Low-noise food processor

A technology for food processing machines and machine bases, which can be used in home appliances, applications, kitchen utensils, etc. It can solve the problems of poor heat dissipation of motors, turbulent air flow, and loud noises, and achieve reduced assembly gaps, enhanced load-bearing strength, and reduced noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

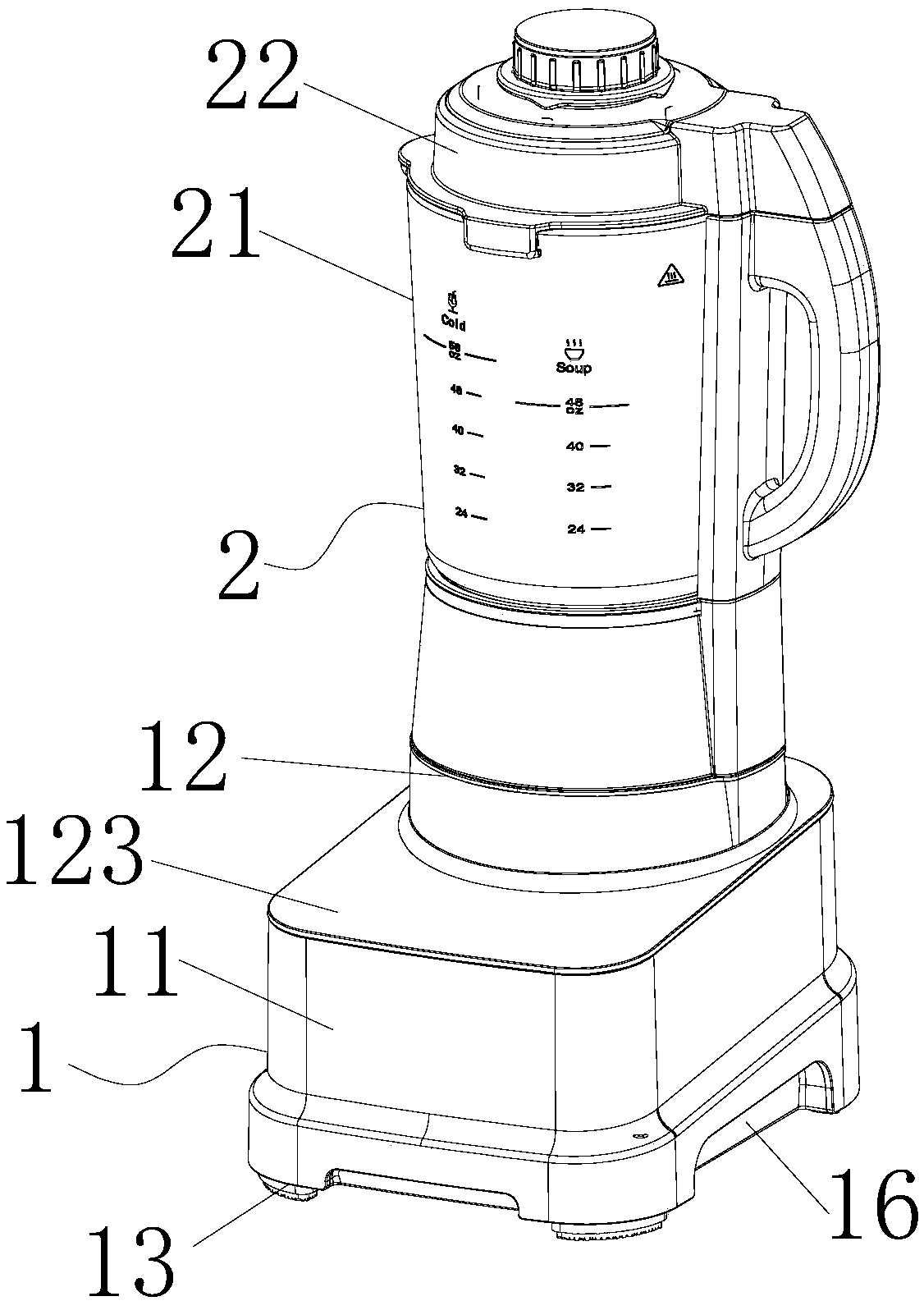

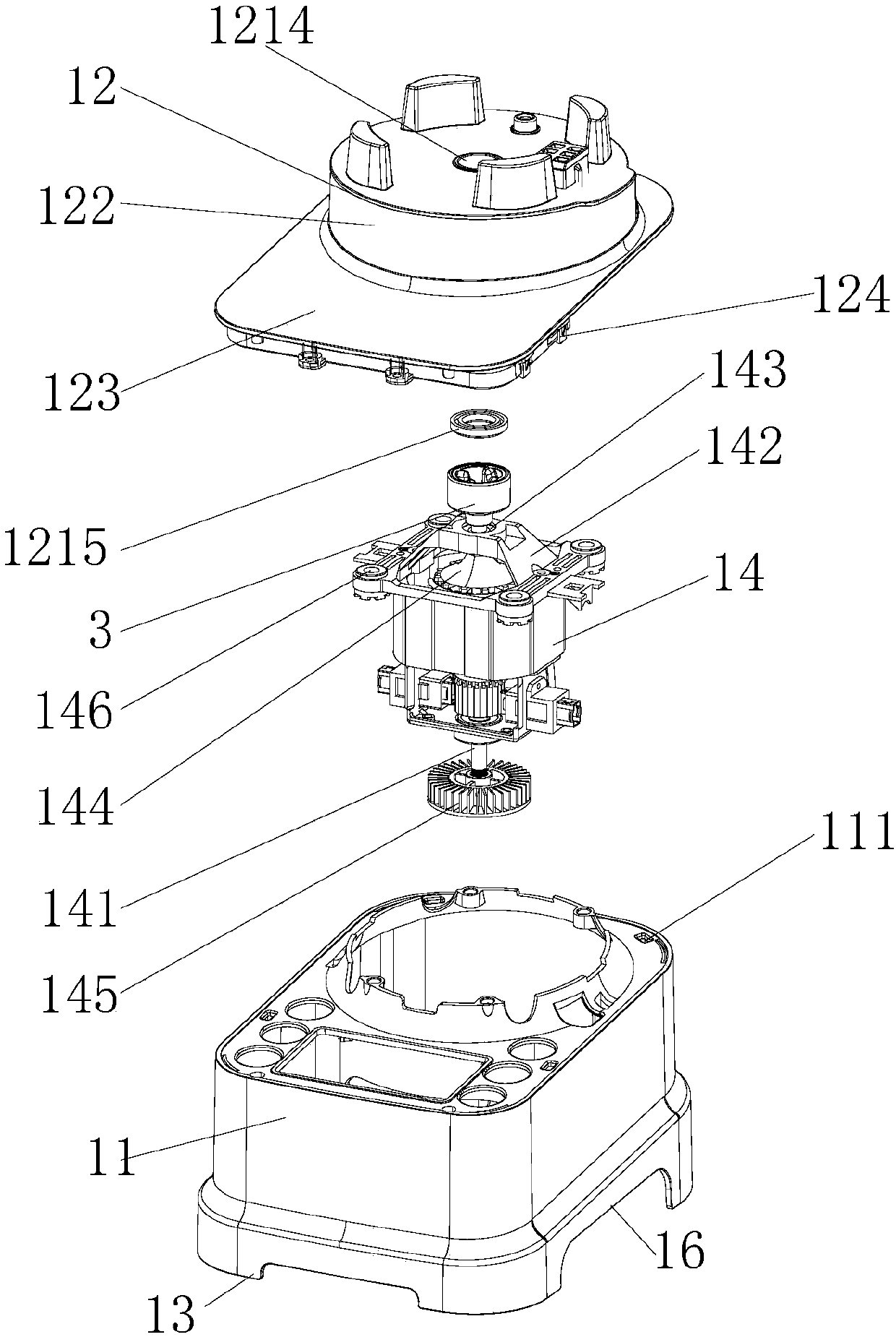

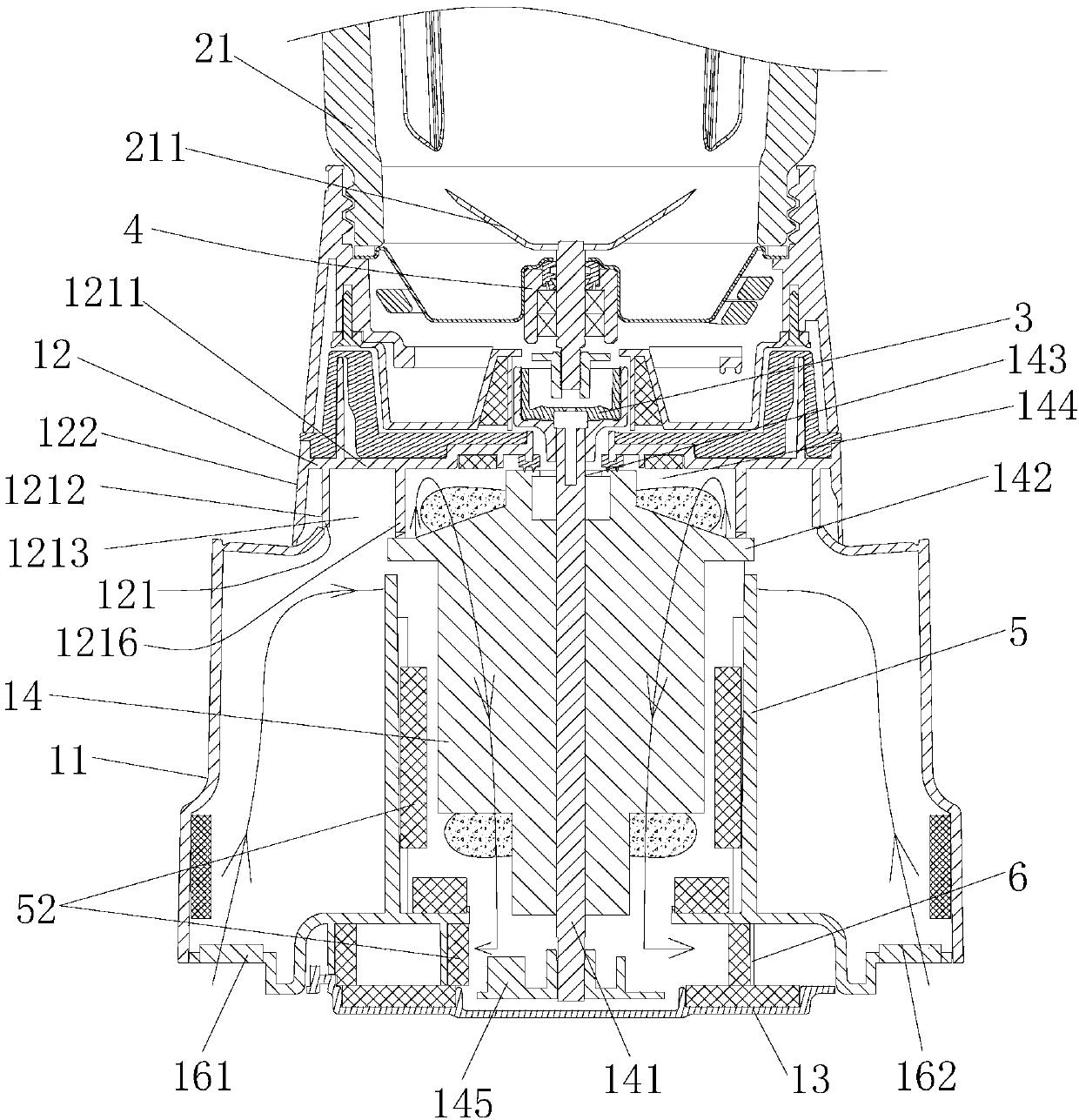

[0042] The structure of the food processing machine of the present embodiment is as Figure 1 to Figure 7 As shown, the food processor includes a base 1 and a stirring cup 2. The base 1 includes a casing 11, a top cover 12 positioned at the top of the casing 11 and a bottom cover 13 positioned at the bottom of the casing 11. Inside the casing 11 is a The motor 14 and the circuit board 15, the stirring cup 2 is arranged on the top of the machine base 1 and on the top cover 12, the stirring cup 2 includes a cup body 21 and a cup cover 22, the cup body 21 is a glass with a handle, and the cup cover 22 rotates Fastened on the cup body 21, the cup cover 22 