Preparing method for high-performance magnesium alloy bar

A magnesium alloy, high-performance technology, used in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of low strain accumulation efficiency, difficulty in meeting engineering requirements, and anisotropy decline, and overcome the strain deviation. Low, the effect of promoting dynamic recrystallization and improving yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

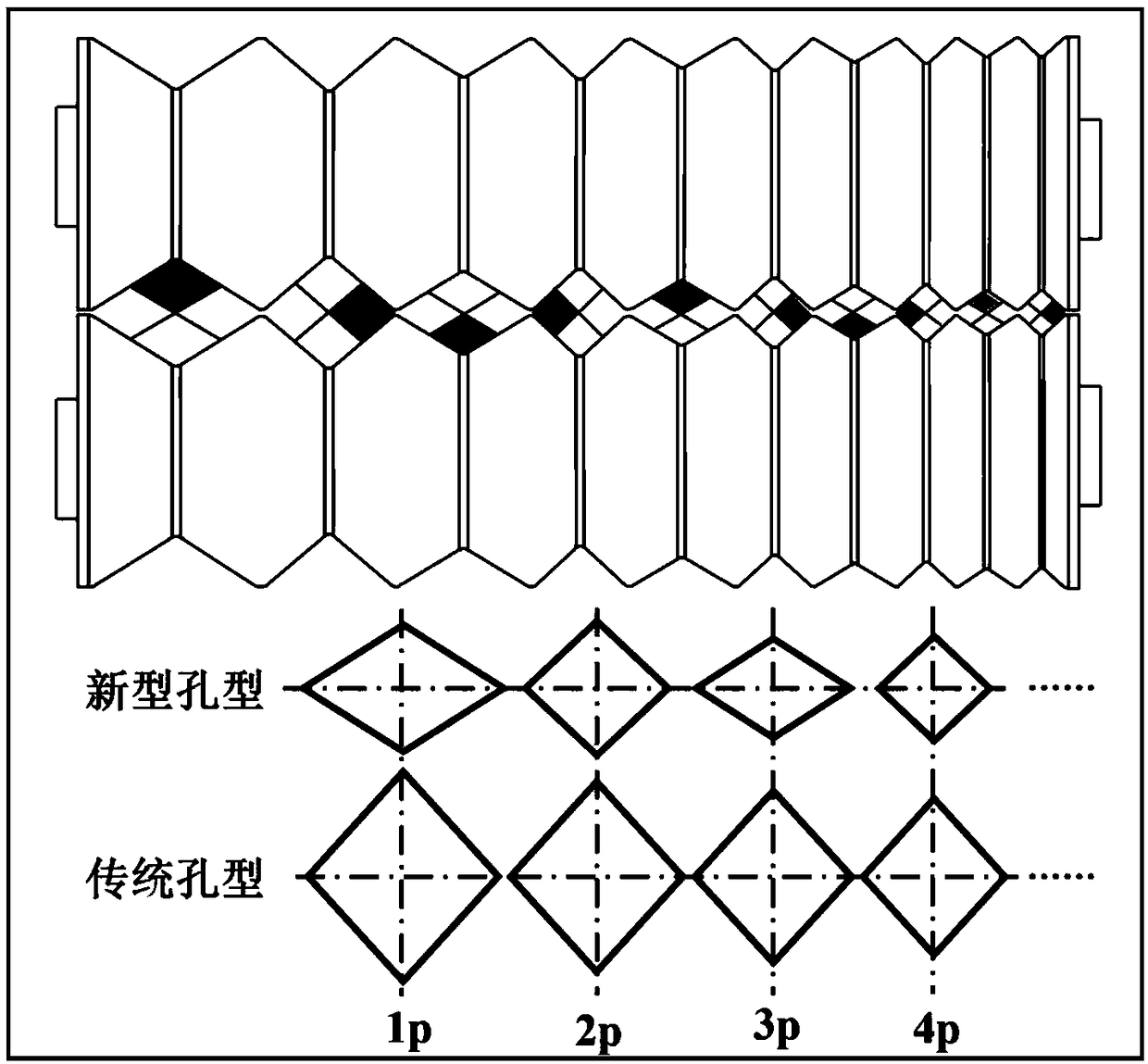

Embodiment 1

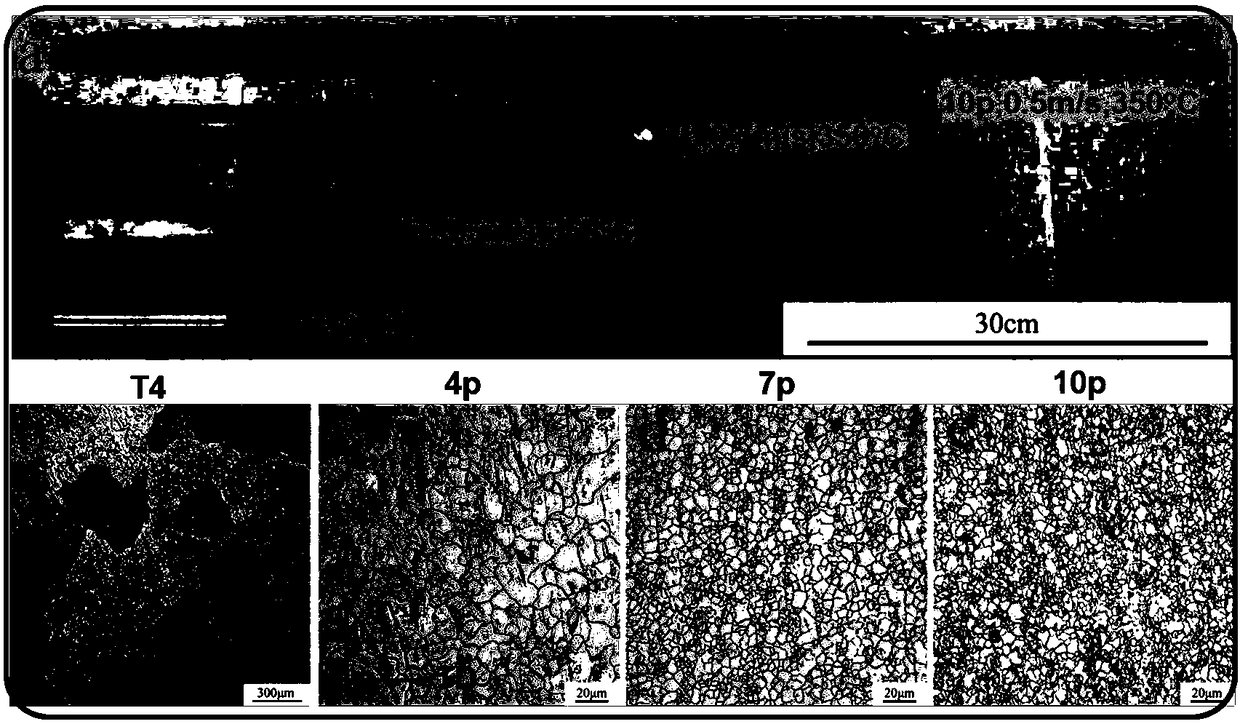

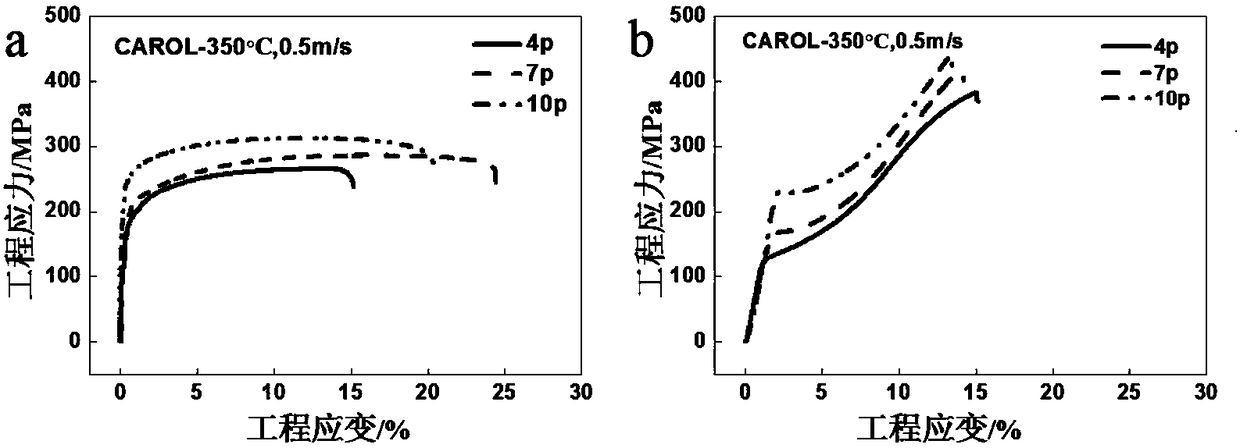

[0042] The billet whose composition is Mg-3.1Al-0.8Zn-0.4Mn (wt.%, AZ31) is selected, and after the selection is completed, its surface is treated with an angle grinder to remove its oil stain and scale. Afterwards, homogenize it, that is, place the billet in a heat treatment furnace filled with argon, raise the temperature to 400°C with the furnace, keep it warm for 8 hours, and then place it in warm water at 35°C for quenching. The homogenized billets were then machined into rods with a diameter d=35 mm. Preheat the machined bar to 350°C, and carry out groove rolling processing, with a rolling speed of 0.5m / s, and rolling 10 