Tab shaping and transferring device, working method of tab shaping and transferring device and cylindrical cell piece production winder

A technology of pole ear shaping and transfer device, which is applied in battery assembly machines, secondary battery manufacturing, and other manufacturing equipment/tools, etc., can solve the problems of easy breakage, low production efficiency, skewed pole ears, etc., to ensure that they are perpendicular to each other. speed, improve production efficiency, and the effect of fast production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

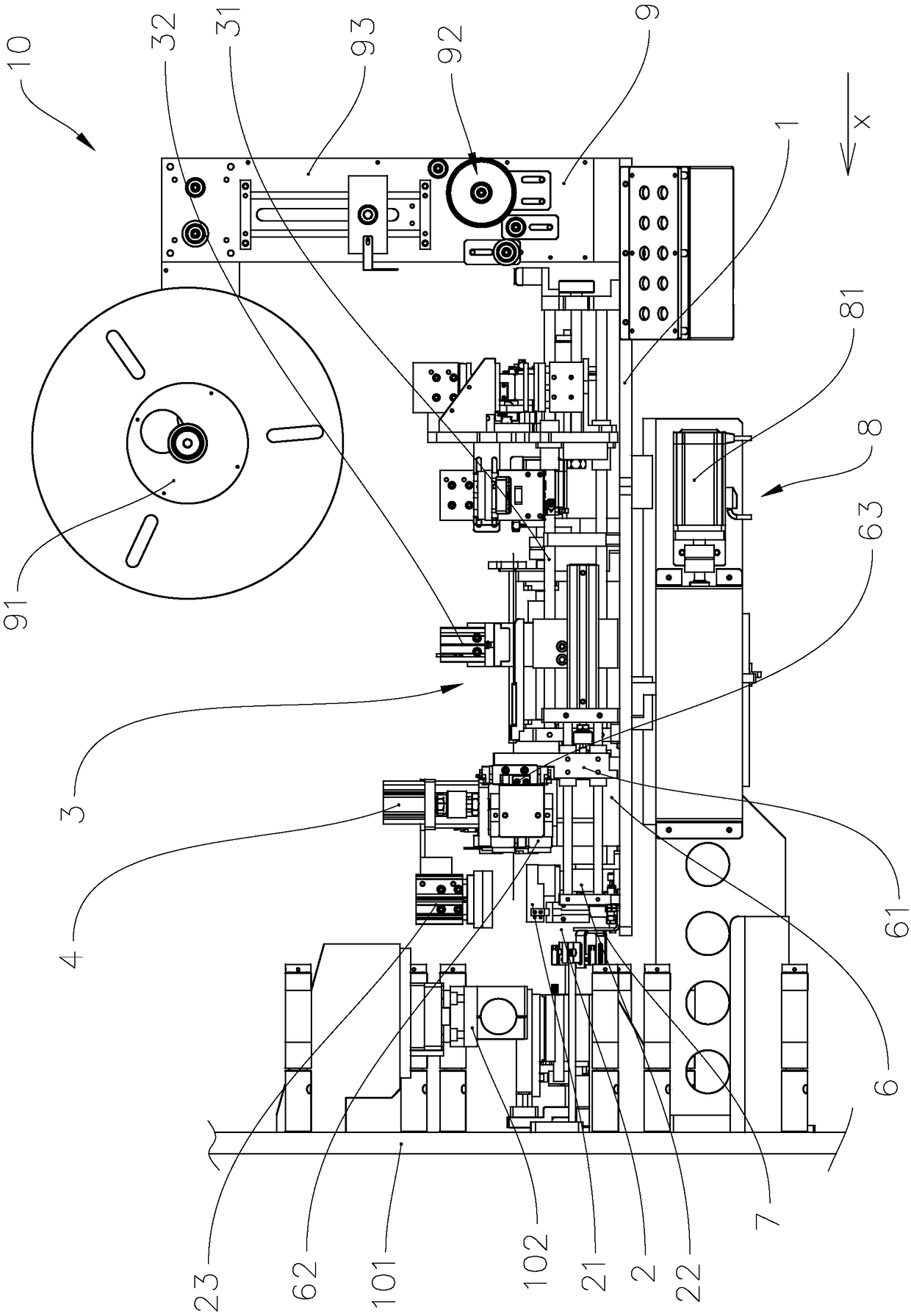

[0035] Cylindrical cell sheet winding machine embodiment:

[0036] refer to Figure 1 to Figure 4 , the cylindrical battery sheet winding machine includes a frame 101, a tab welding device 102 and a tab shaping transfer device 10, wherein the tab welding device 102 is installed on the frame 101, and the tab welding device 102 has a welding head , the tab welding device 102 is used to weld the position-corrected tab and the tab delivered by the tab shaping and transferring device 10 . The tab shaping and transferring device 10 is installed on the frame 101. The tab shaping and transferring device 10 is used to cut off the tab material roll to form a tab, and after correcting the position of the tab, deliver the tab to the tab welding device 102. Do the welding.

