Flexible panel curved-surface adhering device and method

A flexible panel and surface bonding technology, which is applied in the direction of identification devices, instruments, electrical components, etc., can solve the problems of affecting product quality, softness and hardness of cushioning materials, high requirements for deformation effect, and many bubbles in flexible panels and curved surface covers. , to achieve the effect of reducing the occurrence rate of air bubbles and ensuring the bonding effect of curved surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

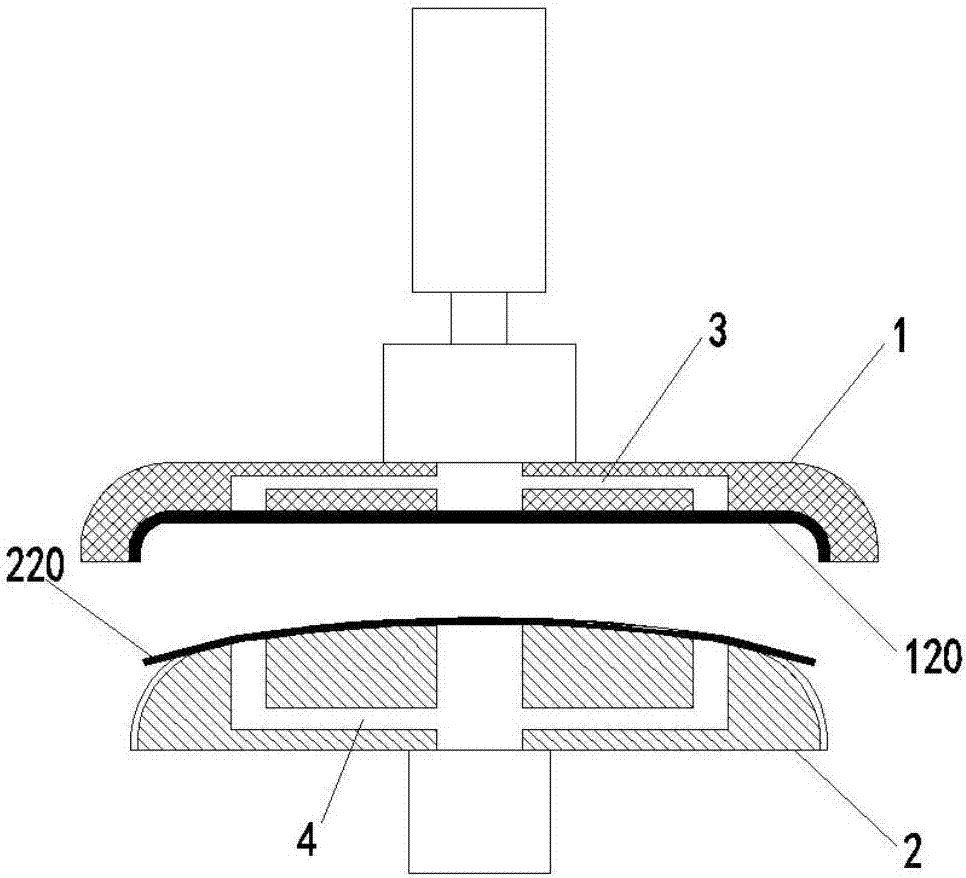

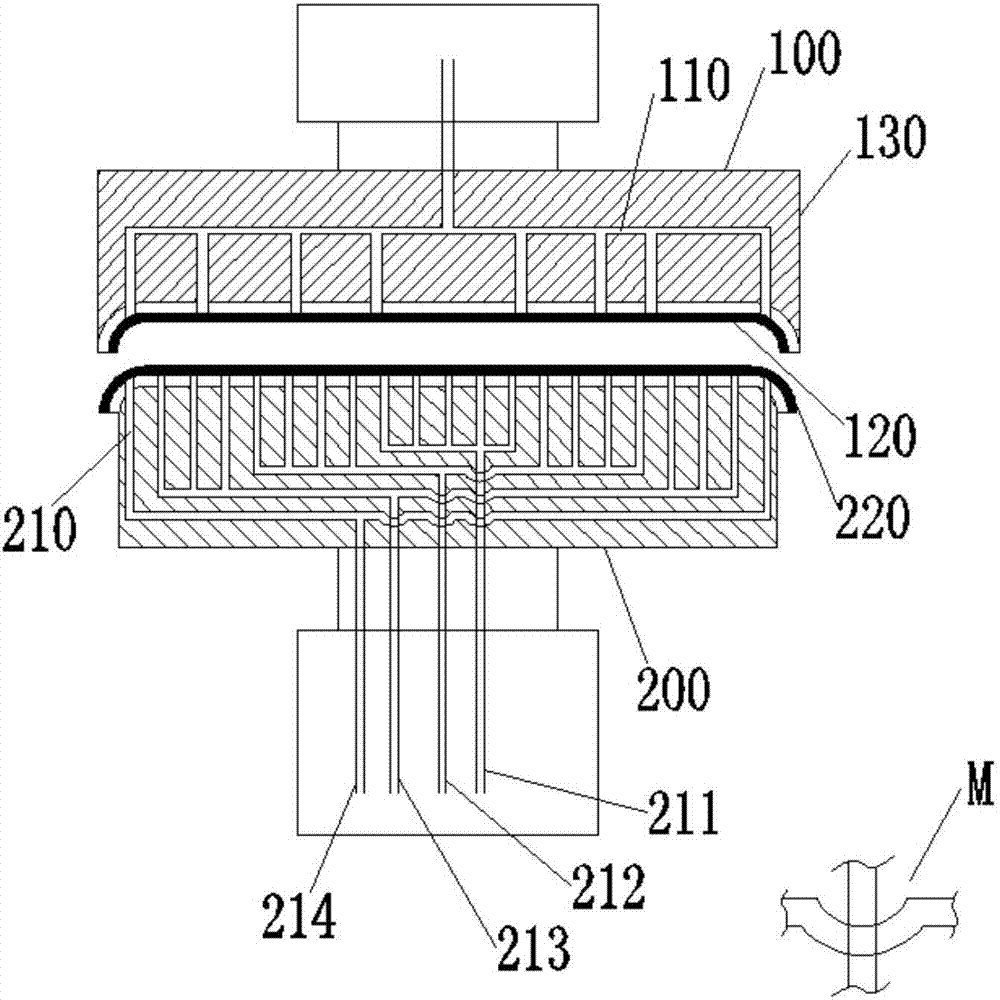

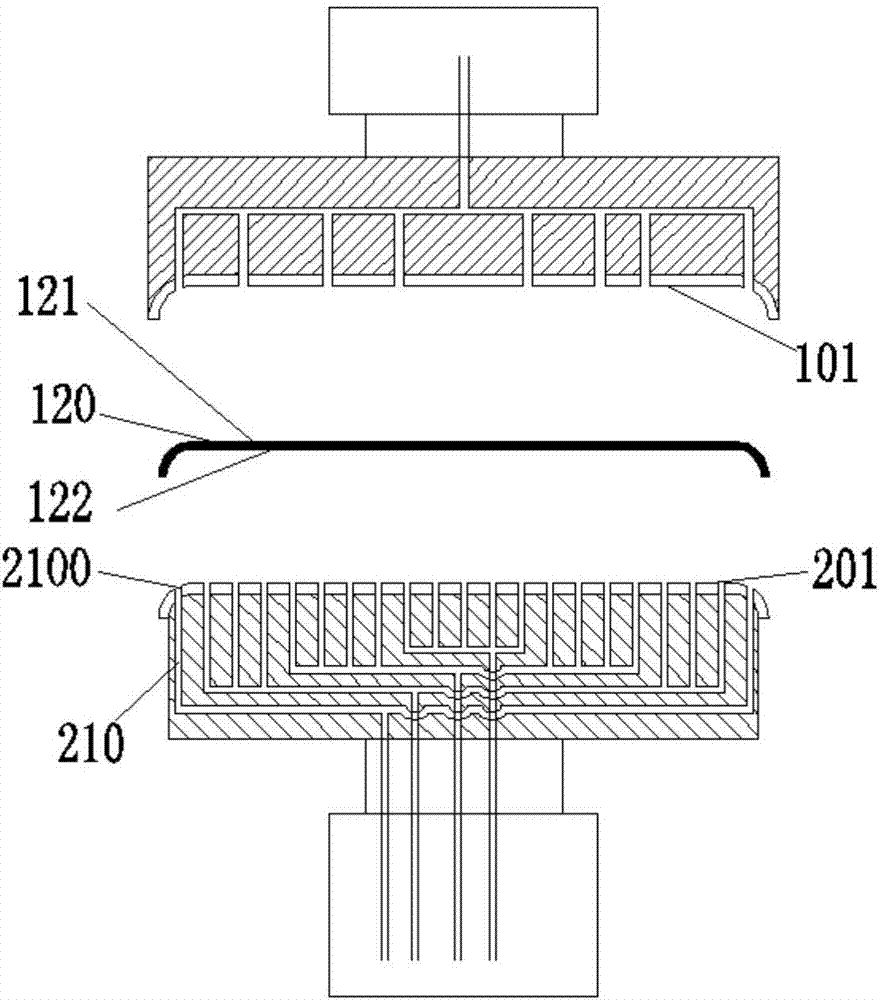

[0038] like Figure 2-6 As shown, this embodiment provides a device for bonding curved surfaces of flexible panels, which includes a curved cover fixing platform 100 and a flexible panel adsorption platform 200. Above the adsorption table 200 , the main body 130 of the curved cover plate fixing table is made of metal material, and the curved surface shape of the curved cover plate is that the edge of the curved surface of the cover plate is curved. The curved cover plate fixing platform 100 includes an adsorption hole 110 for fixing the curved surface cover plate 120 and a first working contact surface for fixing the curved surface cover plate 120 , the first working contact surface faces the flexible panel adsorption platform 200 . Preferably, the curved cover plate fixing table 100 further includes a contact pad 101 , and the first working contact surface is the surface of the contact pad 101 facing the flexible panel adsorption table 200 . The shape of the first working co...

