Graded-hole gold-copper alloy monolithic catalyst and preparation method thereof

A monolithic catalyst, gold-copper alloy technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, carbon-based compound preparation, etc., can solve the problem of poor catalyst dispersion and lack of effective carrier , poor mass and heat transfer capabilities, etc., to achieve the effect of easy recycling, good mass and heat transfer and electrical conductivity, and no loss of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method for preparing the graded pore gold-copper alloy monolithic catalyst includes the following steps:

[0046] (1) At 0.5mol / L CuSO 4 And 0.2mol / L H 2 SO 4 In the mixed solution of, add -0.2V bias voltage for 400s to electrodeposit copper on the surface of the gold-copper alloy wire, the length of the gold-copper alloy is 5cm;

[0047] (2) Anneal the alloy wire processed in step (1) in a nitrogen atmosphere at 500°C for 6 hours;

[0048] (3) Place the alloy wire in 68wt.% concentrated nitric acid in a constant temperature water bath of 30°C for free corrosion for 9h;

[0049] (4) Collect the corroded alloy wire, wash it repeatedly with ultrapure water 10 times, use a wide pH test paper to test that the washed water is neutral, and then dry it in air at 25°C to obtain a graded pore gold-copper alloy monolithic catalyst.

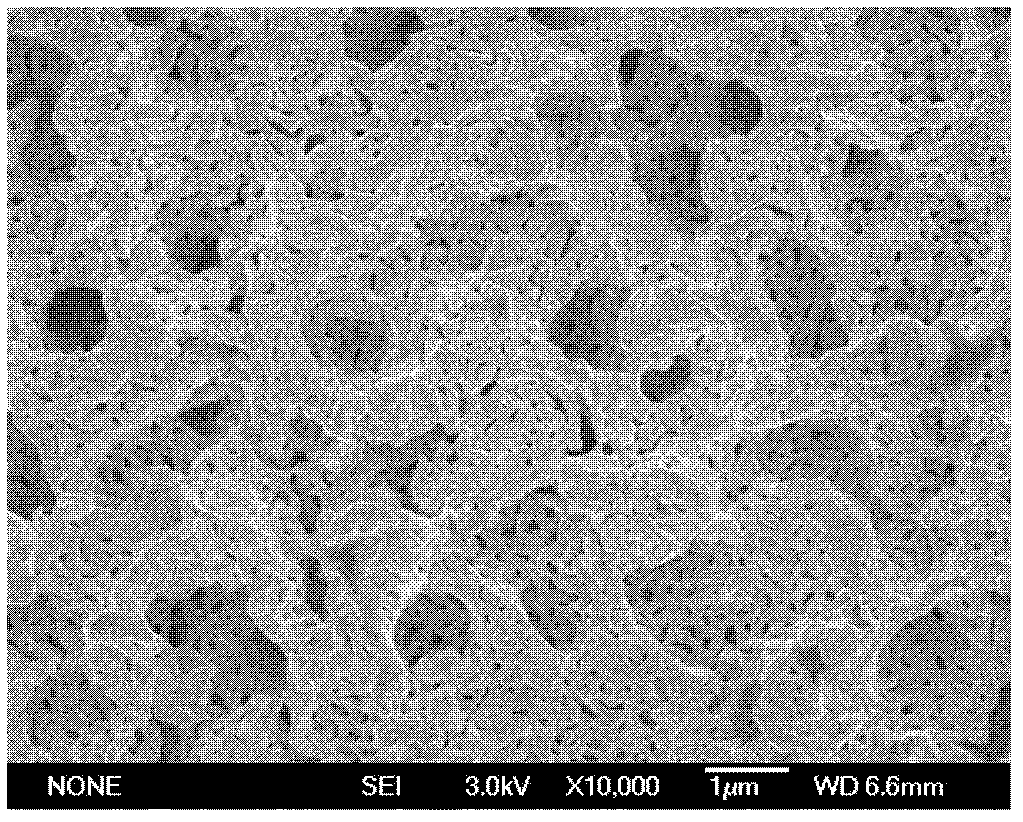

[0050] The above preparation method produces a graded-porous gold-copper alloy monolithic catalyst, which consists of a gold-copper alloy core and a grade...

