Device for detaching suspension arm type component in narrow space

A cantilever, in-space technology, applied to hand-held tools, manufacturing tools, etc., can solve the problems of no supporting reaction force, narrow internal space, and the difficulty of ordinary disassembly tools to meet non-destructive disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

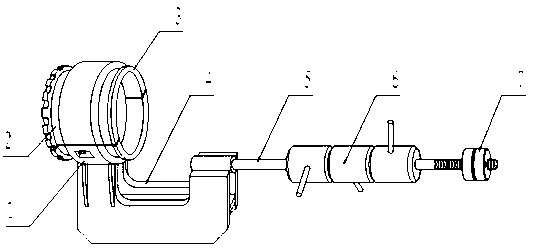

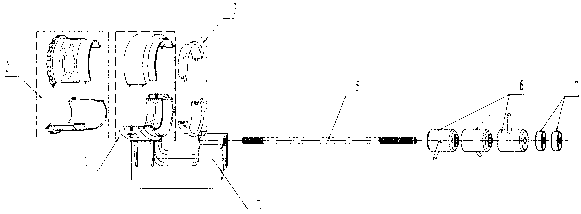

[0022] See Figure 1, figure 2 , the present invention includes a fixed sleeve 1, a bushing 2, an end face contact sleeve 3, a support 4, a pole 5, an inertia hammer assembly 6 and an impact screw sleeve 7, and the support 4 is a flat-bottomed U-shaped frame structure, and on its outside A fixed sleeve 1 is installed on the top, and the fixed sleeve 1 is set on the outside of the bushing 2. The inner side of the bushing 2 is fitted with the end face contact sleeve 3. One end of the support rod 5 is fixed on the inner top of the support 4. The inertia hammer assembly 6 is set on the rod 5, and the impact screw sleeve 7 is assembled on the other end of the strut 5.

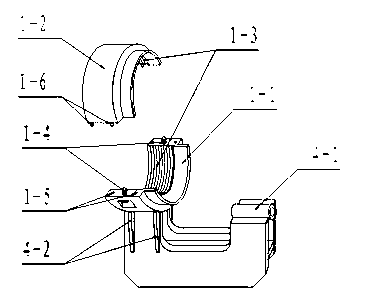

[0023] see image 3 , the present invention is provided with a set of reinforcing blocks 4-2 at the outer end of the support 4 and the mounting part of the fixing sleeve, and a pole fixing sleeve 4-1 is arranged at the inner top of the bearing, and the pole fixing sleeve 4-1 is connected with the pole 5 Screw conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com