Patents

Literature

31results about How to "Improve the problem of easy reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic diaphragm and preparation method thereof

InactiveCN109713204AIncrease coverageIncrease flexibilitySecondary cellsCell component detailsMethacrylatePolyolefin

The present invention provides a ceramic diaphragm comprising a diaphragm substrate having a surface coated with a polymer-coated functional ceramic powder. The polymer coating the surface of the ceramic powder is polystyrene sulfonic lithium (PSSLi) and a polyethylene glycol methacrylate hydrocarbon microporous diaphragm. The diaphragm substrate is a polyolefin microporous diaphragm. The polyethylene glycol methacrylate (PEGMA) has an average molecular weight of 400 to 5000 g / mol. The method provided by the invention comprises firstly activating the ceramic powder by using a silane coupling agent; then introducing a halogen functional group to graft the ceramic powder with a halogen initiator; adding sodium benzenesulfonate monomer (SSNa) and polyethylene glycol methacrylate (PEGMA) for apolymerization reaction; then adding the mixture to a lithium ion aqueous solution for ion exchange to obtain the polymer-coated functional ceramic powder; and finally stirring the polymer-coated functional ceramic powder to form a ceramic slurry and form the polymer-coated ceramic diaphragm by coating. The method provided by the present invention greatly improves the dispersibility and the functionality of lithium ions.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

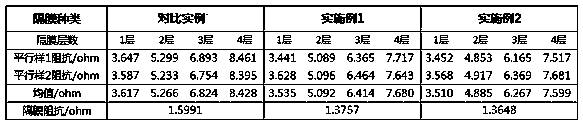

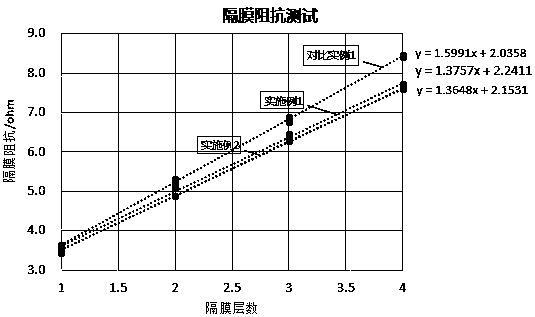

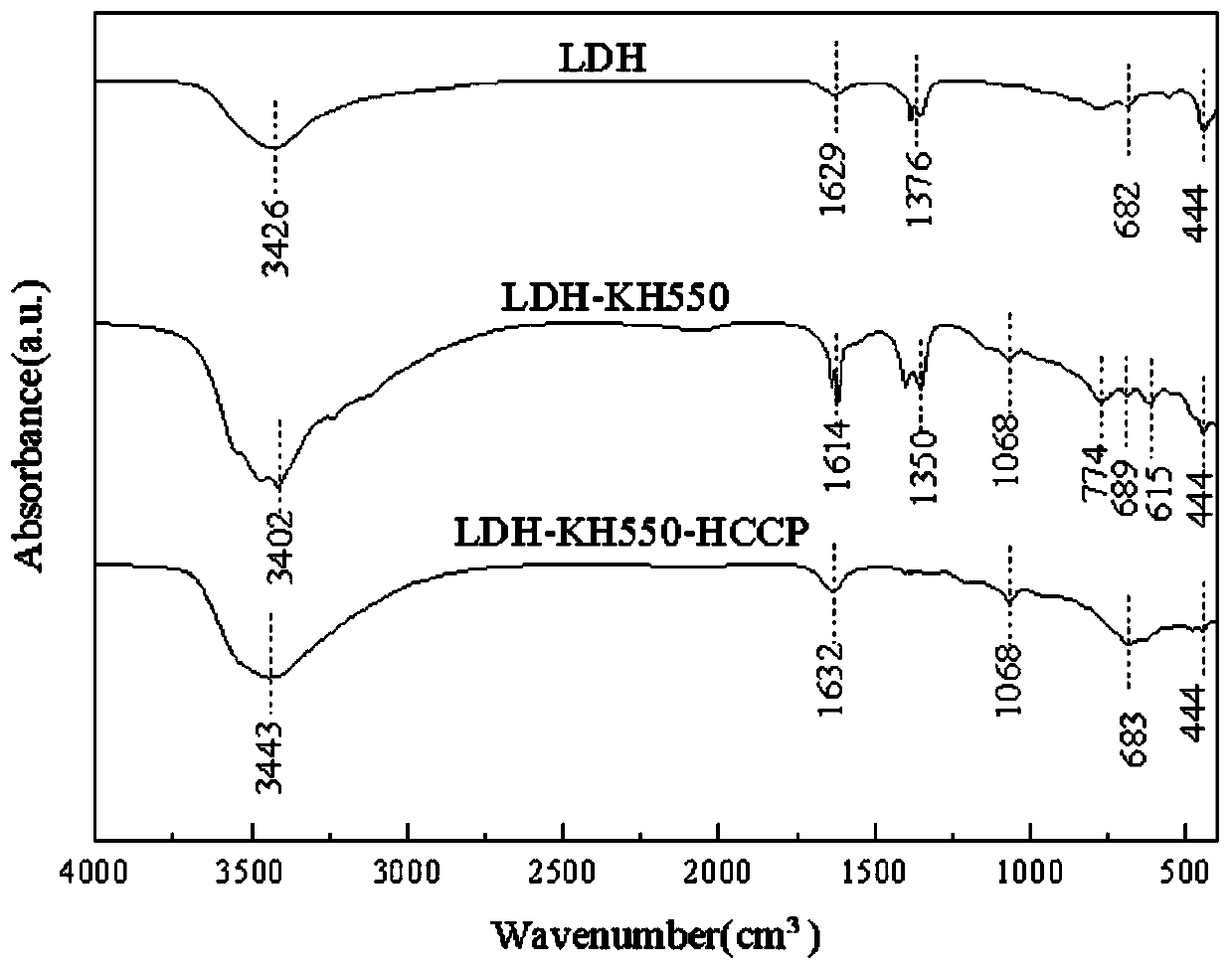

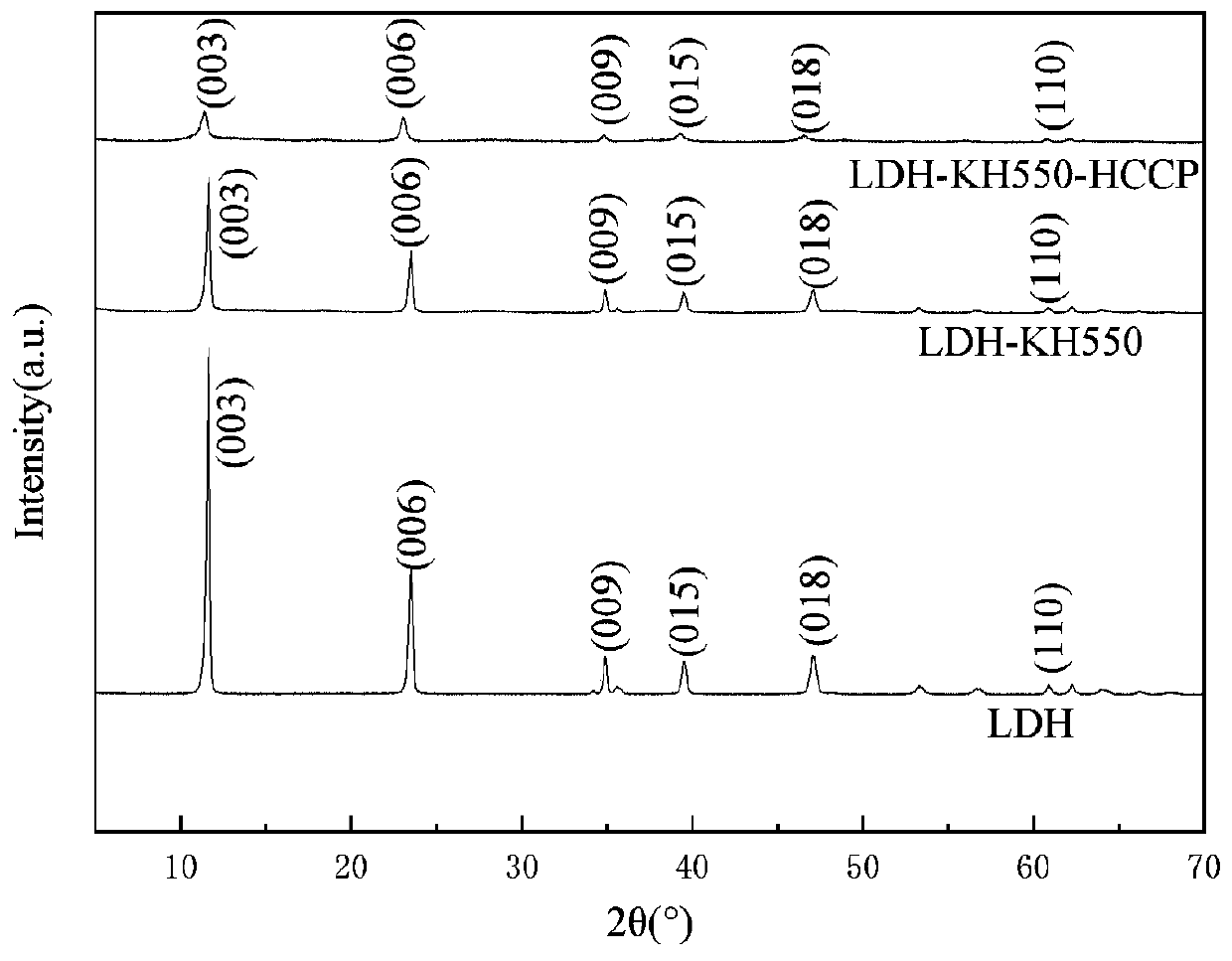

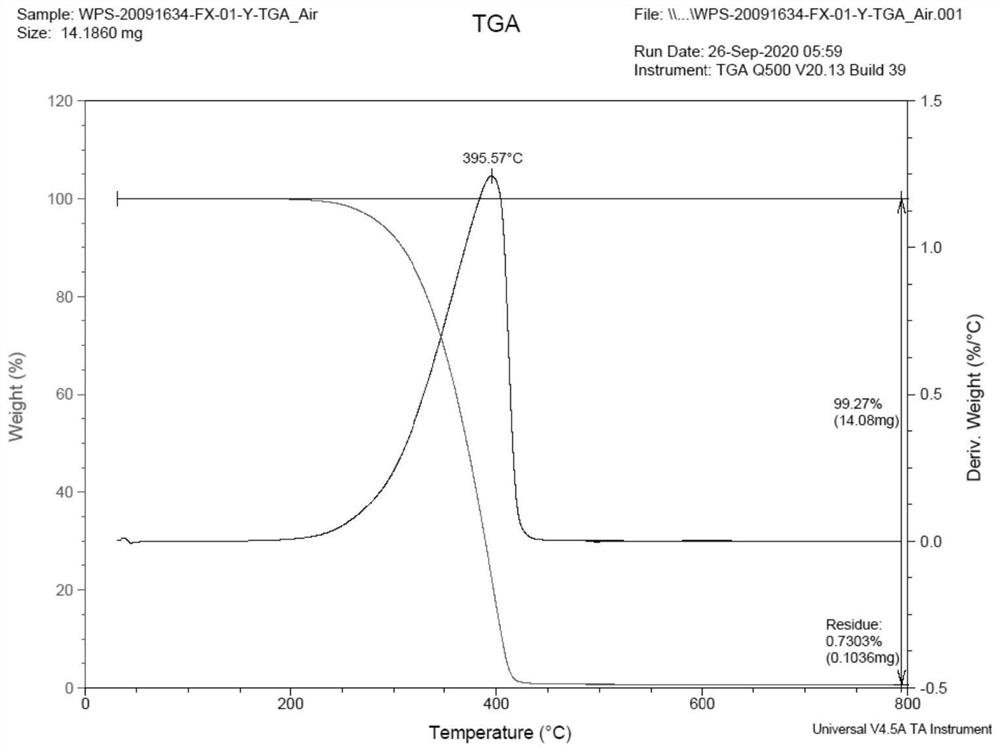

Phosphonitrile grafting-modified hydrotalcite flame retardant and preparation method thereof

InactiveCN110305370AImprove thermal stabilityImprove flame retardant performancePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsChemical LinkagePolymer science

The invention discloses a phosphonitrile grafting-modified hydrotalcite flame retardant and a preparation method thereof and belongs to the field of high-molecular flame retardance and interface chemistry. The preparation method comprises subjecting an amino-containing silane coupling agent to condensation with surface hydroxyl groups of hydrotalcite so that the silane coupling agent is grafted tothe surface of the hydrotalcite so as to introduce amino groups; allowing the amino groups to react with a phosphonitrile flame retardant, and grafting the phosphonitrile flame retardant to the surface of the hydrotalcite through chemical bonds. The invention is intended to graft a flame retardant, having rich flame-retarding elements, such as phosphorus and nitrogen, to the surface of hydrotalcite through chemical bonds so as to obtain novel hydrotalcite with surface modified by grafting the flame retardant; the modified hydrotalcite may be blended with various resin matrixes, so that flameretardance of the hydrotalcite is improved comprehensively, and dispersibility and compatibility of the hydrotalcite in the resin matrixes can be improved. The phosphonitrile grafting-modified hydrotalcite flame retardant prepared herein has good flame retardance, and is well compatible with resin matrixes; the preparation method is simple, has low cost and has a good actual application prospect.

