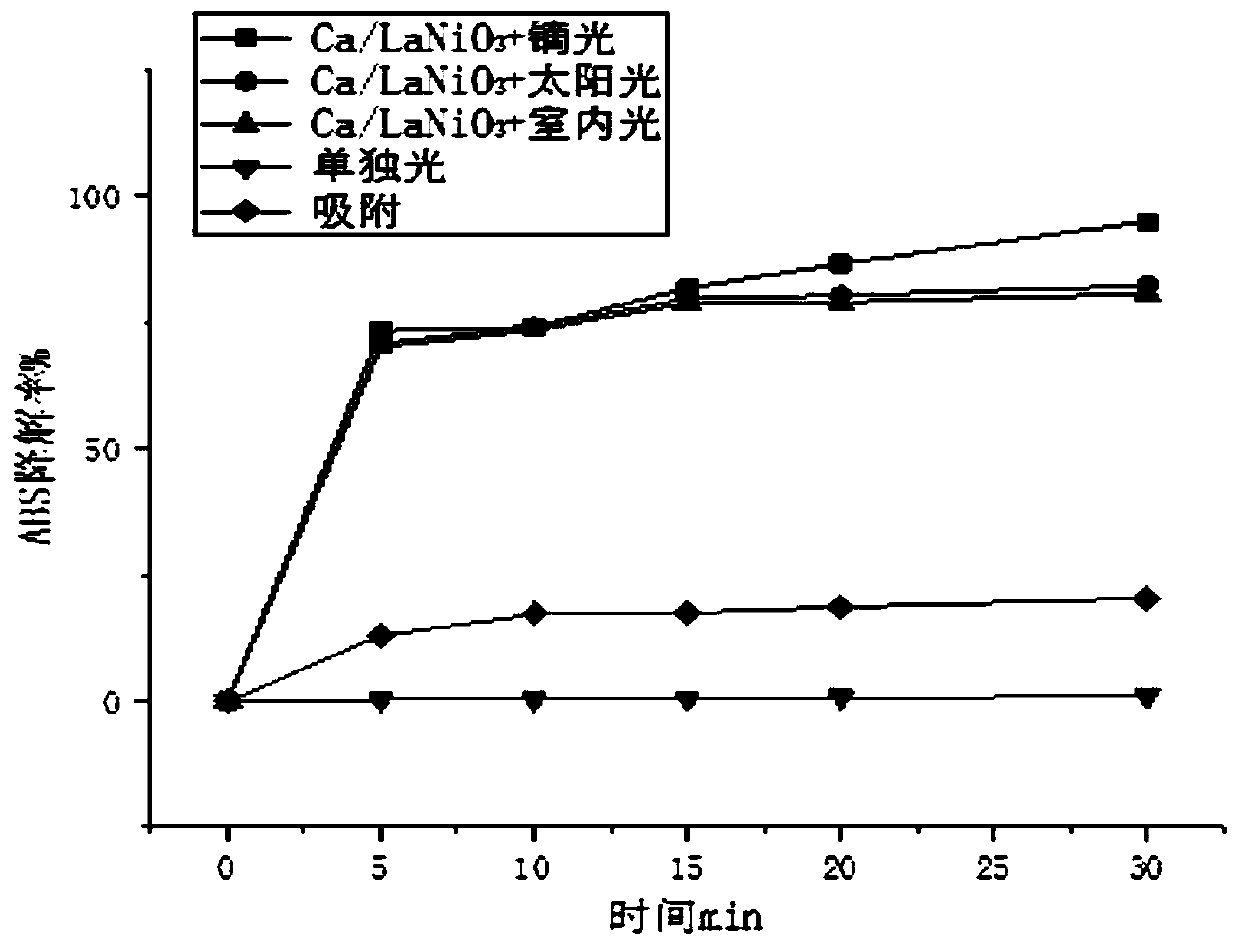

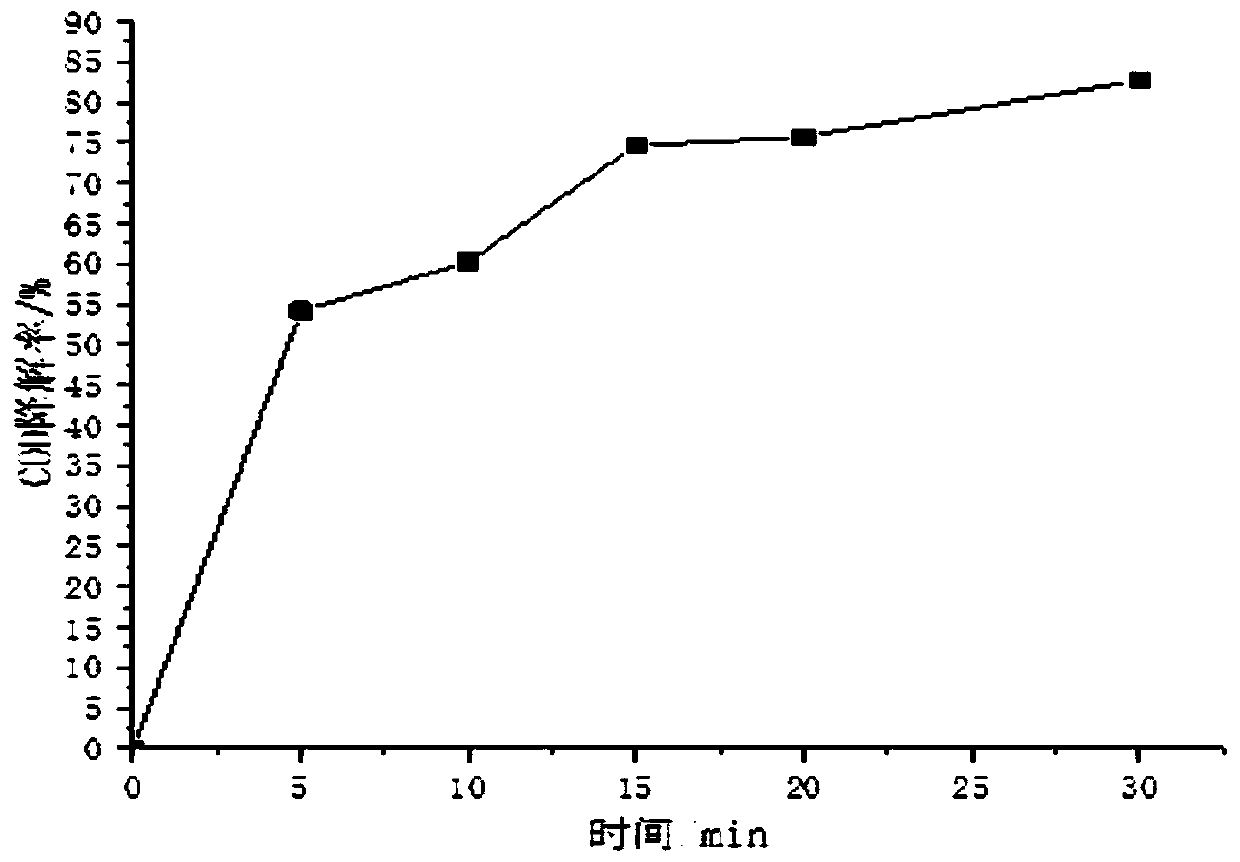

Preparation method and applications of calcium-doped LaNiO3 perovskite type photocatalyst

A perovskite type, photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as failure to achieve degradation effects, and achieve good results Adsorption and photocatalytic effects, small secondary pollution, great use value and research value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

