Preparation method and application of core-shell structural magnetic nano composite catalyst

A composite catalyst, magnetic nanotechnology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of inefficient removal of new organic pollutants, etc. To achieve the effect of reuse, high-efficiency magnetic separation capability, and promotion of electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

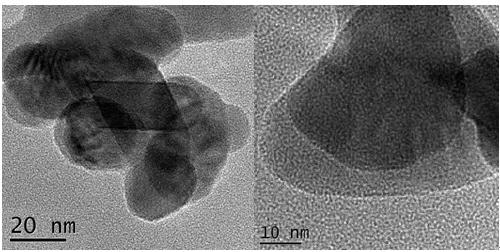

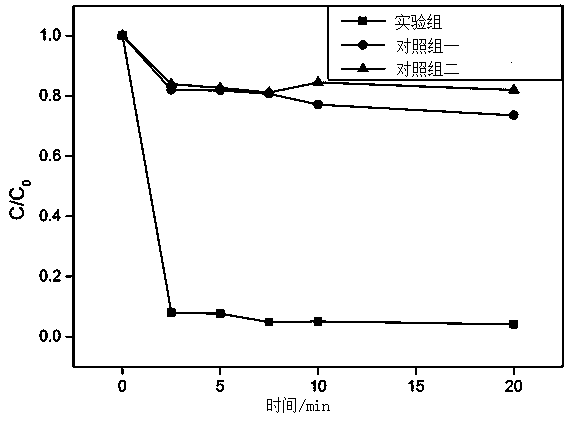

[0034] Embodiment one, a kind of preparation method of core-shell structure magnetic nanocomposite catalyst, it comprises the steps:

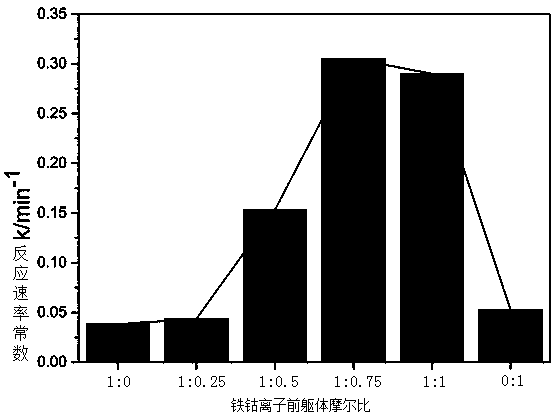

[0035] S1, will contain Fe 2+ Metal salt X and containing Co 2+ The metal salt Y was dissolved in deionized water, the molar ratio of the metal salt X and the metal salt Y was 1:0.75, and stirred for 10 minutes to obtain the mixed solution A;

[0036] S2, by removing the dissolved oxygen in the mixed solution A, to obtain the mixed solution B;

[0037] S3, using the automatic dropwise method of peristaltic pump, adding NaOH solution with a concentration of 0.5mol / L to the mixed solution B dropwise and stirring at a temperature of 25°C, adjusting the pH value of the mixed solution B to 9, Continue to stir to obtain a dark green reaction precursor solution to obtain a mixed solution C;

[0038] S4, transfer the mixed solution C into a water bath, heat under reflux at a temperature of 30° C. and stir for 14 hours, then let it stand for 2 hours,...

Embodiment 2

[0040] Embodiment 2, a method for preparing a magnetic nanocomposite catalyst with a core-shell structure, which comprises the following steps:

[0041] S1, will contain Fe 2+ Metal salt X and containing Co 2+ The metal salt Y was dissolved in deionized water, the molar ratio of the metal salt X and the metal salt Y was 1:0.5, and stirred for 15 minutes to obtain the mixed solution A;

[0042] S2, removing the dissolved oxygen in the mixed solution A through ultrasonic vibration to obtain the mixed solution B;

[0043] S3, using a burette to manually drop, add the NaOH solution with a concentration of 2mol / L to the mixed solution B drop by drop and stir at a temperature of 15°C, adjust the pH value of the mixed solution B to 12, and continue to stir A dark green reaction precursor solution was obtained, and a mixed solution C was obtained;

[0044] S4, transfer the mixed solution C into a water bath, heat and stir under reflux at a temperature of 20°C for 10 h, then let it ...

Embodiment 3

[0046] Embodiment three, a kind of preparation method of core-shell structure magnetic nanocomposite catalyst, it comprises the following steps:

[0047] S1, will contain Fe 2+ Metal salt X and containing Co 2+ The metal salt Y is dissolved in deionized water, the molar ratio of the metal salt X and the metal salt Y is 1:1, and stirred for 20 minutes to obtain the mixed solution A;

[0048] S2, removing the dissolved oxygen in the mixed solution A through ultrasonic vibration to obtain the mixed solution B;

[0049] S3, using the automatic dropwise addition method of the peristaltic pump, adding the NaOH solution with a concentration of 0.1mol / L to the mixed solution B dropwise and stirring at a temperature of 30°C, adjusting the pH value of the mixed solution B to 10, Continue to stir to obtain a dark green reaction precursor solution to obtain a mixed solution C;

[0050] S4, transfer the mixed solution C into a water bath, heat and stir under reflux at a temperature of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com