Method and device for preparing scandium-zirconium powder

A technology of zirconium powder and zirconium precursor, applied in the field of solid electrolyte materials, can solve problems such as easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

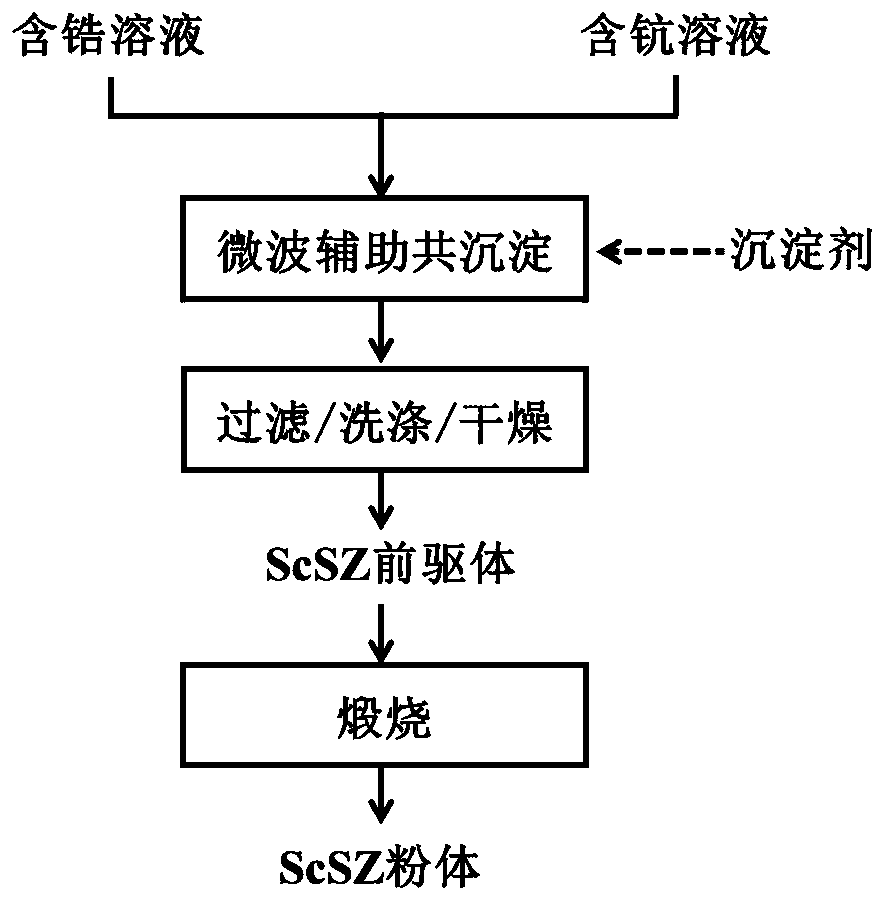

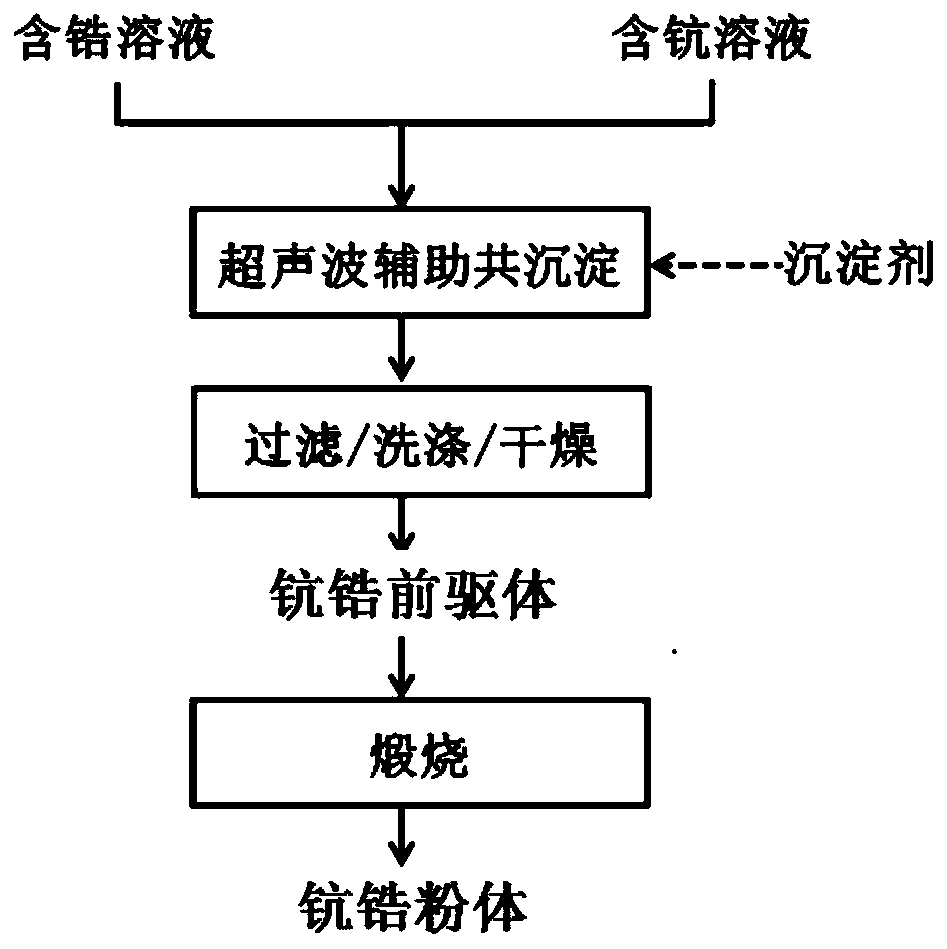

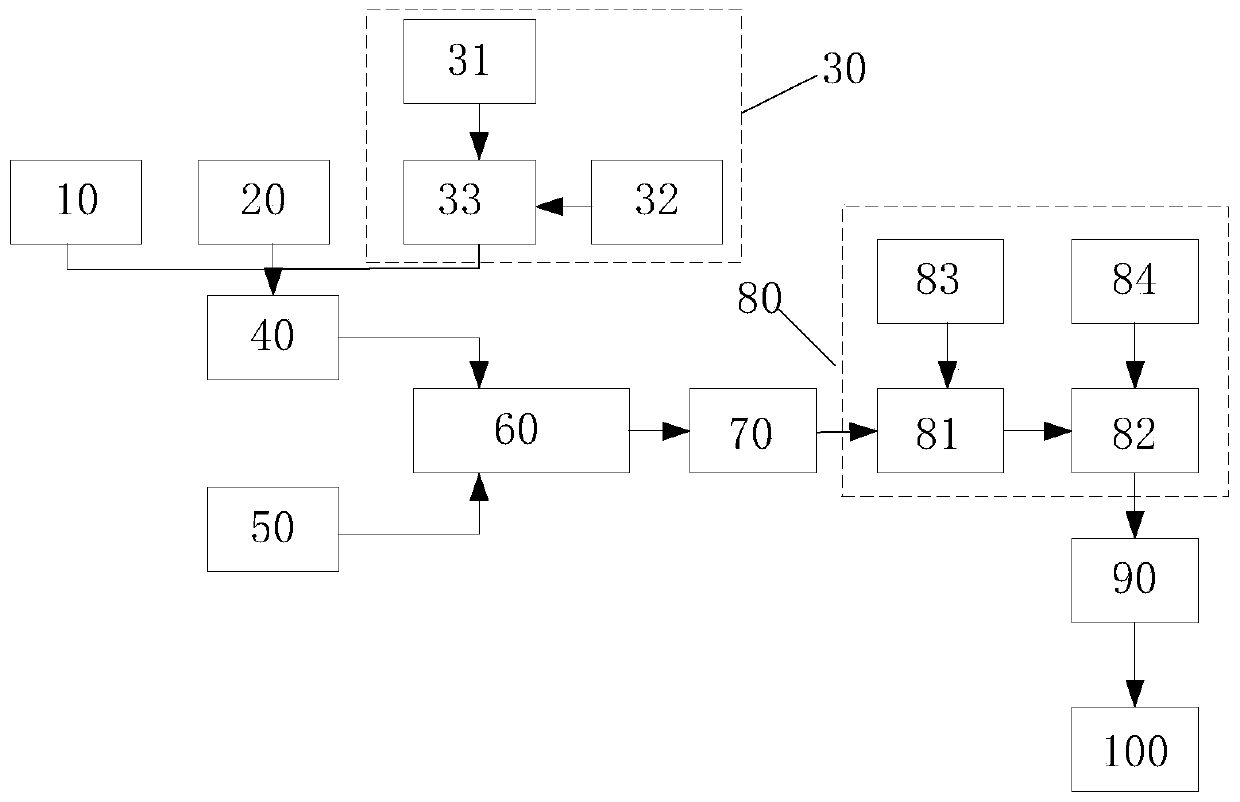

Method used

Image

Examples

Embodiment 1

[0061] Configure the reaction solution: dissolve zirconium oxychloride in water to obtain zirconium oxychloride solution, add Sc 2 o 3 Dissolve in hot hydrochloric acid to obtain a scandium chloride solution, mix and stir the above solutions to obtain a scandium-zirconium mixed solution, wherein the cation concentration of the scandium-zirconium mixed solution is 1.5 mol / l, and the scandium ion is the total number of scandium ions and zirconium ions. 10%.

[0062] Co-precipitation: put the mixed solution in a microwave reactor with a reaction temperature of 80°C, a stirring speed of 200r / min, and a microwave power of 500W, and add ammonia water to adjust the pH of the mixed solution of scandium and zirconium to 9 to prepare a