Owner:XIANGTAN UNIV

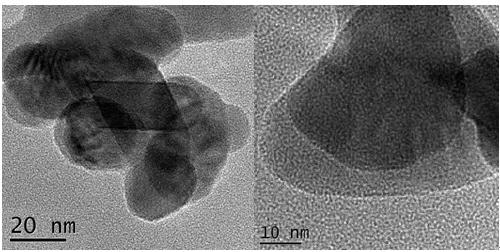

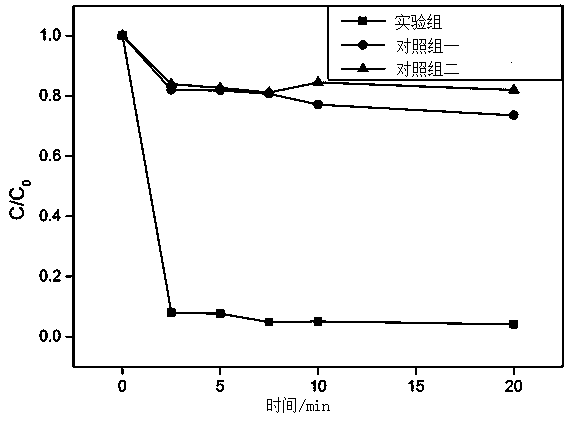

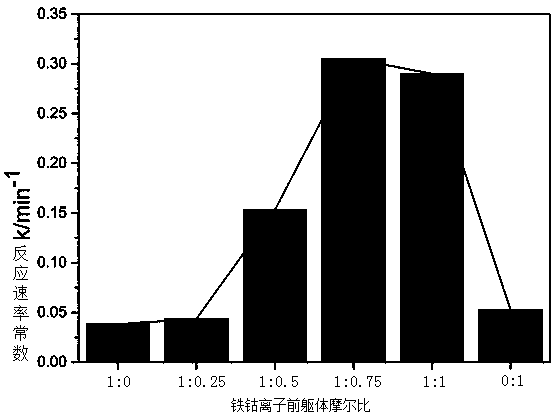

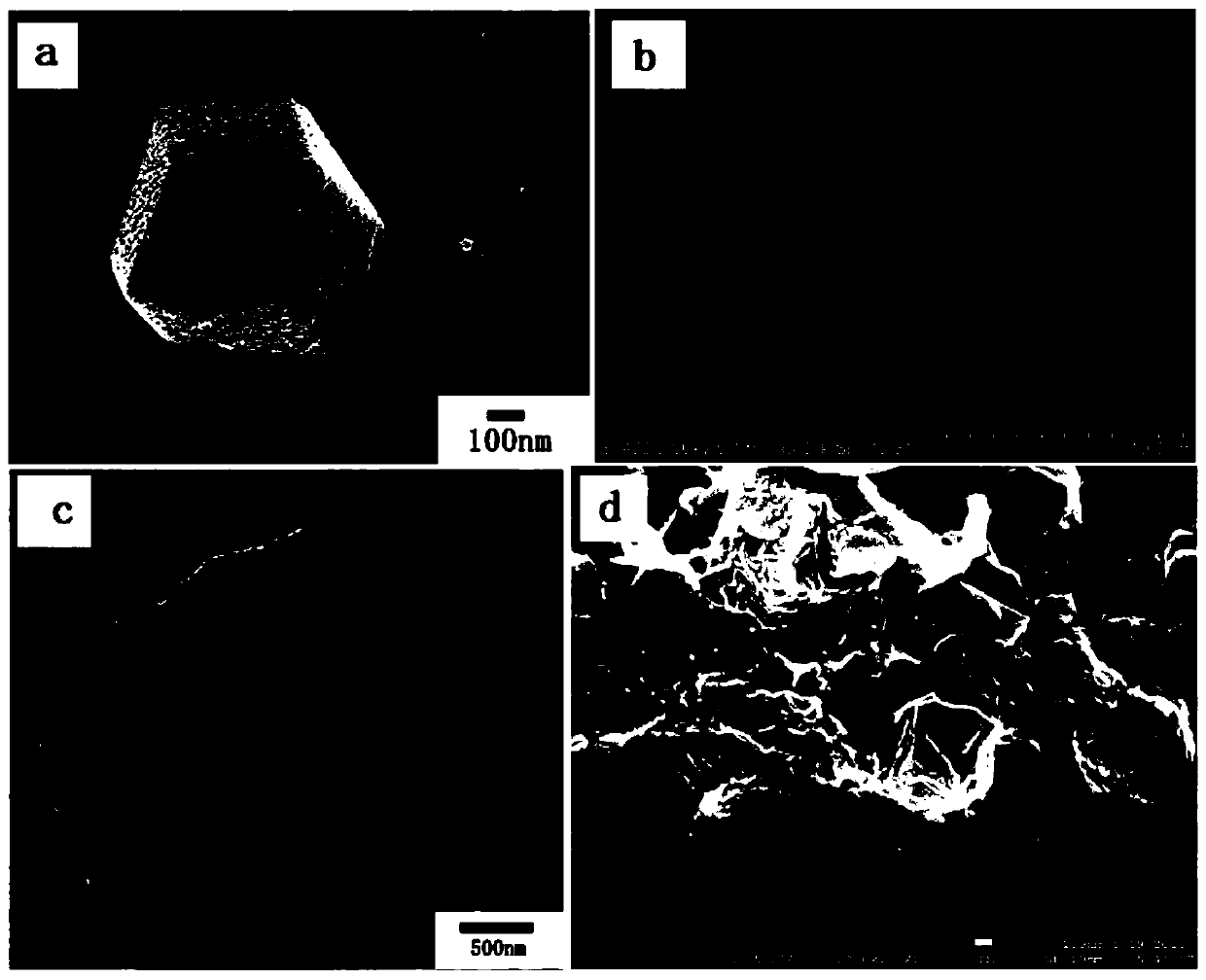

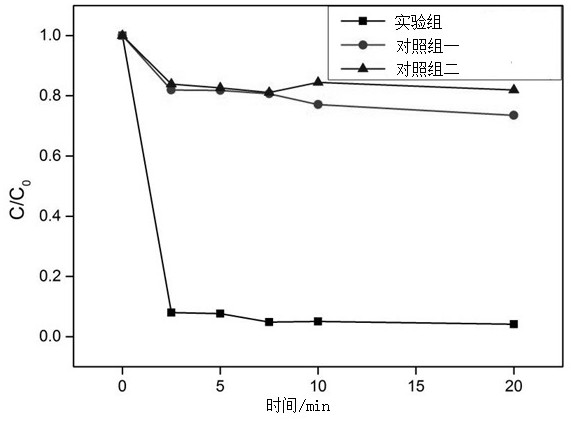

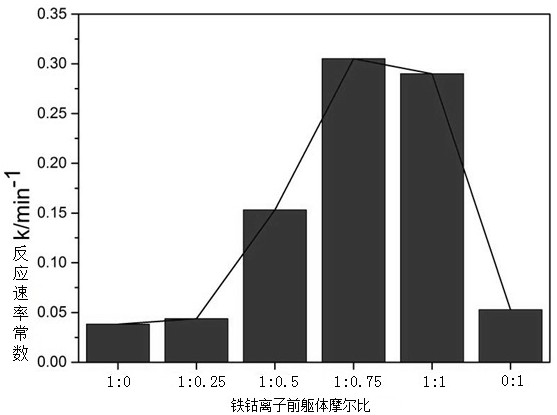

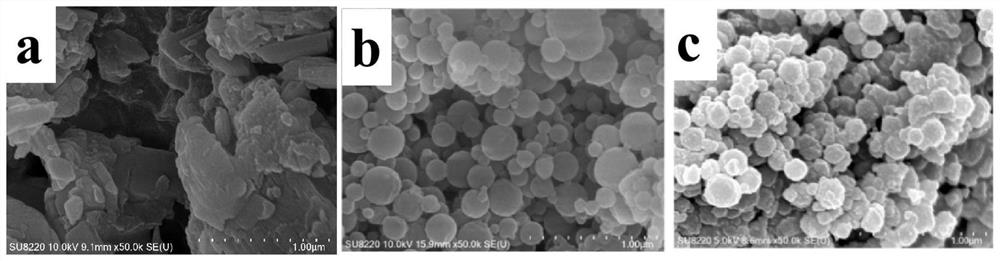

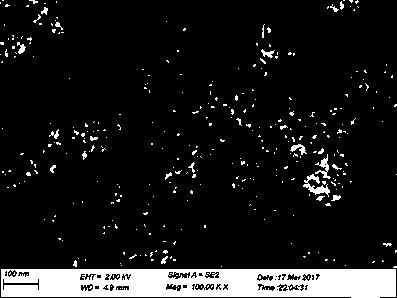

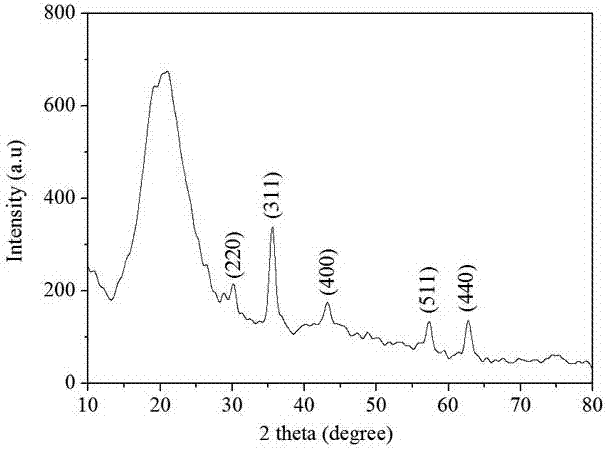

Preparation method and application of core-shell structural magnetic nano composite catalyst

ActiveCN110215921ARealize micro-controlHelp transferWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsFiltrationOxygen

The invention discloses a preparation method and application of a core-shell structural magnetic nano composite catalyst. The method comprises the following steps: step 1, dissolving a metal salt X containing Fe<2+> and a metal salt Y containing Co<2+> into deionized water, and performing uniform stirring to obtain a mixed liquid A; step 2, removing dissolved oxygen in the mixed liquid A by ultrasonic vibration or suction filtration to obtain a mixed liquid B; step 3, adding a NaOH solution dropwise into the mixed liquid B to obtain a mixed liquid C; step 4, performing reflux on the mixed liquid C under heating and stirring, allowing the liquid to stand, taking out a product, performing alternated washing for a plurality of times by using deionized water and absolute ethanol, performing drying, and performing grinding to obtain a powdery magnetic cobalt iron hydroxide; and step 5, performing calcination on the powdered magnetic cobalt iron hydroxide, performing grinding, and performingsieving to obtain the core-shell structural magnetic nano composite catalyst using Co3O4 as a shell and CoFe2O4 as a core. The preparation method provided by the invention has a simple and easily-operated process, and can realize microscopic regulation on the morphology of the composite catalyst, and forms a core-shell structure, thereby facilitating electron transfer in a catalytic reaction process.

Owner:CHONGQING UNIV

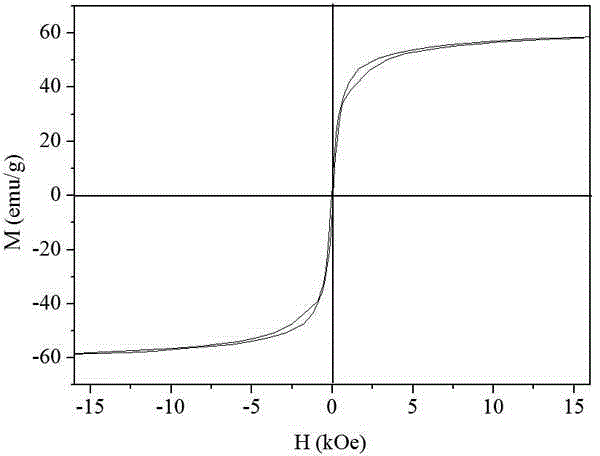

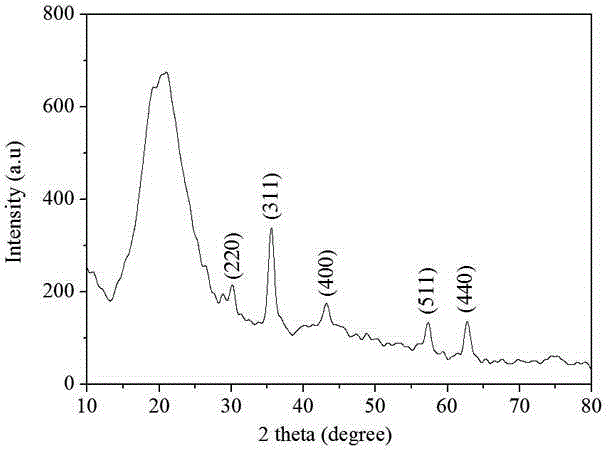

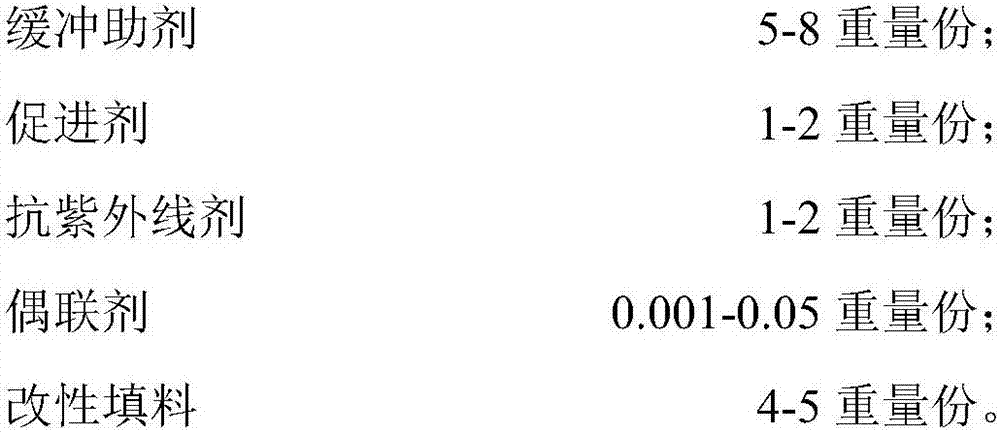

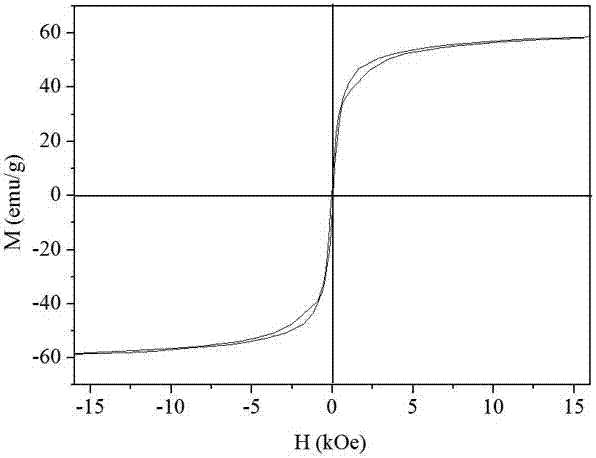

Preparation method for high-performance magnetic Fe3O4/polyurethane elastomer composite material

The invention relates to a preparation method for a magnetic composite material, and particularly to a preparation method for a high-performance magnetic Fe3O4 / polyurethane elastomer composite material, which solves the problems that the mechanical performance and magnetic performance of a current magnetic polyurethane elastomer composite material are difficult to improve simultaneously, and magnetic particles are smaller in filling amount and poor in dispersity, the scheme is that: 1) preparing Fe3O4 with FeCl2.4H2O, FeCl3.6H2O, a surface active agent and NaOH; adding an organic solvent for magnetic separation and purification; adding the organic solvent for ultrasonic dispersion so as to preparing an organic magnetic liquid; 2) adding tetrahydrofuran ether diol, and using anhydrous acid to adjust pH; adding toluene diisocyanate to obtain polyurethane prepolymer; adding chain extender, vacuumizing, defoaming and adding a magnetic field externally to heat and vulcanize, and preparing the Fe3O4 / polyurethane elastomer composite material. The preparation method for the high-performance magnetic Fe3O4 / polyurethane elastomer composite material has the advantages that: 1. Magnetic particles have good dispersity in the elastomer, and form a cross-linked structure with matrix; 2. inorganic acid is added, the viscosity of a polyurethane prepolymer system is reduced, and the high concentration adulteration of magnetic particles is guaranteed; and 4. the mechanical performance and magnetic performance of the magnetic polyurethane elastomer composite material are improved simultaneously.

Owner:ZHONGBEI UNIV

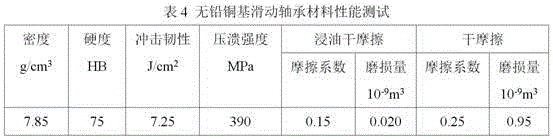

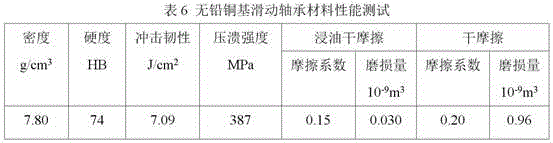

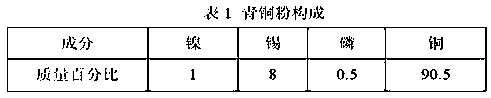

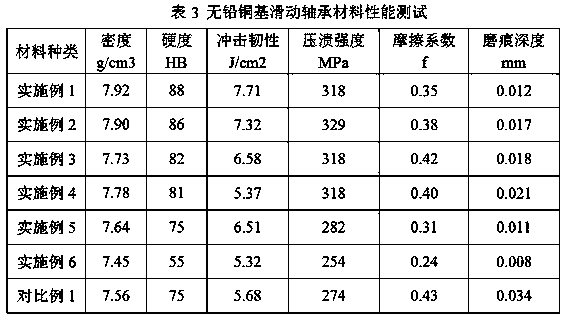

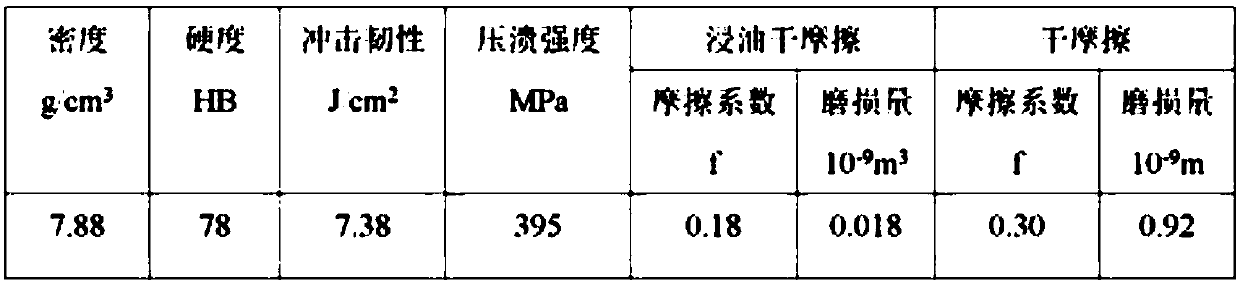

High-strength lead-free copper-base sliding material and preparing method thereof

The invention discloses a high-strength lead-free copper-base sliding bearing material and a preparing method thereof. FeS powder and bronze powder are mechanically alloyed through the ball milling technology, the interface bonding capability between FeS and copper is improved, FeS particles are evenly distributed in a copper base body, the defect that aggregating is likely to happen when the content of the FeS is high is overcome, the dispersion strengthening function of FeS can be brought into play, and the material mechanical performance is improved. According to the high-strength lead-free copper-base sliding bearing material and the preparing method thereof, the good solid self-lubricating capability of FeS is mainly utilized, the friction and abrasion performance of the lead-free copper-base sliding bearing material is improved, effective unification between the high strength and the good lubricating character of the copper-base sliding bearing material is achieved, and application of the lead-free copper-base bearing material under complex work conditions is widened.

Owner:HEFEI UNIV OF TECH

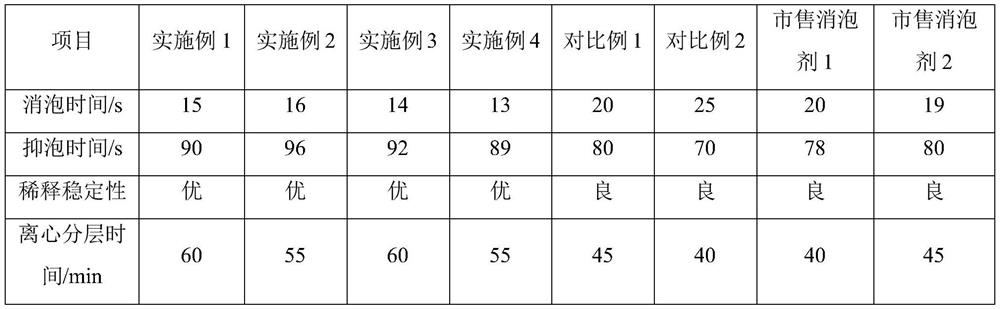

Polyether modified organic silicon defoamer safe to strains and preparation method thereof

PendingCN112057905AGood defoaming effectGuaranteed stabilityFoam dispersion/preventionMicrosphereCentrifugation

The invention belongs to the technical field of defoamers and discloses a polyether modified organic silicon defoamer safe to strains and a preparation method thereof. The preparation method includesthe following steps that: silicon dioxide nanometer microspheres, dimethyl silicone oil, DMF and deionized water are sequentially added into a reaction flask, ammonia water is added while stirring isconducted, heating is conducted to 50-70 DEG C, a reaction is conducted for 1-2 hours, cooling is conducted to the room temperature, and centrifugation is conducted, a precipitate is washed with ethanol, and drying is performed to obtain dimethicone grafted and modified silicon dioxide nano microspheres; 30-60 parts of the dimethicone grafted and modified silicon dioxide nano microspheres, 30-50 parts of polyether modified silicon oil, 1-10 parts of a thickener, 2-10 parts of an emulsifier and 10-50 parts of water are added into a dispersion tank, heating is conducted to 180-200 DEG C, stirring is performed for 2-3 hours, gradient cooling is carried out to 50-60 DEG C in a stirring state, and finally natural cooling is performed to obtain the polyether modified organic silicon defoamer. The defoamer has the advantages of being low in surface tension, high in defoaming speed, long in foam inhibition time, small in dosage, free of toxicity and harm to strains, wide in application range and the like.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

