Integrated porous palladium-gold alloy catalyst and preparation method thereof

A gold-palladium alloy and monolithic technology, which is applied in the field of monolithic porous gold-palladium alloy catalysts, and achieves the effects of good mass transfer, heat transfer and electrical conductivity, easy recovery and reuse, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

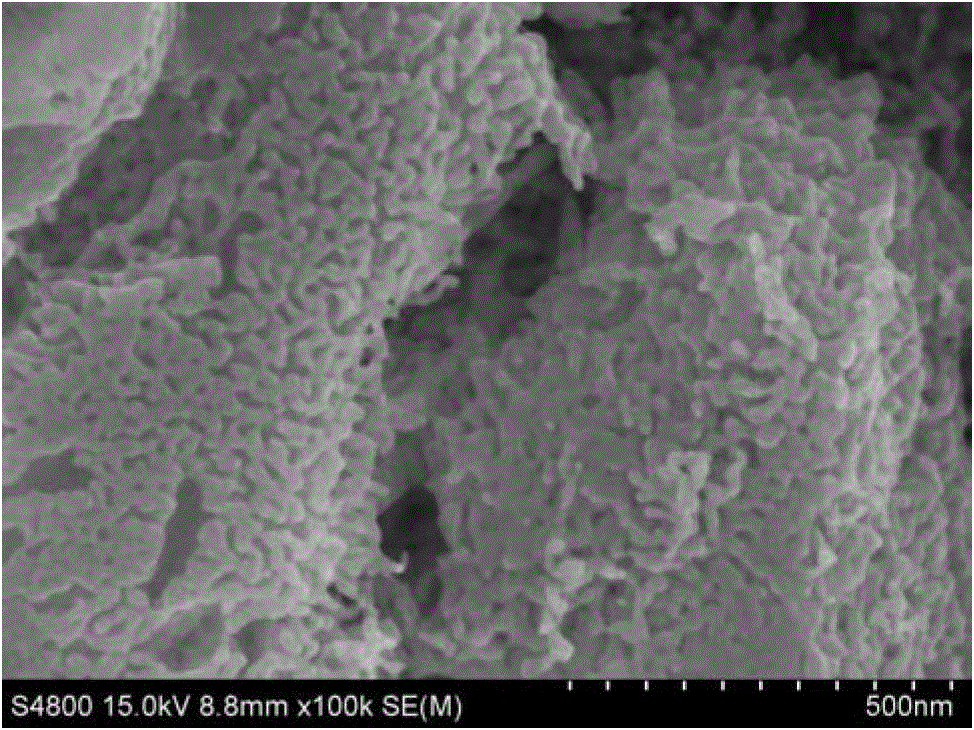

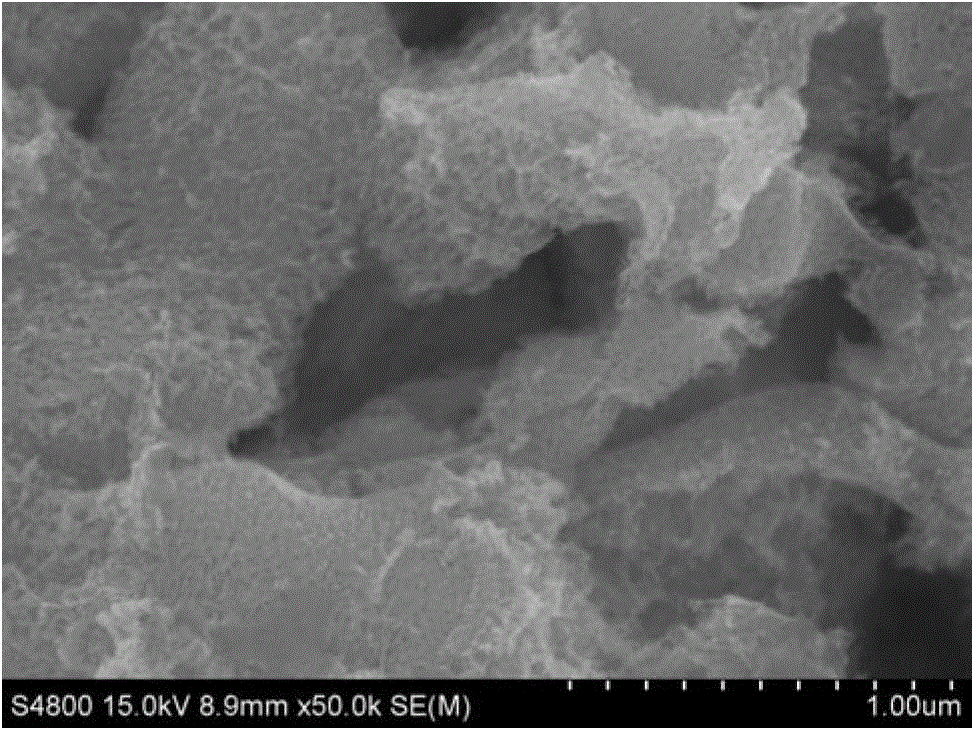

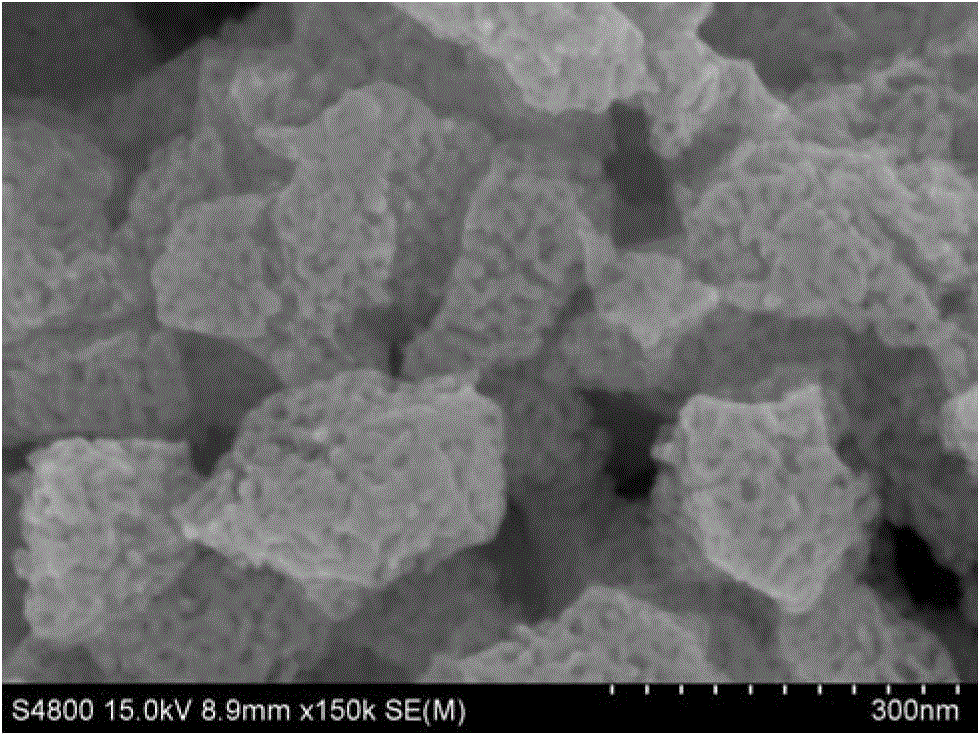

[0008] A monolithic porous gold-palladium alloy catalyst, characterized in that: comprising a gold-palladium-silver alloy core and a porous gold-palladium alloy film with a thickness of 0.1 to 40 μm, the porous gold-palladium alloy film evenly covers the gold-palladium-silver alloy core For the outer layer, the diameter of the gold-palladium-silver alloy core is 1-800 μm, and the mass ratio of gold, palladium, and silver in the gold-palladium-silver alloy core is (25-50): (25-50): 25; the porous gold The palladium alloy film is a porous structure with small holes distributed continuously on the channel wall, the width of the channel is 0.1-10 μm, the diameter of the small holes is 1-500 nm, and the gold content of the porous gold-palladium alloy film is 20-500 nm. 99at.%, palladium content is 80~1at.%.

[0009] Preferably in the present invention, the diameter of the gold-palladium-silver alloy core is 80-120 μm, and the mass ratio of gold, palladium, and silver in the gold-pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com