Method for delivery of substrate to film forming device for disk-like substrate, substrate delivery mechanism and substrate holder used for the method, and method of manufacturing disk-like recording

A technology for substrates and brackets, applied in the manufacture of optical record carriers, optical recording/reproduction, optical record carriers, etc., can solve problems such as warping of the central part of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

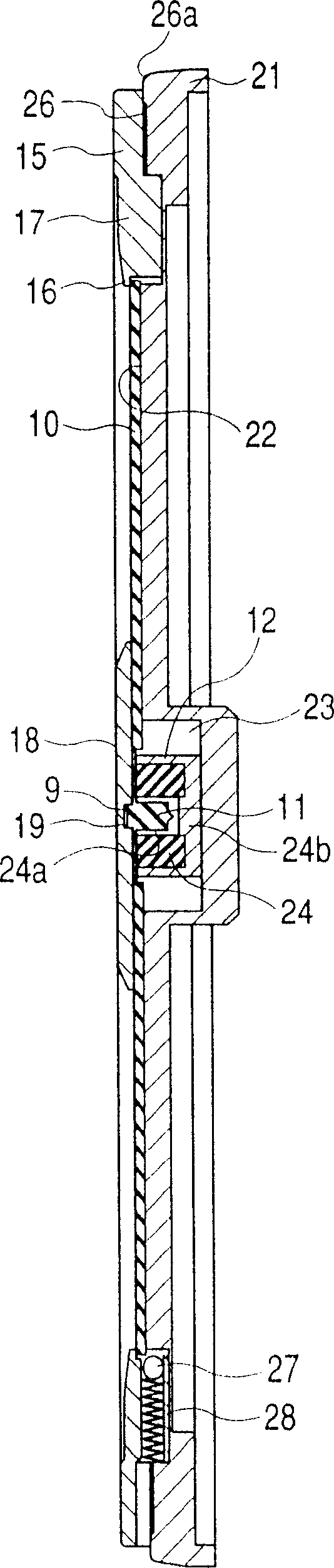

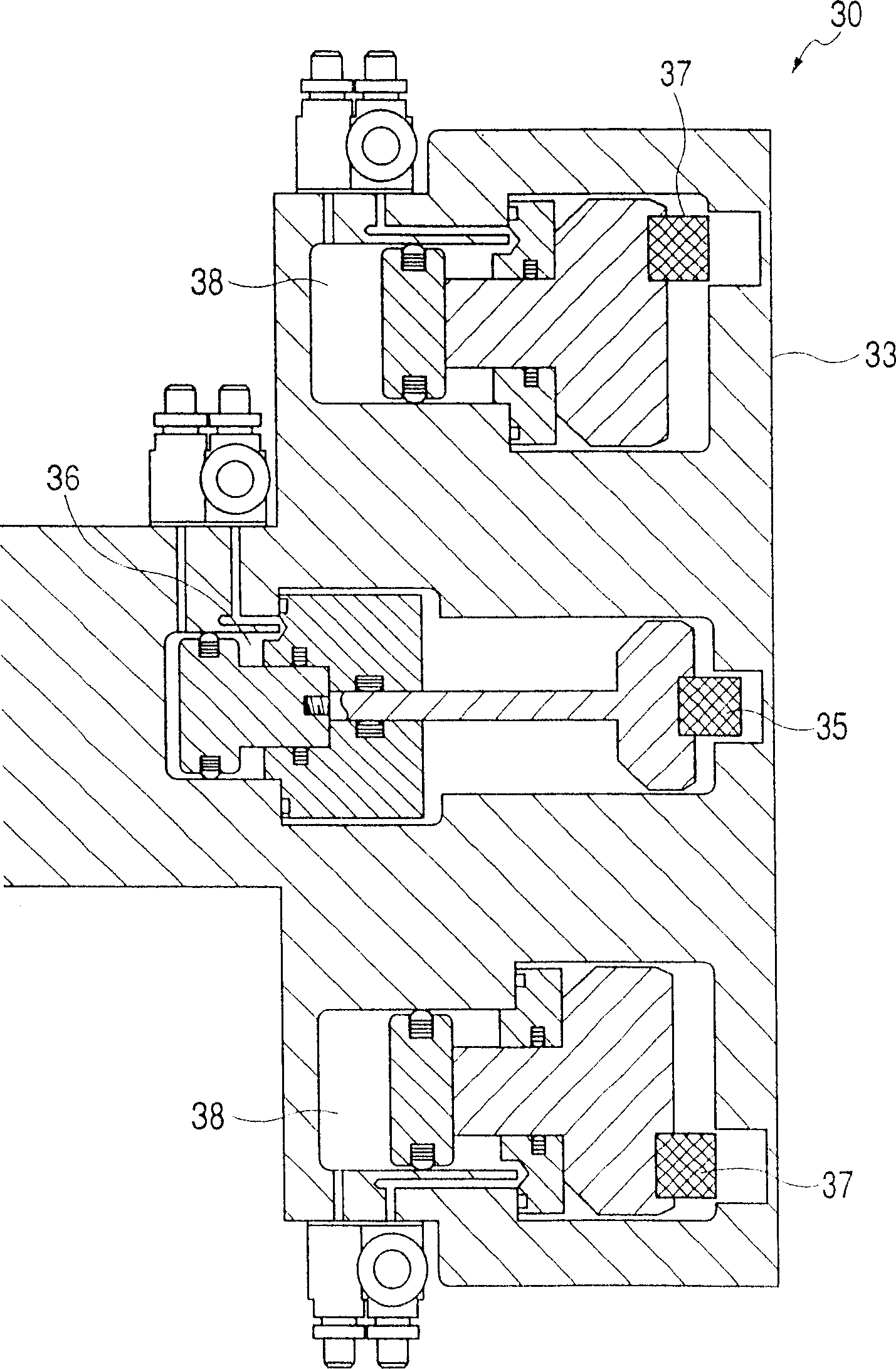

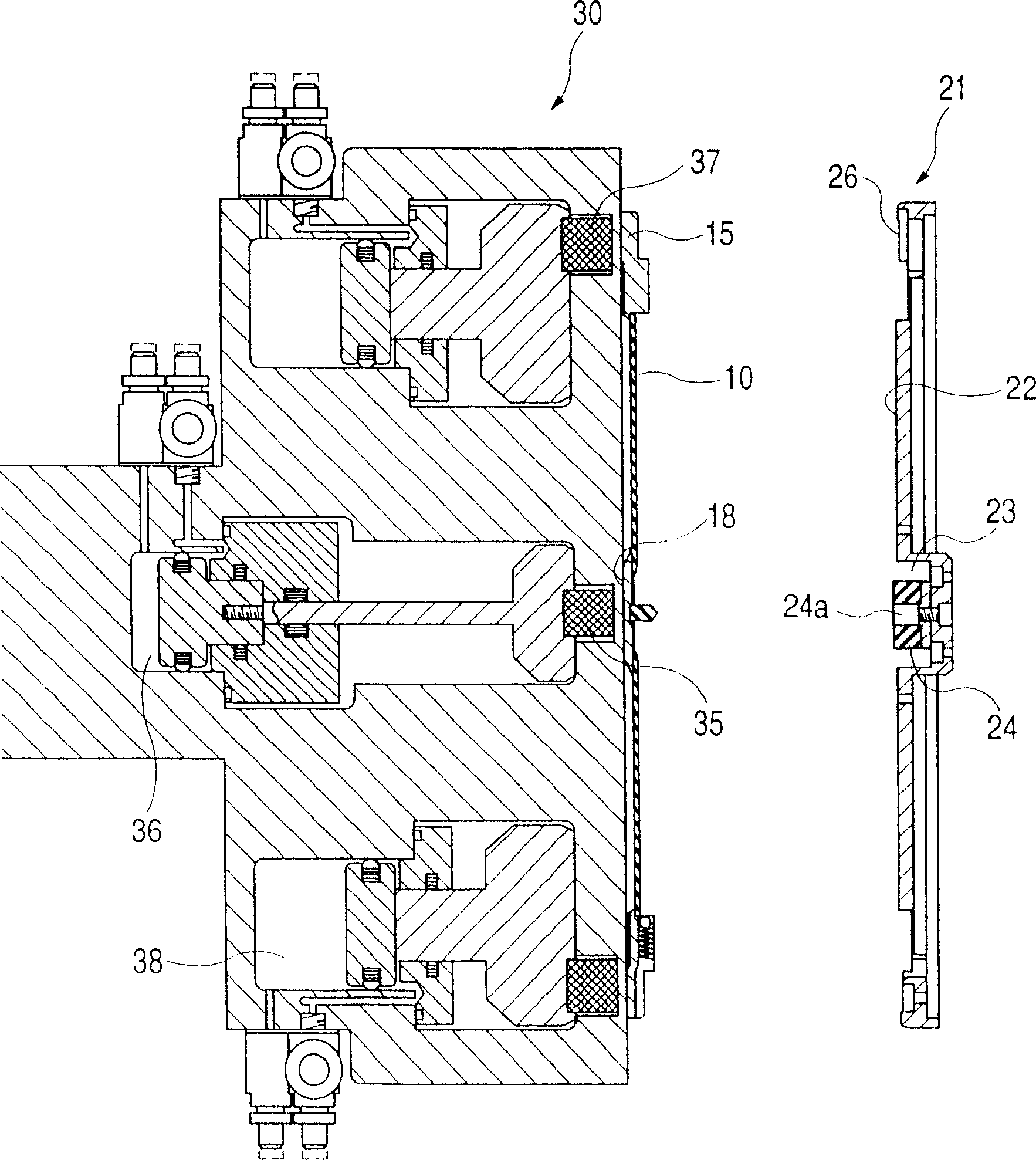

[0030] Hereinafter, a substrate holder, a substrate transfer mechanism, etc. according to a first embodiment of the present invention will be described in detail. figure 1 is a schematic cross-sectional view showing the substrate carrier, the substrate held by the substrate carrier, an outer mask and an inner mask, the substrate carrier can be held with the substrate by the transfer mechanism together and actually hold the substrate during thin film formation using a sputtering device or the like. also, figure 2 is a schematic cross-sectional view of an airside transfer arm with the substrate transfer mechanism positioned substantially opposite the substrate carrier holding the substrate and between the substrate transfer mechanism and the substrate carrier The substrate and the mask are passed between racks. also, Figures 3 to 6 are schematic cross-sectional views each showing how substrate transfer is performed according to the above structure.

[0031] A substrate 10 ...

no. 2 example

[0050] Figure 7 is a schematic sectional view of a substrate carrier according to a second embodiment of the present invention, and a substrate held by the carrier, an outer mask, and an inner mask. The substrate holder can be held together with the substrate by the transfer mechanism according to the present invention, and actually holds the substrate during thin film formation using a sputtering device or the like. It should be noted that, except for the substrate transfer mechanism, the configuration of this embodiment is almost the same as that of the first embodiment, so description thereof is omitted here.

[0051] The difference between the substrate holder of this embodiment and the substrate holder of the first embodiment is that an elastic member is provided on the bottom surface of the magnet 24 . Therefore, the following description focuses only on this point. In the first embodiment, the magnet 24 has a screw hole or the like (not shown) on the bottom surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com