Composite material of silver-silver halide supported iron nanometer minerals and preparation method for composite material

A composite material and silver halide technology, which is applied in the field of environmental wastewater pollution control, can solve problems such as unstable chemical properties, low specific surface area, and low conversion rate, and achieve the effects of short preparation cycle, low preparation cost, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A preparation method of a silver-silver halide-loaded iron nano-mineral composite material specifically comprises the following steps:

[0019] S100: first synthesize iron nano-minerals;

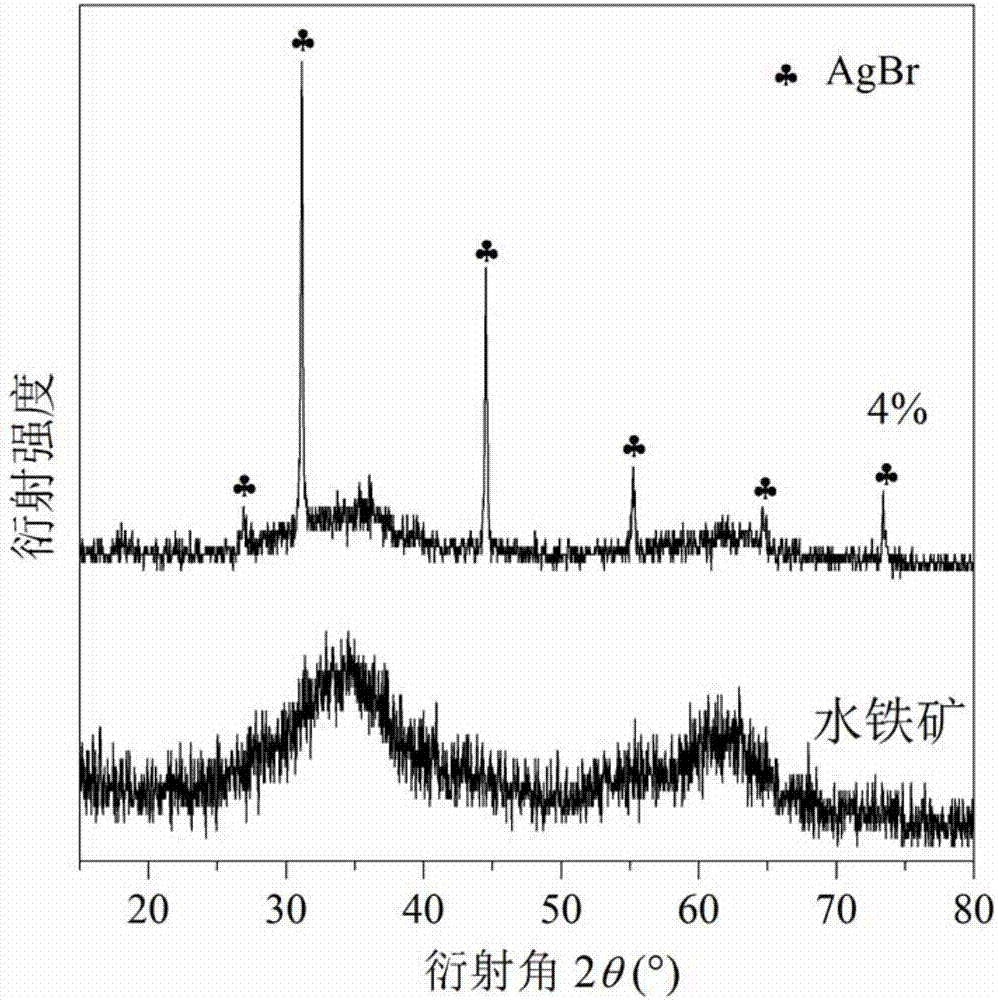

[0020] Among the series of iron oxide Fenton catalytic materials that have been studied, iron nano-minerals have the characteristics of wide range in nature, large surface area and many surface active groups. There are many types of iron nano-minerals, such as: ferrihydrite, Shi's minerals, iron hydroxide, iron oxide, goethite, etc., which are abundant in the natural environment and can be selected from nature. In this embodiment, ferrihydrite and schwartzite are preferably used as iron nano-minerals.

[0021] The preparation method of ferrihydrite and Shi's minerals can be synthesized or prepared by using the prior art for ferrihydrite and Shi's minerals. Next, this article will describe in detail the preparation methods of the ferrihydrite and Shi's mineral used in this embodiment...

