Sheet metal bidirectional stretching apparatus based on die technology

A metal plate, two-way stretching technology, applied to measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve problems such as poor synchronization control, damage to test devices, and complex device structures, etc., to achieve Easy to install, easy to maintain, good synchronization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

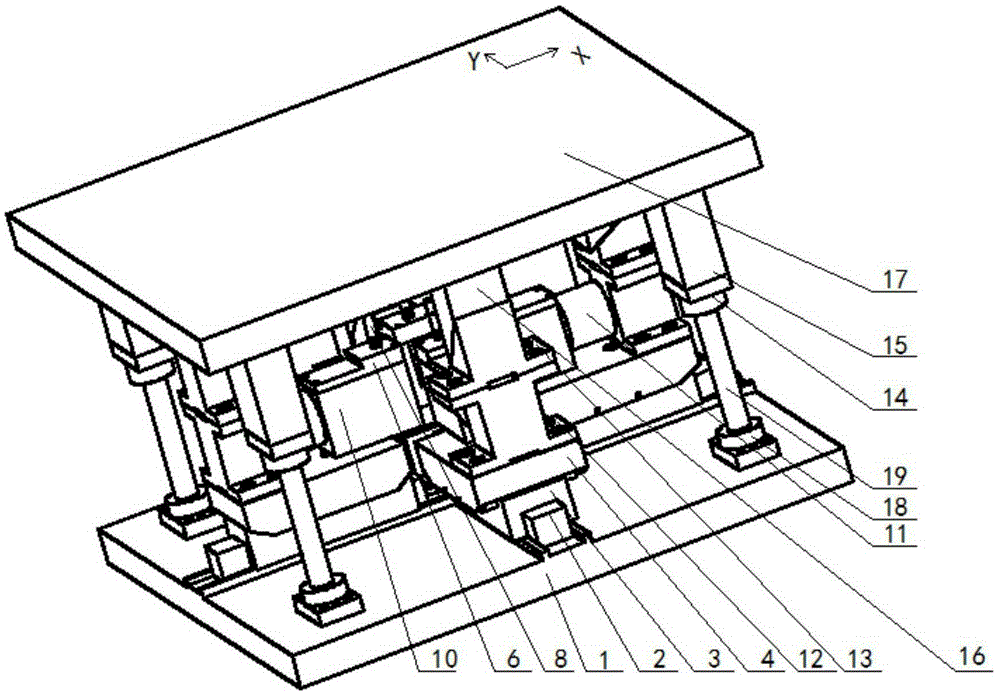

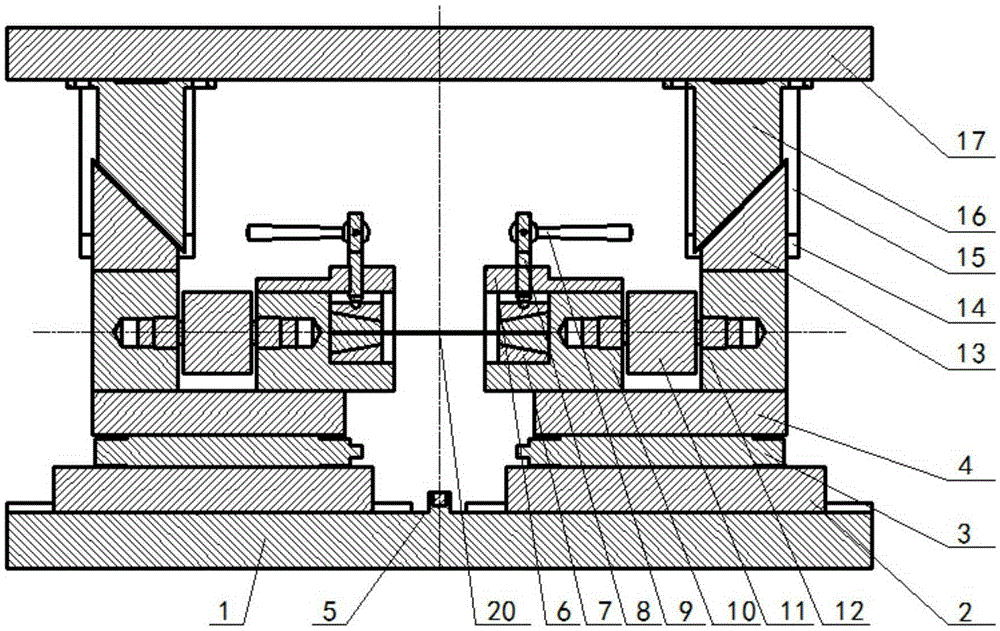

[0043] see figure 1 and figure 2 , a metal plate bidirectional stretching device based on mold technology, its composition includes: workbench 1, camera 5, cross-shaped test piece 20, four sets of stretching mechanisms including tension sensors 11, top plate 17, four sets of seat guides mechanism and computer control system;

