A kind of in-situ titanium dioxide coated lignin composite particle and its preparation and application

A technology of titanium dioxide and composite particles, applied in the field of fine chemicals, can solve the problems of free radical damage, unfavorable engineering application, inability to compound, etc., to improve the problem of easy agglomeration, improve the effect of ultraviolet protection, and improve the effect of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

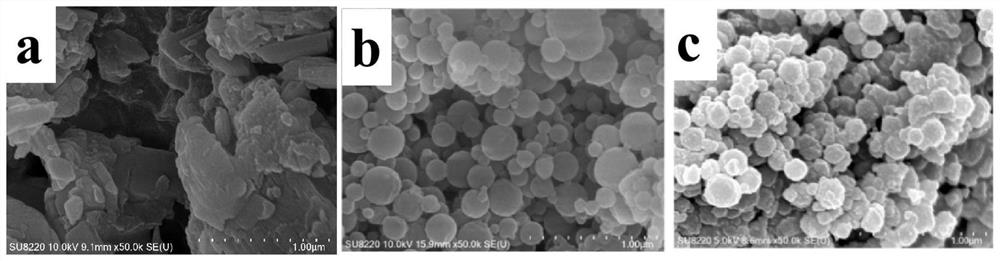

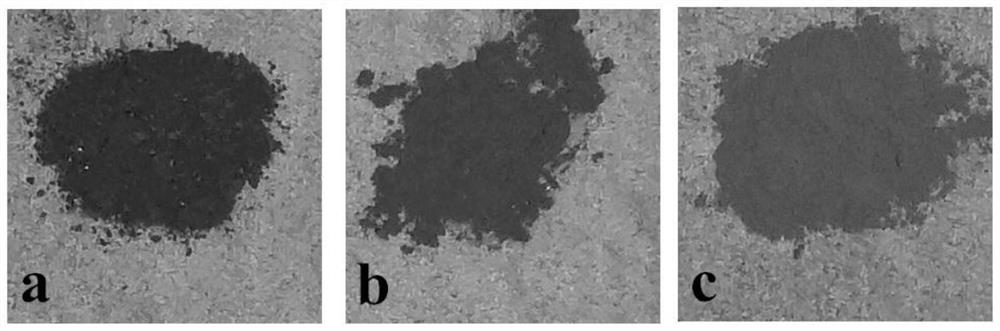

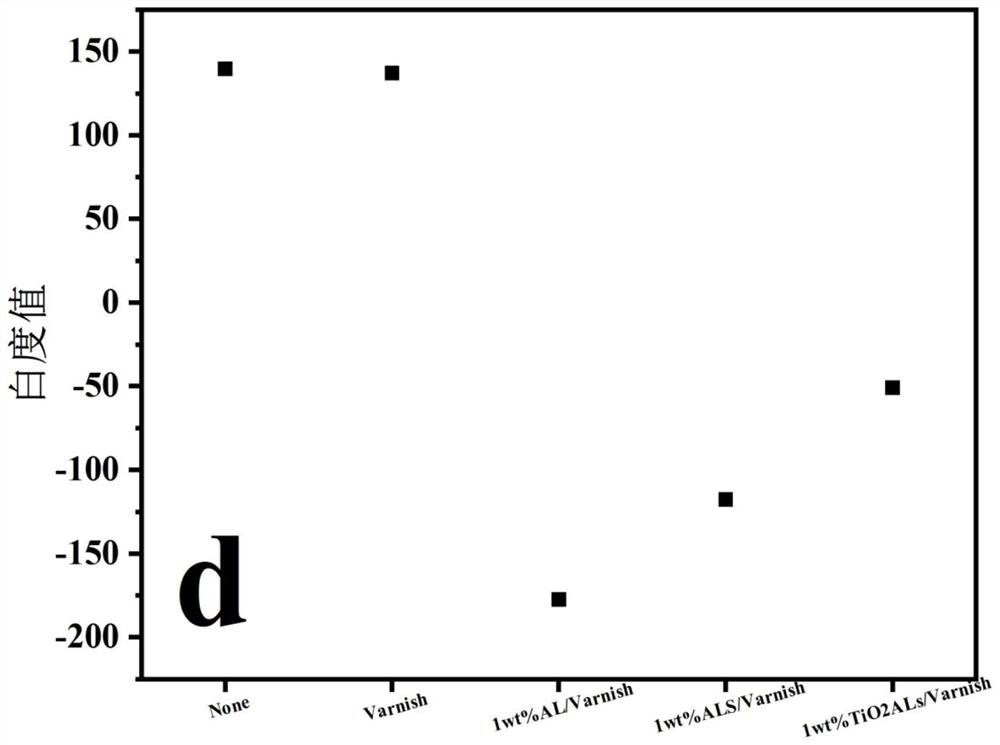

Embodiment 1

[0047] Dissolve 1 g of alkali lignin (AL) in 100 mL of acetone / water mixture (volume ratio: acetone: water = 8:1), stir while adding 400 mL of deionized water; after the addition is complete, rotate the mixture at 45°C, Concentrated and then freeze-dried to obtain lignin colloidal spheres (ALS). Disperse 0.5g of ALS in 250mL of absolute ethanol, sonicate for 30min to disperse evenly, add 4mg of TBOT dropwise within 1.5min under stirring, and record it as dispersion A. Another 250 mL of absolute ethanol was added to 2 mg of concentrated hydrochloric acid (mass fraction: 38%) to form solution B. Use a peristaltic pump to slowly drop solution B into the vigorously stirred dispersion A, and the dropping rate is controlled at 0.8 mL / min. After solution B is added dropwise, continue to stir for 12h to make TiO 2 Fully covered. Afterwards, the dispersion was centrifuged (10000r / min, 30min) and washed three times with absolute ethanol to obtain the product, which was dried in an ov...

Embodiment 2