Embodiment 1

[0050] A preparation method of a silver-silver halide-loaded iron nano-mineral composite material, comprising the following steps:

[0051] 1) Take 16.2g of ferric nitrate nonahydrate reagent and add it to a beaker containing 40mL of ultrapure water, and stir it ultrasonically to dissolve it. Add 2.4 g of sodium hydroxide particles to another beaker containing 50 mL of ultrapure water, and dissolve them by ultrasonic stirring. Use a peristaltic pump to slowly drop the above two solutions into another 250mL beaker to stabilize the final pH at about 7, and continue stirring for 30min. After centrifuging and washing the obtained suspension several times, place it in a freeze dryer to freeze-dry, grind it and pass it through a 200-mesh sieve to obtain the prepared ferrihydrite sample;

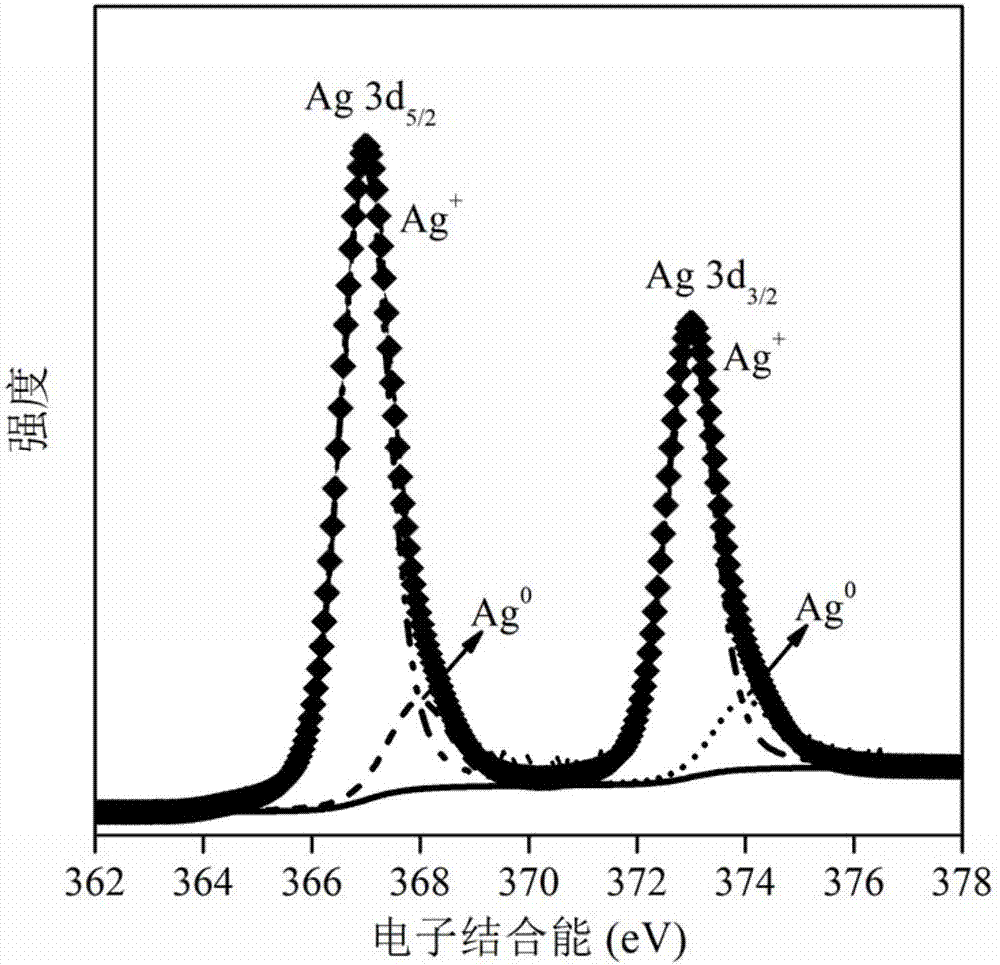

[0052] 2) Take by weighing 0.188g (12%) silver nitrate and dissolve it in 20mL ultrapure water, add 1g of the ferrihydrite prepared in step 1 therein, stir for 30min to make the silver ions fully ...

Embodiment 2

[0064] A preparation method of a silver-silver halide-loaded iron nano-mineral composite material, comprising the following steps:

[0065] 1) Take 16.2g of ferric nitrate nonahydrate reagent and add it to a beaker containing 40mL of ultrapure water, and stir it ultrasonically to dissolve it. Add 2.4 g of sodium hydroxide particles to another beaker containing 50 mL of ultrapure water, and dissolve them by ultrasonic stirring. Use a peristaltic pump to slowly drop the above two solutions into another 250mL beaker to stabilize the final pH at about 8, and continue to stir for 45min. After centrifuging and washing the obtained suspension several times, place it in a freeze dryer to freeze-dry, grind it and pass it through a 220-mesh sieve to obtain the prepared ferrihydrite sample;

[0066] 2) Take by weighing 0.251g (16%) silver nitrate and dissolve it in 20mL ultrapure water, add 1g of ferrihydrite prepared in step 1 therein, stir for 30min to make the silver ions fully dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| conduction band | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com