Noodle processing device

A processing device and technology for noodles, which are applied in the directions of dough extruders, dough forming and cutting equipment, etc., can solve the problems of sticking, not easy to separate, and incoherent processing of noodles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

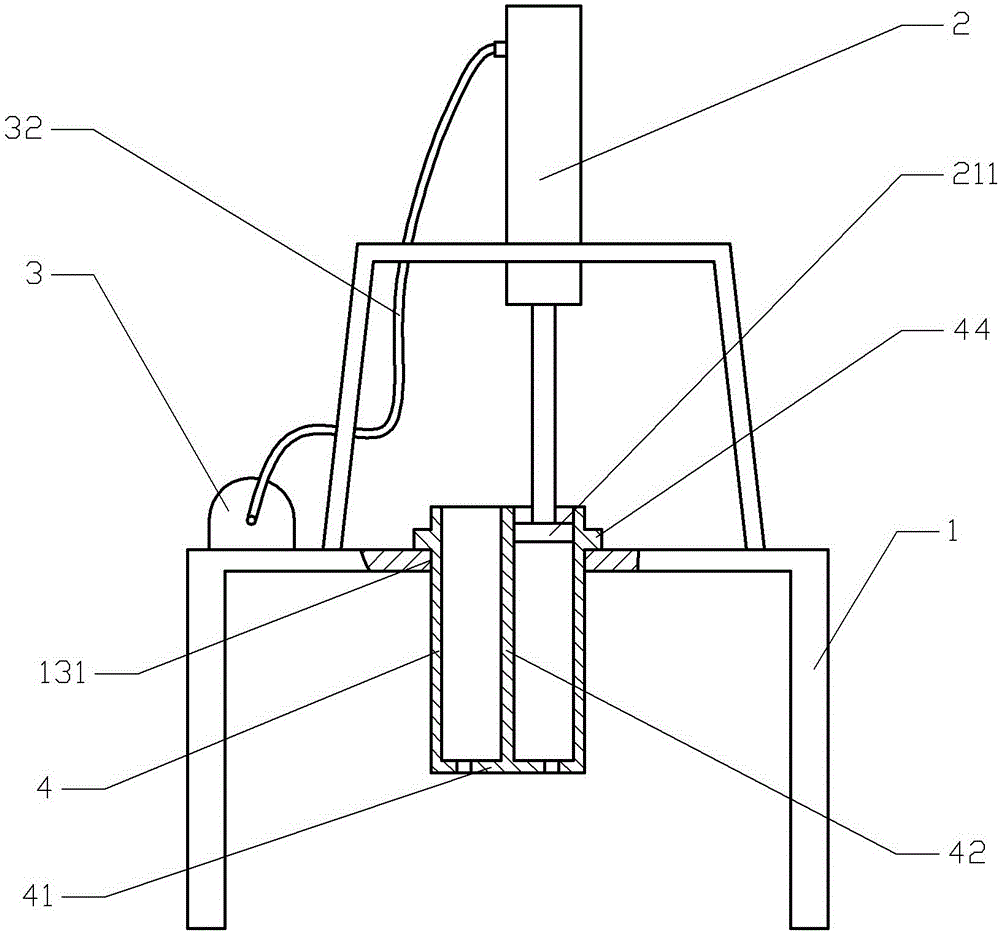

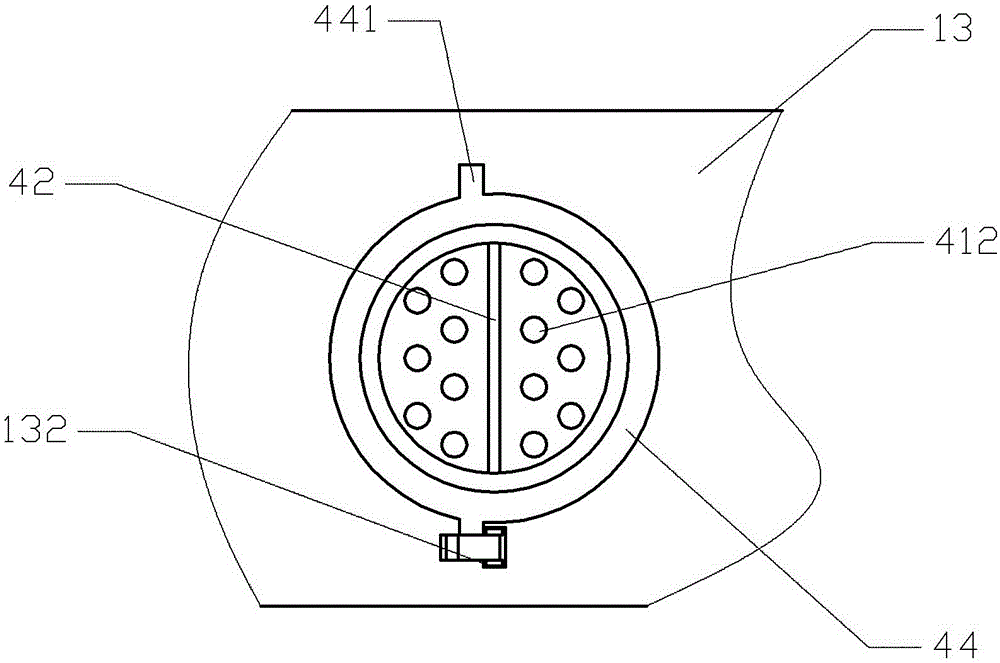

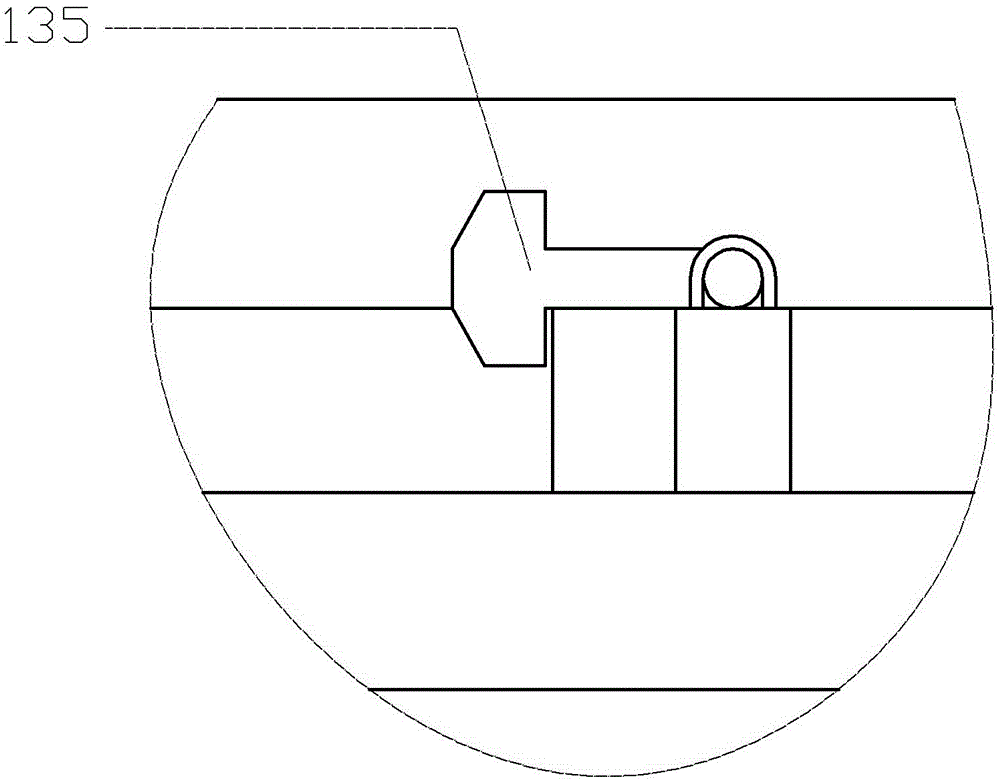

[0016] according to figure 1 , figure 2 , image 3 As shown, the noodle processing device of the present invention includes: a frame 1, a pressurized cylinder 2, an air compressor 3 and a noodle cylinder 4; The rib 44 protruding outward, the rib 44 of the noodle cylinder 4 has a limiting block 441 protruding outward, the bottom of the noodle cylinder 4 has a cutter 41 integrally formed with the noodle cylinder, and the cutter 41 is arranged with a face outlet 412 , and from the partition plate 42 in the center of the noodle cylinder 4 to both sides, the outlet holes 412 are always staggered; a table 13 is provided on the frame 1, and a noodle cylinder positioning hole 131 is opened on the table 13, and the noodle cylinder 4 is inserted. Installed in the positioning hole 131 of the face cylinder, and a positioning block 132 is fixed on the table 13 of the frame 1 to cooperate with the limit block 441 of the face cylinder 4, and a locking block 135 is hinged on the positionin...

Embodiment 2

[0019] Such as Figure 4 The difference between the second embodiment shown and the first embodiment is that the noodle cylinder 4 and the cutter 41 are fixed by threads, that is, the outer ring of the bottom of the noodle cylinder 4 is provided with threads, and the end surface of the cutter 41 is provided with a protruding installation. Ring, the inner peripheral surface of the mounting ring is provided with threads, and the cutter 41 is screwed on the bottom of the dough tube 4 to realize fixing; to facilitate the replacement of the cutter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com