Aspheric lens manufacturing method

A technology of aspheric lens and manufacturing method, which is applied in the direction of lens, manufacturing tools, glass pressing, etc., and can solve problems such as difficult high-precision molding, long working time, and strict molding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the method for manufacturing an aspheric lens according to the present invention will be described below with reference to the drawings. Here, the present invention will be described based on the illustrated embodiment, but the present invention is not limited to this embodiment.

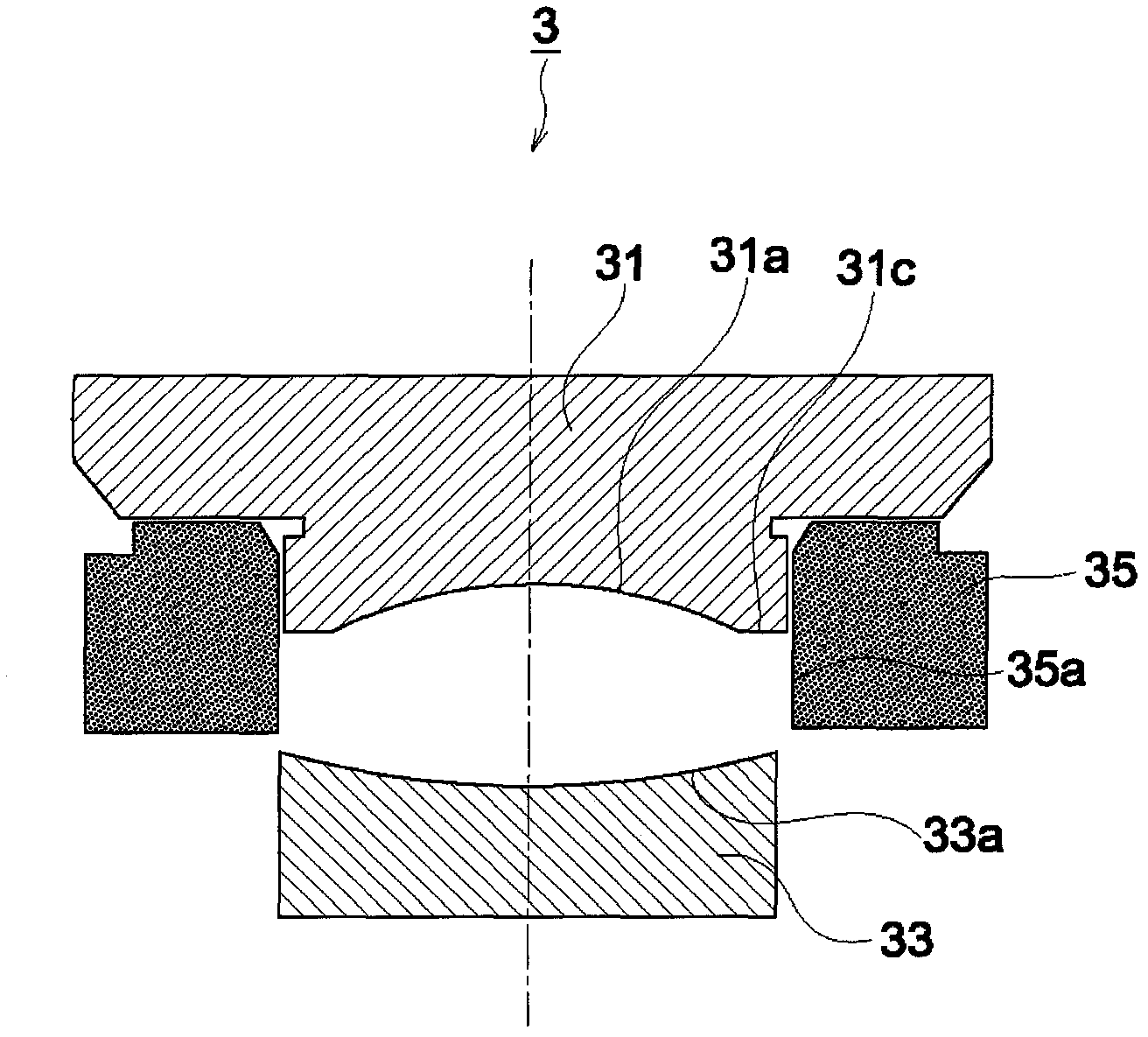

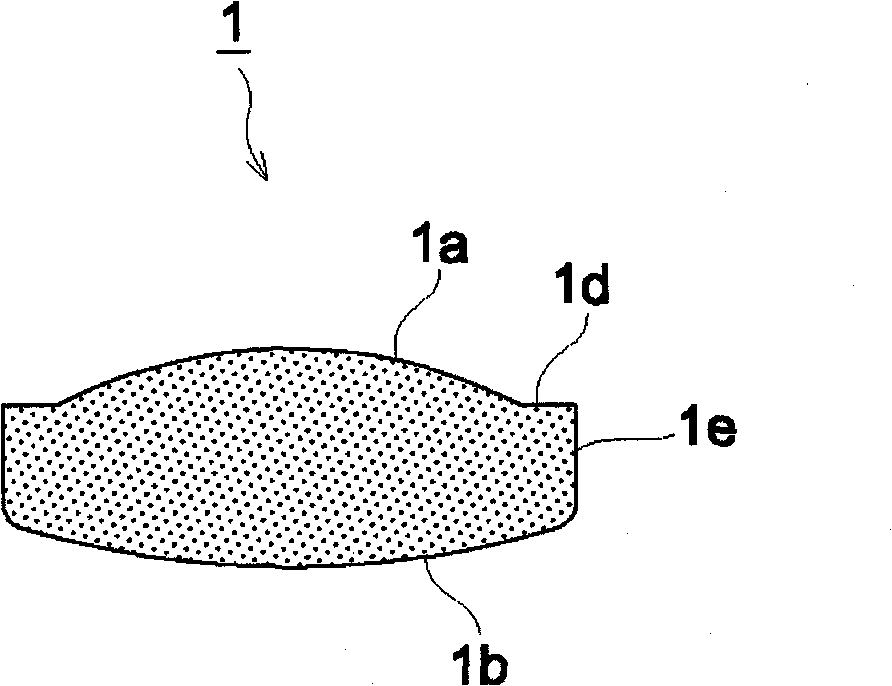

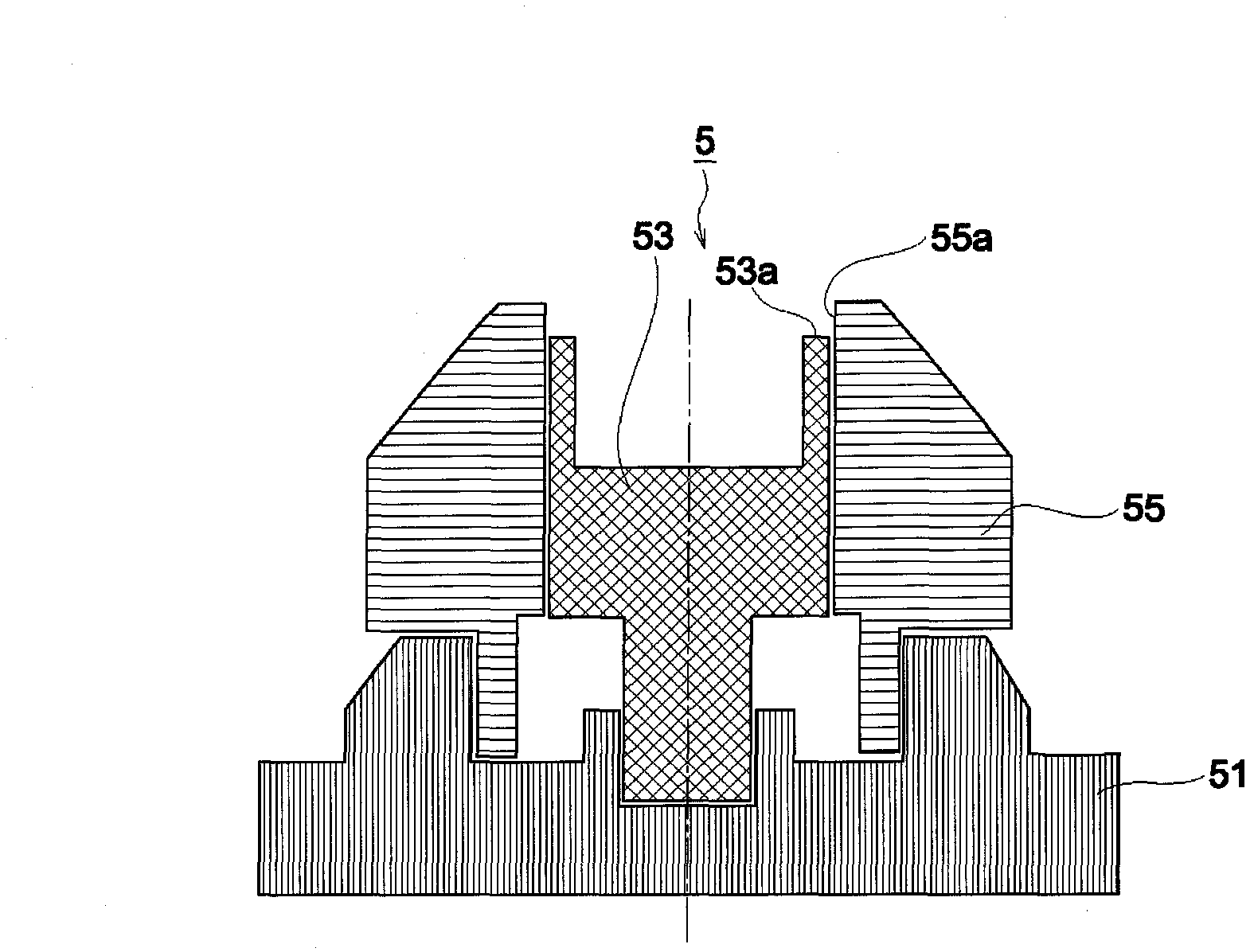

[0035] The method for manufacturing an aspheric lens according to an embodiment of the present invention is to mold a glass material first, and simultaneously form an aspherical surface, a flat surface around the aspheric surface, and a side surface connected to the flat surface to form a glass molded body (molding process). Next, the glass molded body is loaded into a processed mirror frame that touches the flat surface and the side surface of the glass molded body formed in the molding process to support and position the glass molded body (loading process). Then, by machining, a predetermined surface shape is formed on the other side of the molded glass body (machining proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com