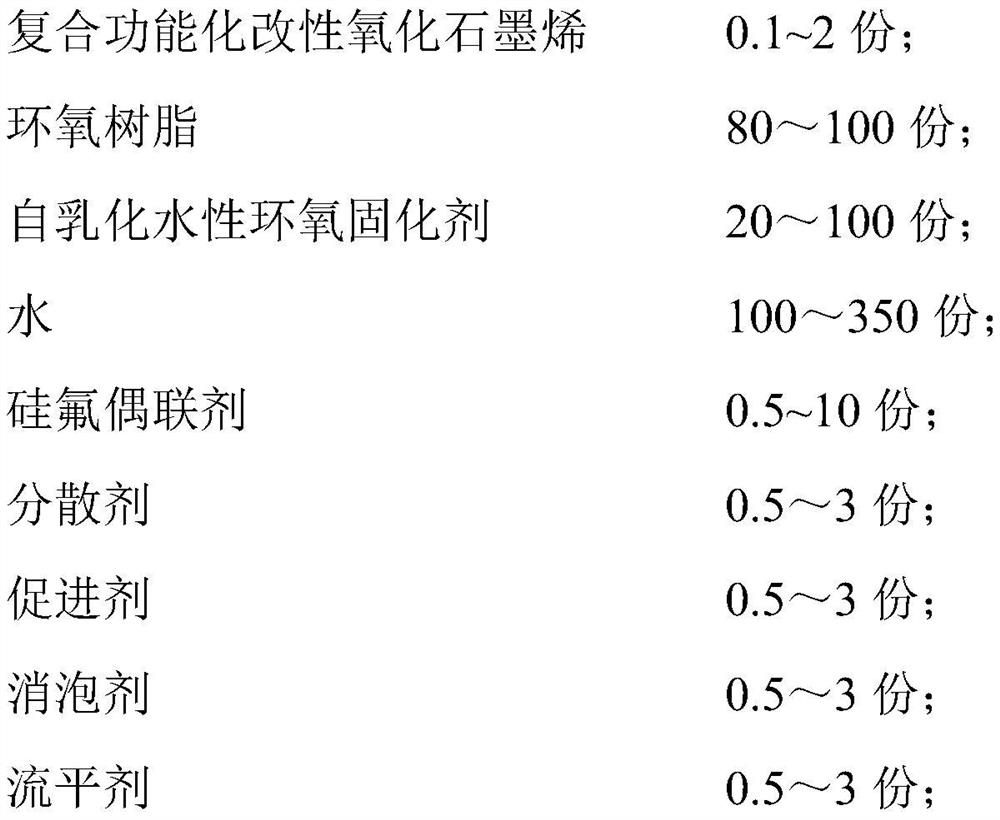

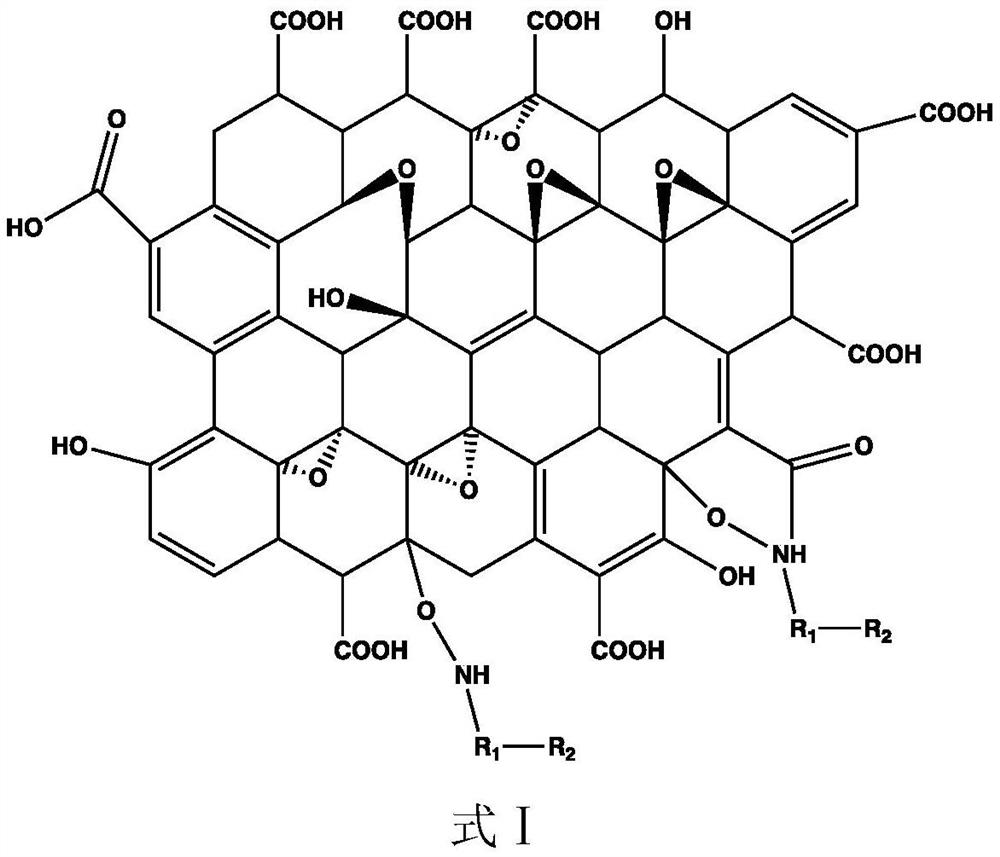

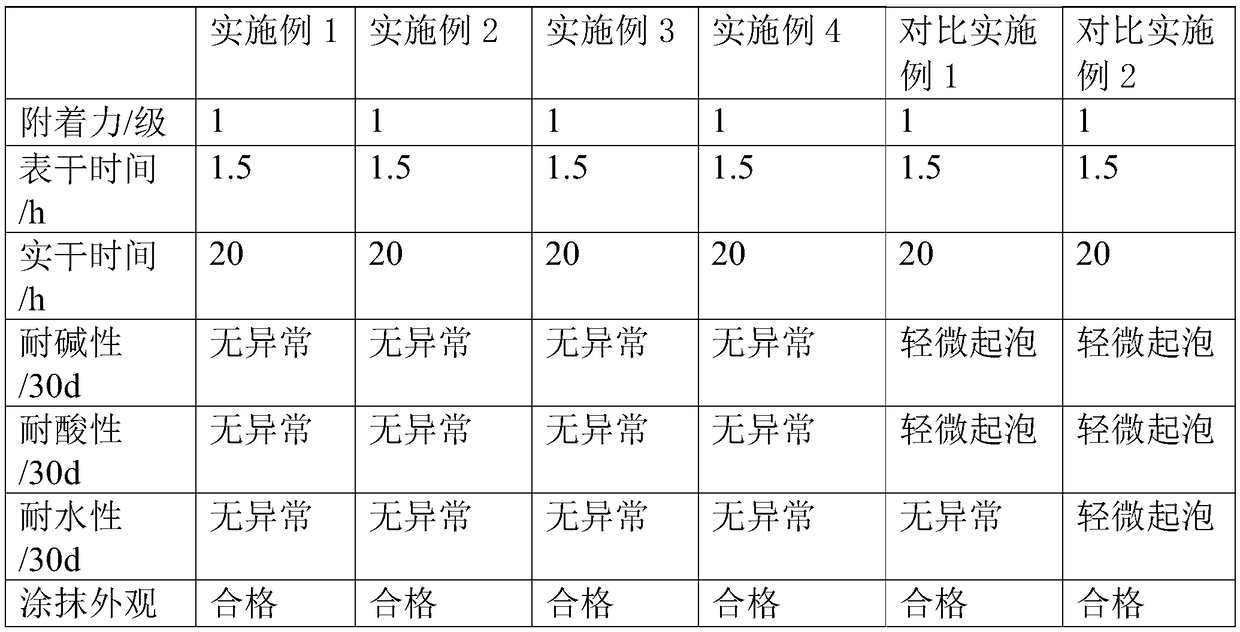

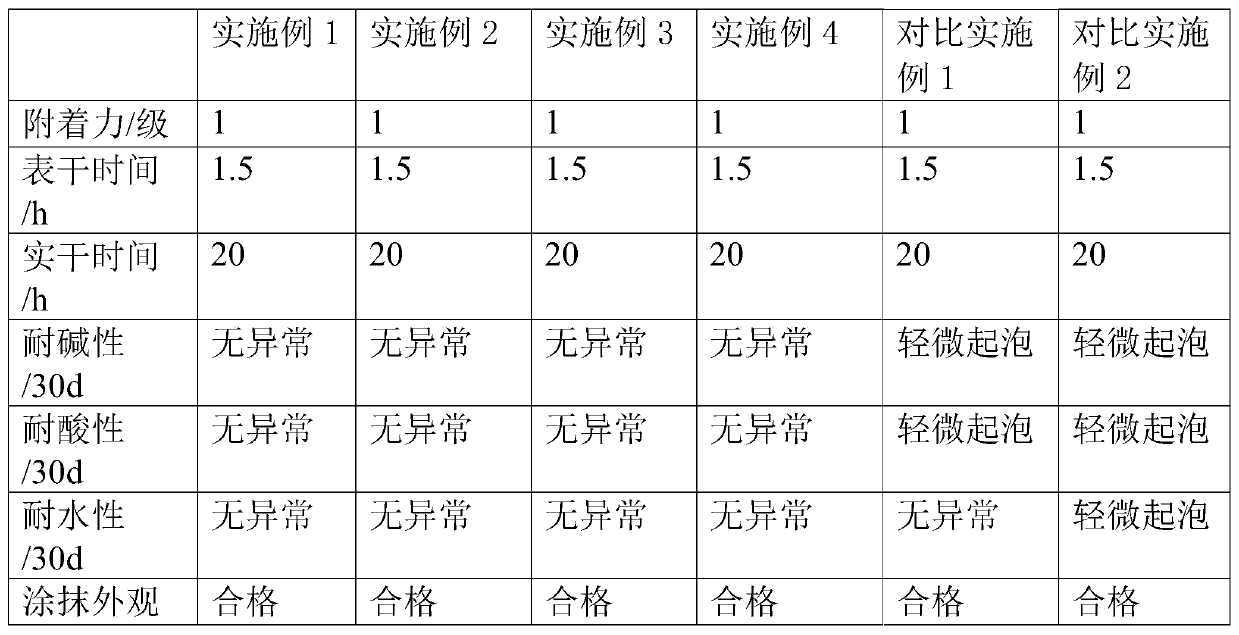

Waterborne epoxy anticorrosive paint containing composite functional modified graphene oxide and preparation method and application

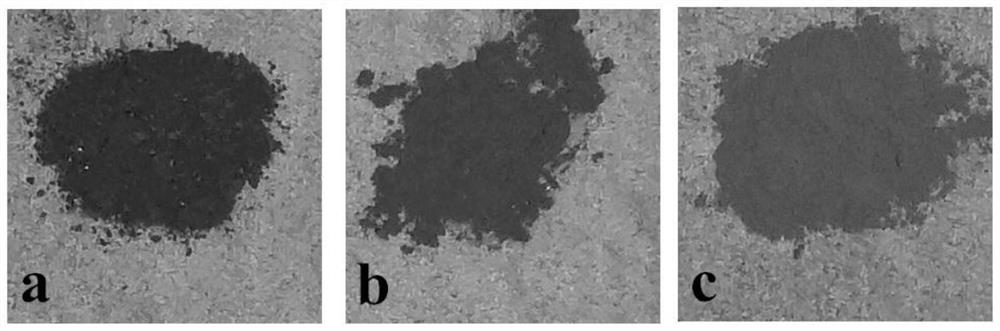

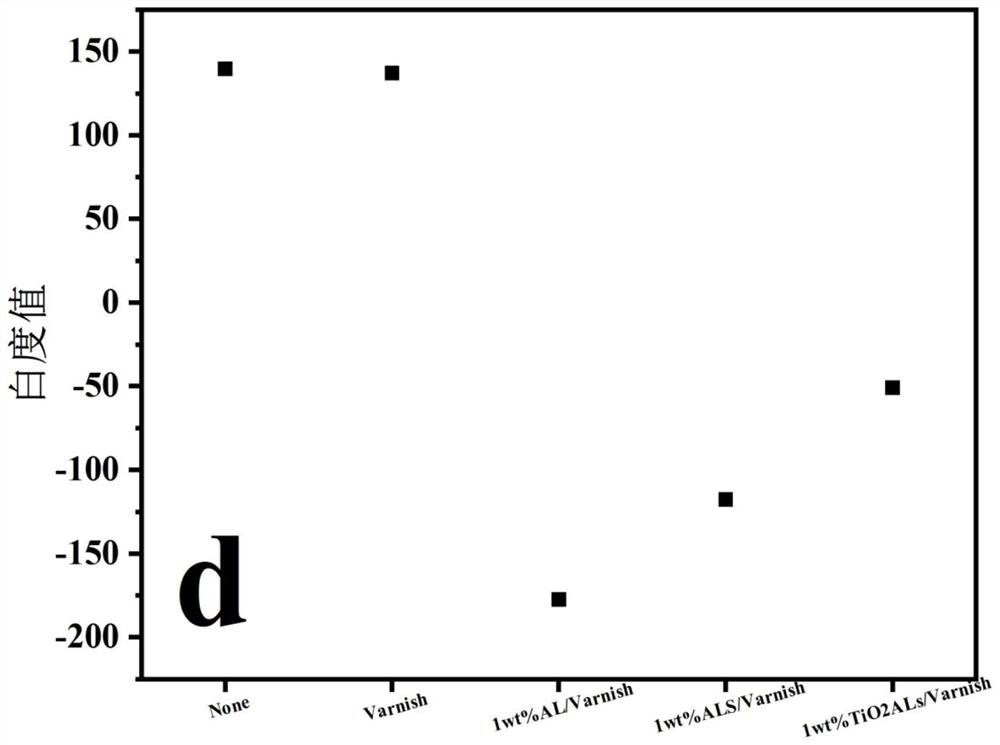

ActiveCN113956746AImprove the problem of easy reunionGood dispersionAnti-corrosive paintsEpoxy resin coatingsFirming agentBis epoxide

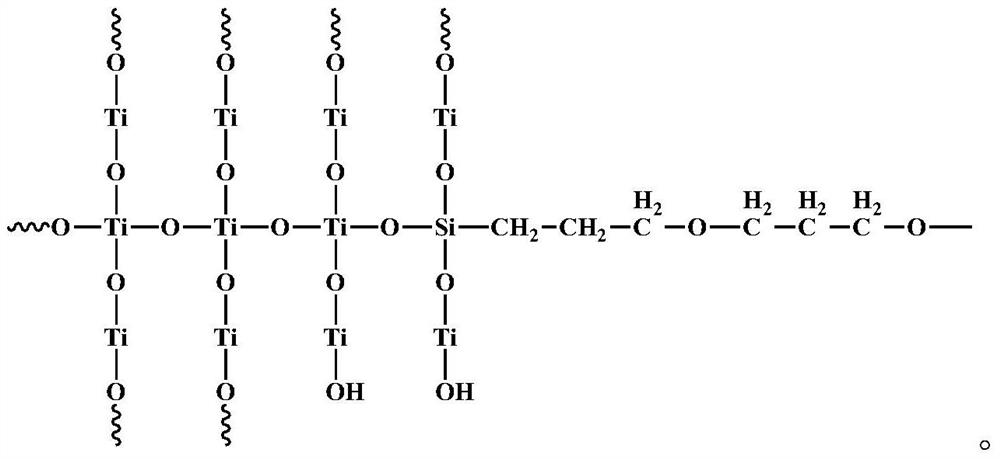

The invention belongs to the field of coatings, and discloses a waterborne epoxy anticorrosive coating containing composite functional modified graphene oxide and a preparation method and application. Graphene oxide is subjected to functional modification by adopting amino acid and titanium dioxide together to obtain composite functional modified graphene oxide, and the composite functional modified graphene oxide is used as a corrosion inhibitor to be compounded with a self-emulsifying waterborne epoxy curing agent, epoxy resin, a silicofluoride coupling agent, a dispersing agent, an accelerant, a defoaming agent and a flatting agent to form the anti-corrosion coating. The anticorrosive paint has excellent acid and alkali resistance, water resistance, salt fog resistance and hydrophobicity after forming a film, and can be applied to the field of metal corrosion prevention.

Owner:国科广化韶关新材料研究院 +3

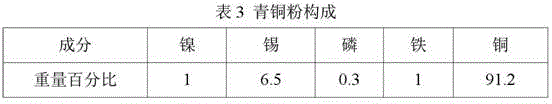

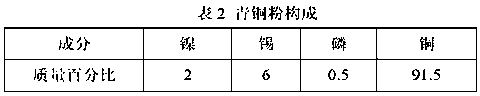

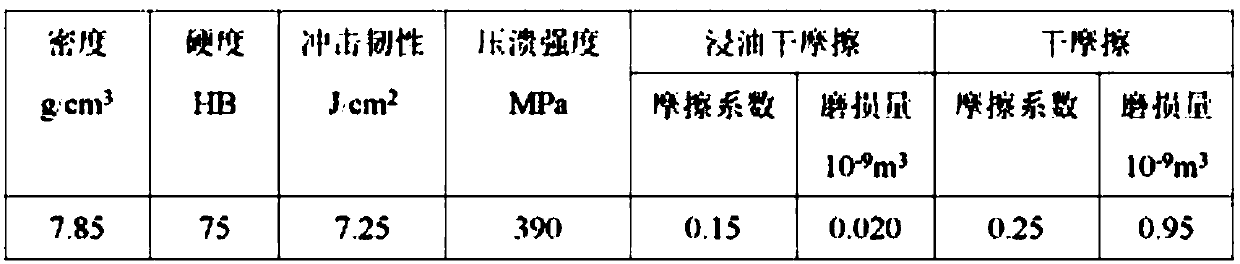

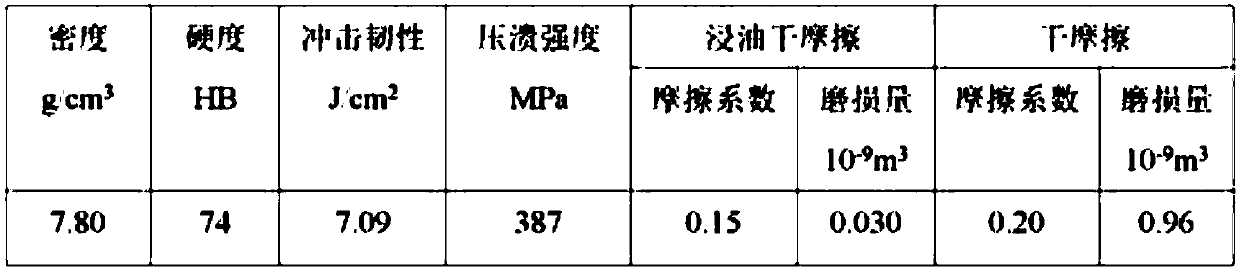

Antifriction lead-free copper-based sliding bearing material and preparation method thereof

InactiveCN108486404AImprove friction and wear propertiesAchieve lead-freeShaftsBearing componentsWear resistantBronze

The invention discloses an antifriction lead-free copper-based sliding bearing material and a preparation method thereof. The ferrous sulfide powder, the bismuth powder and the bronze powder are subjected to mechanical alloying by adopting a ball milling technology to improve the interface adhesive strength of the ferrous sulfide, the bismuth and the bronze, and the phenomenon that the ferrous sulfide is easy to agglomerate when the content of copper matrix is relatively high is improved, the structure of FeS is good in oil storage capacity, the stability of the liquid-solid lubricating film is enabled to be good, so that the process of Bi spalling, the fusion of the low-melting-point component Bi and separating out of the low-melting-point component Bi are relieved, and the liquid-solid lubricating film can also be repaired and completed, so that the antifriction performance of the material is improved; in conclusion, the antifriction and wear-resistant properties of the copper-basedsliding bearing material are improved, the lead which is used as a lubricant in the copper-based bearing material is replaced by the good synergistic effect of the ferrous sulfide and the bismuth, sothat the pollution of lead is avoided; and the antifriction lead-free copper-based sliding bearing material and the preparation method thereof have the advantages of being low in cost and suitable forindustrial production.

