Co-B-P-O nano particle loaded reduced graphene oxide composite material as well as preparation method and application thereof

A nanoparticle and composite material technology, applied in the field of catalytic chemistry, can solve the problems of easy agglomeration, uneven distribution of reduced metal particles, low adhesion, etc. The effect of short response times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

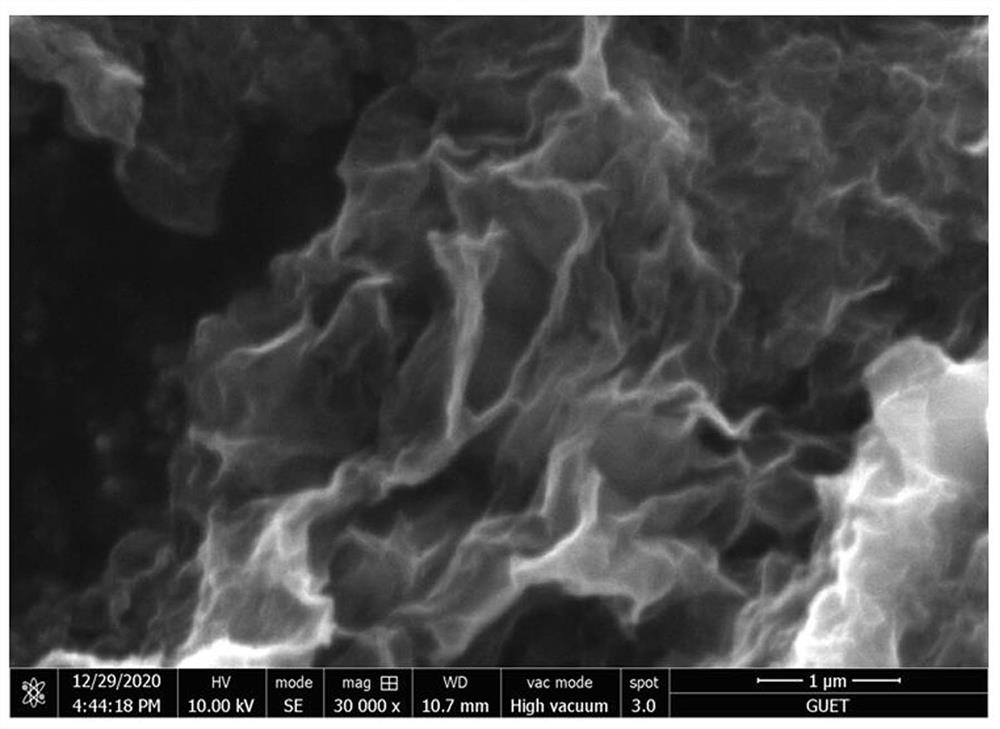

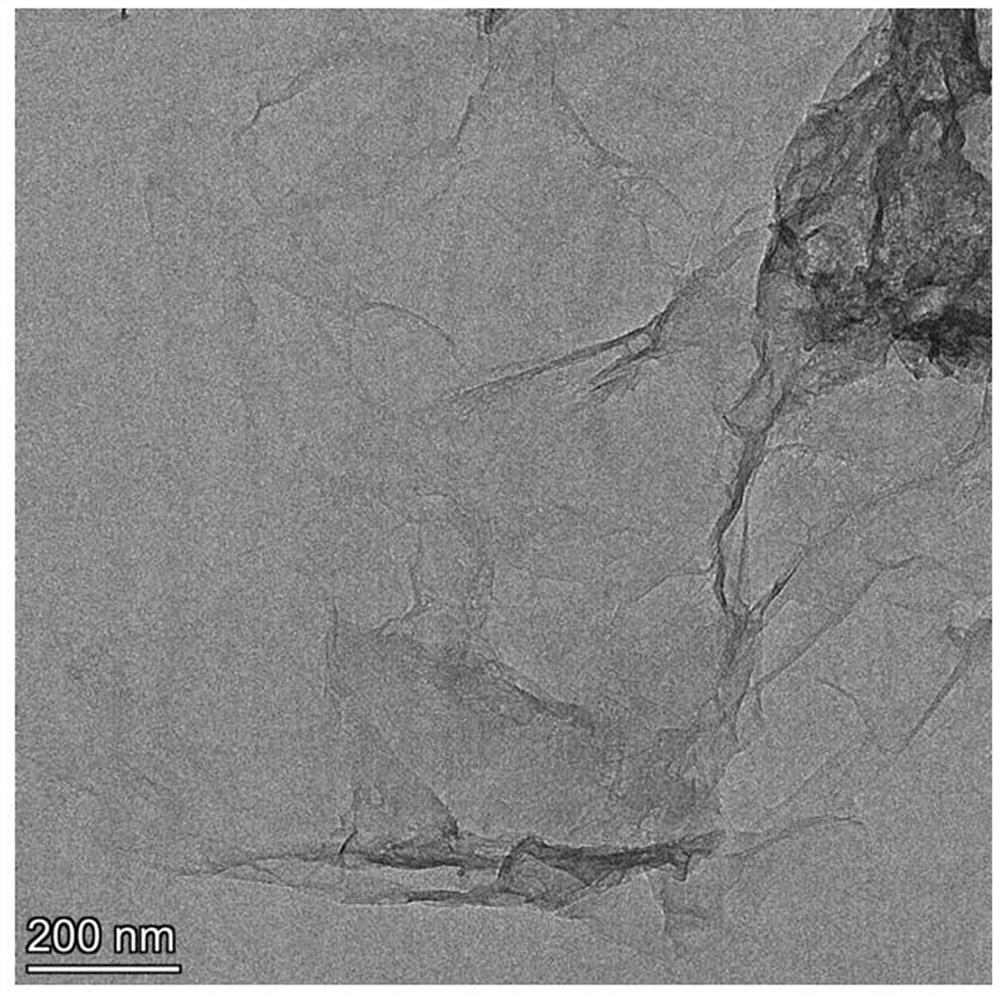

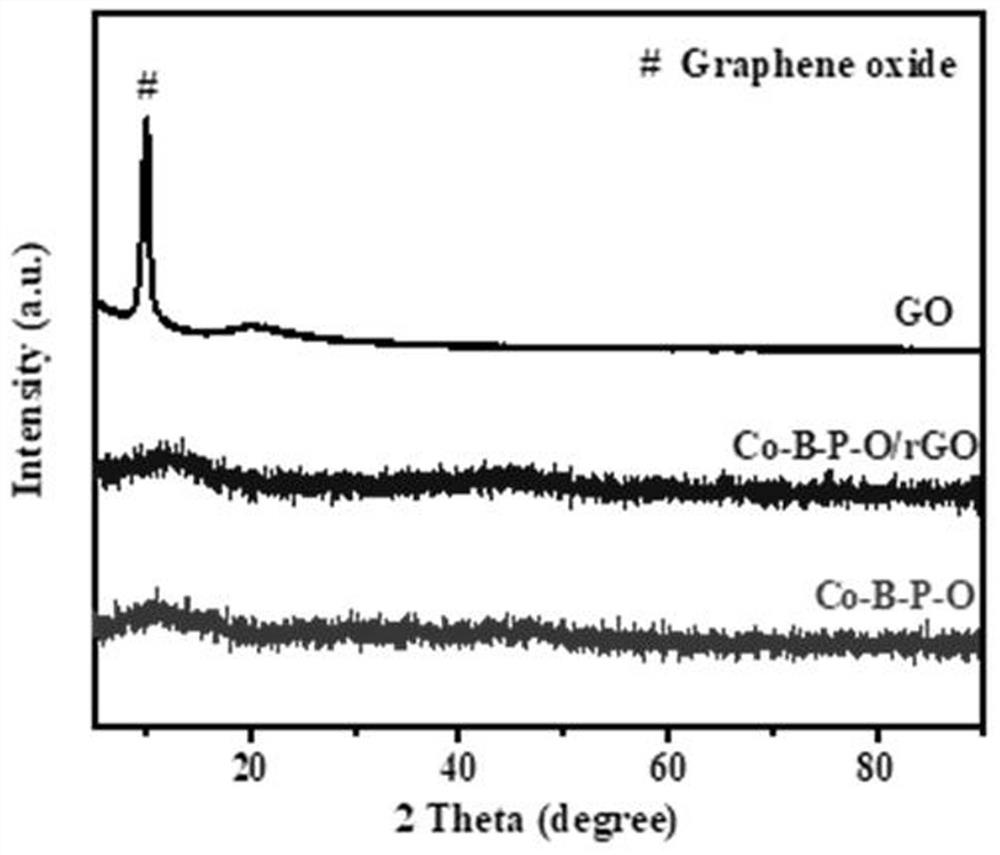

[0069]Method for preparing CO-B-P-O nanoparticle load reductant oxide in graphene composites, the specific steps are as follows:

[0070]Step 1, the preparation of the oxide oxide nanofine carrier, 30 ml of raw sulfuric acid, sodium nitrate 2 g, soda-shaped graphite 2 g, and potassium permanganate 12 g, add water under 0 ° C to obtain a mixed solution; then, then, Under 0 ° C, the mixed solution was allowed to react. After the reaction was completed, the mixed solution was magnetically stirred at 35 ° C constant temperature water bath.

[0071]Thereafter, 200 ml of ice cubes were added to the mixed solution, and the temperature of the mixed solution was reduced to 0 ° C. After the ice is melted, 15 ml of oxygen water is added dropwise to the mixed solution under magnetic stirring conditions, and the mixed solution is brownish The bright yellow stopped the bioxide, and the excess of potassium permanganate was reacted. At the end, the mixed solution was repeatedly centrifuged, and the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com