Palladium/gamma-manganese dioxide/foamed nickel composite electrode and preparation method and application thereof

A composite electrode, nickel foam technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of large load, high cost, low current efficiency, etc., and achieve the effect of low cost, long service life and reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention also provides a Pd / γ-MnO 2 The preparation method of / Ni foam composite electrode includes the following steps:

[0040] (1) Pretreatment of nickel foam: The nickel foam was first ultrasonicated with acetone for 15-20 min to remove the surface organics; then ultrasonicated with 10% hydrochloric acid for 10-15 min to remove the oxide layer on the surface; finally, washed repeatedly with distilled water for 2-20 min. After 5 times, air dry to obtain pretreated nickel foam;

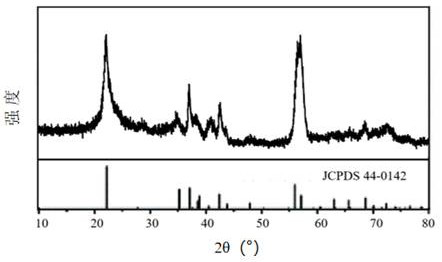

[0041] (2) γ-MnO 2 Preparation of the intermediate layer: the MnSO 4 and KMnO 4 Dissolve in water to prepare reaction solution A; then place the pretreated nickel foam in reaction solution A to carry out a hydrothermal reaction; after the reaction is finished, it is naturally cooled to room temperature, and the reacted nickel foam is taken out and sequentially used with ethanol and Deionized water was cleaned and dried to obtain γ-MnO 2 / Ni foam electrode; ...

Embodiment 1

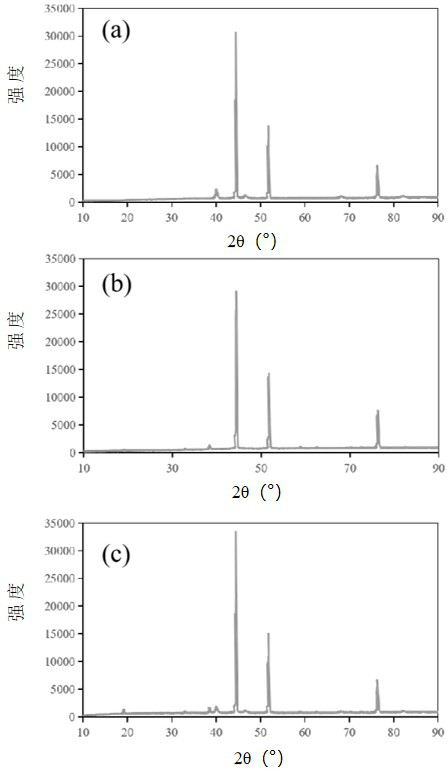

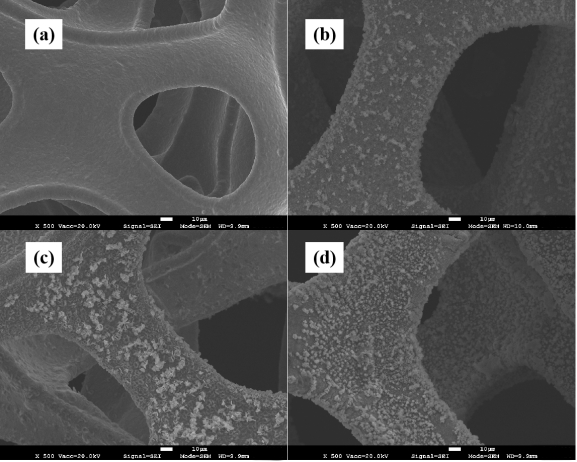

[0053] This embodiment provides a Pd / γ-MnO 2 / Ni foam composite electrode, which is based on foamed nickel, firstly forms γ-MnO on the surface of foamed nickel through hydrothermal reaction 2 intermediate layer, which was then prepared by chemically depositing Pd nanoparticles; the resulting Pd / γ-MnO 2 / Ni foam composite electrode, γ-MnO 2 The loading of the intermediate layer is 0.33 mg / cm 2 , the deposition amount of Pd nanoparticles is 0.7 mg / cm 2 .

[0054] The Pd / γ-MnO 2 The preparation method of / Ni foam composite electrode includes the following steps:

[0055] (1) Pretreatment of nickel foam: The nickel foam (30 mm × 20 mm) was first sonicated with acetone for 15 min to remove organic matter on the surface; then sonicated with 10% hydrochloric acid for 15 min to remove the oxide layer on the surface; and finally repeated with distilled water. After cleaning 3 times, dry in the air to obtain pretreated nickel foam. The scanning electron microscope image of the pre...

Embodiment 2

[0062] In this embodiment, Pd / γ-MnO 2 The preparation process of / Ni foam composite electrode is the same as that in Example 1, the difference is: "In step (2), the MnSO 4 At a concentration of 0.5 mM” in water, the resulting Pd / γ-MnO 2 / Ni foam composite electrode, γ-MnO 2 The loading of the intermediate layer is 0.15 mg / cm 2 , the deposition amount of Pd nanoparticles is 0.7 mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com