Waterborne epoxy anticorrosive paint containing composite functional modified graphene oxide and preparation method and application

A composite function, anti-corrosion coating technology, applied in the field of coatings, can solve the problems of graphene agglomeration, difficult to uniformly disperse polymers, and inapplicability, so as to enhance environmental resistance, avoid human health and environmental hazards, and have a small pungent smell Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

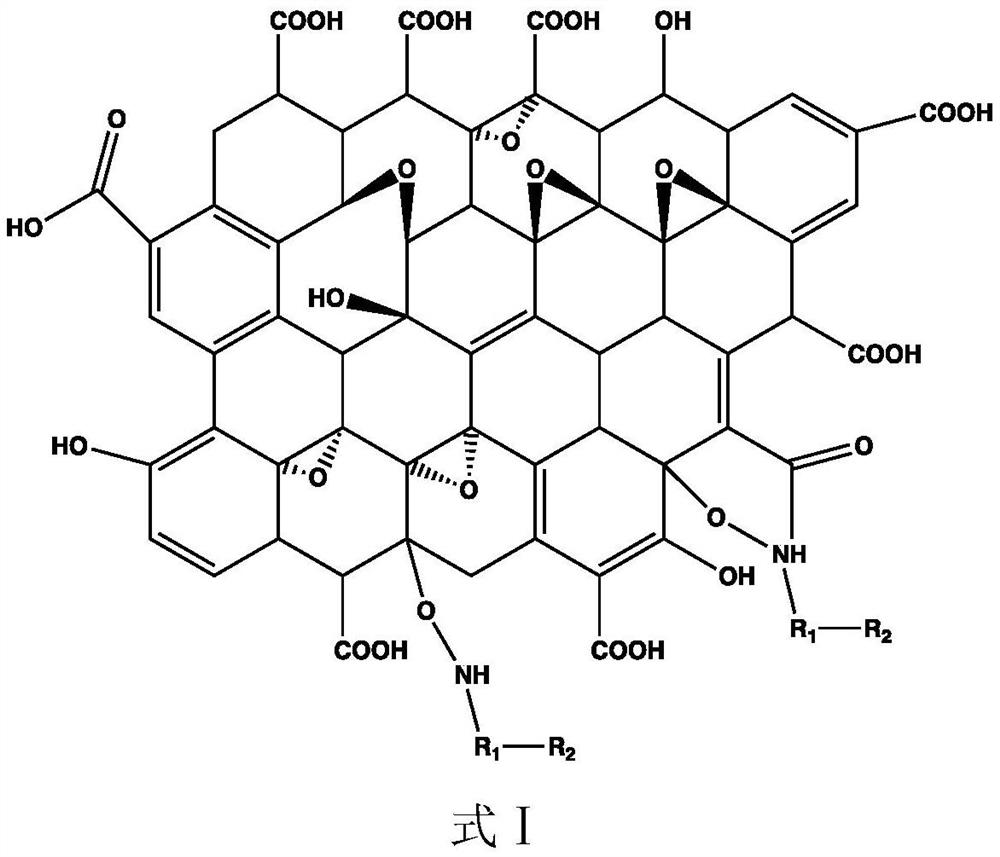

[0045] 1. Preparation of composite functionalized modified graphene oxide:

[0046] (1) Preparation of amino acid modified graphene oxide: 1 mass part of graphene oxide (GO) was dispersed in 100 mass parts of deionized water by ultrasonic treatment for 30 minutes at a power of 300W to obtain uniform graphene oxide Suspension, while stirring, the lysine of 10 mass parts is added dropwise in the suspension, under N 2 Under protection, react at 40° C. for 12 hours, wash the obtained product, remove unreacted lysine by suction filtration, and then dry the obtained solid to obtain a black solid powder of lysine-modified graphene oxide.