Embodiment 2

[0053] The method for preparing the graded pore gold-copper alloy monolithic catalyst includes the following steps:

[0054] (1) At 0.5mol / L CuSO 4 And 0.2mol / L H 2 SO 4 In the mixed solution of, add -0.2V bias voltage for 400s to electrodeposit copper on the surface of the gold-copper alloy wire, the size of the gold-copper alloy wire is 5cm;

[0055] (2) Anneal the alloy wire treated in step (1) in a nitrogen atmosphere at 500°C for 6 hours;

[0056] (3) Place the alloy wire in 68wt.% concentrated nitric acid in a constant temperature water bath at 30°C for free corrosion for 24h;

[0057] (4) Collect the corroded alloy wire, wash it repeatedly with ultrapure water 10 times, use a wide pH test paper to test that the washed water is neutral, and then dry it in air at 25°C to obtain a graded pore gold-copper alloy monolithic catalyst.

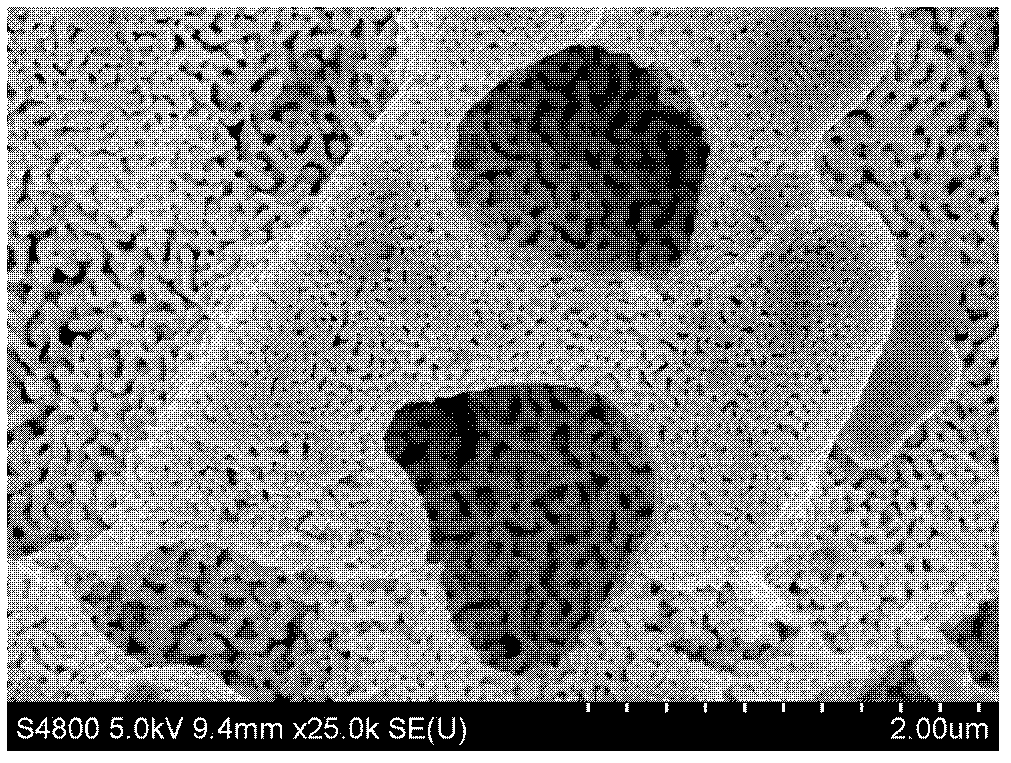

[0058] The above preparation method produces a graded-porous gold-copper alloy monolithic catalyst, which is composed of a gold-copper alloy core and a ...

