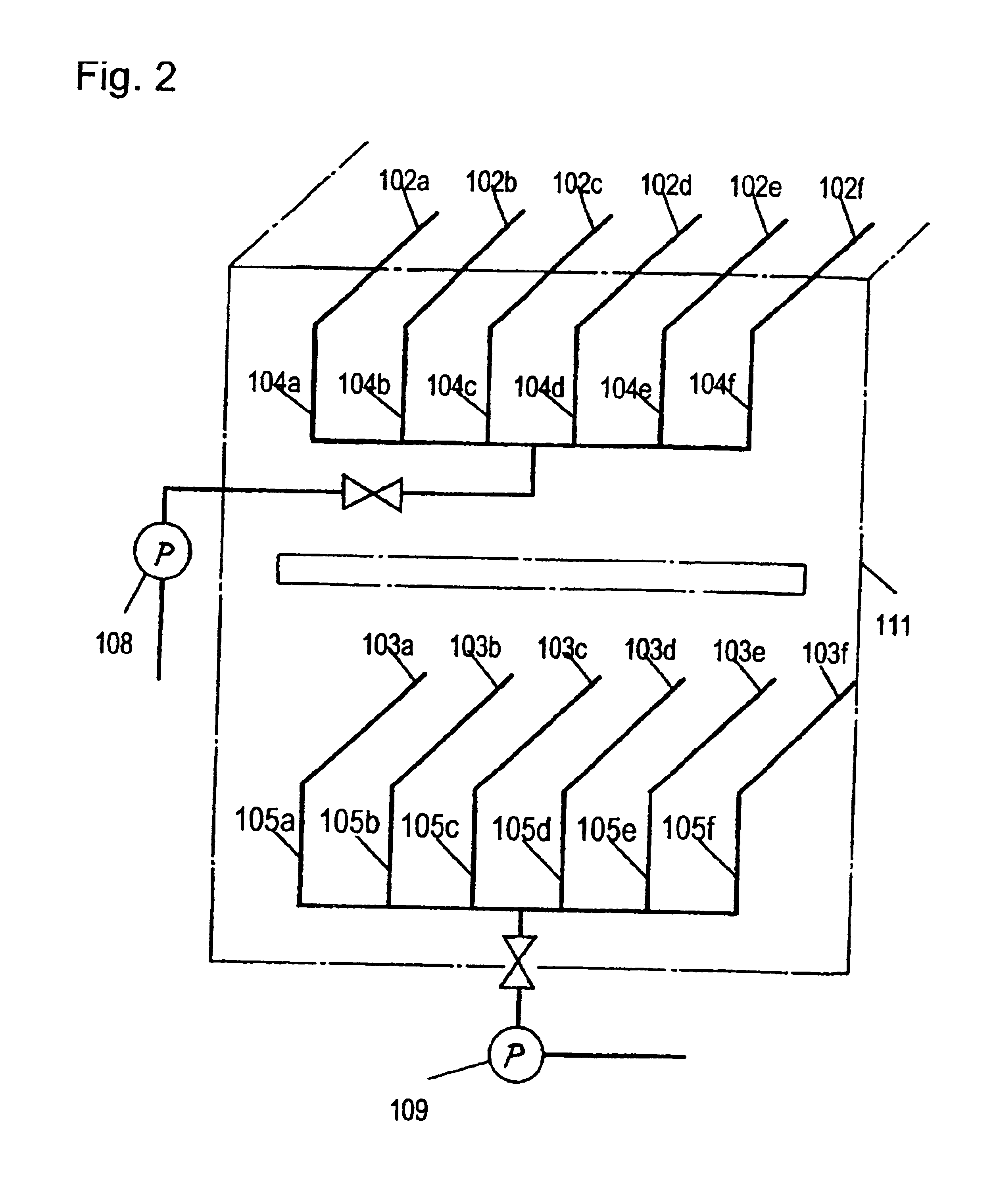

Apparatus for manufacturing printed wiring board and method for manufacturing printed wiring board using the same