Owner:HEFEI UNIV OF TECH

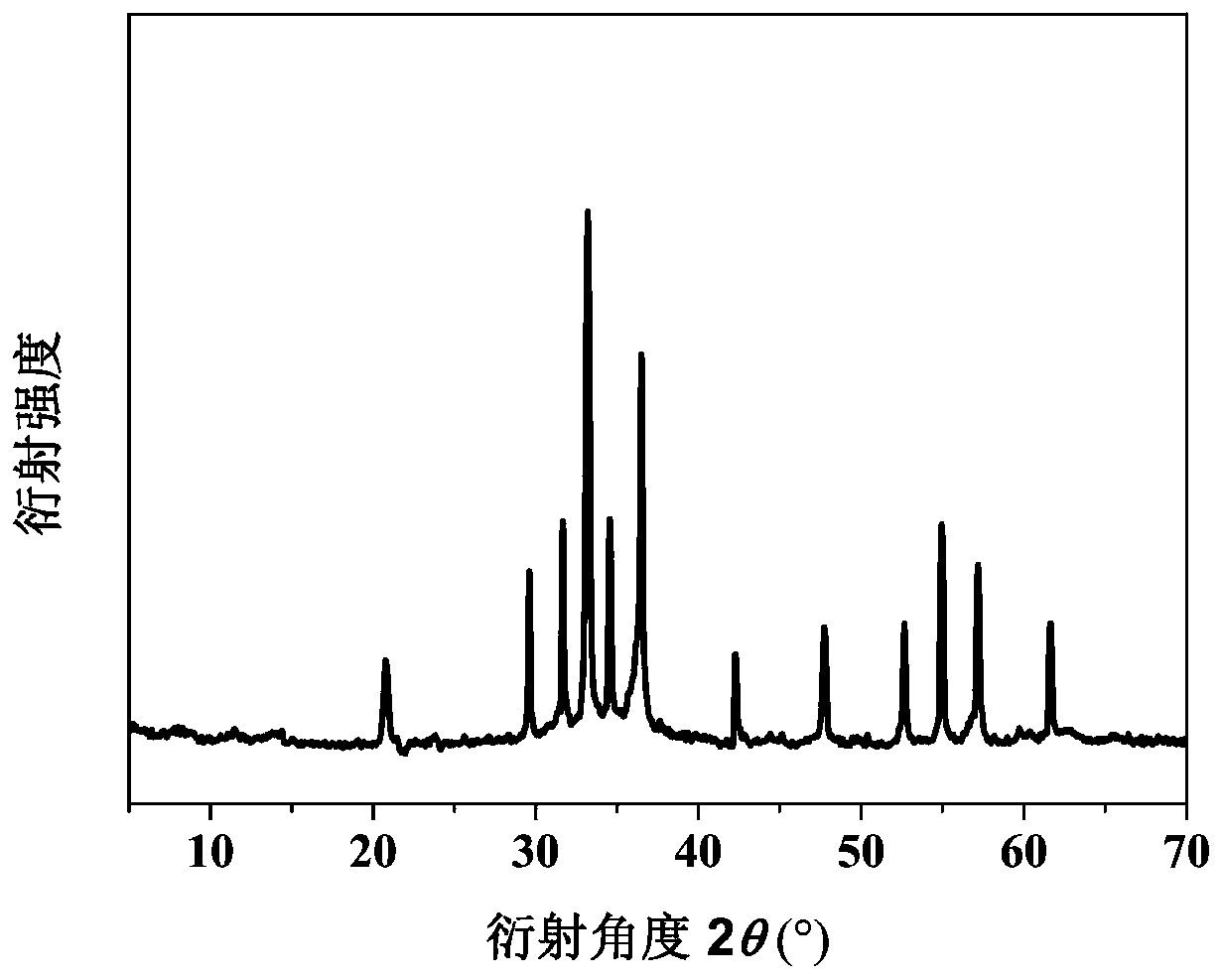

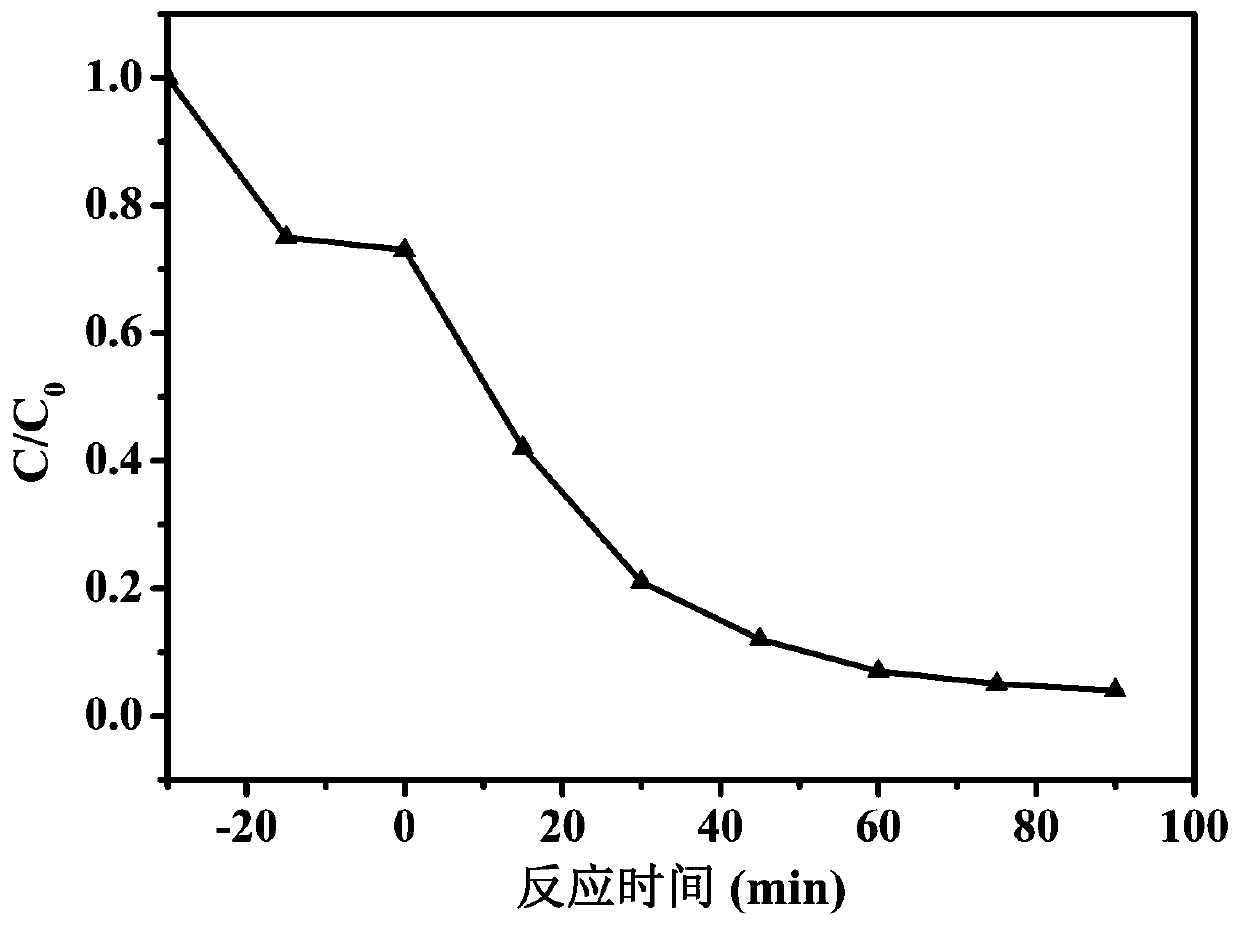

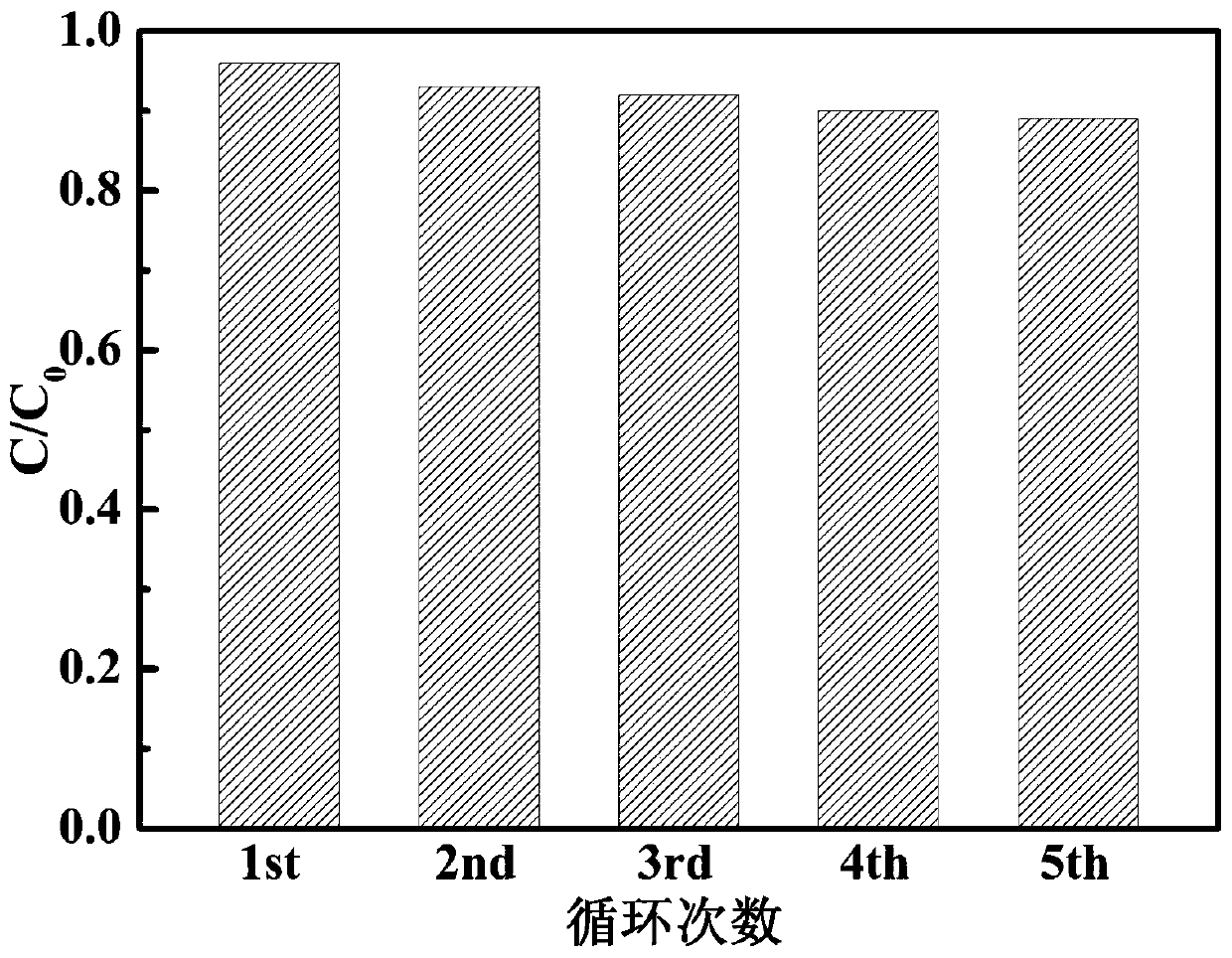

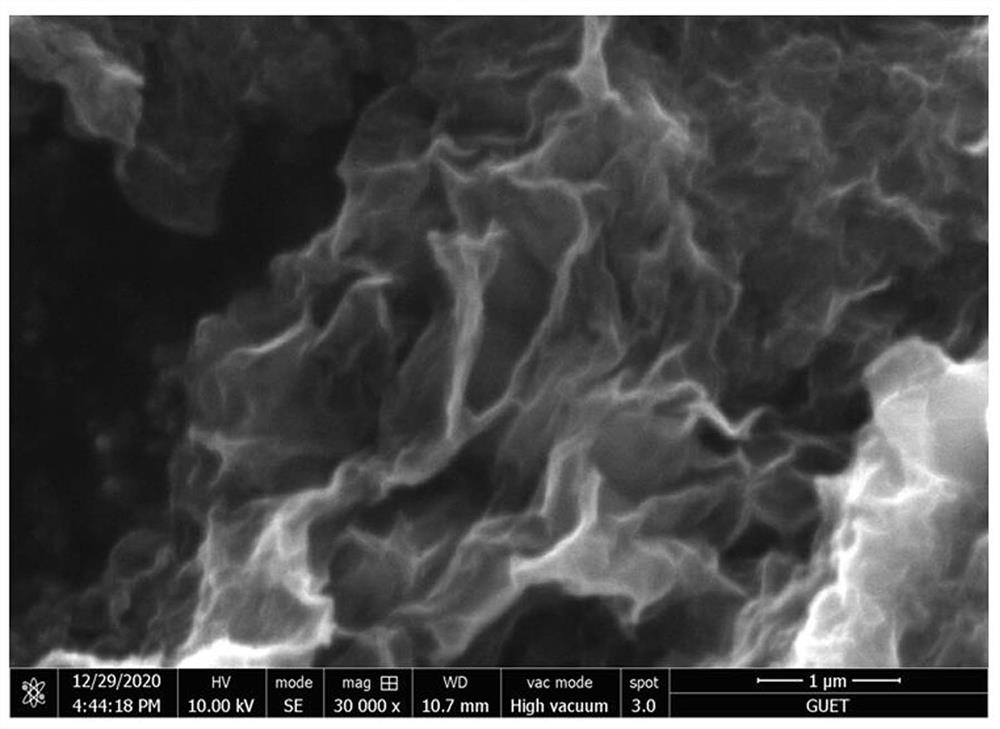

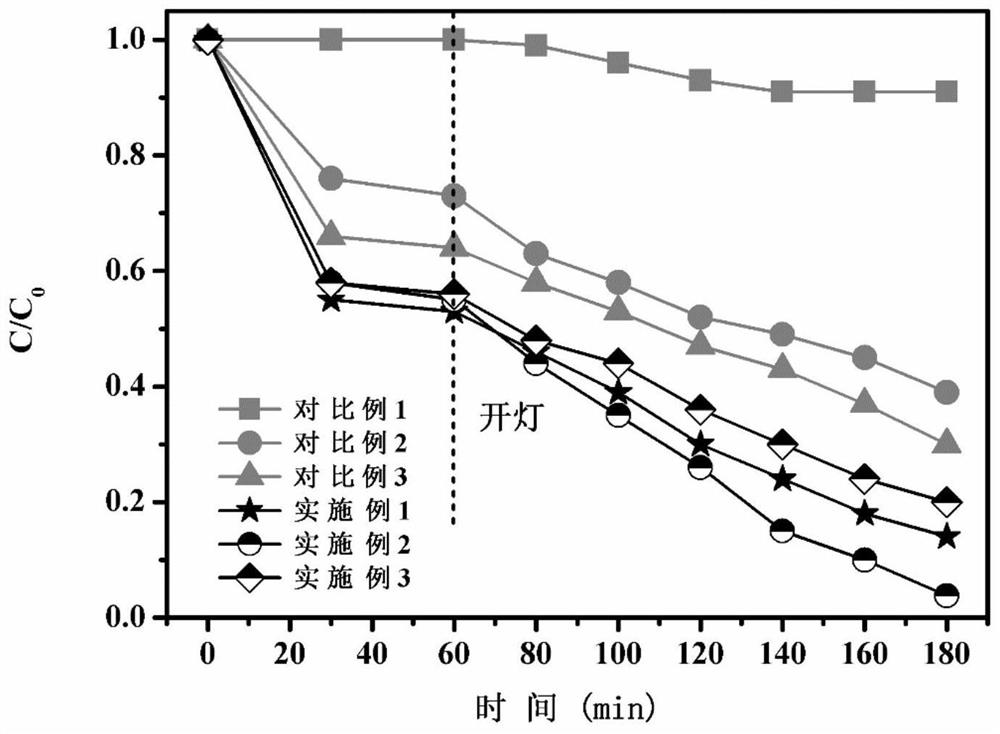

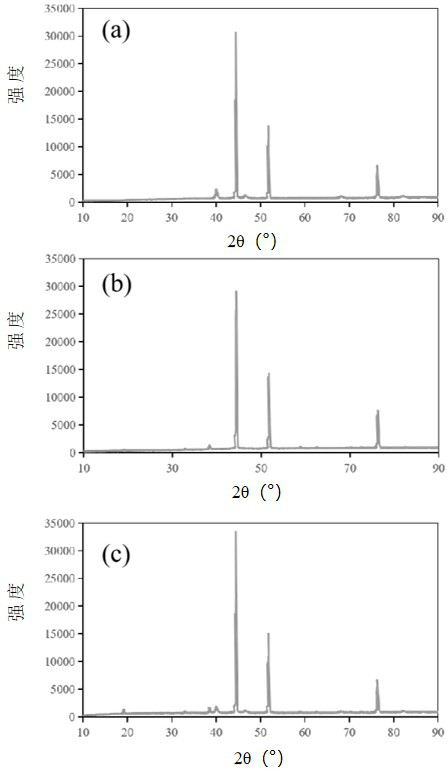

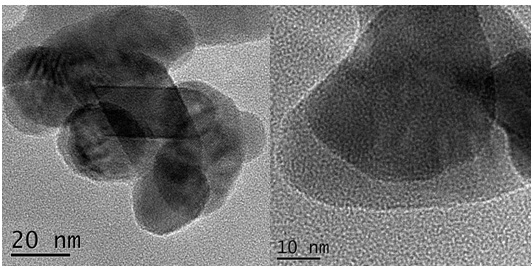

Preparation method of silver phosphate/metal oxide composite photocatalyst capable of efficiently degrading tetracycline

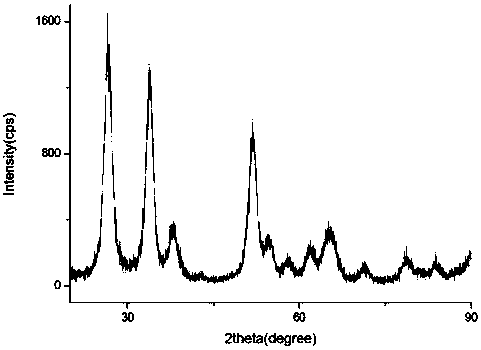

InactiveCN109985647AImprove the problem of easy reunionGood dispersionPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionOxide composite

The invention discloses a preparation method of a silver phosphate / metal oxide composite photocatalyst capable of efficiently degrading tetracycline, and belongs to the field of photocatalysis and inorganic nano materials. According to the preparation method disclosed by the invention, silver phosphate is grown on the surface of a metal oxide, so that the problem that silver phosphate nano particles are agglomerated easily can be effectively solved, and dispersibility of the silver phosphate nano particles is improved. A heterojunction formed by a special structure of the metal oxide and the silver phosphate with narrow band gaps can enhance separation efficiency of a photo-generated carrier, so that light corrosion of silver phosphate can be effectively inhibited, and stability of the catalyst is improved. The specific surface area and rich surface active sites of the metal oxide are beneficial to adsorption of pollutants onto the surface of the catalyst, so that photocatalytic activity is further improved. The prepared silver phosphate / metal oxide composite photocatalyst can efficiently degrade tetracycline under simulated sunlight, and has a good application value in the aspectof environmental pollution remediation. The preparation method disclosed by the invention is simple and feasible, cost is low, reaction conditions are easy to control and the preparation method is suitable for large-scale production.

