High-strength lead-free copper-base sliding material and preparing method thereof

A lead-copper, high-strength technology, applied in the field of bearing materials, can solve the problems of weakening the overall mechanical properties of materials, poor interface bonding quality, and agglomeration of ferrous sulfide, and achieve the effects of broadening applications, improving interface bonding ability, and improving easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0020] This implementation case is implemented according to the following steps:

[0021] 1. Weigh 7.2g of ferrous sulfide powder and 232.8g of bronze powder, 240g in total, wherein the bronze powder is weighed according to Table 1 according to the mass percentage. Put 240g into four ball milling tanks, the total mass of powder in a single ball tank is 60g, add 1wt% ethanol, add stainless steel grinding balls, including 250g of large balls and 350g of small balls, vacuumize, fill with argon gas with a purity of 99.999%, and rotate at a speed of 250r / min, ball milling time 30h. After ball milling, cool naturally to obtain 240g mechanical alloy powder;

[0022]

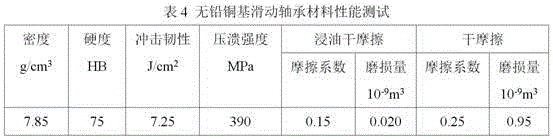

[0023] The mass percentage composition of bronze powder is shown in Table 1.

[0024] 2. Add 0.5wt% zinc stearate as a lubricant to 240g of mechanical alloy powder, and press out friction and wear test samples with a size of 18×6×5 mm on a 100-ton universal hydraulic press, φ15 ×φ25×15mm crush strength test sampl...

Embodiment 2

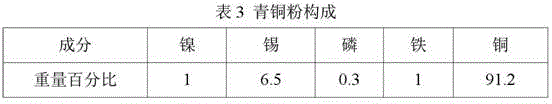

[0031] 1. Weigh 14.4g of ferrous sulfide powder and 225.6g of bronze powder, 240g in total, wherein the bronze powder is weighed according to Table 3 according to the mass percentage. Put 240g into four ball milling tanks, the total mass of powder in a single ball tank is 60g, add 1wt% stearic acid, add stainless steel grinding balls, including 250g of large balls and 350g of small balls, vacuumize, fill with argon gas with a purity of 99.999%, and rotate at a speed of 250r / min, ball milling time 25h. After ball milling, cool naturally to obtain 240g mechanical alloy powder;

[0032]

[0033] The mass percentage composition of bronze powder is shown in Table 3.

[0034] 2. Add 0.5wt% zinc stearate as a lubricant to 240g of mechanical alloy powder, and press out friction and wear test samples with a size of 18×6×5 mm on a 100-ton universal hydraulic press, φ15 ×φ25×15mm crush strength test sample, 55×10×10 mm impact toughness test sample, compression pressure 550MPa.

[0...

Embodiment 3

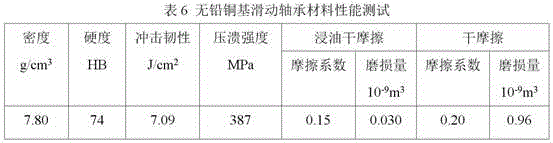

[0039] 1. Weigh 21.6g of ferrous sulfide powder and 218.4g of bronze powder, 240g in total, wherein the bronze powder is weighed according to Table 5 according to the mass percentage. Put 240g into four ball milling tanks, the total mass of powder in a single ball tank is 60g, add 1wt% stearic acid, add stainless steel grinding balls, including 300g of large balls and 300g of small balls, vacuumize, fill with argon gas with a purity of 99.999%, and rotate 300r / min, ball milling time 20h. After ball milling, cool naturally to obtain 240g mechanical alloy powder.

[0040]

[0041] The mass percentage composition of bronze powder is shown in Table 5.

[0042] 2. Add 0.5wt% zinc stearate as a lubricant to 240g of mechanical alloy powder, and press out friction and wear test samples with a size of 18×6×5 mm on a 100-ton universal hydraulic press, φ15× φ25×15mm crush strength test sample, 55×10×10 mm impact toughness test sample, compression pressure 600MPa.

[0043] 3. Then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com