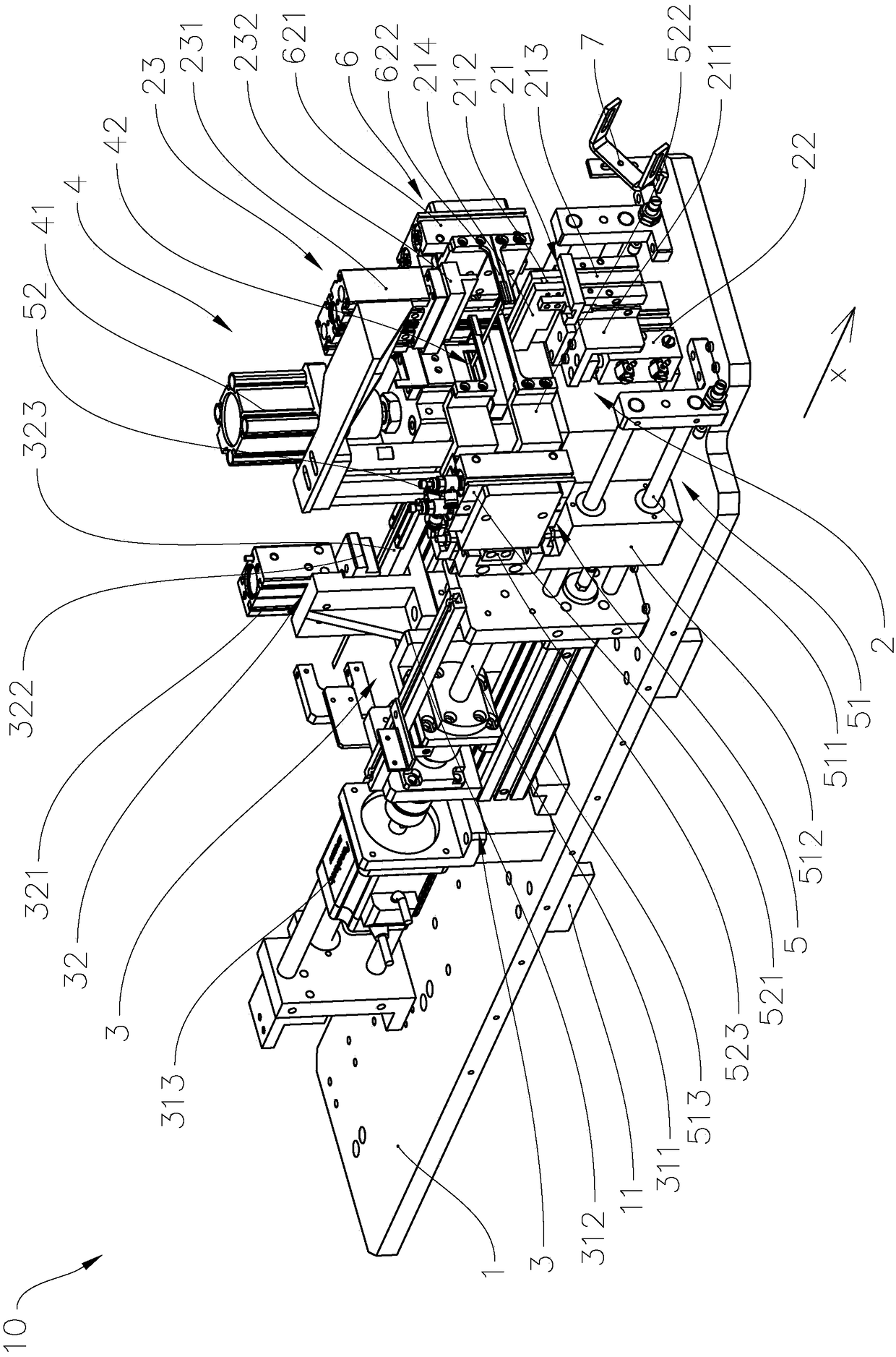

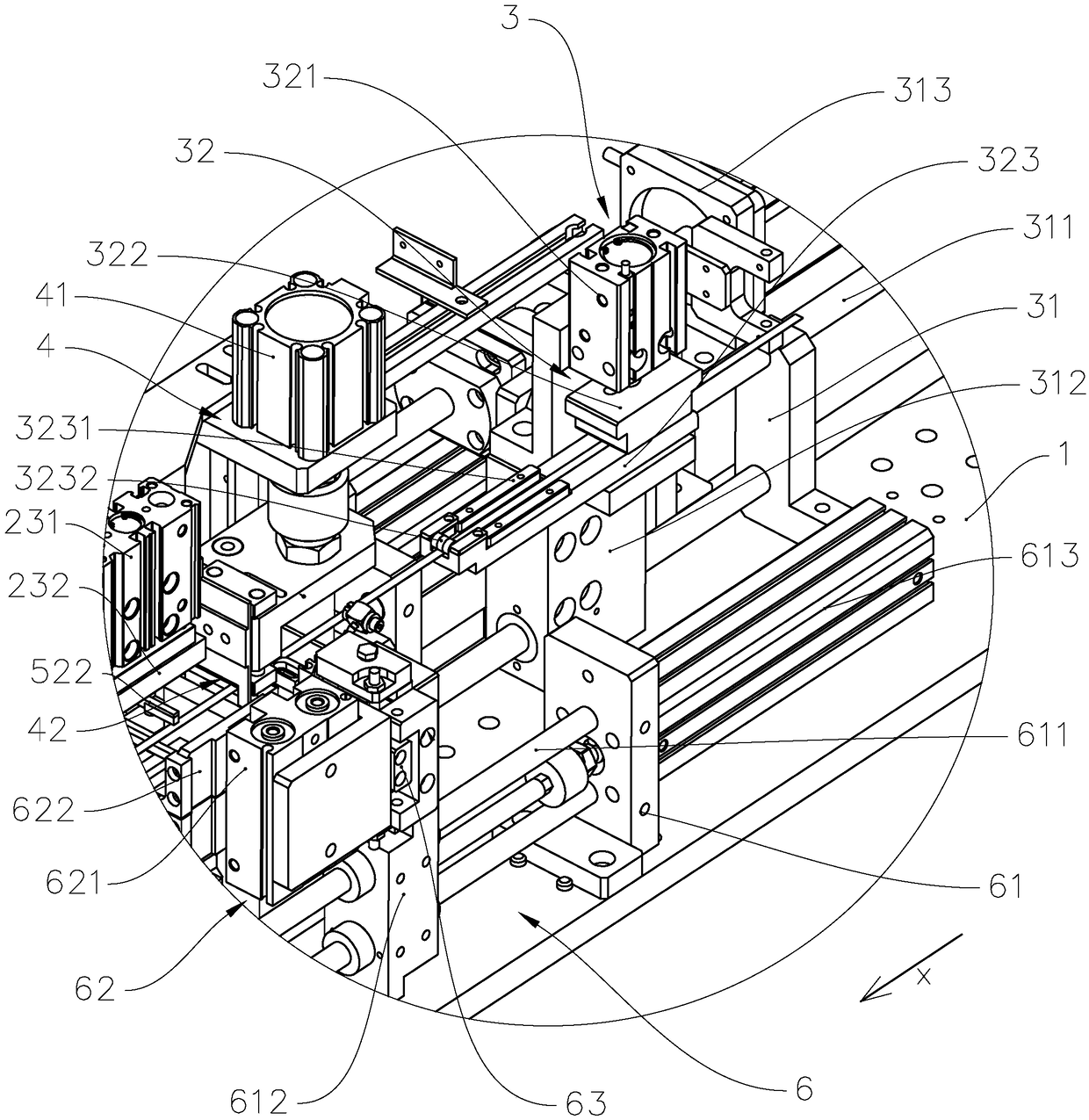

[0037] The tab shaping and transferring device 10 includes a mounting base 1, a shaping unit 2, a traction unit 3, a cutting unit 4, a first gripping unit 5, a second gripping unit 6, a position sensing unit 7, a gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com