Owner:XIANGTAN UNIV

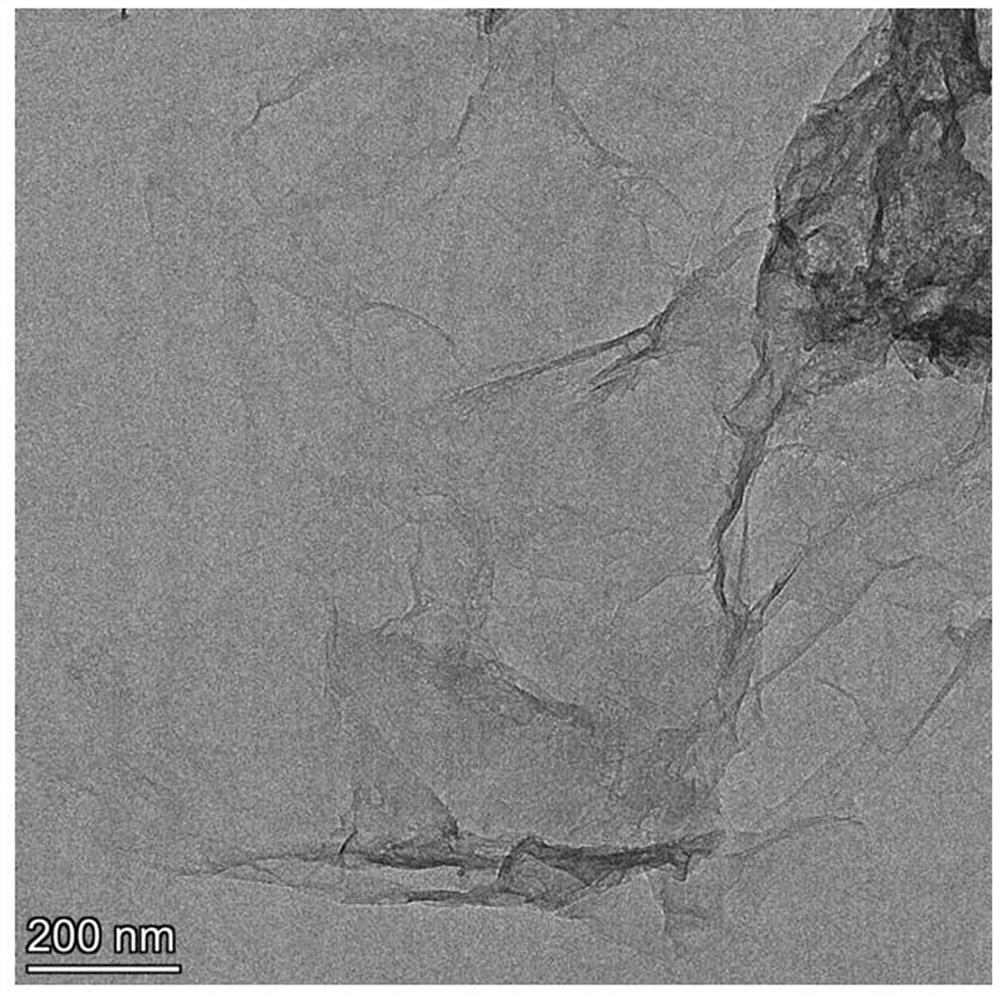

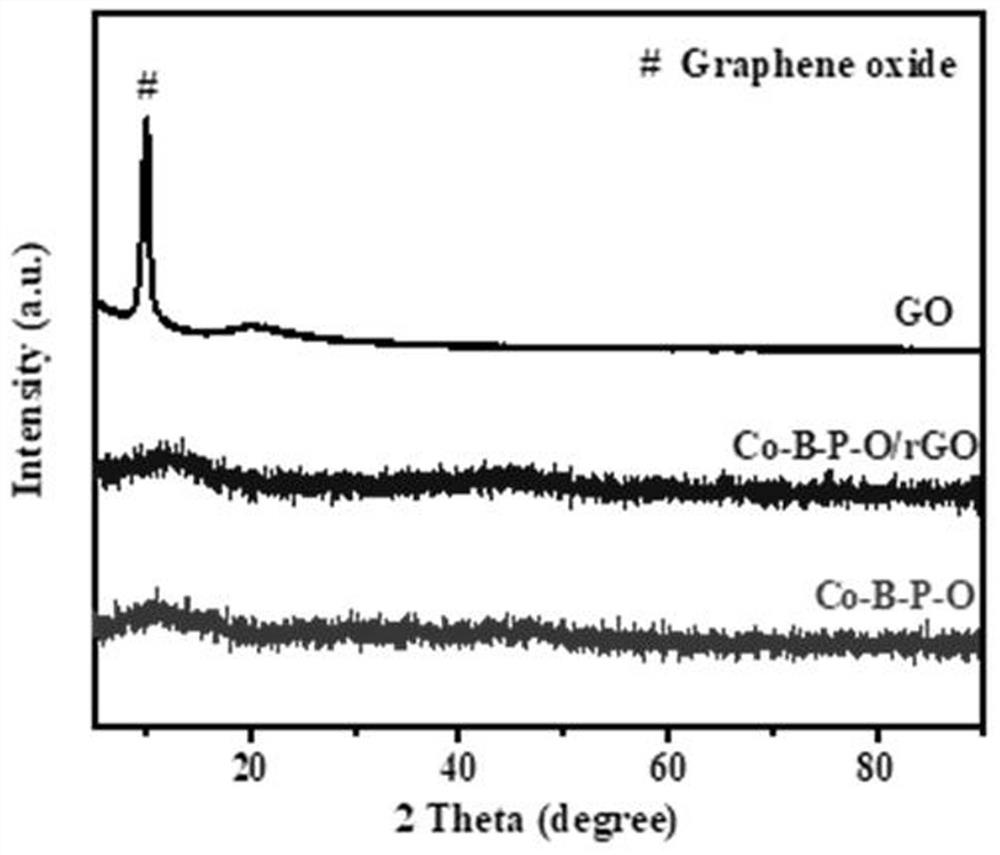

Co-B-P-O nano particle loaded reduced graphene oxide composite material as well as preparation method and application thereof

InactiveCN112844427AReduce aggregationHigh recovery rateCarbon compoundsHeterogenous catalyst chemical elementsPtru catalystOxide composite

The invention discloses a Co-B-P-O nano particle loaded reduced graphene oxide composite material, which is prepared by the following steps: obtaining a graphene oxide material by an improved Hummers method, and then loading Co-B-P-O onto reduced graphene oxide by a chemical in-situ reduction method to obtain the Co-B-P-O nano particle loaded reduced graphene oxide composite material. The specific surface area is 62-120 m<2> g <-1>, and the pore size distribution is 12-14 nm. The preparation method comprises the following steps: 1, preparing the graphene oxide nanosheet carrier; and 2, preparing the Co-B-P-O nano particle loaded reduced graphene oxide composite material. According to the application of the catalyst as a sodium borohydride hydrolysis catalyst, the maximum hydrogen desorption rate provided under 298 K reaches 9036.3 mLmin<-1>g <-1>, the hydrogen desorption amount is 100% of a theoretical value, and the activation energy Ea of catalytic hydrogen desorption is equal to 28.64 kJmol<-1>; 88.9% of the initial catalytic activity of the catalyst on hydrolysis of sodium borohydride is still kept after the catalyst is recycled for 10 times. The catalyst has the characteristics of high catalytic performance, high cycle performance, simple process and short reaction period.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Polyaspartic acid ester finishing paint as well as preparation method and application thereof

ActiveCN108559391AImprove the problem of easy reunionImprove interfacial adhesionAnti-corrosive paintsPolyamide coatingsWeather resistancePolyaspartic acid

The invention provides a polyaspartic acid ester finishing paint and a preparation method thereof. First, a glass flake is subjected to graft modification to enhance the interfacial adhesion between the glass flake and resin, and at the same time, the problem of high possibility of agglomeration of the glass flake is solved. By adding the modified glass flake to the resin, the bonding force between the glass flake and the resin can be improved, a cured film layer forms a solid integral film, and a polyaspartic acid ester finishing paint with good weather resistance, excellent mechanical properties, and good acid and alkali resistance, aging resistance, corrosion resistance and construction performance can be prepared.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Cellulose acetate composite dialysis membrane and preparation method thereof

InactiveCN110743390AIncrease working areaImprove anti-pollution performanceSemi-permeable membranesMembranesDialysis membranesCellulose acetate

The invention belongs to the technical field of membrane materials, and particularly relates to a cellulose acetate composite dialysis membrane and a preparation method thereof. The preparation methodof the cellulose acetate composite dialysis membrane is characterized in that the cellulose acetate composite dialysis membrane is prepared by modifying cellulose acetate, used as a raw material, with ZIF-67-GO as a modifier through adopting an immersion precipitation phase inversion technology. ZIF-67@GO is prepared by adopting an ultrasonic solvothermal technology, and GO is subjected to blending modification by utilizing the characteristics of porous structure and large specific surface area of ZIF-67 in order to improve the problem that the GO is prone to agglomerating and increase the working area of the graphene oxide, so the hydrophilicity and the water flux of the cellulose acetate dialysis membrane and enhance the strength of the composite membrane, the anti-pollution capabilityof the obtained composite dialysis membrane is also improved. The method adopting blending modification can give full play to the performance advantages of GO, and has the advantages of simplicity inmodification operation, and low cost; and the obtained modified composite dialysis membrane has the advantages of good hydrophilicity, good anti-pollution capacity, large flux, high mechanical strength and effectively prolonged service life.

Owner:BEIJING FORESTRY UNIVERSITY

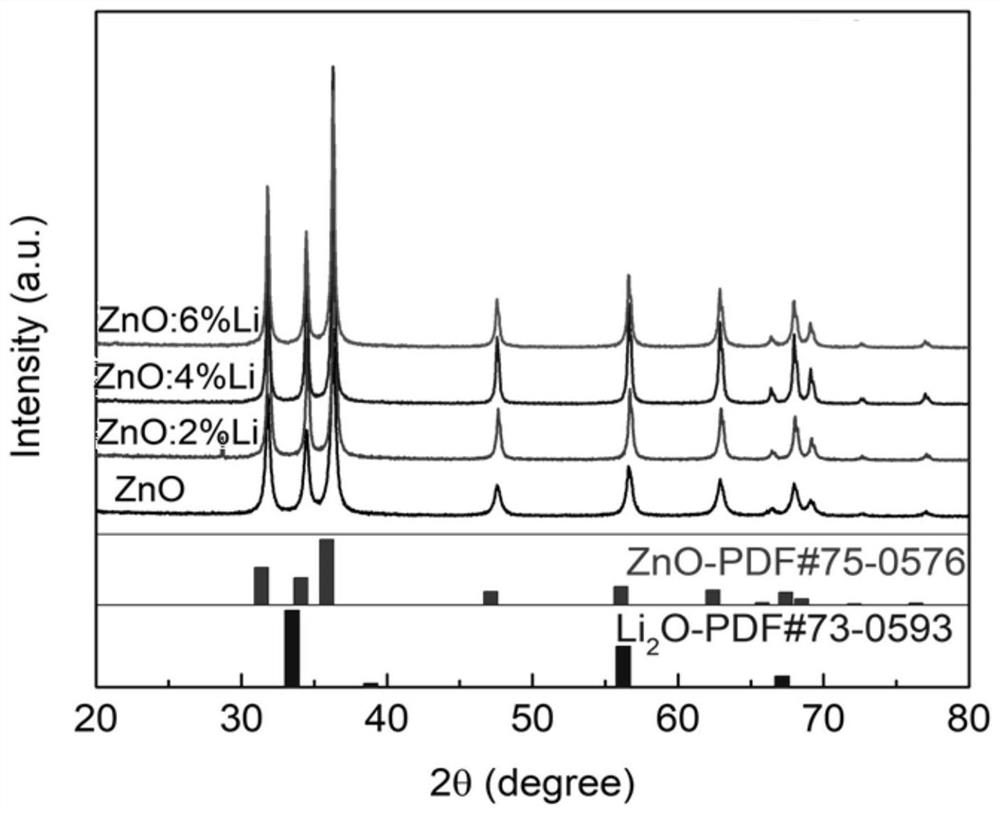

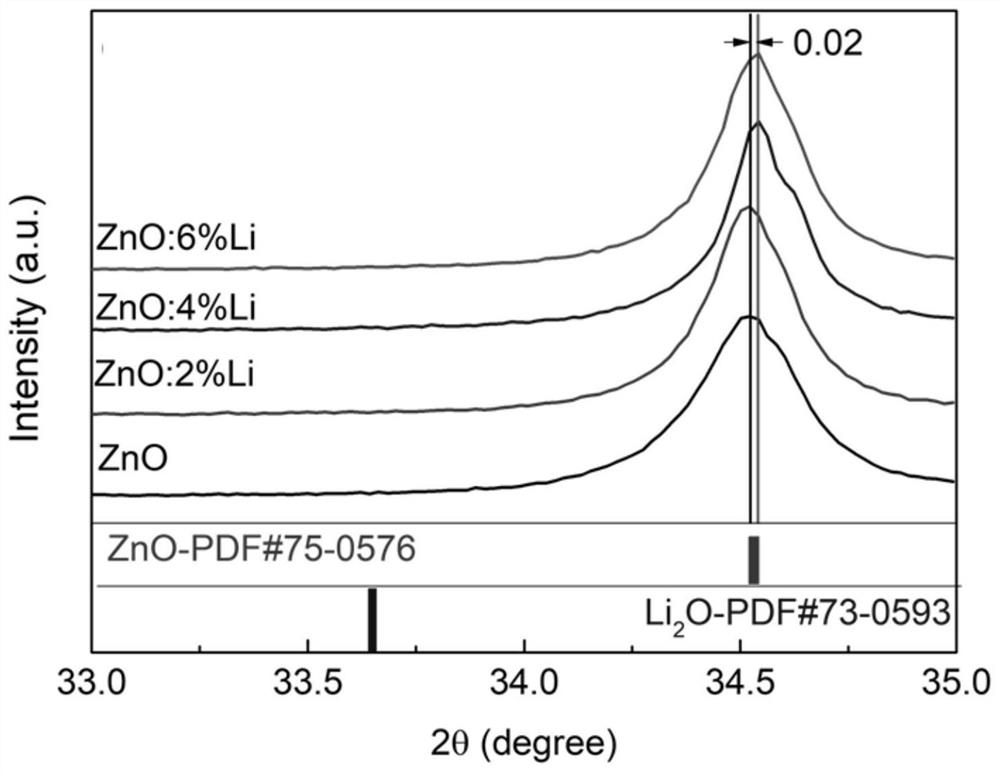

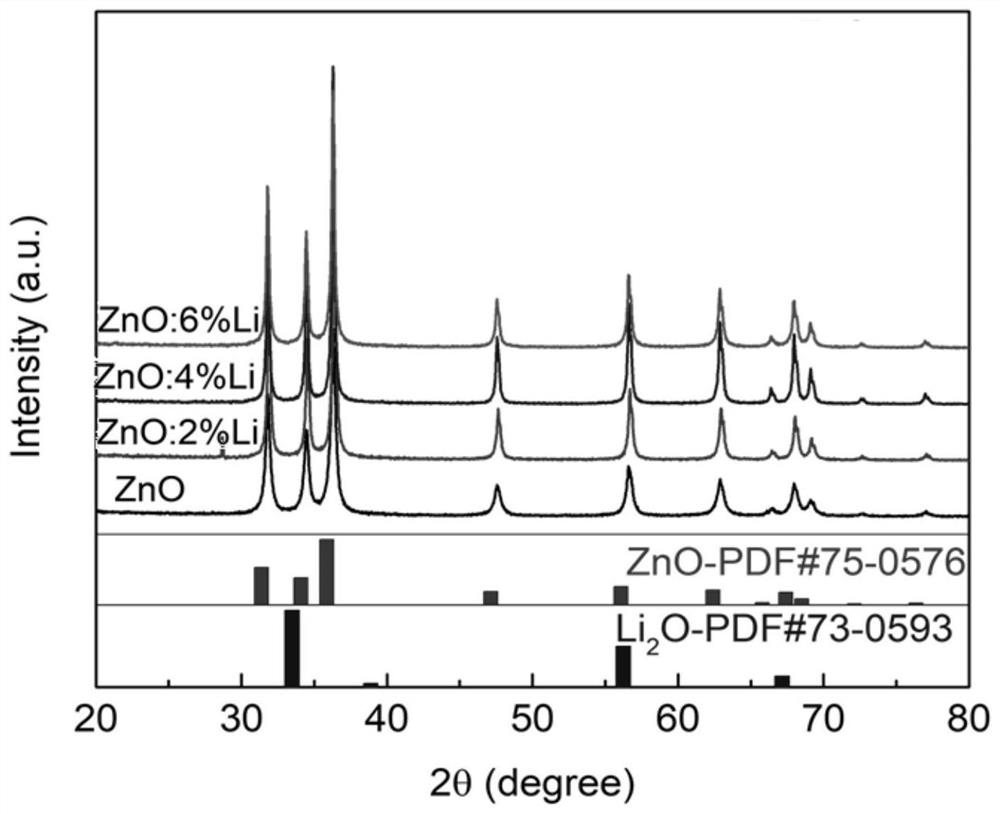

Preparation method of metal ion doped modified silver zinc oxide electric contact material

ActiveCN113957282AEasy reunionGuaranteed efficient densificationOxide conductorsCable/conductor manufactureLithium metalIon doping

The invention discloses a preparation method of a metal ion doped modified silver zinc oxide electric contact material, and relates to a preparation method of an electric contact material. The invention aims to solve the problems of poor wettability between zinc oxide and a silver substrate and short electric contact life caused by easy agglomeration of zinc oxide during preparation of the existing silver zinc oxide electric contact material. The method comprises the following steps: preparing lithium metal doped zinc oxide powder by a self-propagating combustion method, and mixing metal ion doped zinc oxide powder with silver powder to obtain mixed powder; primarily pressing the mixed powder to obtain a blank; primarily sintering the blank to obtain a sintered blank; re-pressing the sintered blank; and re-sintering. The doping of metal ions can improve the wettability between the zinc oxide and the silver substrate and solve the problem that the zinc oxide is easy to agglomerate; and high-energy ball-milling mixed powder is combined to ensure high-efficiency densification of the material, improve the second-phase dispersion effect and improve the electric contact performance. The preparation method of the invention is suitable for preparing the silver zinc oxide electric contact material.

