Phosphonitrile grafting-modified hydrotalcite flame retardant and preparation method thereof

A technology of graft modification and hydrotalcite, which is applied in chemical instruments and methods, fibrous fillers, dyed low-molecular organic compound treatment, etc., can solve the problems that the preparation method has not been reported, achieve good application value, and improve flame retardancy Performance and mechanical properties, the effect of easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

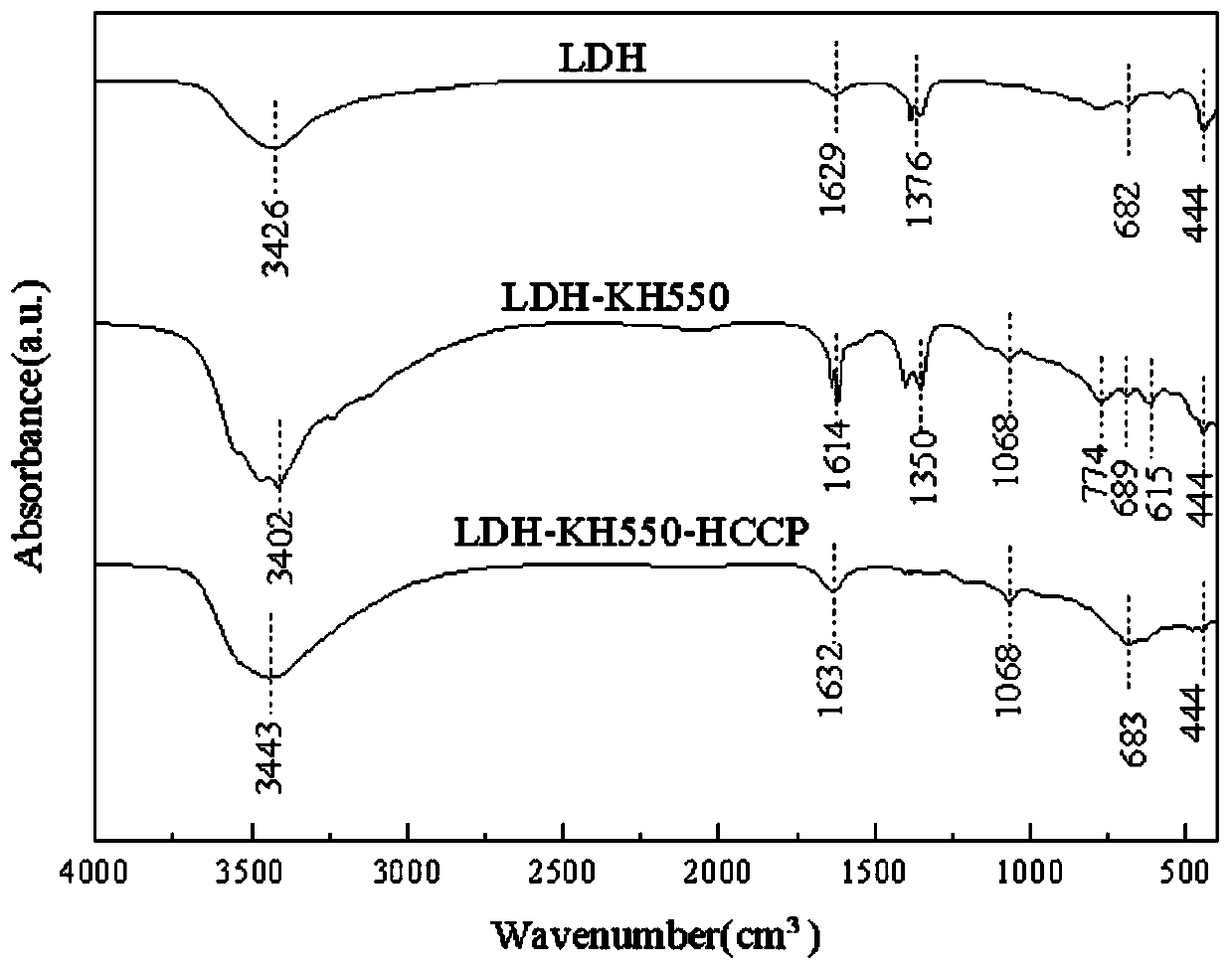

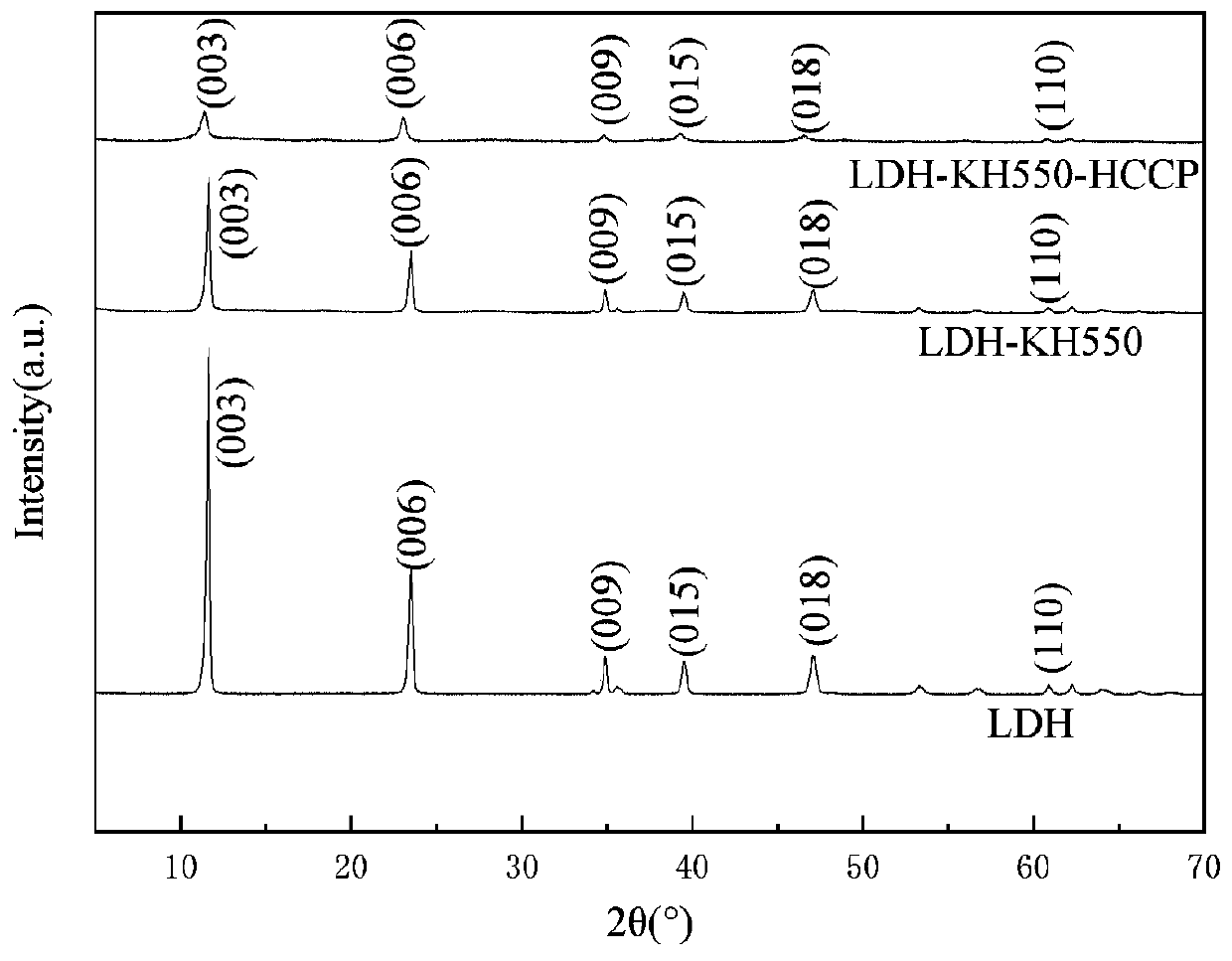

[0035] Weigh Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and urea (according to the Mg:Al molar ratio of 2:1, the amount of urea is 3.3 times the total mass of Mg and Al), dissolved in 400mL of deionized water, reacted in the reactor at 110°C for 24h, filtered and washed, Dry overnight at 80°C to obtain Mg / Al hydrotalcite (LDH).

[0036] Put 6g of Mg / Al hydrotalcite into 300mL of ethanol and water mixture (1:3 volume ratio), and ultrasonically disperse at 50°C for 30min, weigh 0.6g of 3-aminopropyltriethoxysilane in 150mL of ethanol In the mixed solution with water (volume ratio: 9:1), slowly add the silane coupling agent solution to the hydrotalcite suspension under nitrogen gas, add acetic acid to adjust the pH to 4, and stir at 90°C for 24 hours. Filter, wash, and dry to obtain Mg / Al hydrotalcite (LDH-KH550) with amino groups on the surface.

[0037] Using tetrahydrofuran as a solvent, prepare 15g / L Mg / Al hydrotalcite suspension containing amine groups on the surface, we...

Embodiment 2

[0039] Weigh the Zn(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2O and urea (according to the Zn:Fe molar ratio of 3:1, the urea amount is 3.3 times the total mass of Zn and Fe), dissolved in 400mL deionized water, reacted at 110°C in the reactor for 24h, filtered and washed, Dry overnight at 80°C to obtain Zn / Fe hydrotalcite.

