Method for processing soft soil foundation of high vacuum drainage filter pipe capable of being grouted

A treatment method and technology for soft soil foundations, which are applied in soil protection, infrastructure engineering, construction, etc., can solve the problem that the soil settlement and consolidation speed and post-construction settlement are difficult to meet the design and use requirements, and reduce the design of the superstructure. Life, upper foundation and structural damage, etc., to achieve the effect of shortening drainage consolidation time, reducing loss and slow decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

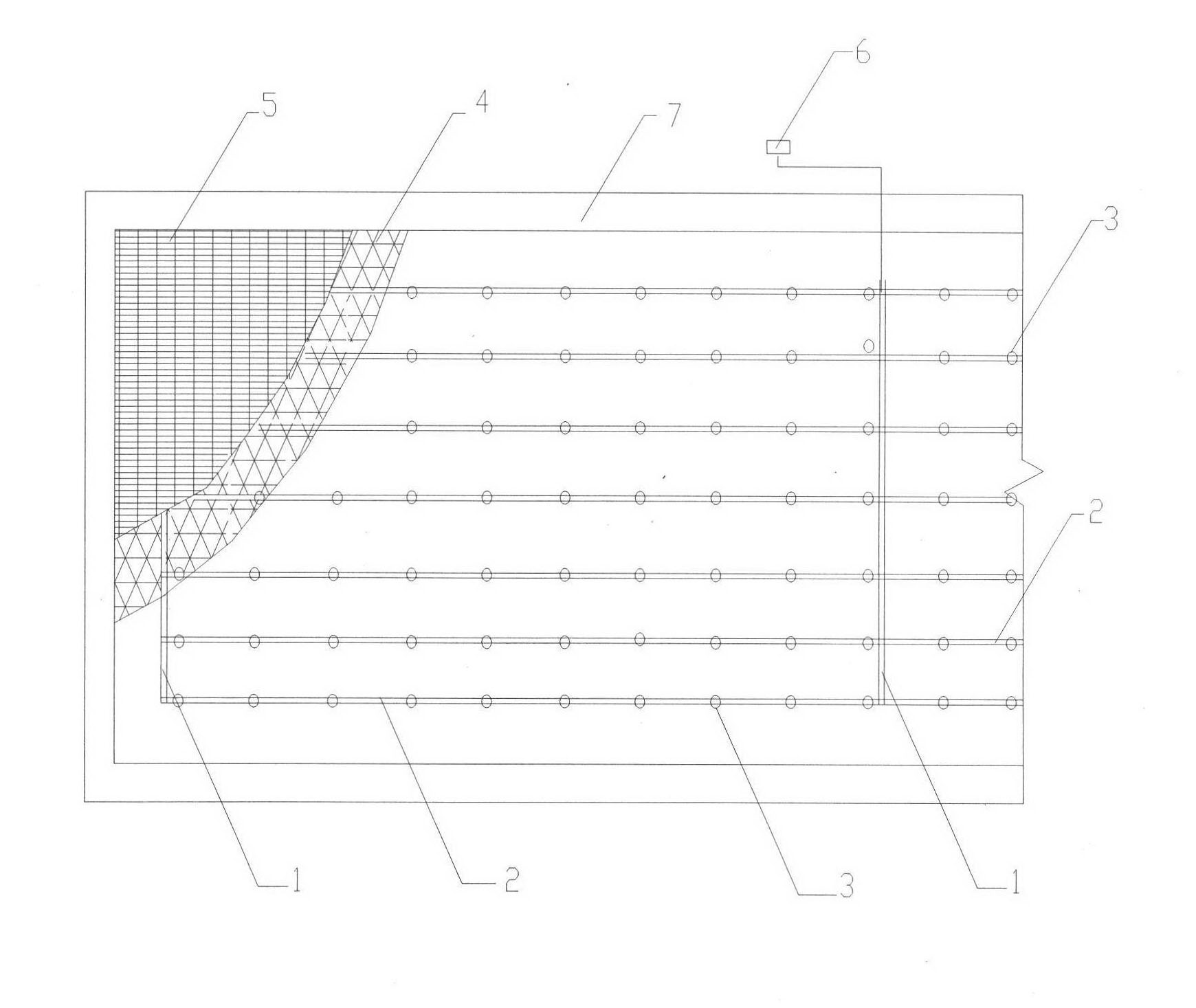

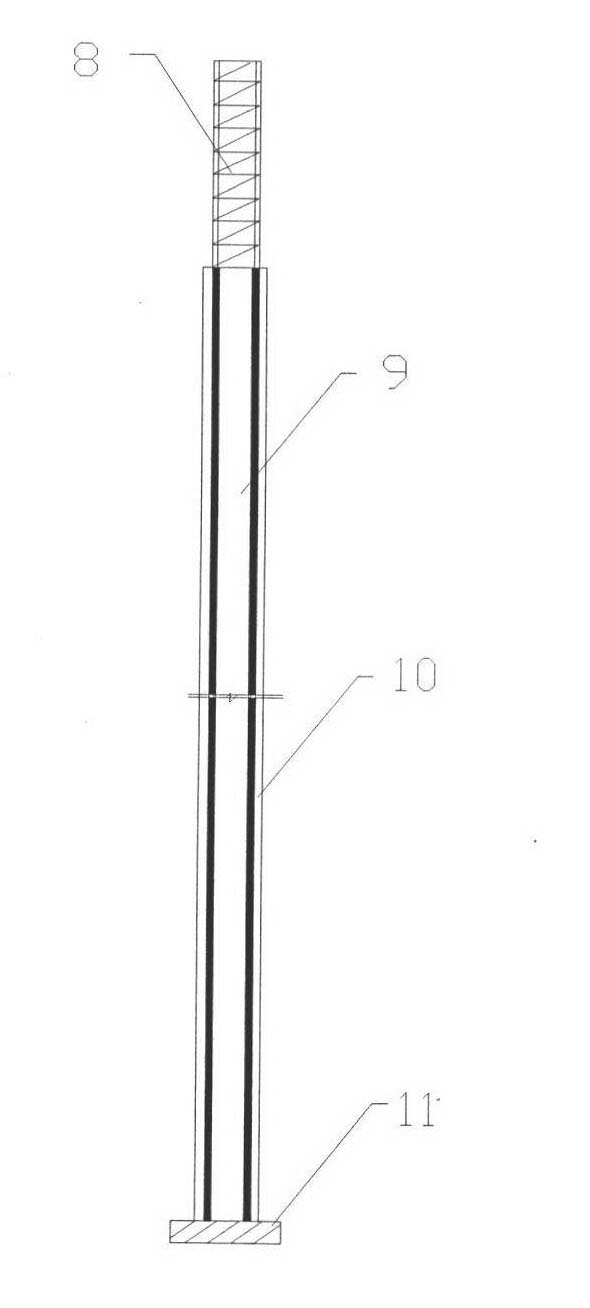

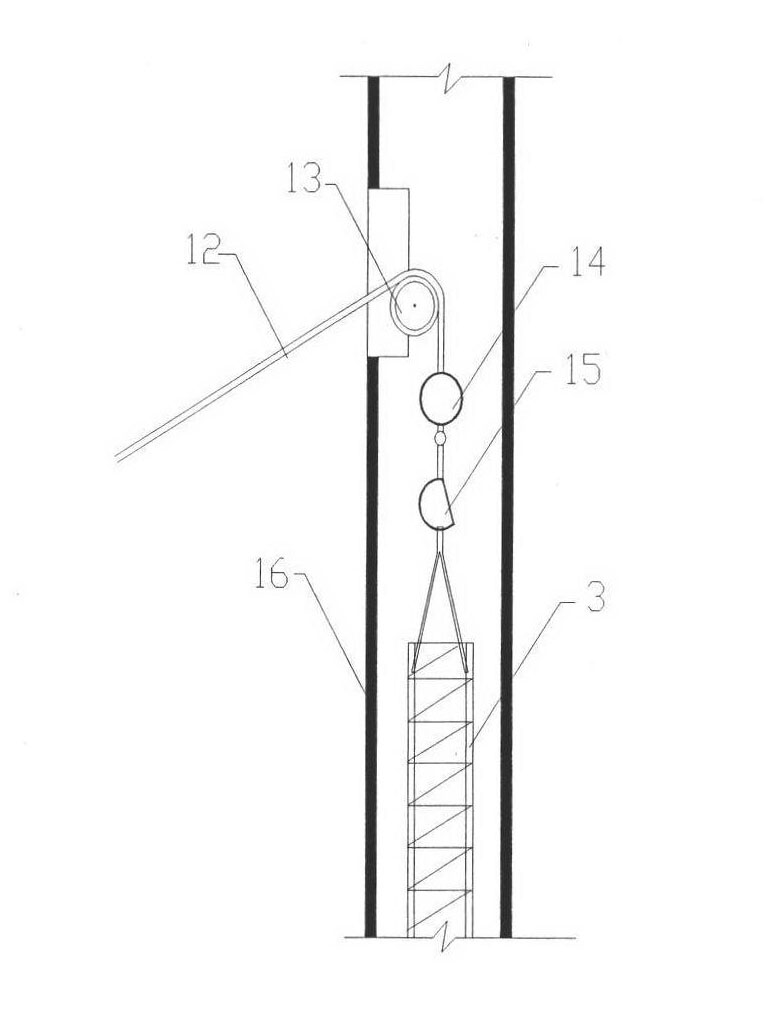

[0035] The technical idea of the present invention is to form a large channel and low friction connection mode of the horizontal drainage main pipe 1-horizontal drainage branch pipe 2-high vacuum vertical drainage filter pipe 3 during vacuum preloading, which slows down the high vacuum vertical drainage. The attenuation speed of the vacuum to the drainage filter pipe 3 shortens the drainage consolidation time of the soft soil. After vacuum unloading, the high-vacuum vertical drainage filter pipe 3 is used as the grouting pipe and pile formwork to grout the site soil, forming a cement mortar pile and a cement-soil composite foundation without drainage channels after construction. The physical and mechanical technical indicators of the treated foundation soil are significantly improved compared with the traditional drainage consolidation preloading technology; its post-construction settlement and bearing capacity can meet the technical requirements of roads, storage yards and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com