and the cup body 21 encircle to form a crushing space, the cup body 21 is provided with a crushing knife 211, the upper end of the motor shaft 141 of the motor 14 passes through the top cover 12 and is connected with a lower coupling 3, The lower end of the cutter shaft of the crushing knife 211 is connected with an upper couplin...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that a guide structure is added, combined with Figure 8 with Figure 9 As shown, the guide structure 7 is located inside the casing 11 and at the periphery of the motor barrel 5 , and the air inlet 16 is located outside the guide structure 7 . When the motor works like this, the fan 145 sucks the external wind into the casing 11 from the air inlet 16, and the external wind forms an airflow under the guidance of the guide structure 7 and transfers it to the motor barrel 5 through the communication port 144. The outside wind is guided and directed as an air flow, so that it enters the motor barrel 5 in an orderly manner to dissipate heat from the motor 14, preventing it from running around and reducing the heat dissipation effect. Due to the existence of the air guide cover 121, the external wind enters the casing and is guided by the guide structure 7, then flows upward to the air guide cover 121 and is guided ...

Embodiment 3

[0063] The difference between this embodiment and the second embodiment is that the guide structure also includes a second guide plate, combined with Figure 10 with Figure 12 As shown, the second guide plate 72 is an arc-shaped plate, and the second guide plate 72 is arranged opposite to the first guide plate 71 and symmetrically arranged on the opposite side of the bottom cover 13 respectively. The inner wall of the casing 11 is clamped, and the first guide plate 71, the second guide plate 72 and the inner wall of the casing 11 are enclosed to form an air inlet guide channel 8 that wraps the lower part of the motor barrel 5, and the air inlet guide channel 8 communicates with the air inlet 16. The increase of the guide plate 72 narrows the air inlet guide passage 8, which is beneficial to quick air guide. In this way, after the outside wind enters the casing 11 symmetrically from the first air inlet 161 and the second air inlet 162, it flows upward after being guided symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com