[0040] Put 6g of Zn / Fe hydrotalcite into 300mL of ethanol and water mixture (1:3 volume ratio), and ultrasonically disperse at 40°C for 50min, weigh 1.5g of 3-aminopropyltriethoxysilane in 150mL of ethanol In the mixed solution with water (volume ratio: 9:1), slowly add the silane coupling agent solution to the hydrotalcite suspension under nitrogen gas, add acetic acid to adjust the pH to 4, and stir at 90°C for 24 hours. filtering, washing and drying to obtain the Zn / Fe hydrotalcite containing amino groups on the surface.

[0041] Using tetrahydrofuran as a solvent, prepare 15g / L of Zn / Fe hydrotalcite suspension containing amine groups on the surface, we...

Embodiment 3

[0043] Weigh Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and urea (according to the Ni:Al molar ratio of 4:1, the amount of urea is 3.3 times the total mass of Ni and Al), dissolved in 400mL of deionized water, reacted at 110°C for 24h in the reactor, filtered and washed, Dry overnight at 80°C to obtain Ni / Al hydrotalcite.

[0044] Put 6g of Ni / Al hydrotalcite into 300mL of ethanol and water mixture (1:3 volume ratio), and ultrasonically disperse at 45°C for 40min, weigh 1.8g of 3-aminopropyltriethoxysilane in 150mL of ethanol In the mixed solution with water (volume ratio: 9:1), slowly add the silane coupling agent solution to the hydrotalcite suspension under nitrogen gas, add acetic acid to adjust the pH to 4, and stir at 90°C for 24 hours. Filtrate, wash, and dry to obtain Ni / Al hydrotalcite with amino groups on the surface.

[0045] Using tetrahydrofuran as a solvent, prepare 15g / L Ni / Al hydrotalcite suspension containing amine groups on the surface, weigh 2.5g hexachl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com