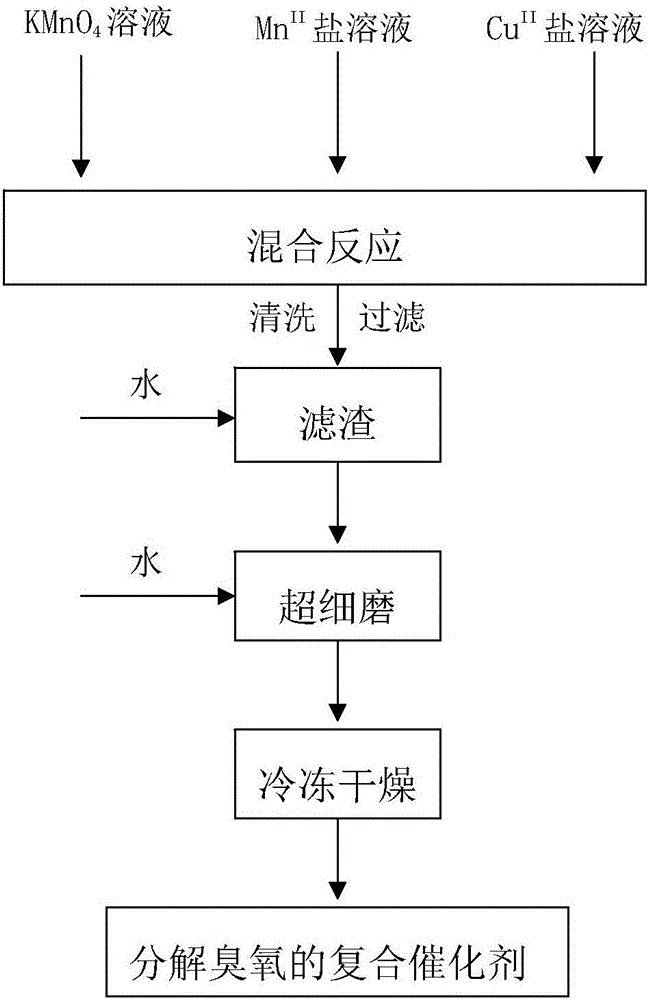

Composite catalyst for decomposing ozone and preparation method of composite catalyst

A composite catalyst and composite oxide technology, applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reducing catalyst catalytic activity, unfavorable safety production, and complicated preparation processes. and other problems, to achieve the effect of improving the catalytic effect, fewer synthesis steps, and good dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Fully dissolve 19.8g manganese chloride tetrahydrate in 100mL pure water, fully dissolve 34.76g potassium permanganate in 200mL pure water, then dissolve 0.25g copper sulfate pentahydrate in 50mL pure water, and mix the above three solutions Fully dissolved for use. The above-mentioned three solutions were quickly mixed and stirred, and the above-mentioned mixed solution was stirred and reacted at room temperature for 10 h, and then cleaned by suction filtration to obtain a composite oxide filter residue. Add the filter residue obtained above to the ultrafine grinding equipment, add 19g of water to obtain a suspension with a solid content of 50%, select 0.2mm zirconia balls, and set the speed of the ultrafine mill to 2100r / min for grinding for 10h. The ground suspension was freeze-dried at -50°C for 20 hours to obtain a highly dispersed composite catalyst powder.