passes (during the groove rolling process, the number of passes is diamond hole-square hole pass-diamond hole pass - The order of the square hole passes is carried out alternately, that is, the diamond hole pass - the square hole pass alternately for 5 cycles, and the final rolling is set as square hole rolling; after each pass of rolling, the bar is rot...

Embodiment 2

[0047] The billet whose composition is Mg-3.1Al-0.8Zn-0.4Mn (wt.%, AZ31) is selected, and after the selection is completed, the surface is treated with 1000 mesh sandpaper to remove its oil stain and scale. Afterwards, homogenize it, that is, place the billet in a heat treatment furnace filled with argon, raise the temperature to 400°C with the furnace, keep it warm for 8 hours, and then place it in warm water at 35°C for quenching. The homogenized billets were then machined into rods with a diameter d=35 mm. Preheat the machined bar to 250°C, and carry out groove rolling processing. The rolling speed is 0.2m / s, and the rolling is 8 passes (during the groove rolling process, it is divided into diamond hole pass-square hole pass-diamond hole pass - The order of the square hole passes is carried out alternately, that is, the diamond hole pass - the square hole pass alternates 4 cycles, and the final rolling is set as the square hole rolling; after each pass is rolled, the bar is...

Embodiment 3

[0050] The billet whose composition is Mg-3.1Al-0.8Zn-0.4Mn (wt.%, AZ31) is selected, and after the selection is completed, its surface is treated with an angle grinder to remove its oil stain and scale. Afterwards, homogenize it, that is, place the billet in a heat treatment furnace filled with argon, raise the temperature to 400°C with the furnace, keep it warm for 8 hours, and then place it in warm water at 35°C for quenching. The homogenized billets were then machined into rods with a diameter d=35 mm. Preheat the machined bar to 250°C for groove rolling at a rolling speed of 0.5m / s for 8 passes (during the groove rolling process, the number of passes is diamond hole-square hole-diamond hole - The order of the square hole passes is carried out alternately, that is, the diamond hole pass - the square hole pass alternates 4 cycles, and the final rolling is set as the square hole rolling; after each pass is rolled, the bar is rotated 90° and immediately proceeds to the next p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com