Preparation method of 1, 1, 1, 3-tetrachloropropane

A technology of tetrachloropropane and carbon tetrachloride, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as easy oxidation, easy agglomeration of iron powder, and increase of iron specific surface area , to achieve the effect of increasing the contact area, good catalytic effect and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

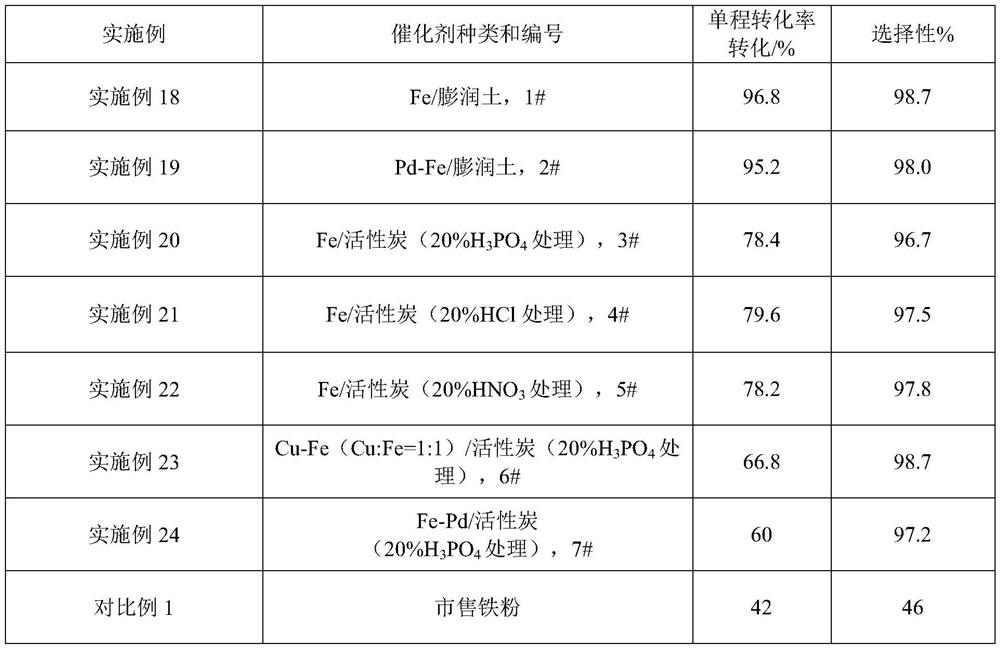

Examples

preparation example Construction

[0067] In another preferred embodiment, the preparation method of the catalyst comprises the steps:

[0068] (i) Using a metal salt (FeSO4) with a carrier (organic bentonite) 4 ·7H 2 O) ethanol-aqueous solution with reducing agent (NaBH) 4 ) solution to carry out reduction reaction, thereby obtaining the nano-zero valent iron supported by organobentonite; continue to add the second metal component (PdCl 2 ); continue the reduction reaction; the Pd content in the obtained catalyst is: 0.04%. Suction filtration, vacuum drying oven drying. During the whole reaction process, nitrogen gas was continuously introduced to isolate the air.

[0069] In another preferred embodiment, the metal salt is FeCl 2 ·4H 2 O.

[0070] In another preferred embodiment, the carrier is modified activated carbon.

[0071] In another preferred embodiment, the reducing agent is KBH 4 .

[0072] In another preferred embodiment, the second metal component is K 2 PdCl 6 .

[0073] In another pr...

Embodiment 1

[0104] The preparation of embodiment 1 catalyst

[0105] Add 5g of organic bentonite to 250mL, 0.054mol / L FeSO 4 ·7H 2 O solution, stir for 6h; adjust PH4 The aqueous solution was dropped into the above solution, stirred for 2 hours, and the whole process was vented with nitrogen to isolate the air to prevent the nano-zero valent iron from being oxidized by oxygen in the air. Filter, wash with deionized water and alcohol. Dry in a vacuum oven.

Embodiment 2

[0106] The preparation of embodiment 2 catalyst

[0107] Add 5g of organic bentonite to 250mL, 0.054mol / L FeCl 2 ·4H 2 O solution, stir for 6h; adjust PH4 The aqueous solution was dropped into the above solution, stirred for 2 hours, and the whole process was vented with nitrogen to isolate the air to prevent the nano-zero valent iron from being oxidized by oxygen in the air. Filter, wash with deionized water and alcohol. Dry in a vacuum oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com