Preparation method of silver phosphate/metal oxide composite photocatalyst capable of efficiently degrading tetracycline

A technology of oxide and silver phosphate, which is applied in the field of photocatalysis and inorganic nanomaterials, can solve the problems that the catalytic activity and spectral response range need to be further improved, the preparation method has not been reported, and it is unfavorable for continuous production. It achieves good application value, Effects of suppressing photocorrosion and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the silver phosphate / metal oxide composite photocatalyst of efficient degradation tetracycline is:

[0028] (1) Weigh 8.92g of zinc nitrate hexahydrate and 3.75g of aluminum nitrate nonahydrate and dissolve them in 100mL of deionized water, then add 16.21g of urea, react at 110°C for 24h, centrifuge, wash, dry at 80°C, and grind to obtain Zn / Layered ZnAl hydroxide with an Al molar ratio of 3;

[0029] (2) Calcining ZnAl hydroxide at 500°C for 4h at a heating rate of 10°C / min to obtain ZnAl oxide;

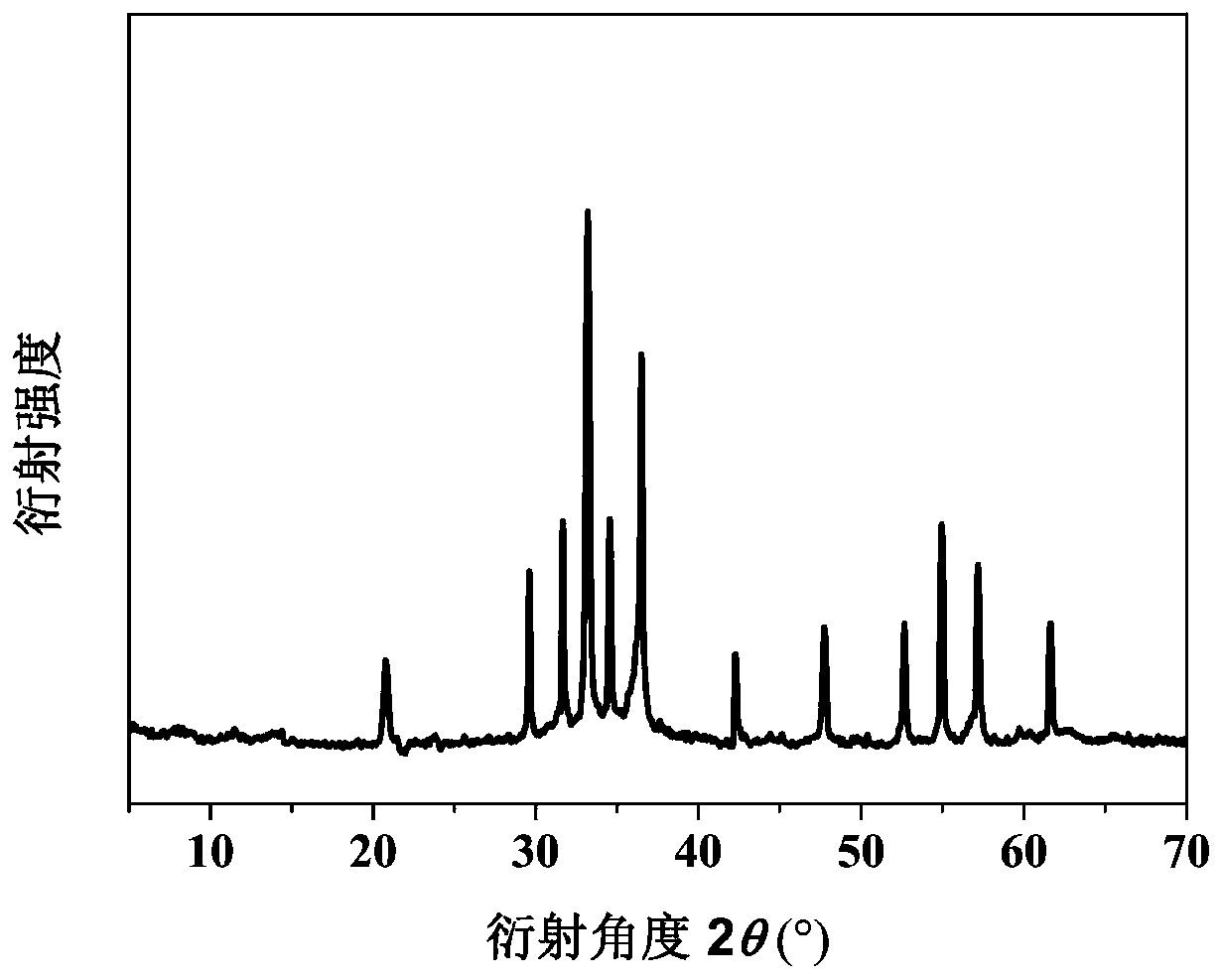

[0030] (3) Put 0.5g of ZnAl oxide into 100mL of AgNO with a concentration of 0.006mol / L 3 In the solution, ultrasonically disperse at 50KHz for 30min, and add 20mLPO dropwise 4 3- Sodium dihydrogen phosphate solution with a concentration of 0.01mol / L was continuously stirred for 4 hours, washed by centrifugation, dried at 80°C, and ground to obtain a silver phosphate / ZnAl oxide composite photocatalyst. The XRD diagram is as follows figure 1 .