Embodiment 2

[0043] The flexible panel curved surface laminating device provided in this embodiment is roughly the same as that in Embodiment 1, the difference is that, as Figure 7 As shown, in this embodiment, the flexible panel adsorption table 200 is located above the curved cover plate adsorption table 100. In this way, after the vacuum is released from the adsorption hole 210 in any area, the flexible panel 220 is attached to the corresponding position of the area. When the surface of the cover plate 120 is curved, due to the effect of gravity, the fit between the two will be more compact, further reducing the generation rate of air bubbles.

Embodiment 3

[0045] like Figure 2-6 As shown, this embodiment provides a method for bonding curved surfaces. When the flexible panel 220 is to be bonded, the flexible panel 220 and the curved cover 120 are close to each other but not in contact. Preferably, the curved cover 120 is fixed on the curved cover fixing platform 100 through the adsorption channel 110, the flexible panel 220 is adsorbed on the flexible panel adsorption platform 200 through the adsorption channel 210, and after image alignment and correction, the flexible panel The suction table 200 and the curved cover plate fixing table 100 approach each other and reach the position to be bonded, so that the flexible panel 220 and the curved cover plate 120 are close to each other but not in contact. The above preferred mode does not constitute a limitation to the present invention, as long as the flexible panel 220 and the curved surface cover 120 are in a position to be bonded close to but not in contact with each other when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com