InactiveUS6918989B2Increase pressureDecrease productivityFluid heatersSpraying apparatusEngineeringPiping

In a manufacturing apparatus of printed wiring board an aperture of a nozzle pipe located in a central position is larger than that at both sides, or the aperture of the piping to the nozzle pipe in the central position is larger than that of the piping at both sides. The mutual interval is narrower with the central nozzle pipes. The interval of the individual nozzle pipes is variable, and is also variable in the vertical direction. A pressure-proof flexible tube is provided between each nozzle pipe and the pump, and the interval of the individual nozzle pipes is variable, and is also variable in the vertical direction. Further, the spray pressure, oscillating angle, and oscillating speed can be set individually in each nozzle pipe, and such setting can be automated.

Owner:PANASONIC CORP

Method for producing a toner, and toner

InactiveUS7709175B2Uniform particle sizeImprove liquidityGranule coatingGranulation by liquid drop formationConstant frequencyColoring agents

The object of the present invention is to provide a method for producing a toner which includes ejecting a toner composition fluid containing a toner composition which contains a toner and a colorant, from a nozzle vibrated at a constant frequency to make the toner composition fluid into droplets, and solidifying the droplets to be made into particles, in which the toner composition fluid comprises a toner composition, and the toner composition contains a resin, and a colorant.