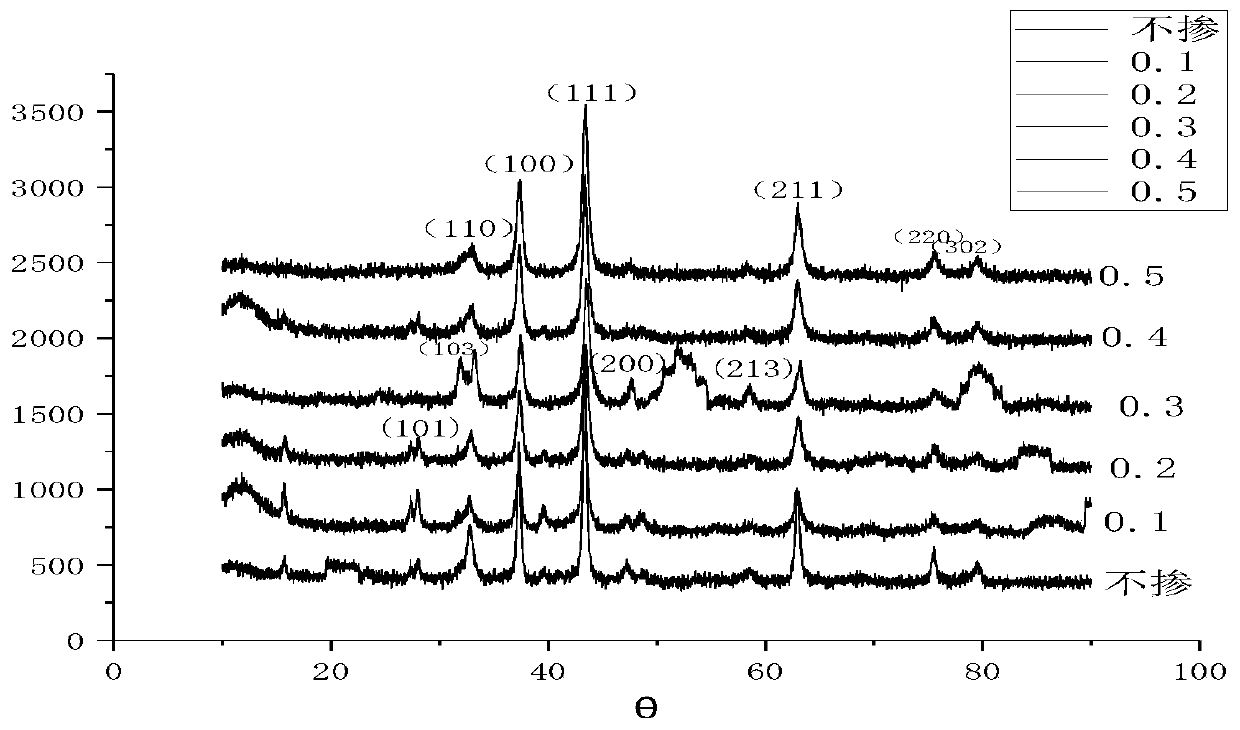

Embodiment 1

[0030] NeO 3 The preparation of A-site doped calcium ions is based on the ratio of nickel ions to lanthanum ions + calcium ions (calcium ions: lanthanum ions molar ratio = 0.1, 0.4, 0.5) = 1:1, respectively weigh lanthanum nitrate 0.8127g and calcium nitrate 0.06g in the same beaker, 1.1g of nickel nitrate in another beaker, add 30mL of distilled water each time, fully dissolve and mix well in the same volume, then place it on a multi-point magnetic stirrer at a speed of 230r / min Stir in medium for 30min, add 3mol / L ammonia solution drop by drop with a rubber dropper under the condition of stirring (one drop every 1min), and stop until the pH of the solution is greater than or equal to 12 (measured by extensive test paper) , in a circulating water vacuum pump, washed (2-3 times with distilled water), filtered, and dried in a blast drying oven at 90°C, after drying, it was fully ground and placed in an artificial intelligence box-type resistance furnace at 600°C Medium roasti...

Embodiment 2

[0032] The difference from Example 1 is that 0.8866g of lanthanum nitrate, 0.12g of calcium nitrate, calcium ion: lanthanum ion molar ratio = 0.2, after drying, it is fully ground and baked in an artificial intelligence box-type resistance furnace at 700°C 2h.

Embodiment 3

[0034] The difference from Example 1 is that lanthanum nitrate is 0.9605g, calcium nitrate is 0.18g, and the calcium ion:lanthanum ion molar ratio is 0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com