A kind of polyaspartate topcoat and its preparation method and application

A technology of aspartic acid ester and polyisocyanate, which is applied in polyamide coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor wettability of substrate materials, poor aging resistance, and poor surface effects, and achieve mechanical Excellent performance, good weather resistance, and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

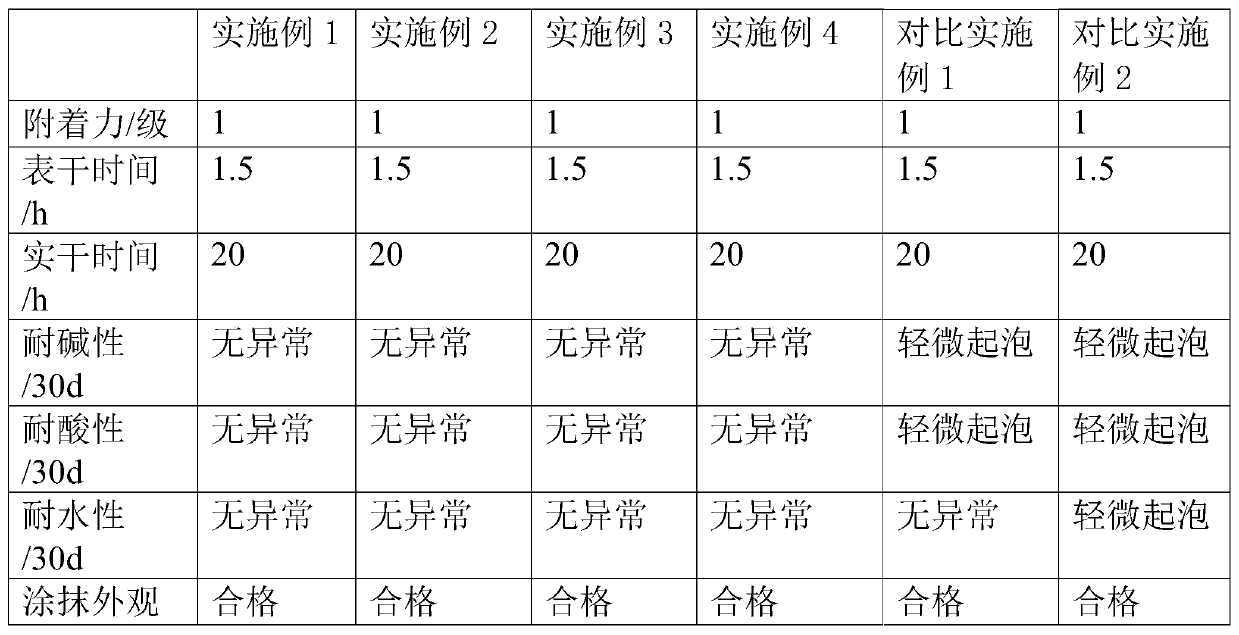

Examples

Embodiment 1

[0026] (1) Mix 85 parts of elastic isocyanate curing agent and 15 parts of aliphatic polyisocyanate trimer to obtain component A.

[0027] (2) Polystyrene grafted modified glass flakes

[0028] ① Add 100 parts of glass flakes and 1 part of silane coupling agent to the container, and mechanically stir for 15 minutes at room temperature to obtain glass flakes treated with silane coupling agent.

[0029] ② Mix 1 part of glass flakes treated with silane coupling agent, 10 parts of distilled water and 90 parts of ethanol, then ultrasonically shake for 30 minutes, pour into a 500mL three-necked flask, control the stirring speed to 450rpm; combine 10 parts of styrene and 2 parts of AIBN After mixing uniformly, pour it into the above-mentioned three-necked flask at one time, under nitrogen protection, and react at 60°C for 24 hours. After centrifugation and drying, polystyrene grafted modified glass flakes are obtained.

[0030] (3) Preparation of component B

[0031] ① Mix 30 parts of polyas...

Embodiment 2

[0036] (1) Mix 70 parts of elastic isocyanate curing agent and 30 parts of aliphatic polyisocyanate trimer to obtain component A.

[0037] (2) Polystyrene grafted modified glass flakes

[0038] ① Add 100 parts of glass flakes and 1 part of silane coupling agent to the container, and mechanically stir at room temperature for 15 minutes to obtain glass flakes treated with silane coupling agent.

[0039] ② Mix 1 part of glass flakes treated with silane coupling agent, 10 parts of distilled water and 90 parts of ethanol, then ultrasonically shake for 30 minutes, pour into a 500mL three-necked flask, control the stirring speed to 450rpm; combine 10 parts of styrene and 2 parts of AIBN After mixing uniformly, pour it into the above-mentioned three-necked flask at one time, under nitrogen protection, and react at 60°C for 24 hours. After centrifugation and drying, polystyrene grafted modified glass flakes are obtained.

[0040] (3) Preparation of component B

[0041] ① Mix 50 parts of polyas...

Embodiment 3

[0046] (1) Mix 70 parts of elastic isocyanate curing agent and 30 parts of aliphatic polyisocyanate trimer to obtain component A.

[0047] (2) Polystyrene grafted modified glass flakes

[0048] ① Add 100 parts of glass flakes and 1 part of silane coupling agent to the container, and mechanically stir at room temperature for 15 minutes to obtain glass flakes treated with silane coupling agent.

[0049] ② Mix 1 part of glass flakes treated with silane coupling agent, 10 parts of distilled water and 90 parts of ethanol, then ultrasonically shake for 35 minutes, pour into a 500mL three-necked flask, control the stirring speed at 500rpm; combine 10 parts of styrene and 2 parts of AIBN After mixing uniformly, pour it into the above-mentioned three-necked flask at one time, under nitrogen protection, and react at 60°C for 24 hours. After centrifugation and drying, polystyrene grafted modified glass flakes are obtained.

[0050] (3) Preparation of component B

[0051] ① Mix 60 parts of polyas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com