Cellulose acetate composite dialysis membrane and preparation method thereof

A cellulose acetate and dialysis membrane technology, applied in the field of membrane materials, can solve the problems of slow diffusion rate of solvent and coagulation bath, difficult water flux to meet practical application, thick dialysis membrane skin, etc., and achieve good hydrophilicity and stability. Anti-pollution ability, improve hydrophilicity and water flux, improve the effect of hydrophilic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

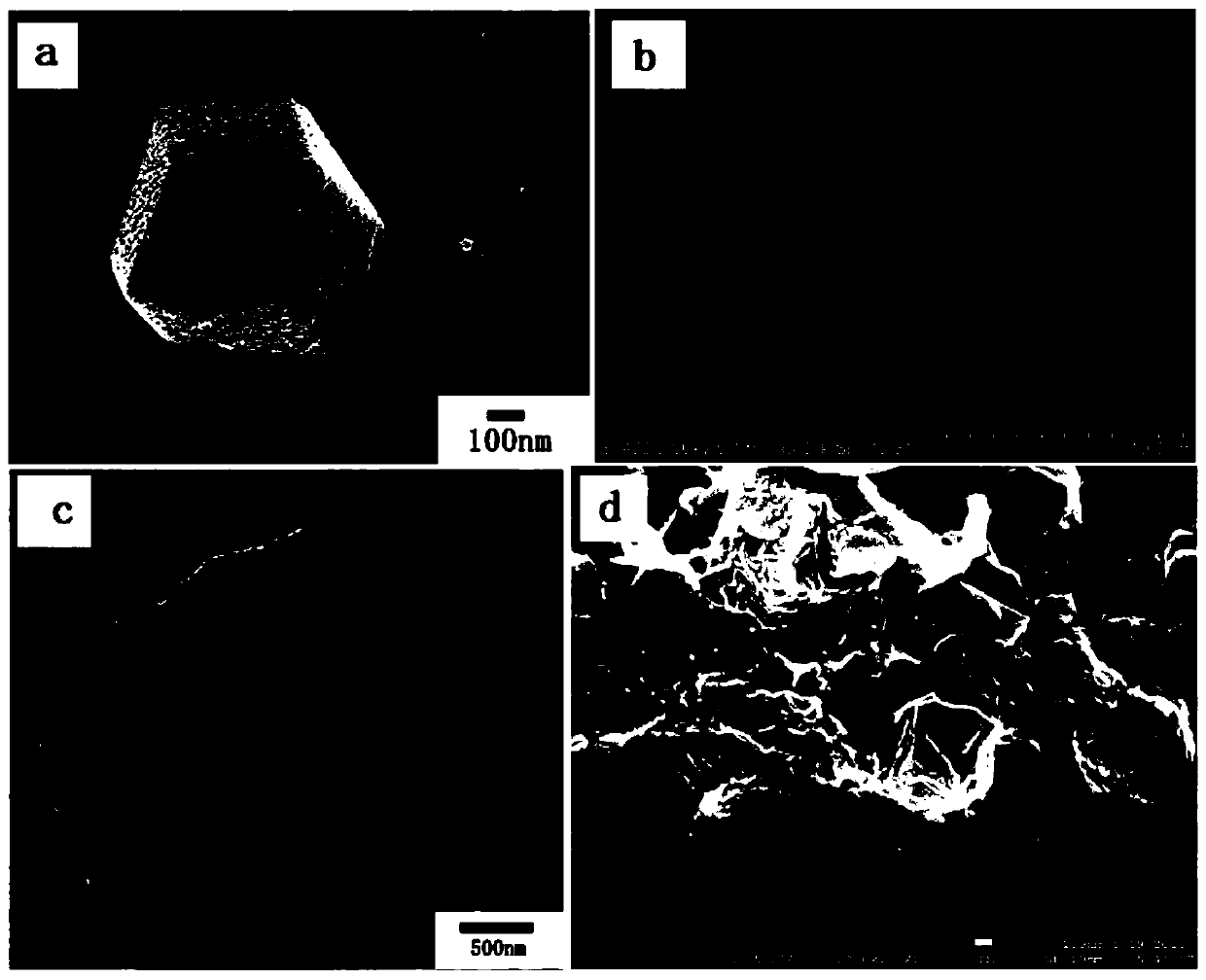

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of preparation method of cellulose acetate composite dialysis membrane, comprising:

[0044] (1) Prepare materials according to the following ratio

[0045] Co(NO 3 ) 2 ·6H 2 O 1.50g, 2-methylimidazole 1.65g, GO 0.75g, methanol 200mL; ZIF-67@GO 0.10g, cellulose acetate 15g, polyethylene glycol 400 12g, N,N-dimethylformamide 72.90mL .

[0046] (2) Preparation method of ZIF-67@GO:

[0047] Take Co(NO 3 ) 2 ·6H 2 O) and 2-methylimidazole as raw materials, Co(NO 3 ) 2 ·6H 2 The solids of O (1.50g) and 2-methylimidazole (1.65g) were dissolved in 40mL of methanol and 160mL of methanol respectively, and stirred until the solids were completely dissolved, then the cobalt nitrate solution was quickly dropped into the 2-methylimidazole solution. At the same time, a certain mass of GO (0.75 g) was added into the mixed solution, and the solution was sonicated for 3 h (temperature 30 °C, ultrasonic power 80 Hz).

[0048] After the r...

Embodiment 2

[0058] The present embodiment provides a kind of preparation method of cellulose acetate composite dialysis membrane, comprising:

[0059] (1) Prepare materials according to the following ratio

[0060] Co(NO 3 ) 2 ·6H 2 O 1.50g, 2-methylimidazole 1.65g, GO 0.75g, methanol 200mL; ZIF-67@GO 0.20g, cellulose acetate 15g, polyethylene glycol 400 12g, N,N-dimethylformamide 72.80mL .

[0061] (2) Preparation method of ZIF-67@GO:

[0062] With (Co(NO 3 ) 2 ·6H 2 O) and 2-methylimidazole as raw materials, Co(NO 3 ) 2 ·6H 2 The solids of O (1.50g) and 2-methylimidazole (1.65g) were dissolved in 40mL of methanol and 160mL of methanol respectively, and stirred until the solids were completely dissolved, then the cobalt nitrate solution was quickly dropped into the 2-methylimidazole solution. At the same time, a certain mass of GO (0.75 g) was added into the mixed solution, and the solution was sonicated for 3 h (temperature 30 °C, ultrasonic power 80 Hz).

[0063] After the ...

Embodiment 3

[0071] The present embodiment provides a kind of preparation method of cellulose acetate composite dialysis membrane, comprising:

[0072] (1) Prepare materials according to the following ratio

[0073] Co(NO 3 ) 2 ·6H 2 O 1.50g, 2-methylimidazole 1.65g, GO 0.75g, methanol 200mL; ZIF-67@GO 0.30g, cellulose acetate 15g, polyethylene glycol 400 12g, N,N-dimethylformamide 72.70mL .

[0074] (2) Preparation method of ZIF-67@GO:

[0075] With (Co(NO 3 ) 2 ·6H 2 O) and 2-methylimidazole as raw materials, Co(NO 3 ) 2 ·6H 2 The solids of O (1.50g) and 2-methylimidazole (1.65g) were dissolved in 40mL of methanol and 160mL of methanol respectively, and stirred until the solids were completely dissolved, then the cobalt nitrate solution was quickly dropped into the 2-methylimidazole solution. At the same time, a certain mass of GO (0.75 g) was added into the mixed solution, and the solution was sonicated for 3 h (temperature 30 °C, ultrasonic power 80 Hz).

[0076] After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com