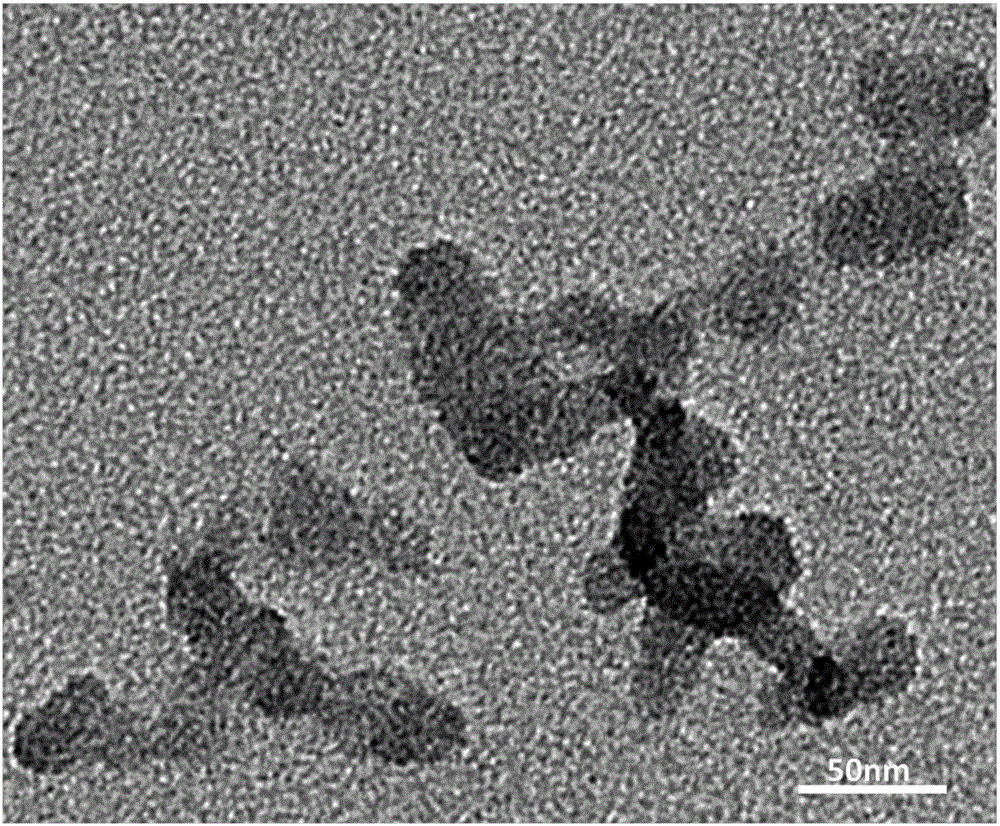

[0032] SEM tested (see figure 2 ), showing that the synthesized composite catalyst for decomposing ozon...

Embodiment 2

[0035] Fully dissolve 7.8g manganese sulfate tetrahydrate in 100mL pure water, fully dissolve 22.1g potassium permanganate in 100mL pure water, then dissolve 6.03g copper chloride dihydrate in 95mL pure water, and mix the above three solutions Fully dissolved for use. The above three solutions were quickly mixed and stirred, and the above mixed solution was stirred and reacted at 0° C. for 30 h, and then filtered and washed to obtain a composite oxide filter residue. Add the filter residue obtained above to the ultrafine milling equipment, add 36.4g of water to obtain a suspension with a solid content of 30%, select 0.3mm alumina balls, and set the speed of the ultrafine mill to 1500r / min for grinding for 6h. The ground suspension was freeze-dried at -20°C for 15 hours to obtain a composite catalyst powder for decomposing ozone.

[0036] The catalytic performance test is the same as in Example 1. The test results show that the highly dispersed composite catalyst prepared in t...

Embodiment 3

[0038]Fully dissolve 14.35g manganese nitrate hexahydrate in 130mL pure water, fully dissolve 22.1g potassium permanganate in 200mL pure water, fully dissolve 8.45g copper nitrate trihydrate in 85mL pure water, and fully dissolve the above three solutions Dissolve and set aside. The above three solutions were quickly mixed and stirred, and the above mixed solution was stirred and reacted at 40° C. for 5 hours, and then filtered and washed to obtain a composite oxide filter residue. Add the filter residue obtained above to the ultrafine grinding equipment, add 187.4g of water to obtain a suspension with a solid content of 10%, select 0.4mm alumina balls, and set the speed of the ultrafine mill to 1800r / min for grinding for 1h. The ground suspension was freeze-dried at 0° C. for 30 h to obtain a composite catalyst powder for decomposing ozone.

[0039] The catalytic performance test is the same as in Example 1, and the test results show that the highly dispersed composite catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com