Efficient cutting equipment for PVC pipe production and PVC pipe production process

A PVC pipe and cutting equipment technology, applied in metal processing and other directions, can solve the problems of slow speed, time-consuming and labor-intensive, low precision of PVC pipes, and achieve the effects of reasonable structure, improved cutting accuracy, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

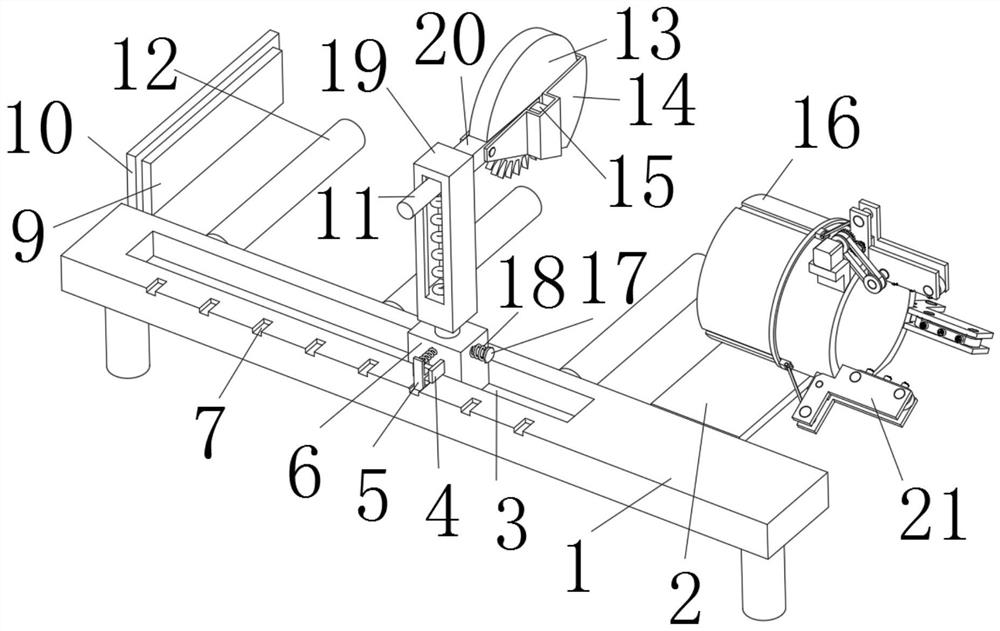

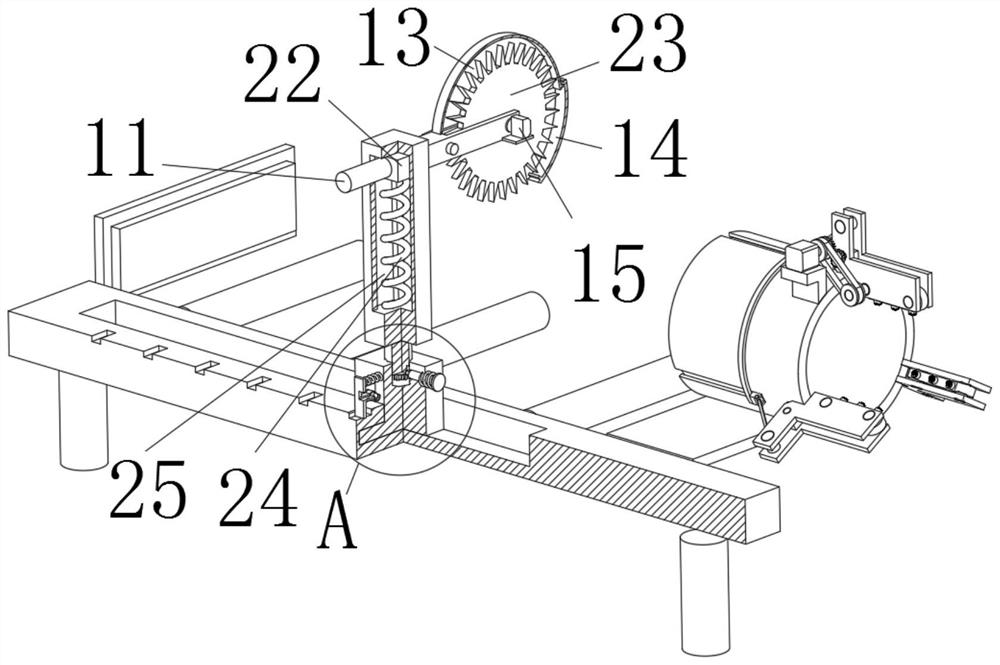

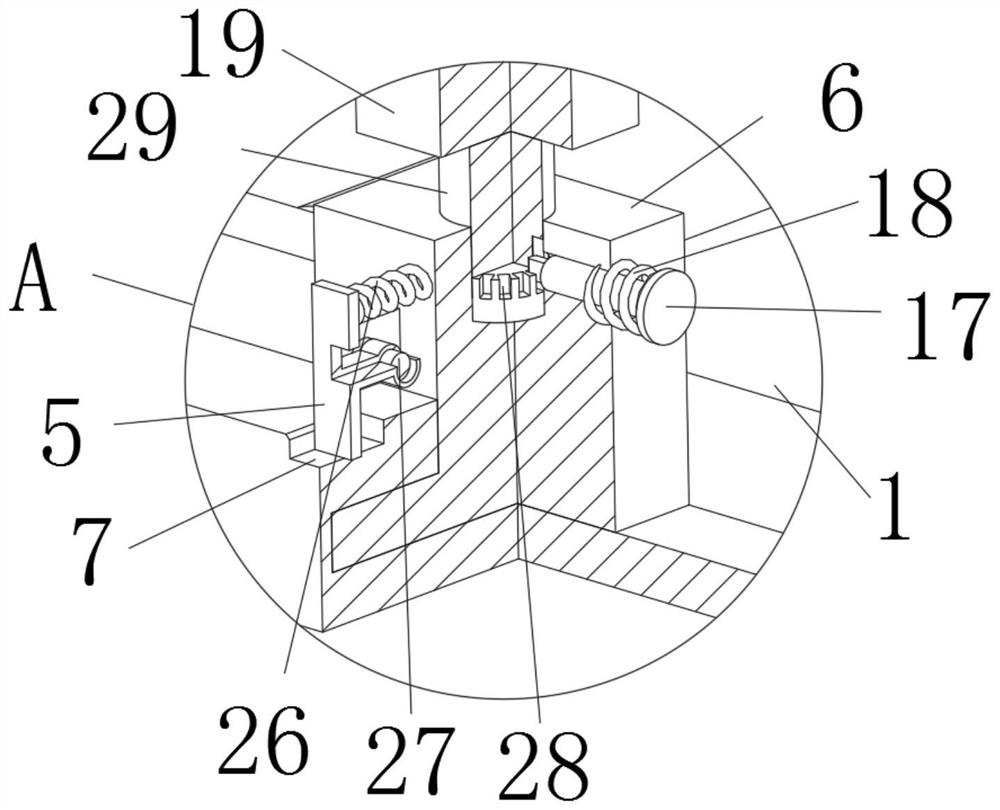

[0044] Example: Reference Figure 1-9 The shown high-efficiency cutting equipment for PVC pipe production includes a base 1, and the base 1 can be a metal plate in the prior art.

[0045] A mounting plate 2 is fixedly connected to one side of the base 1, and the mounting plate 2 may be a metal plate in the prior art, which is fixedly connected to the base 1 by welding.

[0046] A mounting ring 16 is fixedly connected to the top of the mounting plate 2, and the mounting ring 16 may be a metal ring in the prior art, which is fixedly connected to the mounting plate 2 by welding.

[0047] A PVC pipe clamping mechanism is installed on the side wall of the installation ring 16, and a PVC pipe transmission mechanism is installed on the PVC pipe clamping mechanism. A hollow rod 12 is rotatably sleeved, a cutting portion is installed on the top of the base 1 , a baffle 10 is fixedly connected to one side of the base 1 , and a buffer plate 9 is fixedly connected to one side of the baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com