Powder-Metallurgically Produced, Wear-Resistant Material

a technology of wear-resistant materials and powders, which is applied in the direction of thin material handling, transportation and packaging, etc., can solve the problems of insufficient hardening of large-walled composite parts, insufficient hardening of thick-walled composite parts, and insufficient hardening of steel powders known today,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

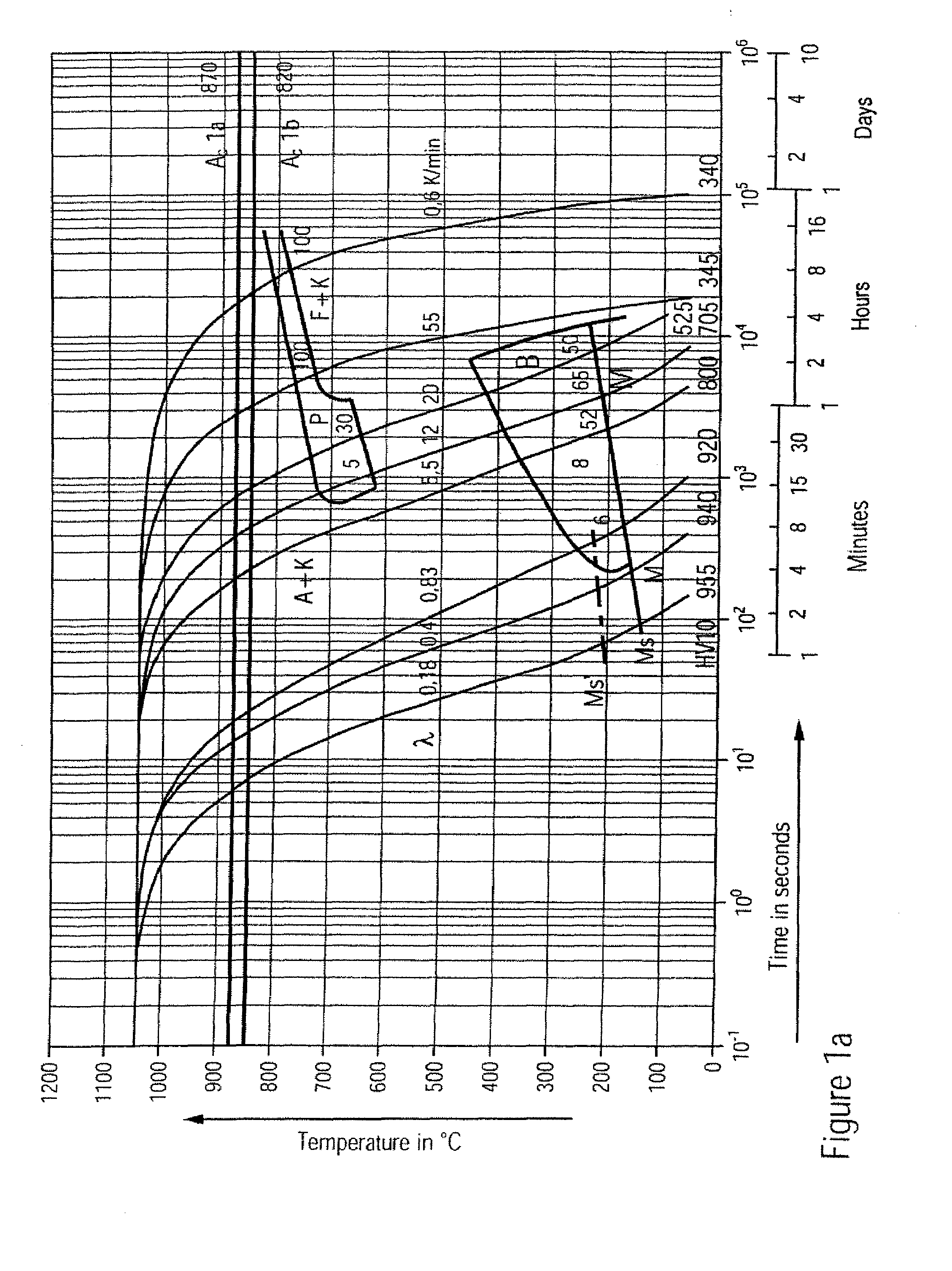

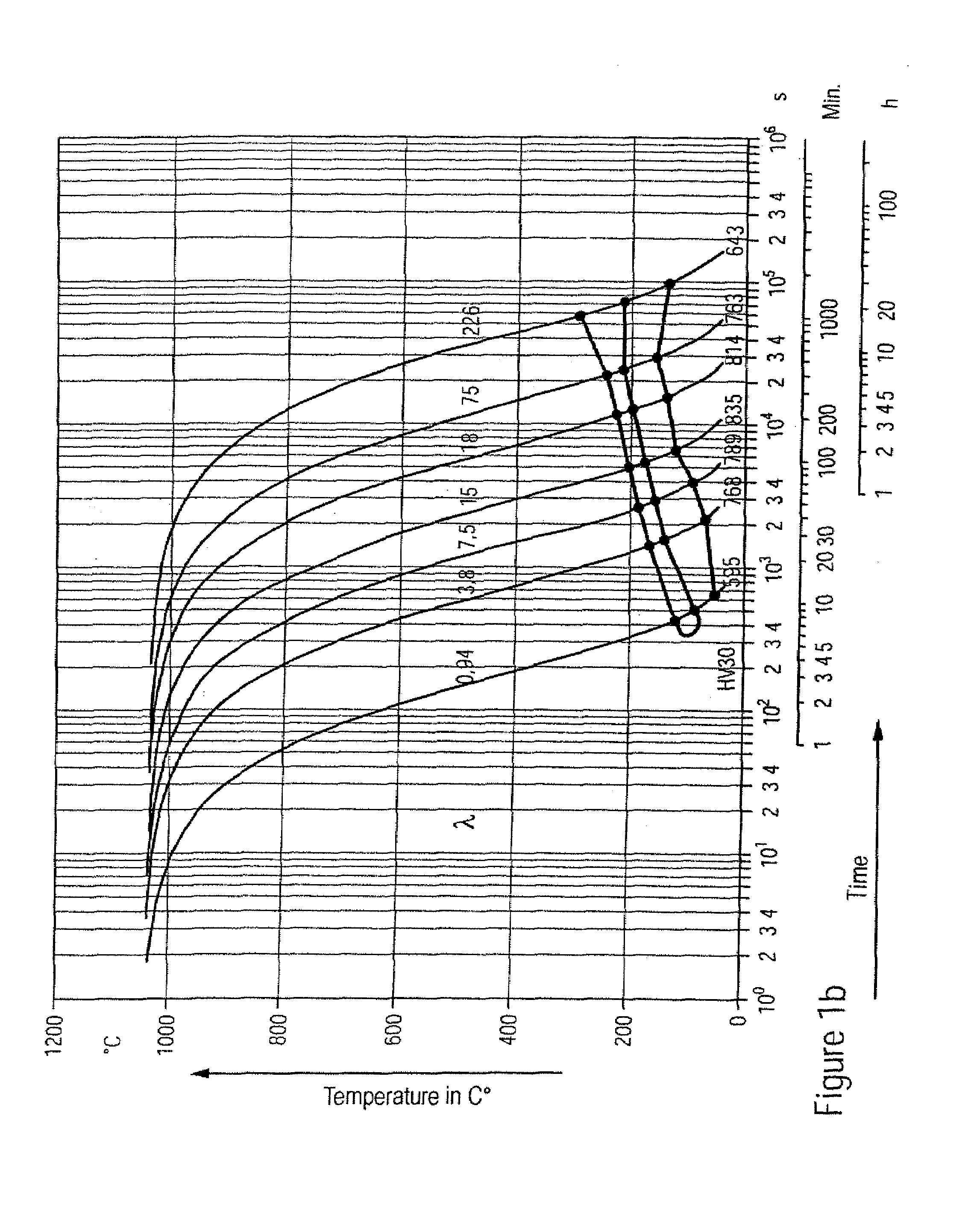

[0054]The heat treatment characteristic of hardenable steels and alloys is generally evaluated on the basis of time-temperature transformation diagrams (TTT diagrams). The TTT diagram shown in FIG. 1 serves to compare an alloy according to the disclosure with a commercially available powder metallurgical steel with the composition X230CrVMo13-4 (material no. 1.2380). Because the martensite formation for the mentioned material group is indispensable, the cooling from the hardening temperature (in this case, 1,050° C.) must take place so quickly that the ferrite and perlite soft structure phases are avoided in the layer substance. For this reason, the cooling rate deserves increased attention, which is described in heat treatment technology by the cooling time from 800° C. to 500° C. The cooling parameter λ, which is noted as a numerical value for several cooling curves in FIG. 1, is formed by dividing the cooling time (in seconds) by 100.

[0055]From the TTT diagram for the steel X230C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com