Owner:HARBIN INST OF TECH

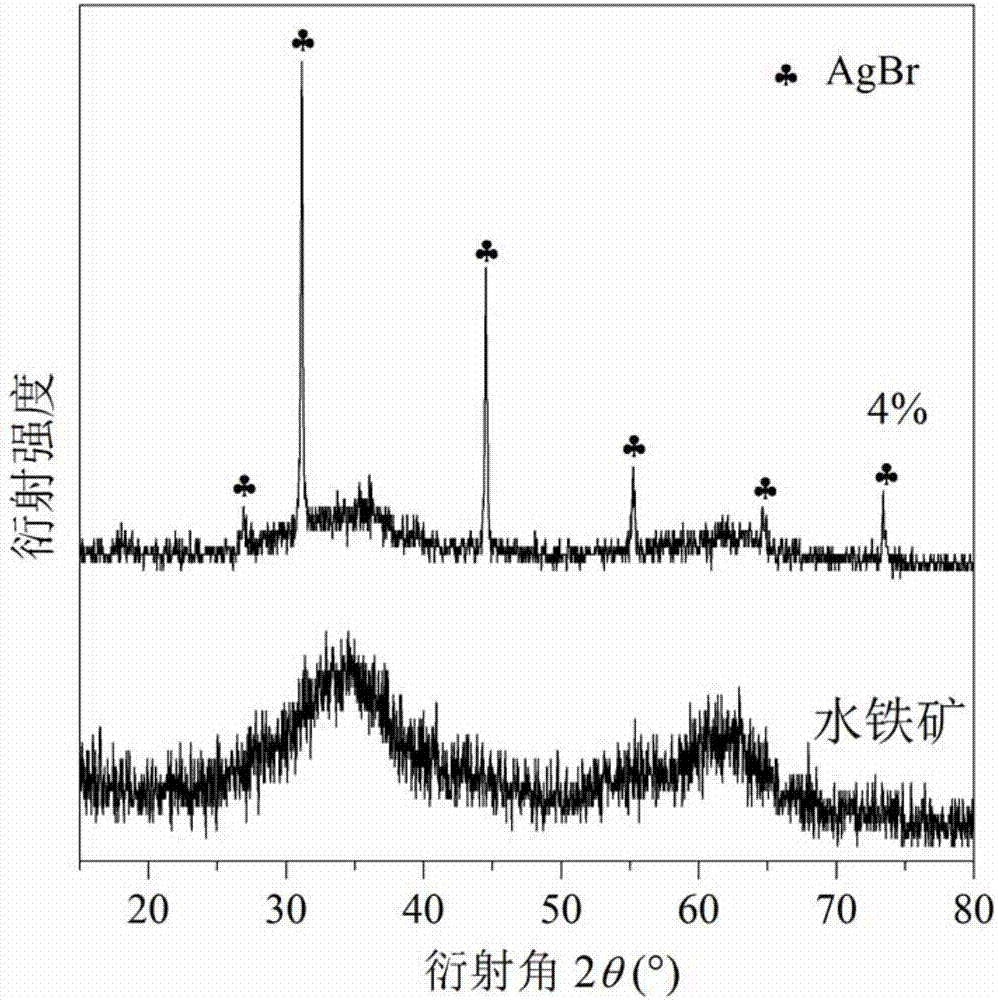

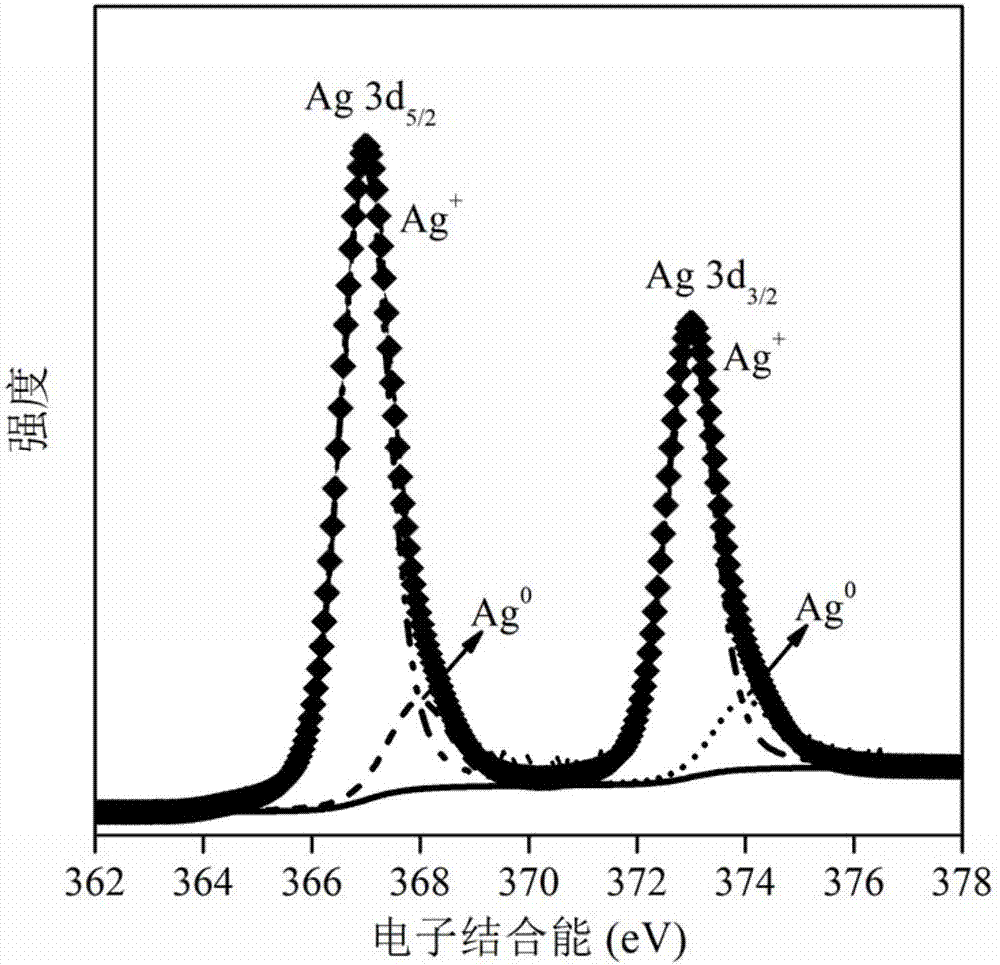

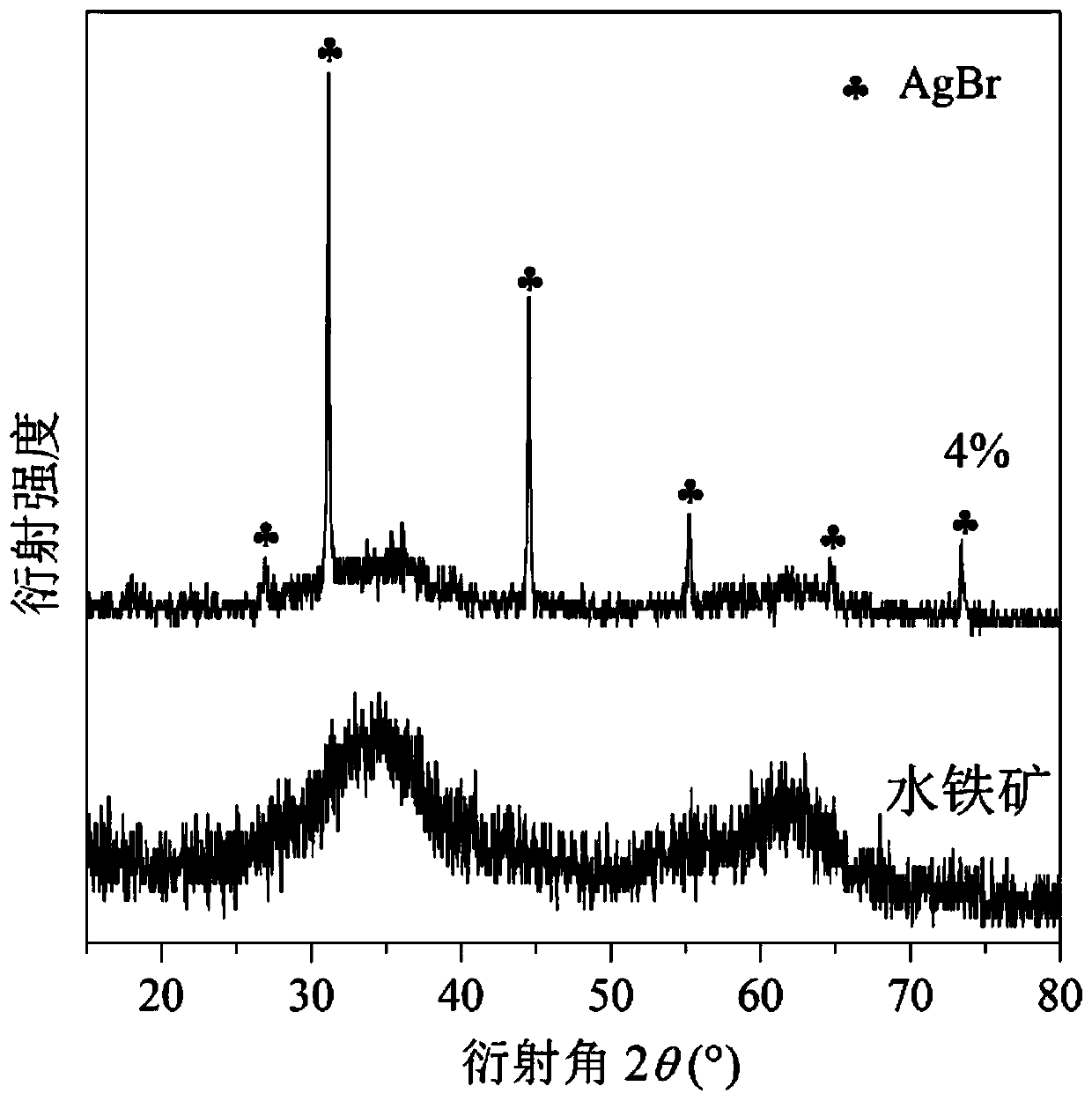

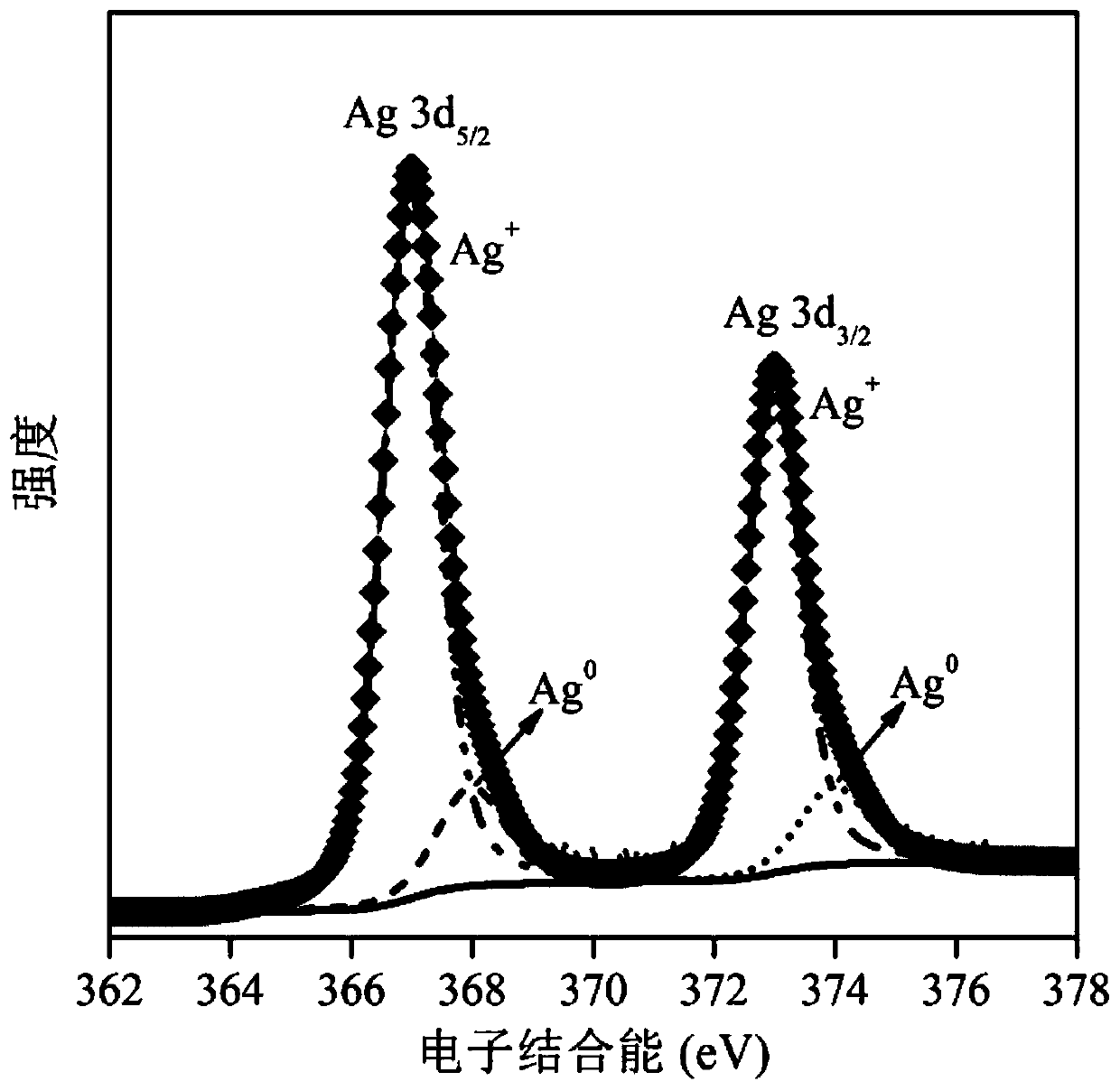

Composite material of silver-silver halide supported iron nanometer minerals and preparation method for composite material

ActiveCN107537522ASynthesis conditions are simpleReduce manufacturing costWater/sewage treatment by irradiationWater contaminantsFreeze-dryingUltraviolet lights

The invention provides a composite material of silver-silver halide supported iron nanometer minerals, and a preparation method for the composite material of the silver-silver halide supported iron nanometer minerals, and relates to the field of environmental wastewater pollution control. The preparation method comprises the following steps: adding the iron nanometer minerals into a silver nitratesolution to obtain a first mixed solution; adding an alkali metal halide solution for enabling silver nitrate to completely form silver halide precipitates into the first mixed solution, so as to obtain a second mixed solution; adding a hole trapping agent into the second mixed solution, and carrying out a photoreduction reaction on a part of silver halide with ultraviolet light to generate elemental silver, so as to obtain a third mixed solution; and carrying out freeze-drying on the third mixed solution after centrifugally washing repeatedly. The preparation method is low in cost and high in recycling rate, and can lower the wastewater treatment cost. The prepared composite material has the advantages of uniform particle size, less agglomeration, high dispersibility and the like, can effectively remove organic pollutants in water under visible light, and further is high in times of repeated use and low in iron dissolving-out quantity to avoid secondary pollution, thereby being an environmentally-friendly and economical process technology.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

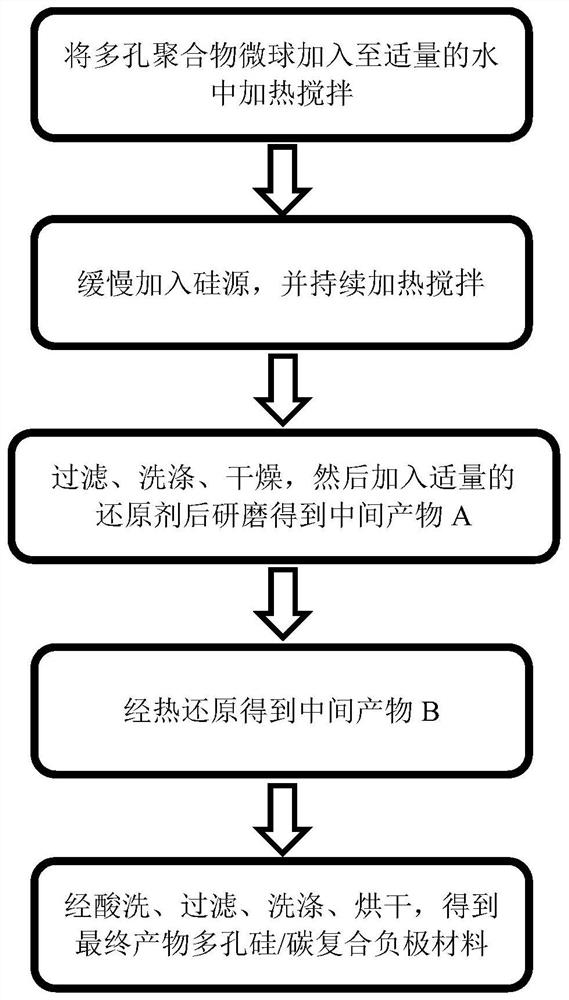

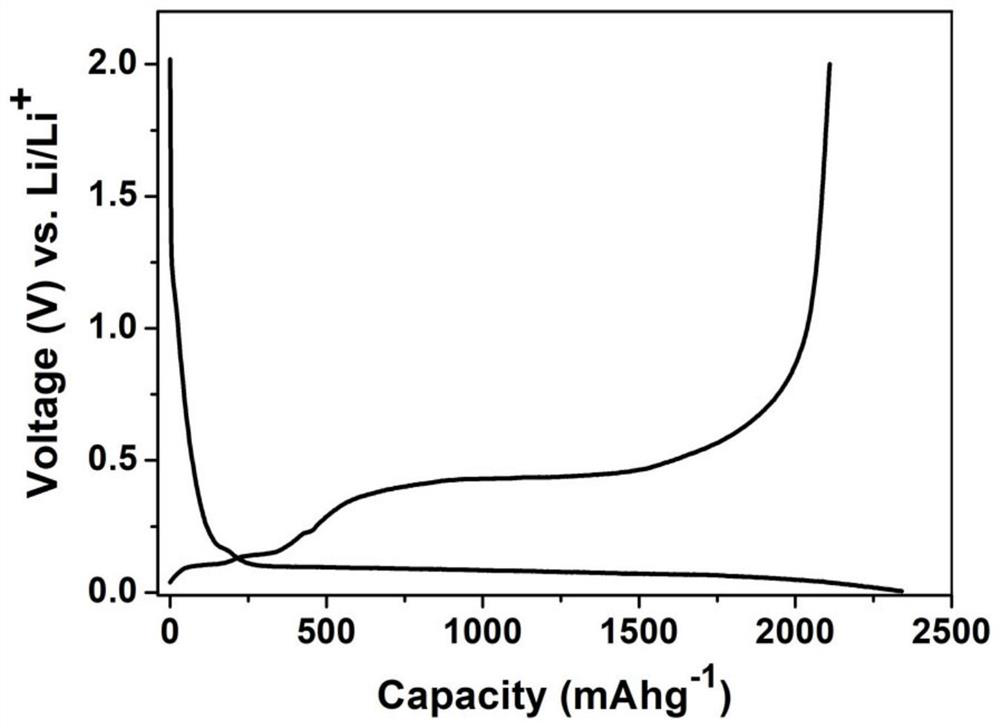

Porous silicon/carbon composite material synthesized in situ by taking porous polymer microspheres as template, preparation method and lithium ion battery

PendingCN114079045AInhibition of volume expansionImprove ionic conductivityNegative electrodesSecondary cellsCarbon compositesDischarge efficiency

The invention relates to a porous silicon / carbon composite negative electrode material in-situ synthesized by taking porous polymer microspheres as a template, a preparation method and a lithium ion battery. The preparation process comprises the following steps of: adding porous polymer microspheres into water, heating and stirring to obtain a suspension solution; adding a silicon source into the suspension solution to obtain a mixed solution; filtering the mixed solution, washing the mixed solution with deionized water and drying the mixed solution in sequence, then adding a reducing agent, and conducting grinding and mixing to obtain an intermediate product A; treating the intermediate product A through a thermal reduction process to obtain an intermediate product B; and carrying out acid pickling on the intermediate product B, washing with deionized water, filtering, and drying to obtain a final product. Compared with the prior art, a carbon layer obtained through in-situ compounding can better improve the electrical conductivity, the cycling stability, the charge-discharge efficiency, the rate capability and other electrochemical properties of a silicon negative electrode, and the unique micro-nano pores reserve a lithium-intercalation expansion space for silicon and reduces the absolute volume change of the composite material in the charge-discharge process.