precursor solution of scandium and zirconium. Filter the prepared scandium-zirconium precursor solution and wash it repeatedly with water until there is no Cl - , and then washed three times with alcohol, and dried at 100°C to obtain a scandium-zirconiu...

Embodiment 2

[0065] Configure the reaction solution: dissolve zirconium oxychloride in water to obtain zirconium oxychloride solution, mix Sc 2 o 3 Dissolve in hot hydrochloric acid to obtain a scandium chloride solution, mix and stir the above solutions to obtain a scandium-zirconium mixed solution, wherein the cation concentration of the scandium-zirconium mixed solution is 2mol / l, and the scandium ion is 8% of the total molar amount of the scandium ion and the zirconium ion %.

[0066] Co-precipitation: put the mixed solution in a microwave reactor with a reaction temperature of 30°C, a stirring speed of 100r / min, and a microwave power of 1000W, and ammonium bicarbonate was added to adjust the pH of the mixed solution of scandium and zirconium to 7 to prepare a precursor solution of scandium and zirconium. Filter the prepared scandium-zirconium precursor solution and wash it repeatedly with water until there is no Cl - , and then washed three times with alcohol, and dried at 80°C to o...

Embodiment 3

[0069] Configure the reaction solution: dissolve zirconium oxychloride in water to obtain zirconium oxychloride solution, mix Sc 2 o 3 Dissolve in hot hydrochloric acid to prepare a scandium chloride solution, mix and stir the above solutions to obtain a scandium-zirconium mixed solution, wherein the cation concentration of the scandium-zirconium mixed solution is 1 mol / l, and the scandium ion is 13% of the total moles of scandium ion and zirconium ion %.

[0070] Co-precipitation: put the mixed solution in a microwave reactor with a reaction temperature of 250°C, a stirring speed of 1000r / min, and a microwave power of 200W, and add ammonia water to adjust the pH of the mixed solution of scandium and zirconium to 8 to prepare a precursor solution of scandium and zirconium. Filter the prepared scandium-zirconium precursor solution and wash it repeatedly with water until there is no Cl - , and then washed three times with alcohol, and dried at 100°C to obtain a scandium-zircon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com