Embodiment 3

[0061] The method for preparing the graded pore gold-copper alloy monolithic catalyst includes the following steps:

[0062] (1) At 0.5mol / L CuSO 4 And 0.2mol / L H 2 SO 4 In the mixed solution of, add -0.2V bias voltage for 400s to electrodeposit copper on the surface of the gold-copper alloy wire, the size of the gold-copper alloy wire is 5cm;

[0063] (2) Anneal the alloy wire treated in step (1) in a nitrogen atmosphere at 500°C for 6 hours;

[0064] (3) Put the alloy wire in 0.5mol / L sulfuric acid in a water bath with a constant temperature of 30℃, and use a gold-copper alloy as the working electrode, platinum as the counter electrode and calomel electrode as the reference under the condition of a constant temperature of 30℃. Electrode, add bias voltage 0.1~2V for corrosion treatment, corrosion for 0.1h;

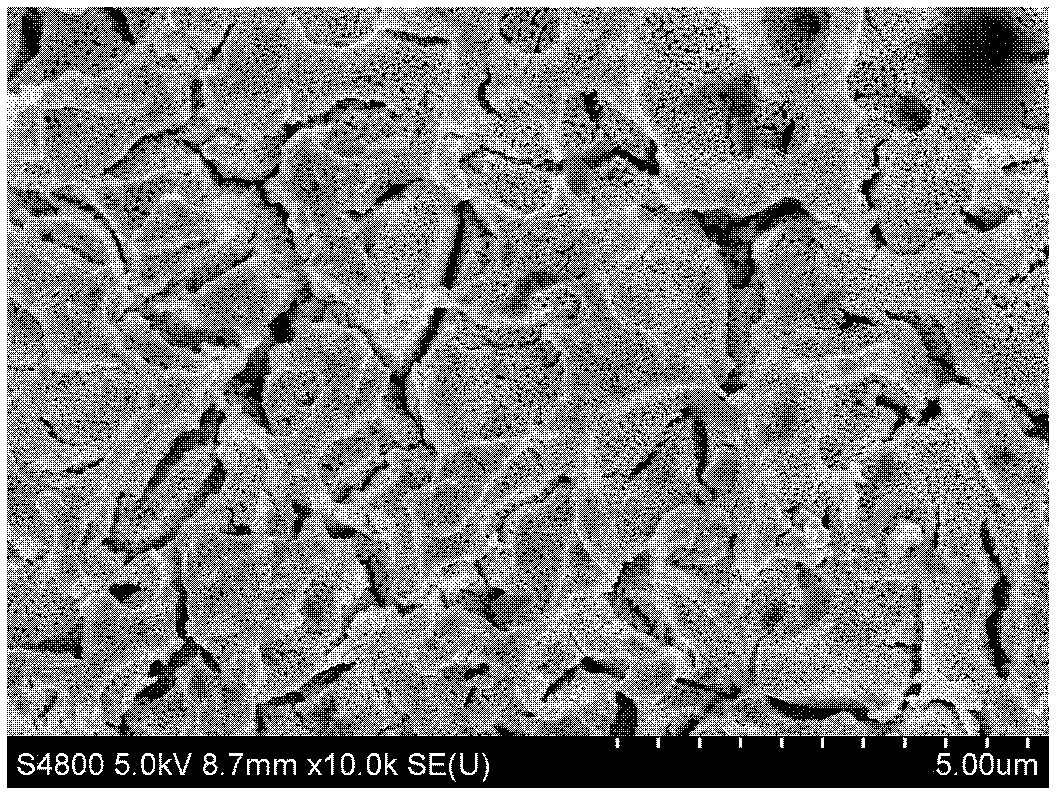

[0065] (4) Collect the corroded alloy wire, repeatedly wash it with ultrapure water 15 times, use a wide pH test paper to test that the rinsed water is neutral, and then dry it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com