Double-chamber single air suction type guiding device

A flow-guiding device and wind-type technology, applied in the field of aluminum processing, can solve the problems of long circulating air stroke, low wind speed, unfavorable thermal uniformity of aluminum alloy profiles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

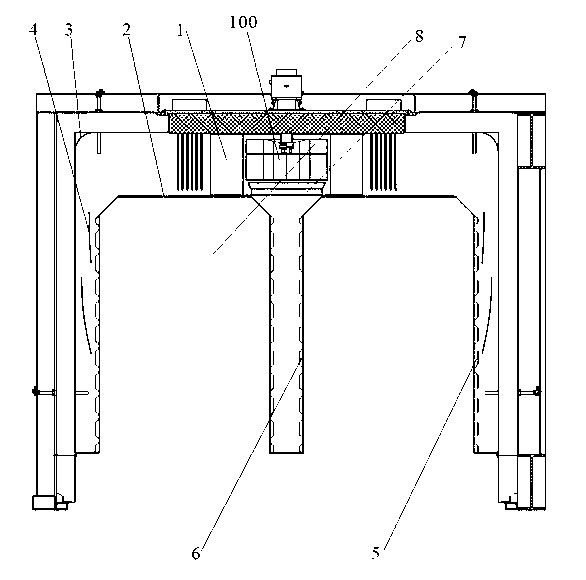

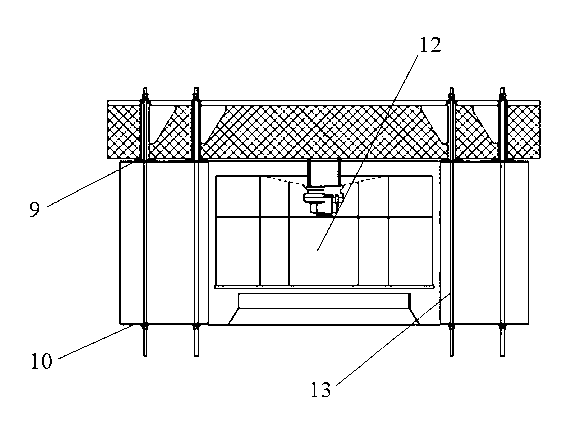

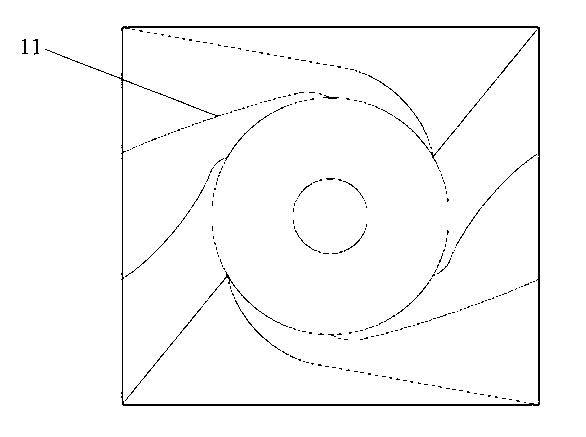

[0029] figure 1 It is a schematic diagram of the front view of an embodiment of a double-chamber single-suction deflector of the present invention, which includes a circulating fan 100, a fan deflector 1, a horizontal deflector 2, a corner deflector 3, two Side air channel wind deflector 4, side air channel spray devices 5, middle air channel spray device 6, air suction port 7 and wind zone partition 8; wherein the circulation fan 100 is placed in the fan deflector 1, The middle part of the horizontal deflector 2 is connected with the fan deflector 1, and the two sides are connected with the middle air duct jet flow device 6 and the two side air duct jet flow devices 5, and the top corner wind deflector 3 is connected with the furnace roof and side wall of the aging furnace Welded together, the air guide plates 4 on both sides are located in the air ducts on both sides, the air jet devices 5 on both sides and the jet device 4 in the middle air duct are connected to the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com