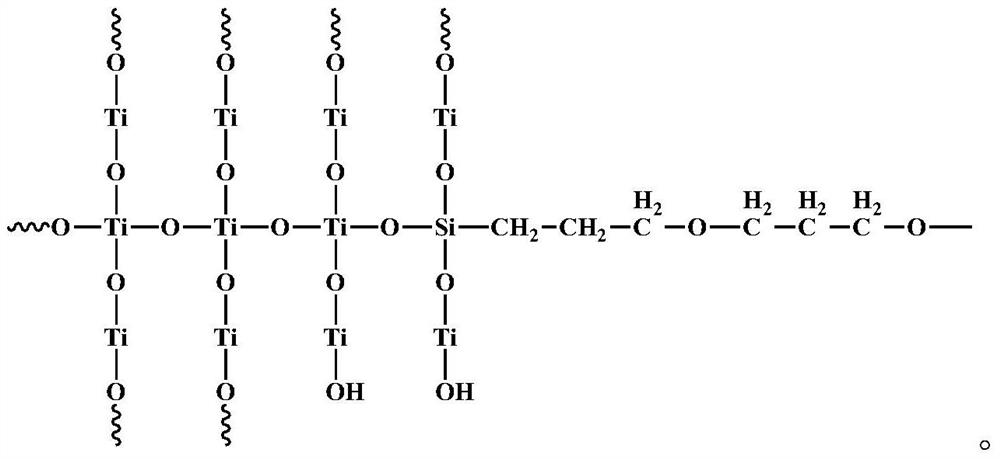

[0047] (2) Preparation of silane coupling agent modified titanium dioxide: 1 mass part of titanium dioxide was dispersed in a mixed solution of 100 mass parts deionized water and absolute ethanol (deionized Water / absolute ethanol (V1:V2=1:9)) to obtain a titanium dioxide suspension, while stirring, 10 parts by mass of γ-glycidyl etheroxypropyltrim...

Embodiment 2

[0056] 1. Preparation of composite functionalized modified graphene oxide:

[0057] (1) Preparation of amino acid modified graphene oxide: 1 mass part of graphene oxide (GO) was dispersed in 120 mass parts of deionized water by ultrasonic treatment at 400W for 50 minutes to obtain uniform graphene oxide Suspension, while stirring, the lysine of 15 mass parts is added dropwise in the suspension, under N 2 Under protection, react at 45° C. for 16 h, wash the obtained product, remove unreacted lysine by suction filtration, and then dry the obtained solid to obtain a black solid powder of lysine-modified graphene oxide.

[0058] (2) Preparation of silane coupling agent modified titanium dioxide: 1 mass part of titanium dioxide was dispersed in a mixed solution of 120 mass parts deionized water and absolute ethanol (deionized Water / absolute ethanol (V1:V2=1:9)) to obtain a titanium dioxide suspension, while stirring, 15 parts by mass of γ-glycidyl etheroxypropyltrimethoxysilane (K...

Embodiment 3

[0067] 1. Preparation of composite functionalized modified graphene oxide:

[0068] (1) Preparation of amino acid modified graphene oxide: 1 mass part of graphene oxide (GO) was dispersed in 150 mass parts of deionized water by ultrasonic treatment for 60 minutes at a power of 600W to obtain uniform graphene oxide Suspension, while stirring, the lysine of 20 mass parts is added dropwise in the suspension, under N 2 Under protection, react at 50° C. for 18 hours; wash the obtained product, remove unreacted lysine by suction filtration, and then dry the obtained solid to obtain a black solid powder of lysine-modified graphene oxide.

[0069] (2) Preparation of silane coupling agent modified titanium dioxide: 1 mass part of titanium dioxide was dispersed in a mixed solution of 150 mass parts deionized water and absolute ethanol (deionized Water / absolute ethanol (V1:V2=1:9)) to obtain a titanium dioxide suspension, while stirring, 20 parts by mass of γ-glycidyl etheroxypropyltrim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com