Lead-free copper-based sliding bearing material and preparation method thereof

A sliding bearing, lead-free copper-based technology, applied in the field of lead-free materials, can solve the problems of poor ductility, anti-friction, weak anti-adhesion performance, etc., to improve wettability, increase interface bonding strength, and improve anti-adhesion properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The quality of a single sample of the lead-free copper-based sliding bearing material of the present embodiment is 44g, and the composition of each raw material by weight percentage is as shown in Table 1:

[0029] Table 1 Raw material composition of lead-free copper-based sliding bearing materials

[0030] Element nickel tin iron bismuth phosphorus Molybdenum disulfide copper Content (wt%) 1 8 2 3 0.3 2 margin

[0031] The preparation method of lead-free copper-based sliding bearing material comprises the steps:

[0032] (1) each raw material is carried out batching according to the weight percentage of table 1;

[0033] (2) The method of electroless plating is adopted to form a copper coating on the surface of molybdenum disulfide powder, and the plating solution formula is as follows:

[0034] CuSO 4 ·5H 2 O 10g / L, C 4 h 4 KNa·4H 2 O 50g / L, HCHO: 30g / L; pH=12.

[0035] (3) Add copper, tin, and bismuth into the intermedi...

Embodiment 2

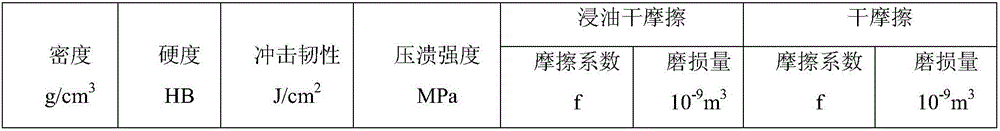

[0046] The preparation method, plating solution formulation, performance testing method and conditions of the lead-free copper-based sliding bearing material in this example are the same as those in Example 1, except that the composition of each raw material by weight percentage is shown in Table 3. The mechanical and friction and wear properties of the obtained materials are shown in Table 4.

[0047] Table 3 Raw material composition of lead-free copper-based sliding bearing materials

[0048] Element nickel tin iron bismuth phosphorus Molybdenum disulfide copper Content (wt%) 1 7 1 3 0.3 4 margin

[0049] Table 4 Performance tests of lead-free copper-based sliding bearing materials

[0050]

Embodiment 3

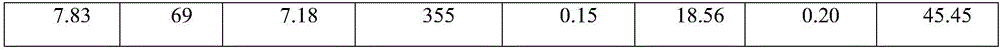

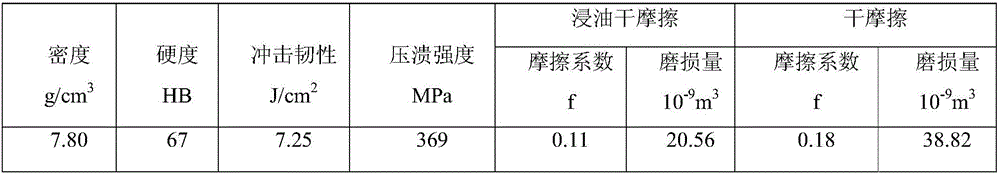

[0052]The preparation method, performance testing method and conditions of the lead-free copper-based sliding bearing material in this example are the same as in Example 1, except that the composition of each raw material by weight percentage is shown in Table 5, and the formulation of the plating solution is shown in Table 6. The mechanical and friction and wear properties of the obtained materials are shown in Table 7.

[0053] Table 5. Raw material composition of lead-free copper-based sliding bearing materials

[0054] Element nickel tin iron bismuth phosphorus Molybdenum disulfide copper Content (wt%) 1 8 1 3 0.4 5 margin

[0055] Table 6 Plating solution formula

[0056]

[0057] Table 7 Performance tests of lead-free copper-based sliding bearing materials

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com