Efficient horizontal garment thread residue adsorbing machine

A thread suction machine, a horizontal technology, applied in the field of high-efficiency horizontal garment thread suction machines, can solve the problems of low thread suction processing efficiency, easy fatigue of operators, low work efficiency, etc., and achieves simple structure, high work efficiency, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

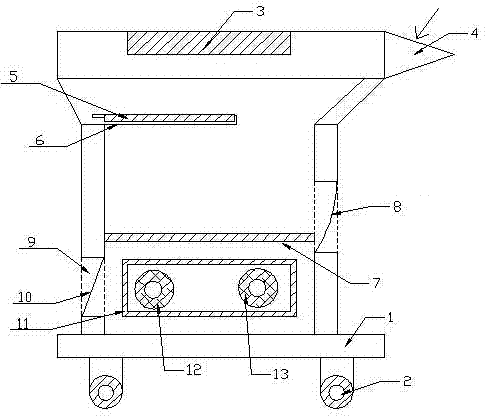

[0020] further as figure 1 As shown, turn on the first motor 12 and the second motor 13 (you can also only turn on a motor according to needs), and the clothes to be processed are deployed at the air inlet 4 positions, then the first motor 12 and the second motor 13 produce powerful The suction sucks the thread ends and dust mixed in the clothes into the frame box 1, and then the mixture such as thread ends and dust that enters is first filtered through the first filter plate 5, and then passed through the second filter plate 7 (one end of the second filter plate plate 4 is embedded in the machine) On the inner wall of the rack box, the other end has a threaded hole and is fixed by a screw through the rack box) to filter, and finally the filtered air that enters is discharged through the air outlet 9, and the filter screen 10 located at the air outlet 9 is used to filter the air to be discharged. Further filtering ensures that the discharged air is mixed with dust and dust, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com