...

Embodiment 2

[0033] The preparation method of the silver phosphate / metal oxide composite photocatalyst of efficient degradation tetracycline is:

[0034] (1) Weigh 8.72g of nickel nitrate hexahydrate and 3.75g of aluminum nitrate nonahydrate and dissolve them in 100mL of deionized water, then add 15.61g of urea, react at 100°C for 20h, wash by centrifugation, and dry at 80°C to obtain the Ni / Al molar ratio 3 layered NiAl hydroxide;

[0035] (2) Calcining NiAl hydroxide at 400°C for 5 hours at a heating rate of 15°C / min to obtain NiAl oxide;

[0036] (3) Put 0.8g NiAl oxide into 100mL AgNO with a concentration of 0.014mol / L 3 In the solution, ultrasonically disperse at 40KHz for 35min, and add 20mLPO dropwise 4 3- Sodium phosphate solution with a concentration of 0.01mol / L was continuously stirred for 3.5h, washed by centrifugation, dried at 80°C, and ground to obtain a silver phosphate / NiAl oxide composite photocatalyst, as shown in the SEM image Figure 4 .

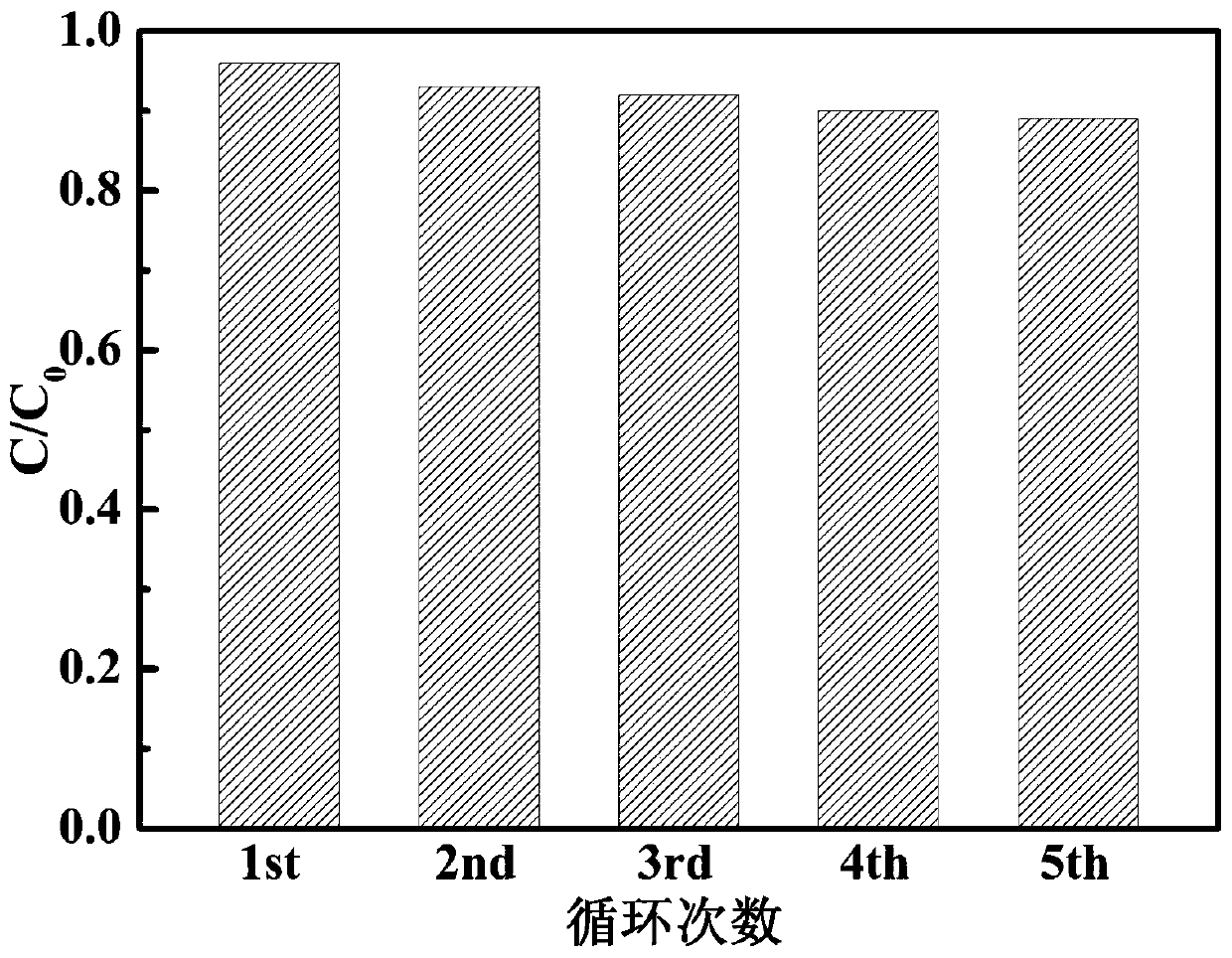

[0037] Using a 500W xeno...