Owner:昱瓴新能源科技(浙江)有限公司

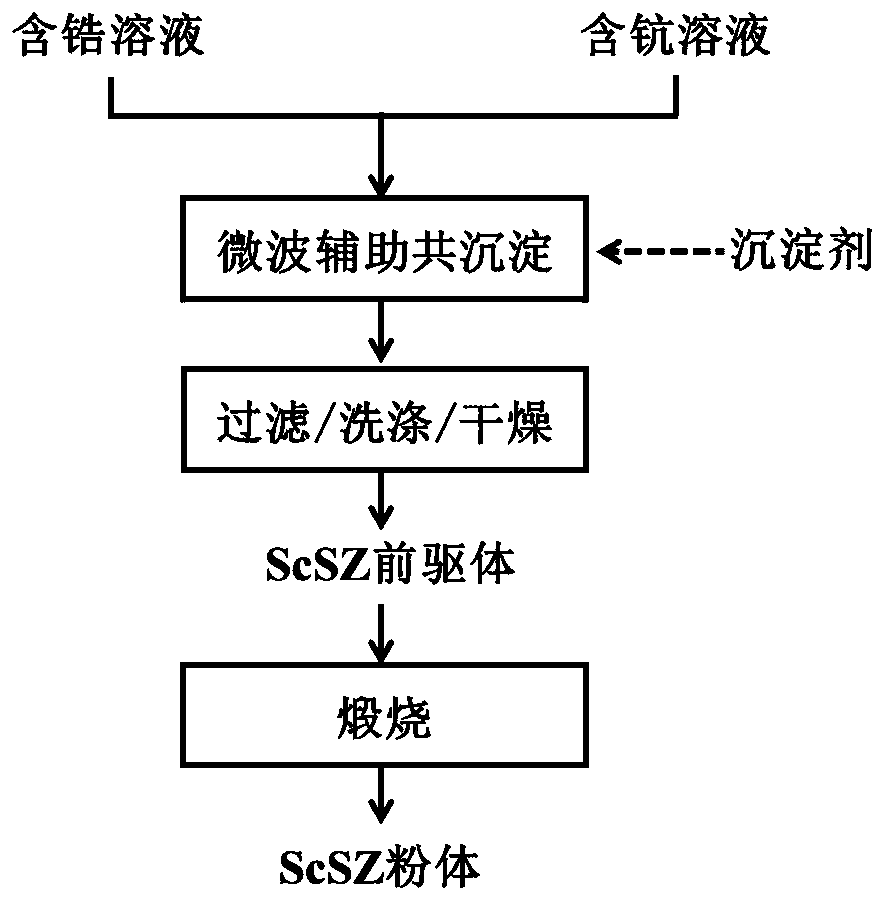

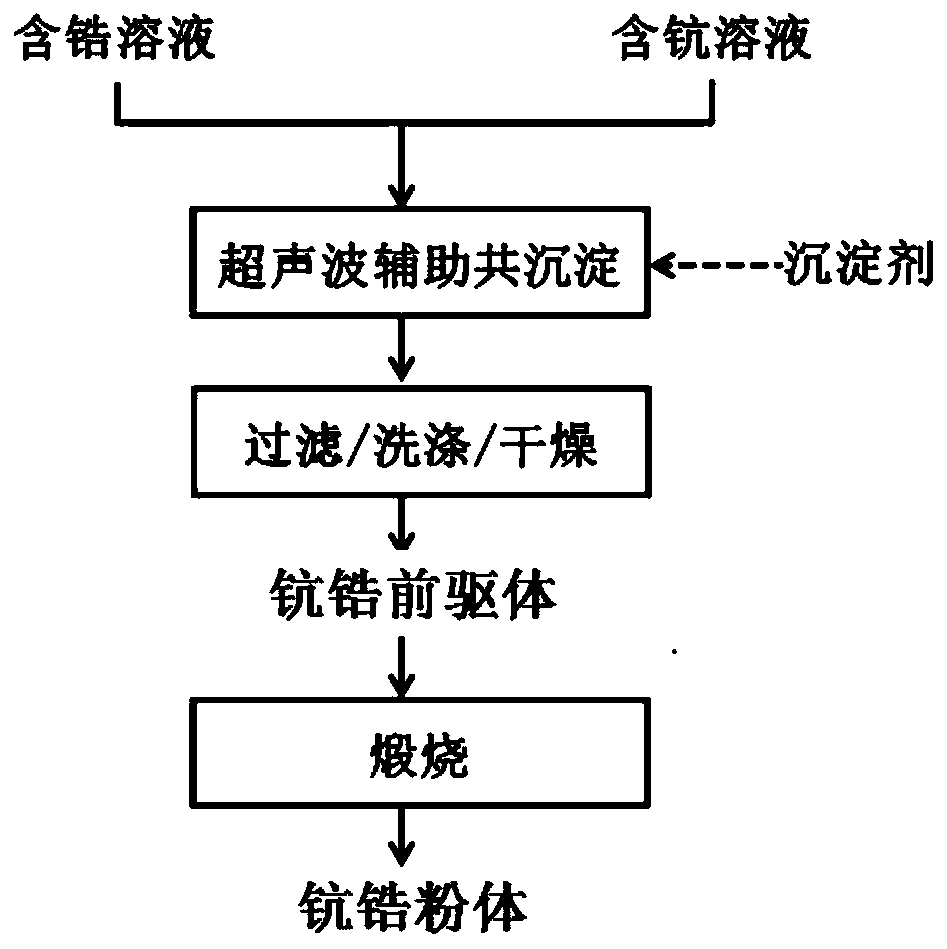

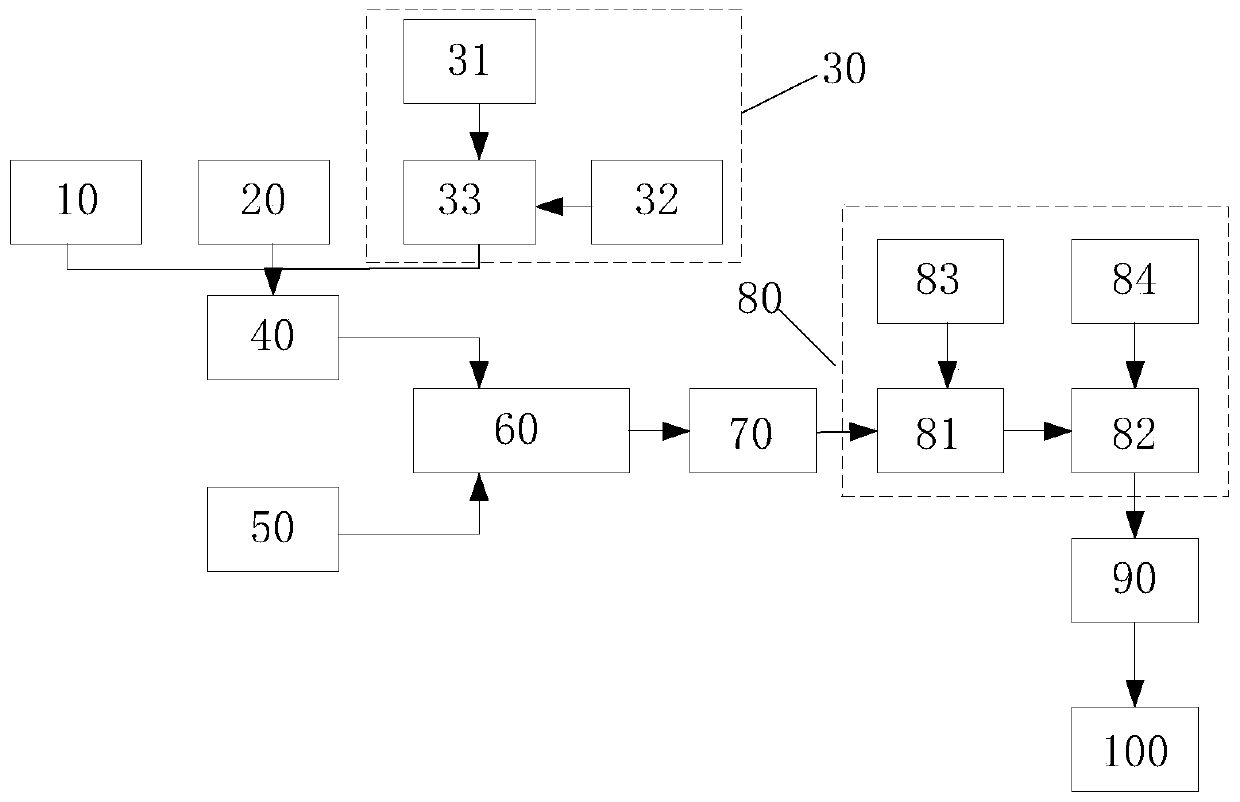

Method and device for preparing scandium-zirconium powder

PendingCN111138189AHigh purityHeating evenly and quicklySolid electrolytesSecondary cellsUltrasonic assistedPhysical chemistry

The invention provides a method and a device for preparing scandium-zirconium powder. The method comprises the following steps: mixing a scandium-containing solution and a zirconium-containing solution to obtain a scandium-zirconium mixed solution; putting the scandium-zirconium mixed solution into a microwave reactor or an ultrasonic reactor, then adding a precipitant into the scandium-zirconiummixed solution under the action of microwave heating or ultrasonic waves, and adjusting the pH value of the system to be 7-11, so that the system is subjected to a precipitation reaction to obtain a scandium-zirconium precursor solution; filtering a scandium-zirconium precursor solution to obtain a precipitate; then sequentially carrying out water washing, alcohol washing and drying on the precipitate to obtain a scandium-zirconium precursor; calcining the scandium-zirconium precursor to obtain scandium-zirconium powder. The scandium-zirconium powder is prepared by utilizing a microwave or ultrasonic-assisted coprecipitation method, so that the problem that a product obtained by a coprecipitation method in the prior art is easy to agglomerate is effectively solved, and the conductivity ofthe scandium-zirconium powder serving as solid electrolyte powder is correspondingly improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Silver-silver halide-loaded iron nano-mineral composite material and preparation method thereof

ActiveCN107537522BSynthesis conditions are simpleReduce manufacturing costWater/sewage treatment by irradiationWater contaminantsFreeze-dryingUltraviolet lights

The invention provides a composite material of silver-silver halide supported iron nanometer minerals, and a preparation method for the composite material of the silver-silver halide supported iron nanometer minerals, and relates to the field of environmental wastewater pollution control. The preparation method comprises the following steps: adding the iron nanometer minerals into a silver nitratesolution to obtain a first mixed solution; adding an alkali metal halide solution for enabling silver nitrate to completely form silver halide precipitates into the first mixed solution, so as to obtain a second mixed solution; adding a hole trapping agent into the second mixed solution, and carrying out a photoreduction reaction on a part of silver halide with ultraviolet light to generate elemental silver, so as to obtain a third mixed solution; and carrying out freeze-drying on the third mixed solution after centrifugally washing repeatedly. The preparation method is low in cost and high in recycling rate, and can lower the wastewater treatment cost. The prepared composite material has the advantages of uniform particle size, less agglomeration, high dispersibility and the like, can effectively remove organic pollutants in water under visible light, and further is high in times of repeated use and low in iron dissolving-out quantity to avoid secondary pollution, thereby being an environmentally-friendly and economical process technology.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method of high-temperature-resistant coating material for liquid-state light hydrocarbon gasification device

InactiveCN110903740AImprove high temperature resistanceHigh hardnessFireproof paintsEpoxy resin coatingsPolymer sciencePolymer chemistry

The invention discloses a preparation method of a high-temperature-resistant coating material for a liquid-state light hydrocarbon gasification device, and relates to the technical field of coating materials, wherein the prepared high-temperature-resistant coating material has high high-temperature resistance, can ensure that a coating film does not crack at a high temperature of 460 DEG C, and isexcellent in hardness and adhesive force. According to the preparation method, treating is performed by utilizing excessive maleic anhydride to carry out an esterification reaction with the hydroxylon the surface, so that the maleic anhydride is grafted to the surface of boehmite; the boehmite grafted with the maleic anhydride reacts with heptaphenyl silsesquioxane trisilanol, so that the heptaphenyl silsesquioxane trisilanol is combined with the boehmite through the maleic anhydride to obtain a boehmite-heptaphenyl silsesquioxane trisilanol complex; and the hydroxyl on the heptaphenyl silsesquioxane trisilanol and the hydroxyl of an epoxy resin are subjected to a condensation reaction, so that the cross-linking degree is improved, the adhesive force of a coating film is improved, and the high-temperature resistance of the epoxy resin is remarkably improved.

Owner:安徽启东热能科技有限公司

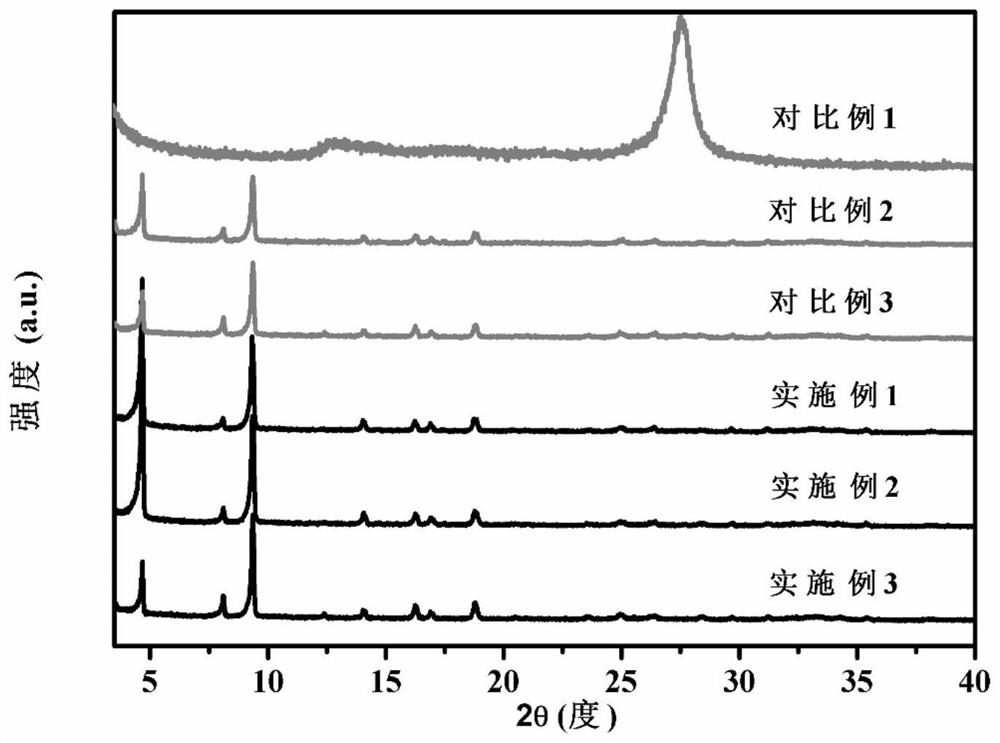

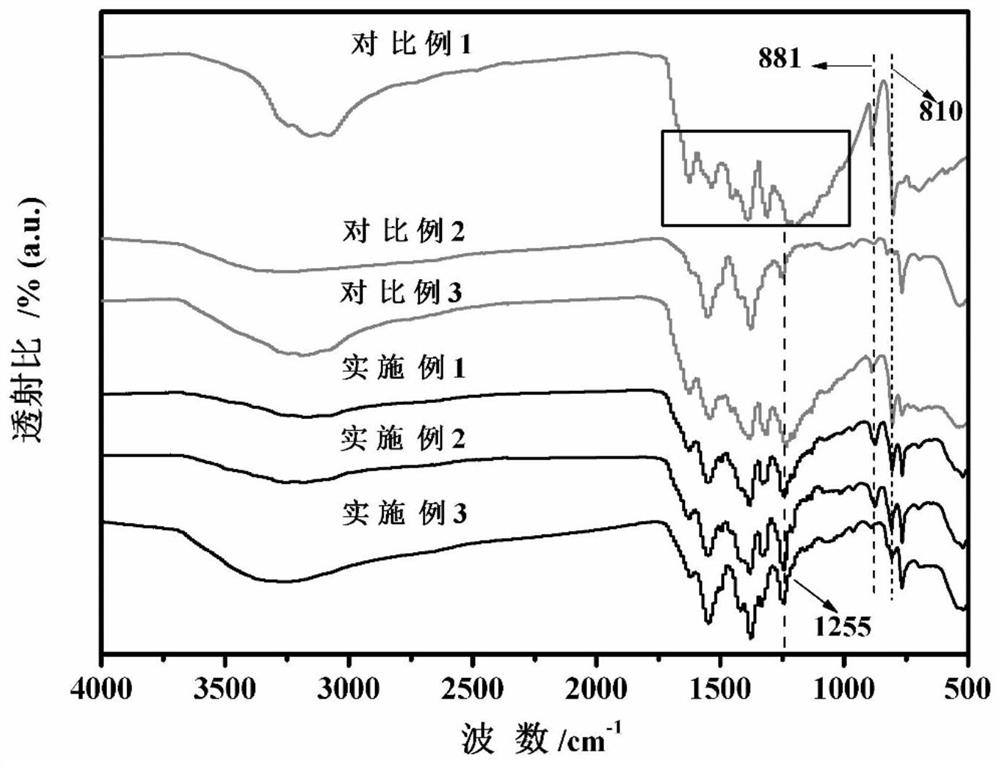

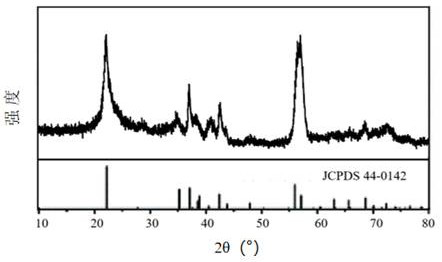

A kind of indium-based metal-organic framework/graphite-like phase nitrogen carbide nanosheet composite material and its preparation method and application

ActiveCN110280285BImprove the problem of easy reunionIncrease the areaMaterial nanotechnologyWater/sewage treatment by irradiationIndiumMetal-organic framework

The invention belongs to the field of photocatalytic materials, and discloses an indium-based metal organic framework / graphite-like phase nitrogen carbide nanosheet composite material and a preparation method and application thereof, comprising the following steps: (1) preparing graphite-like phase nitrogen carbide nanosheets; (2) Preparation of indium-based metal organic framework / graphite-like phase nitrogen carbide nanosheet composite material; (3) Continuous heating of the mixed solution obtained in step (2) at 110-140°C for 6h-24h, and suction filtration after cooling to obtain the initial product; (4) washing and purifying the initial product obtained in step (3) with a solvent, and drying in vacuum to obtain the final product. The invention has low cost and simple preparation method, and the obtained composite material has excellent photocatalytic performance, and has remarkable effect in completely degrading ibuprofen-containing wastewater.

