A kind of indium antimony tin oxide nanopowder and preparation method thereof

An indium-antimony tin oxide and nano-powder technology is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., and can solve the problems of inconsistent solubility of different metal salts and their hydrolyzed products, complex preparation processes, difficult to enlarge, and large differences in solubility. and other problems, to achieve easy industrial production, improve the problem of easy agglomeration, and achieve the effect of less powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

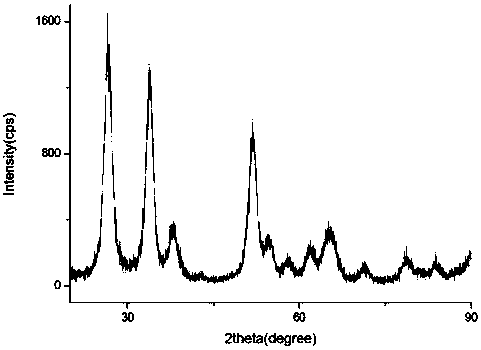

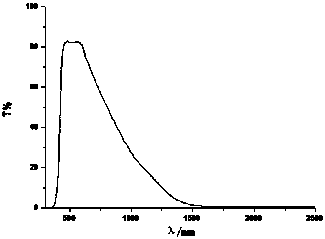

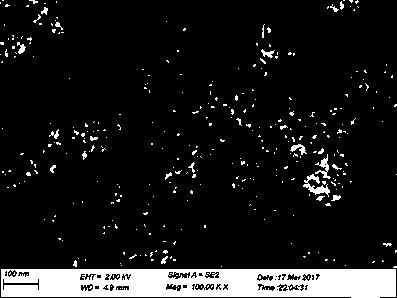

Image

Examples

Embodiment 1

[0030] A preparation method of indium antimony tin oxide nanopowder, comprising the steps of:

[0031] (1) Mix antimony salt, tin salt and indium salt and dissolve in acidic solution to obtain solution A; dissolve alkaline precipitant and surfactant in deionized water in turn to obtain solution B;

[0032] (2) Add solution A to solution B under stirring, after the reaction is completed, age to obtain solution C;

[0033] (3) Centrifuge the solution C, and wash, dry, grind and sinter the separated precipitate to obtain indium-antimony-doped tin oxide nanopowder.

[0034] In the step (1), the surfactant is sodium dodecylbenzenesulfonate.

[0035] In the step (1), the molar ratio of antimony salt, tin salt and indium salt is 15:1:1, and the antimony salt is SbF 5 , the tin salt is SnCl 4 ·5H 2 O, the indium salt is InCl 3 4H 2 O.

[0036] In the step (1), the acidic solution is citric acid with a concentration of 1.8mol / L; the alkaline precipitating agent is a weakly alkal...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] In the step (1), the surfactant is stearic acid.

[0045] In the step (1), the molar ratio of antimony salt, tin salt and indium salt is 16:2:1, and the antimony salt is SbF 3 , the tin salt is SnCl 2 , the indium salt is In(NO 3 ) 3 .

[0046] In the step (1), the acidic solution is oxalic acid with a concentration of 1.9mol / L; the alkaline precipitant is a weakly alkaline precipitant, and the weakly alkaline precipitant is urea, the amount of urea It is 3 times of the total substance amount of the anions of antimony salt, tin salt and indium salt.

[0047] In the step (1), the process of sequentially dissolving the alkaline precipitating agent and the surfactant in the deionized water is carried out under heating, and the heating temperature is 78°C.

[0048] In the step (2), the solution A is dropped into the solution B through a constant pressure dropping funnel, and this process is carried o...

Embodiment 3

[0053] The difference between this embodiment and embodiment 1 and 2 is:

[0054] In the step (1), the surfactant is compounded by sodium dodecylbenzenesulfonate, sodium dodecylsulfate and sodium dioctylsuccinatesulfonate in a weight ratio of 2.2:1.5:1.

[0055] In the step (1), the molar ratio of antimony salt, tin salt and indium salt is 17:3:1, and the antimony salt is SbCl 3 and SbCl 5 Compounded according to the molar ratio of 1:1, the tin salt is SnCl 4 ·5H 2 O, SnCl 2 Compounded according to the molar ratio of 1:1, the indium salt is InCl 3 4H 2 O and InCl 2 It is formulated according to the molar ratio of 2:1.

[0056] In the step (1), the acidic solution is compounded with citric acid and tartaric acid at a volume ratio of 1:2, and the concentration of the acidic solution is 2mol / L; the alkaline precipitating agent is weakly alkaline precipitation agent, the weakly basic precipitating agent is urea, and the amount of urea is 4 times of the total amount of anio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com