Embodiment 3

[0039] The preparation method of the silver phosphate / metal oxide composite photocatalyst of efficient degradation tetracycline is:

[0040] (1) Weigh 11.64g of cobalt nitrate hexahydrate and 4.04g of ferric nitrate nonahydrate and dissolve them in 100mL of deionized water, then add 15.61g of urea, react at 120°C for 18h, wash by centrifugation, and dry at 80°C to obtain the Co / Fe molar ratio 4 layered CoFe hydroxide;

[0041](2) Calcining CoFe hydroxide at 450°C for 6 hours at a heating rate of 8°C / min to obtain CoFe oxide;

[0042] (3) Put 0.3g CoFe oxide into 100mL AgNO with a concentration of 0.008mol / L 3 In the solution, ultrasonically disperse at 30KHz for 38min, and add 20mLPO dropwise 4 3- Disodium hydrogen phosphate solution with a concentration of 0.015 mol / L was continuously stirred for 3 hours, washed by centrifugation, dried at 80° C., and ground to obtain a silver phosphate / CoFe oxide composite photocatalyst.

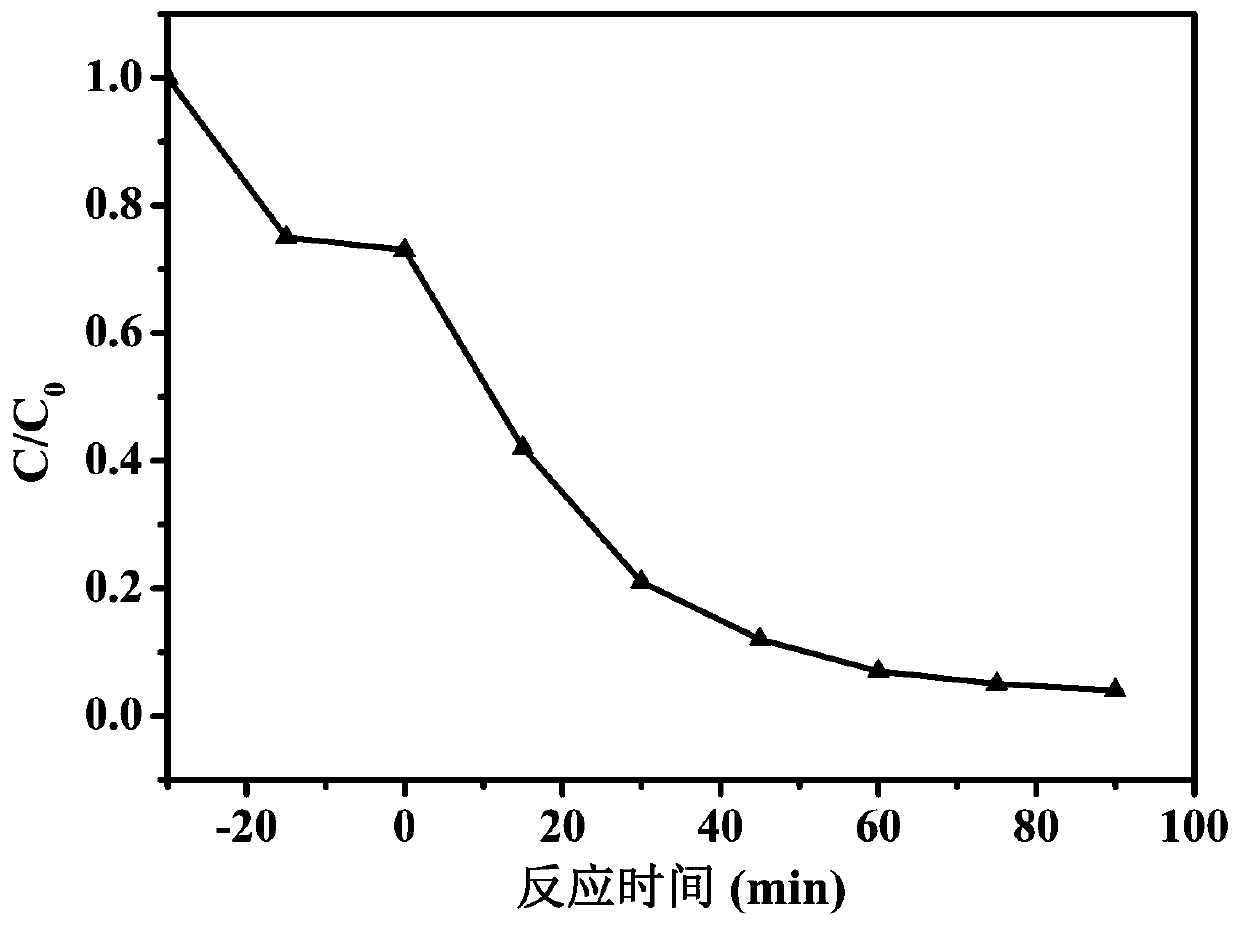

[0043] Using a 500W xenon lamp as a simulated su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com