[0056] Dissolve 1 g of alkali lignin (AL) in 100 mL of acetone / water mixture (volume ratio: acetone: water = 8:1), stir while adding 400 mL of deionized water; after the addition is complete, rotate the mixture at 45°C, Concentrated and then freeze-dried to obtain lignin colloidal spheres (ALS). Disperse 0.5g of ALS in 250mL of absolute ethanol, sonicate for 30min to disperse evenly, add 2mg of TBOT dropwise within 1.5min under stirring, and record it as dispersion A. Another 250 mL of absolute ethanol was added to 2 mg of concentrated hydrochloric acid (mass fraction: 38%) to form solution B. Use a peristaltic pump to slowly drop solution B into the vigorously stirred dispersion A, and the dropping rate is controlled at 0.8 mL / min. After solution B is added dropwise, continue to stir for 12h to make TiO 2 Fully covered. Afterwards, the dispersion was centrifuged (10000r / min, 30min) and washed three times with absolute ethanol to obtain the product, and dried in an oven at ...

Embodiment 3

[0059]Dissolve 1 g of alkali lignin (AL) in 100 mL of acetone / water mixture (volume ratio: acetone: water = 8:1), stir while adding 400 mL of deionized water; Concentrated and then freeze-dried to obtain lignin colloidal spheres (ALS). Disperse 0.5g of ALS in 250mL of absolute ethanol, ultrasonically treat for 30min to disperse evenly, add 6mg of TBOT dropwise under stirring, and record it as dispersion A. Another 250 mL of absolute ethanol was added to 2 mg of concentrated hydrochloric acid (mass fraction: 38%) to form solution B. Use a peristaltic pump to slowly drop solution B into the vigorously stirred dispersion A, and the dropping rate is controlled at 0.8 mL / min. After solution B is added dropwise, continue to stir for 12h to make TiO 2 Fully covered. Afterwards, the dispersion was centrifuged (10000r / min, 30min) and washed three times with absolute ethanol to obtain the product, and dried in an oven at 100°C for 12h to obtain TiO 2 / Lignin ball-based composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com