Owner:RICOH KK

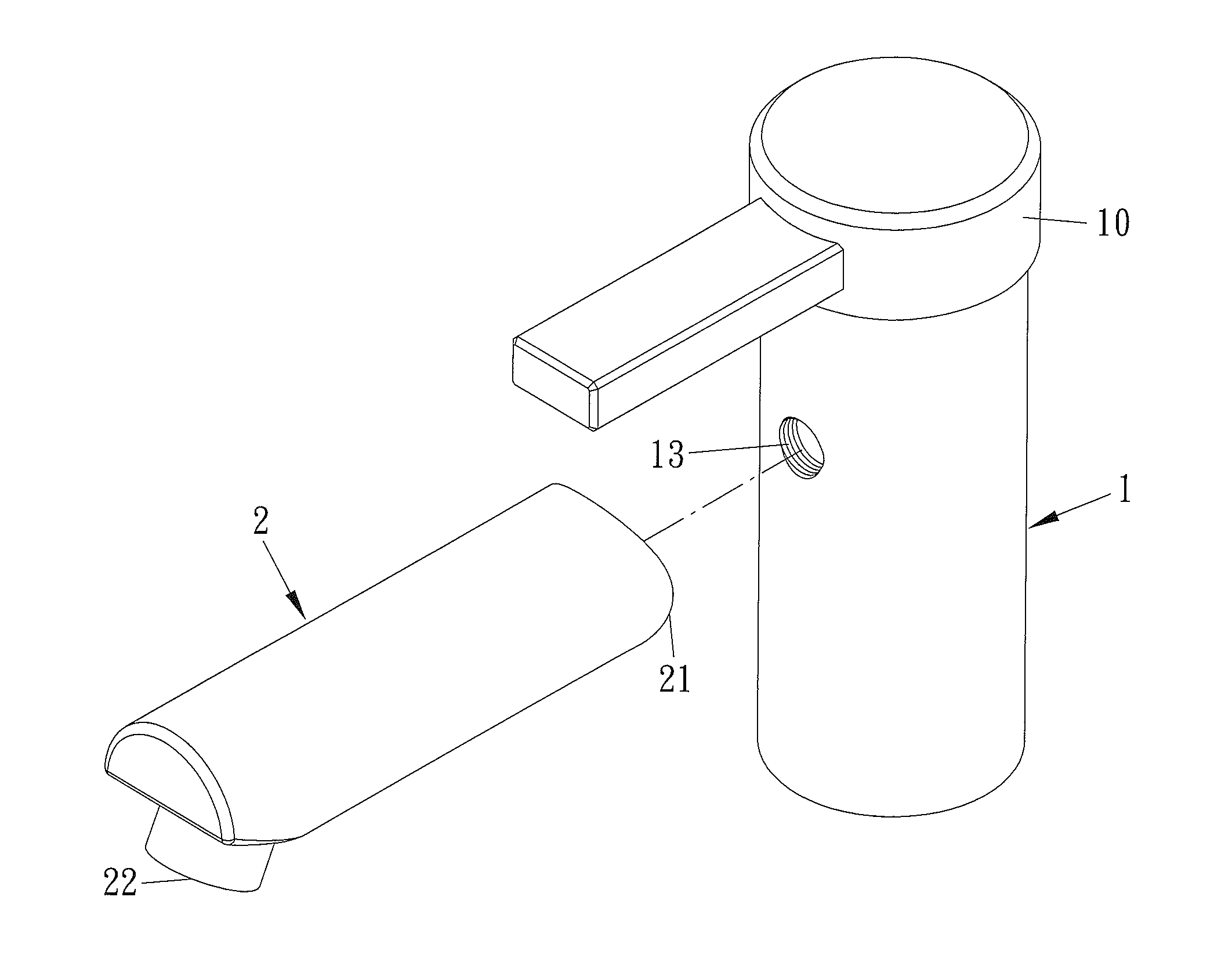

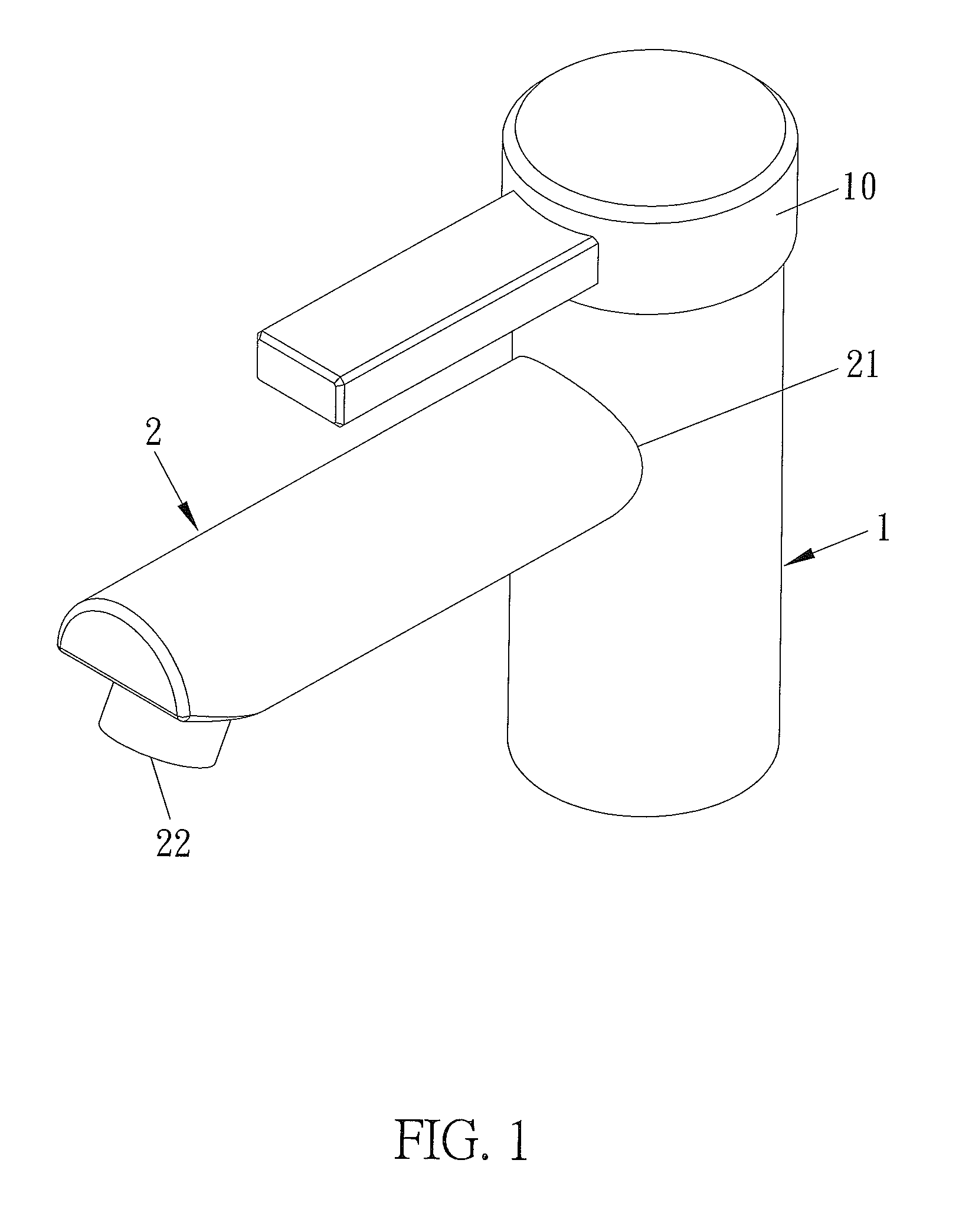

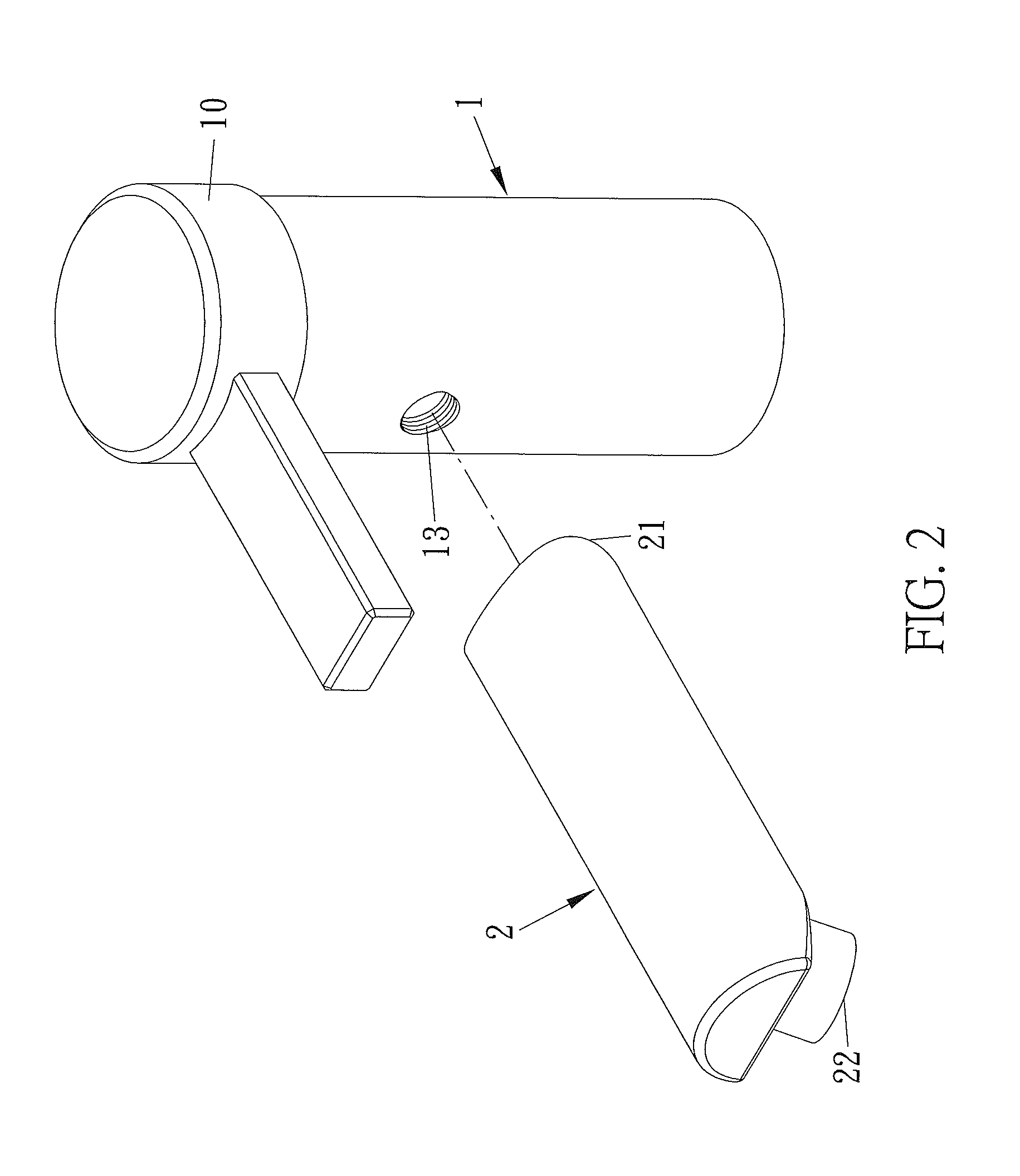

Connecting Structure for Outlet Pipe of Faucet

InactiveUS20170044746A1Connection securityLow costDomestic plumbingScrew threaded jointsEngineeringMechanical engineering

A connecting structure for an outlet pipe of a faucet contains: a body and an outlet pipe. The body is a thinly hollow cylinder and includes a circular orifice stamped on an inner wall thereof, a fitting tube horizontally extending outward to the body from a peripheral side of the circular orifice, and inner threads formed in the circular orifice and the fitting tube as one piece. The outlet pipe includes a connecting segment, an outlet segment, and a rotary connector fitted and limited in the connecting segment. The rotary connector has an outer threaded tube partially extending out of the connecting segment of the outlet pipe to screw with the inner threads formed in the circular orifice and the fitting tube, thus securely connecting the outlet pipe and the body together.

Owner:CHING SHENGER

Versatile processes for preparing and using novel composite particles in powder coating compositions

InactiveUS7105201B2Easily co-processedWide range of usesLiquid surface applicatorsPowdery paintsParticulatesDrug product

Methodology for constructing composite particles from ingredients comprising two or more particulate components. The resultant particles are usefully incorporated into powder coating compositions. The approach also finds utility in other applications, including but not limited to the food, drug, and cosmetics industry. Fluidized particles are subjected to an intense, but relatively brief heating event. This causes associated particles to fusingly assemble into fused composite clusters.