Owner:SOUTH CHINA UNIV OF TECH +1

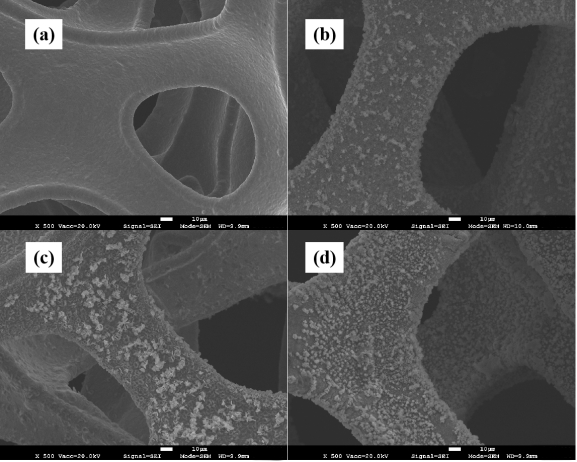

Palladium/gamma-manganese dioxide/foamed nickel composite electrode and preparation method and application thereof

ActiveCN114540873AHigh catalytic activityLarge specific surface areaElectrodesMaterials scienceWater treatment

The invention discloses a palladium / gamma-manganese dioxide / foamed nickel composite electrode and a preparation method and application thereof, and belongs to the technical field of electrochemical water treatment.The composite electrode is prepared in the mode that foamed nickel serves as a matrix, a gamma-crystal-form MnO2 middle layer is formed on the surface of the foamed nickel through a hydrothermal reaction, and then Pd nanoparticles are chemically deposited; wherein the loading capacity of the gamma-MnO2 intermediate layer on the foamed nickel is 0.30 mg / cm < 2 > to 0.35 mg / cm < 2 >; the deposition amount of the Pd nano particles is 0.68 mg / cm < 2 > to 0.72 mg / cm < 2 >. The invention also provides a preparation method of the composite electrode. The Pd / gamma-MnO2 / Ni foam composite electrode prepared by the invention is large in specific surface area, high in catalytic activity and good in cycling stability, can be used for quickly and efficiently electrocatalytically treating chlorophenol pollutants in wastewater, and has a wide application prospect.

Owner:TSINGHUA UNIV

Composite adhesive and preparation method and use method thereof

InactiveCN112226188AHigh strengthImprove wear resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention discloses a composite adhesive as well as a preparation method and a use method thereof. The composite adhesive comprises a component A and a component B. The component A is a repairingagent base material component, and contains bisphenol A epoxy resin, bisphenol F epoxy resin and a component A filler, and the component A filler contains nano Ti3C2. The component B is a curing agent, and comprises benzyl alcohol, dimethylamine and a component B filler, and the component B filler contains nano Ti3C2. The invention aims to provide the composite adhesive as well as the preparationmethod and the use method thereof, so as to solve the technical problem that the existing composite adhesive cannot be applied to the field of air leakage plugging due to poor strength and wear resistance. According to the invention, Ti3C2 is introduced into epoxy resin and is organically matched with other inorganic filling materials, so that the problems of strength and wear resistance are effectively improved, and the composite adhesive is particularly suitable for air leakage sealing of metal surfaces.

Owner:CHINA ELECTRIC POWER RES INST +3

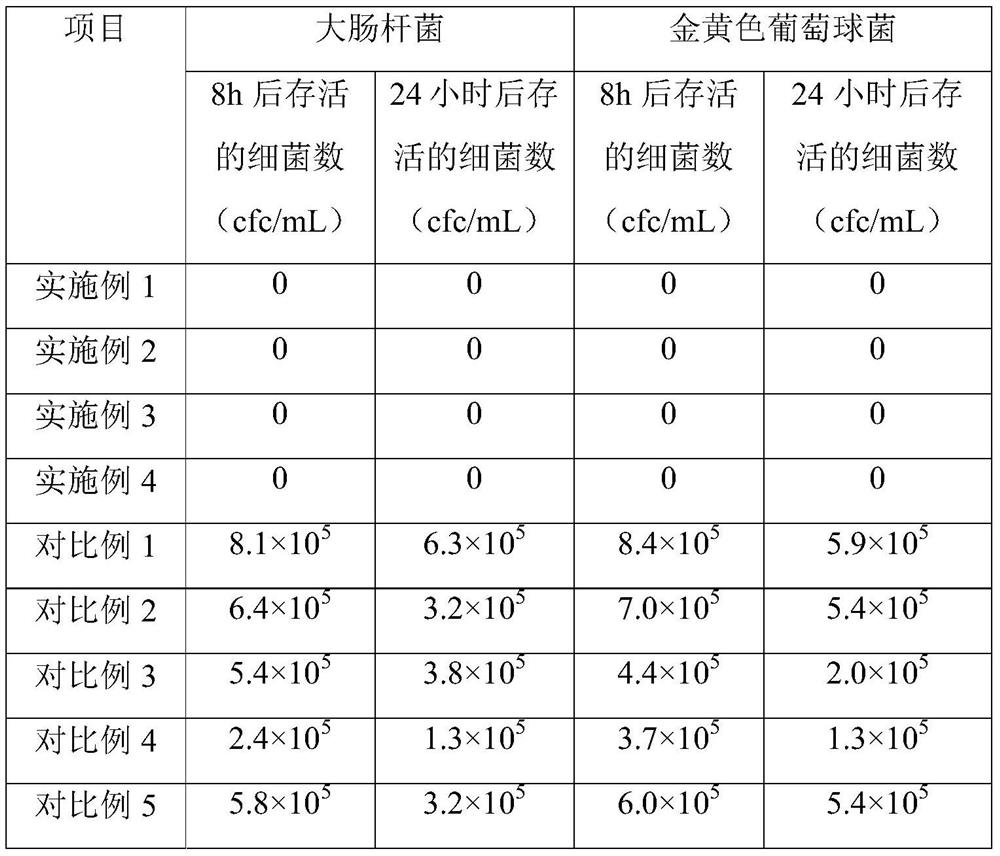

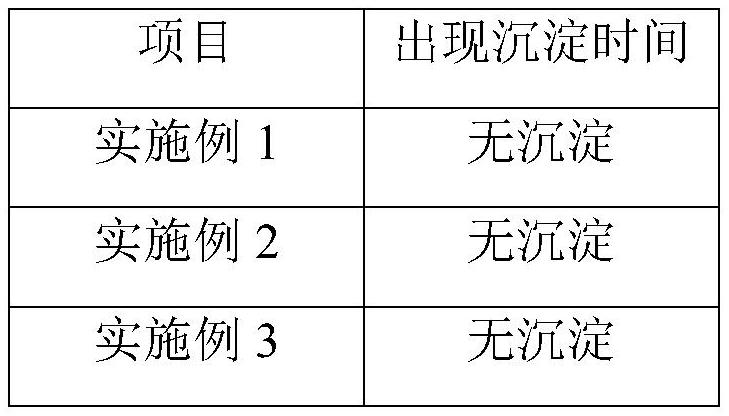

Stable and efficient antibacterial composition and preparation method thereof

PendingCN114747592AImprove antibacterial propertiesEfficient and stableBiocideDisinfectantsMicroorganismBiochemical engineering

The invention provides a stable and efficient antibacterial composition and a preparation method thereof, and the antibacterial composition comprises solvent oil, a two-dimensional material and an organic dispersant, and also comprises a metal hydrate. The graphene and the metal hydrate are added into the composition, the problem that graphene is prone to agglomeration is solved, an antibacterial component with a stronger surface effect is formed, the adsorption capacity of the antibacterial composition to microorganisms is improved, meanwhile, white oil is preferably selected as a main base material, compatibility of an inorganic phase and an organic phase in a system is good, and the antibacterial composition has the advantages of being environmentally friendly and free of pollution. And the antibacterial composition can still keep a uniformly dispersed storage state after being cyclically placed at high and low temperatures. The stable and efficient antibacterial composition provided by the invention has efficient antibacterial property, stability and wear resistance, and can be widely applied to antibacterial materials. The preparation method provided by the invention is simple and convenient, has strong repeatable operability and is beneficial to large-scale production.

Owner:JIANGSU JONNYMA NEW MATERIALS CO TLD

Preparation method and application of a core-shell magnetic nanocomposite catalyst

ActiveCN110215921BRealize micro-controlHelp transferWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystUltrasonic vibration

The invention discloses a preparation method and application of a magnetic nanocomposite catalyst with a core-shell structure, comprising the following steps: S1, comprising Fe 2+ Metal salt X and containing Co 2+ Dissolve the metal salt Y in deionized water, stir evenly, to the mixed solution A; S2, remove the dissolved oxygen in the mixed solution A by ultrasonic vibration or suction filtration, and obtain the mixed solution B; S3, add the NaOH solution dropwise to the mixed solution In liquid B, mixed liquid C is obtained; in S4, the mixed liquid C is refluxed, heated and stirred, and the product is taken out after standing still, and washed multiple times with deionized water and absolute ethanol, then dried and ground to obtain powdered magnetic cobalt Iron hydroxide; S5, the powdered magnetic cobalt-iron hydroxide is calcined, ground and sieved to obtain the 3 o 4 For the shell, CoFe 2 o 4 A magnetic nanocomposite catalyst with a core-shell structure as the core. The preparation process is simple and easy to operate, and it can realize the microscopic control of the composite catalyst morphology, form a core-shell structure, and help the electron transfer in the catalytic reaction process.

Owner:CHONGQING UNIV

A kind of polyaspartate topcoat and its preparation method and application

ActiveCN108559391BImprove the problem of easy reunionImprove interfacial adhesionAnti-corrosive paintsPolyamide coatingsPolymer sciencePolyaspartic acid

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

A kind of in-situ titanium dioxide coated lignin composite particle and its preparation and application

ActiveCN113101235BImprove the problem of easy reunionImproves UV protectionCosmetic preparationsToilet preparationsSunscreen agentsUv protection

Owner:SOUTH CHINA UNIV OF TECH

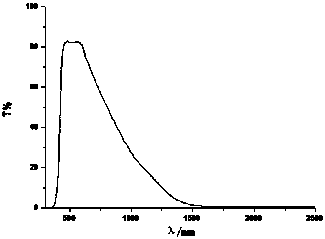

A kind of indium antimony tin oxide nanopowder and preparation method thereof

ActiveCN107188225BSimple processProcess safetyMaterial nanotechnologyAntimony oxides/hydroxides/oxyacidsIndiumSURFACTANT BLEND

The invention relates to the technical field of transparent heat-insulating conductive nanometer materials and particularly relates to antimony-indium-doped tin oxide nano-powder and a preparation method thereof. The preparation method comprises (1) mixing an antimony salt, a tin salt and an indium salt, dissolving the mixture in an acid solution to obtain a solution A, and orderly dissolving an alkaline precipitant and a surfactant in deionized water to obtain a solution B, (2) adding the solution A into the solution B along with stirring, and after the reaction, carrying out aging to obtain a solution C, (3) centrifuging the solution C and washing, drying, grinding and sintering the precipitates to obtain the antimony-indium-doped tin oxide nano-powder. The preparation method has simple processes, is safe, utilizes mild reaction conditions, realizes a low preparation cost, realizes industrial production and greatly solves the problem of easy agglomeration of nano-powder in production. The antimony-indium-doped tin oxide nano-powder has small particle sizes and narrow particle size distribution, reduces agglomeration and has wide application values.

Owner:广东拓扑中润科技发展有限公司

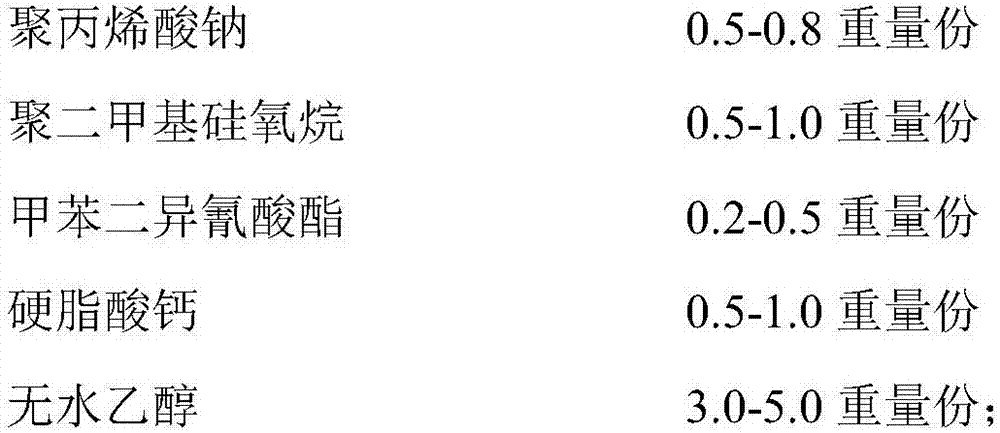

Elastic anti-buffer rubber material and preparation method thereof

The invention relates to an elastic anti-buffer rubber material and a preparation method thereof. The elastic anti-buffer rubber material is prepared from the following ingredients including 80 to 90weight parts of elastomeric polymers, 15 to 20 weight parts of tensile polymers, 4 to 6 weight parts of metal oxides and 12 to 18 weight parts of auxiliary agents, wherein the elastomeric polymers areat least one kind of materials from olefin segmented copolymers and / or olefin random copolymers; the tensile polymers are polyolefin. The preparation method comprises the following steps of S1, preparing a buffer auxiliary agent; S11, preparing an alcohol solution; S12, preparing an ester solution; S13, buffering auxiliary agents; S2, mixing filling materials; S3, preparing a pre-mixing solution;S4, preparing gross rubber; S5, preparing the elastic anti-buffer rubber material. The elastic anti-buffer rubber material has the advantages that the cost is low; the anti-oxidization function is realized; the anti-oxidization effect is good; the shaping rate is high; defective products are few.

Owner:宁波秦鼎材料科技有限公司

high performance magnetic 3 o 4 /Preparation method of polyurethane elastomer composite material

The invention relates to a preparation method for a magnetic composite material, and particularly to a preparation method for a high-performance magnetic Fe3O4 / polyurethane elastomer composite material, which solves the problems that the mechanical performance and magnetic performance of a current magnetic polyurethane elastomer composite material are difficult to improve simultaneously, and magnetic particles are smaller in filling amount and poor in dispersity, the scheme is that: 1) preparing Fe3O4 with FeCl2.4H2O, FeCl3.6H2O, a surface active agent and NaOH; adding an organic solvent for magnetic separation and purification; adding the organic solvent for ultrasonic dispersion so as to preparing an organic magnetic liquid; 2) adding tetrahydrofuran ether diol, and using anhydrous acid to adjust pH; adding toluene diisocyanate to obtain polyurethane prepolymer; adding chain extender, vacuumizing, defoaming and adding a magnetic field externally to heat and vulcanize, and preparing the Fe3O4 / polyurethane elastomer composite material. The preparation method for the high-performance magnetic Fe3O4 / polyurethane elastomer composite material has the advantages that: 1. Magnetic particles have good dispersity in the elastomer, and form a cross-linked structure with matrix; 2. inorganic acid is added, the viscosity of a polyurethane prepolymer system is reduced, and the high concentration adulteration of magnetic particles is guaranteed; and 4. the mechanical performance and magnetic performance of the magnetic polyurethane elastomer composite material are improved simultaneously.

Owner:ZHONGBEI UNIV

A high-strength lead-free copper-based sliding material and its preparation method

The invention discloses a high-strength lead-free copper-base sliding bearing material and a preparing method thereof. FeS powder and bronze powder are mechanically alloyed through the ball milling technology, the interface bonding capability between FeS and copper is improved, FeS particles are evenly distributed in a copper base body, the defect that aggregating is likely to happen when the content of the FeS is high is overcome, the dispersion strengthening function of FeS can be brought into play, and the material mechanical performance is improved. According to the high-strength lead-free copper-base sliding bearing material and the preparing method thereof, the good solid self-lubricating capability of FeS is mainly utilized, the friction and abrasion performance of the lead-free copper-base sliding bearing material is improved, effective unification between the high strength and the good lubricating character of the copper-base sliding bearing material is achieved, and application of the lead-free copper-base bearing material under complex work conditions is widened.

Owner:HEFEI UNIV OF TECH

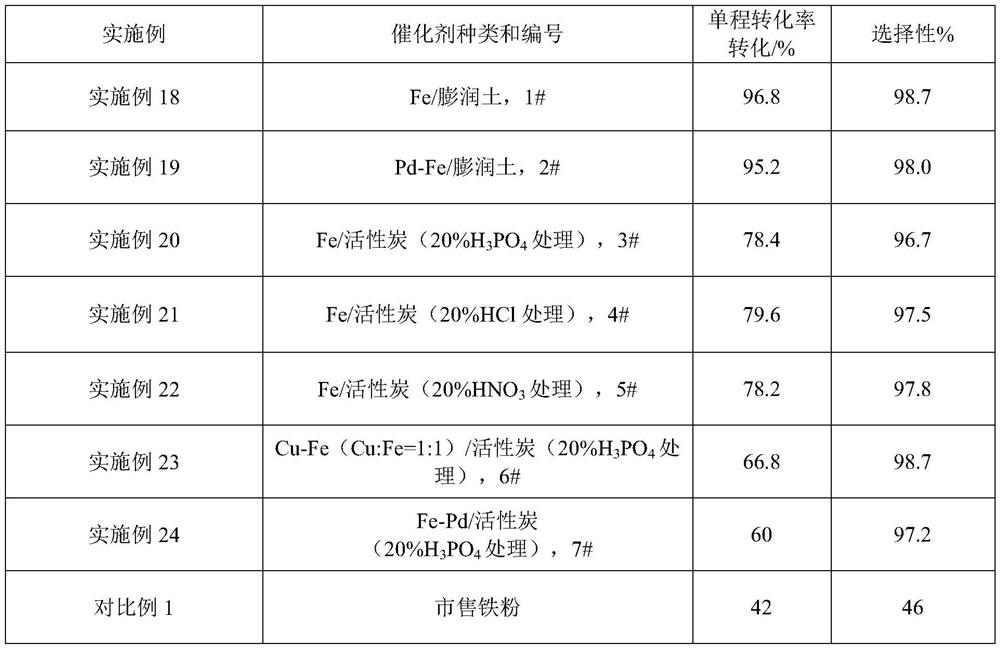

Preparation method of 1, 1, 1, 3-tetrachloropropane

PendingCN114835554AEasy to removeImprove the problem of easy reunionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTetrachloropropylene1-Chloropropane

The invention discloses a preparation method of 1, 1, 1, 3-tetrachloropropane, which comprises the following steps: in the presence of a first catalyst and a second catalyst, reacting raw materials containing carbon tetrachloride and ethylene to obtain the 1, 1, 1, 3-tetrachloropropane, the first catalyst comprises a carrier and an active component loaded on the carrier; the active component comprises nano zero-valent iron; the second catalyst comprises an ester compound. According to the preparation method, the supported iron catalyst is adopted, so that the problem of easy agglomeration when pure commercially available iron powder is used as the catalyst can be remarkably improved, the specific surface area of iron is increased, and the reaction is facilitated.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com