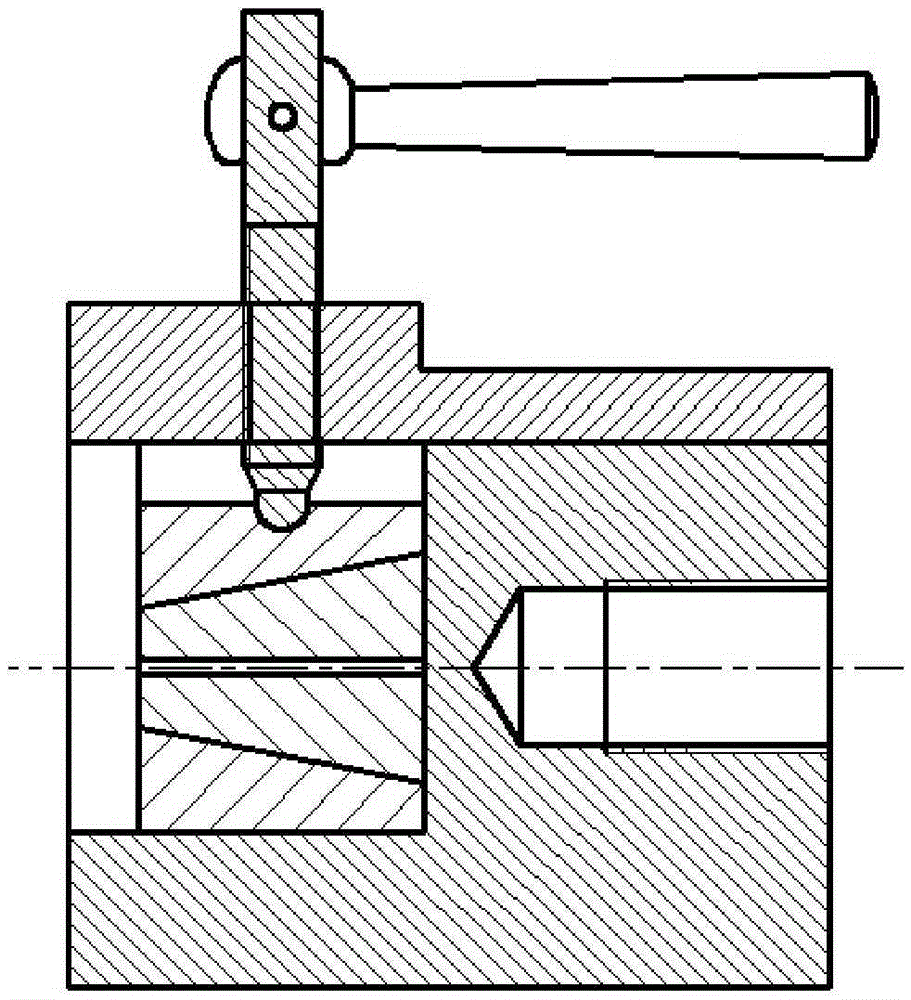

[0044] The workbench 1 is provided with a cross chute; the camera 5 is placed in the boss hole at the center of the cross chute of the workbench 1, and is located directly below the center of the cross-shaped test piece 20; in the four directions of the cross chute There are four sets of the same stretching mechanism; each set of stretching mechanism includes a linear slide rail composed of a guide rail 2 and a slider 3, a connecting piece 4, a tension sensor 11, a fixture and a mold; the linear slide rail is arranged on a cross chute , that is, the linear slide rail and the workbench 1 are connected by threads; the linear slide rail adopts a roller-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com