Owner:SWIMC LLC

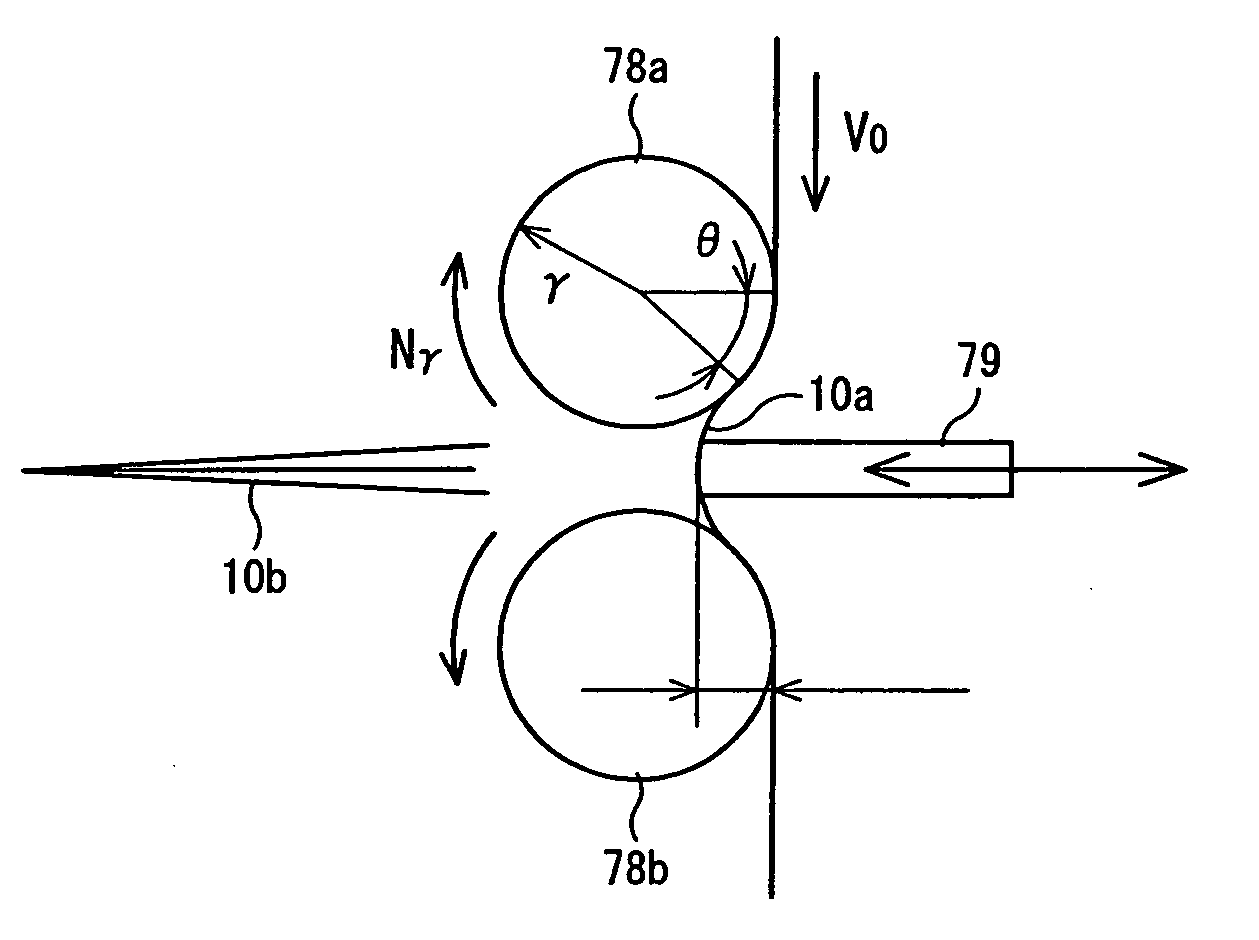

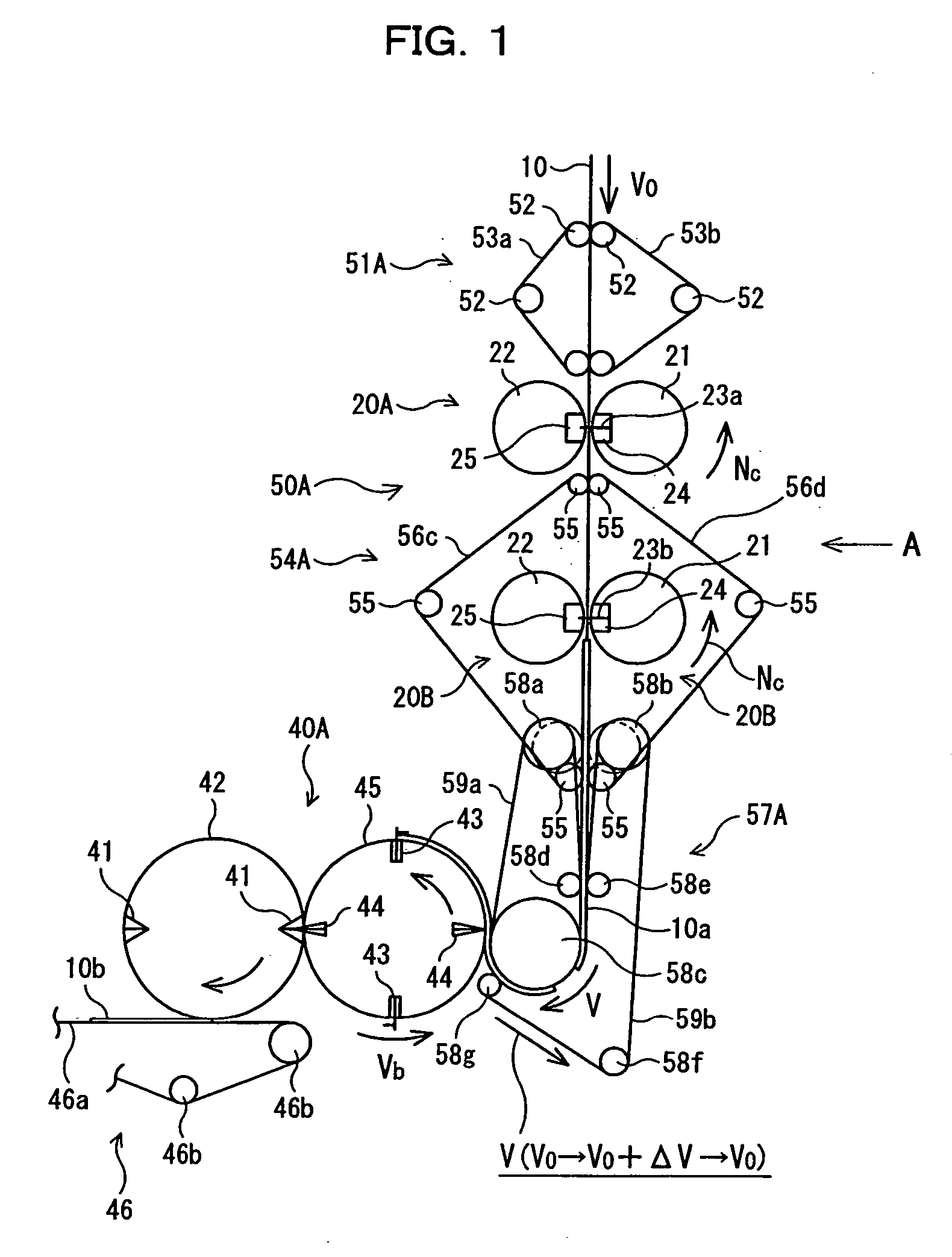

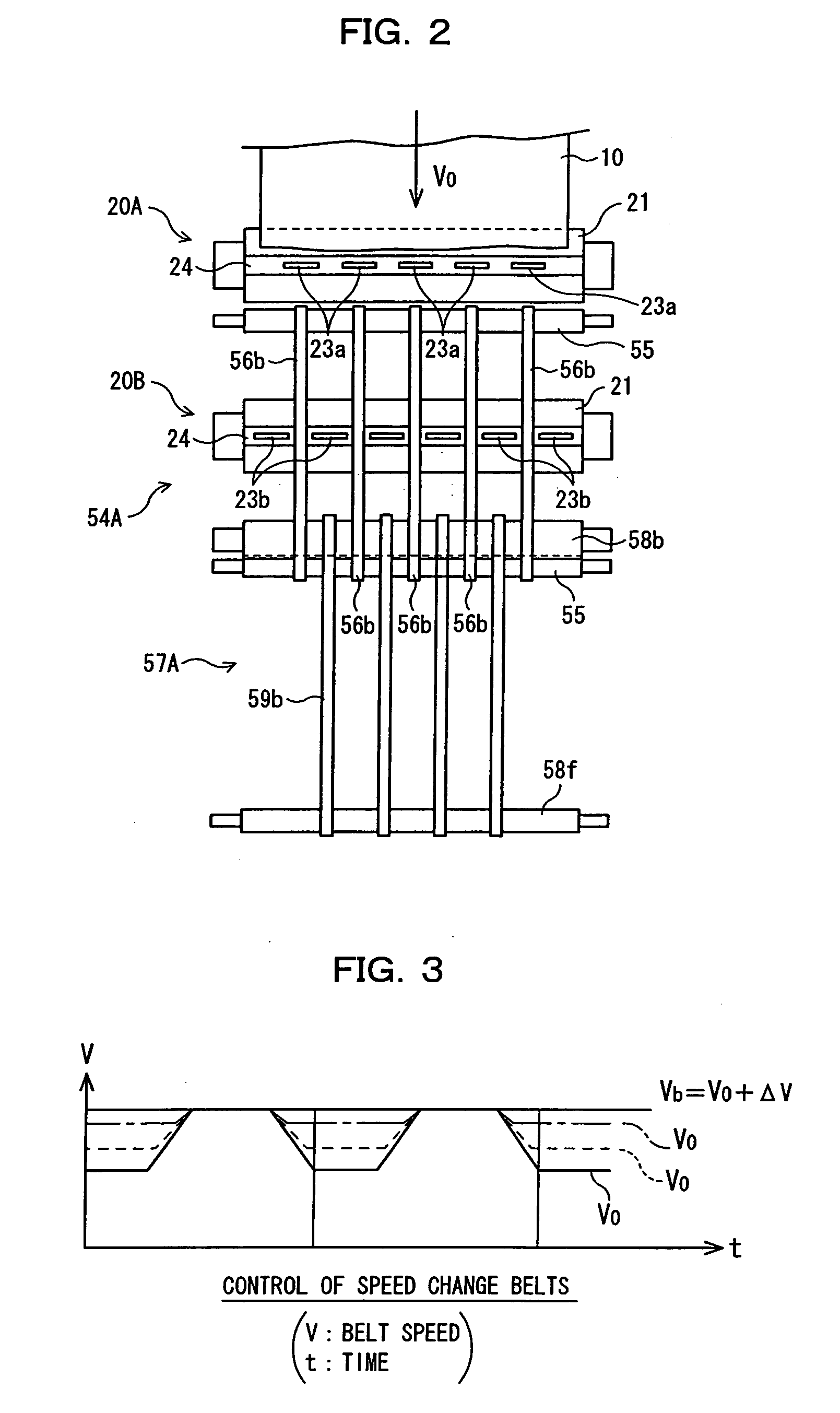

Folder for rotary press

InactiveUS20070018373A1High precisionPrecise processingMechanical working/deformationBox making operationsPrinting pressBelt conveyor

In a variable cut-off length type rotary printing machine, to perform processes such as a process of folding a cut-off sheet with a high degree of accuracy, a folding machine includes a cut-off unit capable of varying and cutting a cut-off length of a web fed from a printing machine of the rotary printing machine, and a processor (such as a folder, etc.) for processing a sheet 10a cut off by the cut-off unit. Between the cut-off unit 50 and the processor, the folding machine further includes a first belt conveyor for conveying the sheet at a speed equal to the web, and a second belt conveyor for receiving the sheet from the first belt conveyor at a speed approximately equal to the sheet conveying speed of the first belt conveyor, then varying the conveying speed to a speed approximately equal to the sheet conveying speed of the processor, and delivering the sheet to processor.

Owner:MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

Method and device for operating a user interface for displaying the travel range of a vehicle

ActiveUS8831807B2Increase the itineraryLow costAnalogue computers for vehiclesAnalogue computers for trafficSimulationEnergy expenditure

In a method and a device for operating a user interface in a vehicle, in particular for determining and displaying information in connection with electrical consumers, an operator action is detected, by which the operation of an electrical consumer disposed in the vehicle is modified, and a change in the energy consumption of the electrical consumer caused by the operator action is determined. Using the determined energy consumption, a change in the travel range of the vehicle caused by the modified operation of the electrical consumer is calculated, and the calculated change in travel range is displayed directly. The method and the device are especially suitable for a vehicle driven by an electric motor.

Owner:VOLKSWAGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com