High-resistance substrate for high-electron-mobility transistor and growing method thereof

A high electron mobility, transistor technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of deteriorating electrical properties of devices, crystal quality degradation, and no withstand voltage, so as to achieve excellent crystal quality and reduce lattice distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the high-resistance substrate for high electron mobility transistors and the growth method provided by the present invention will be described in detail below with reference to the accompanying drawings.

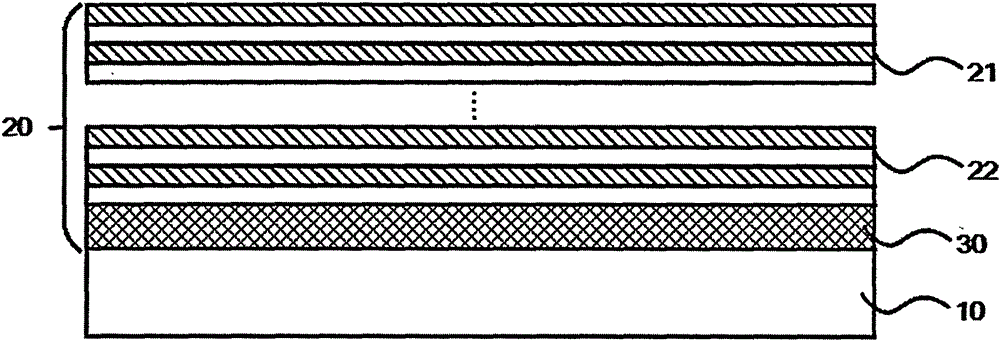

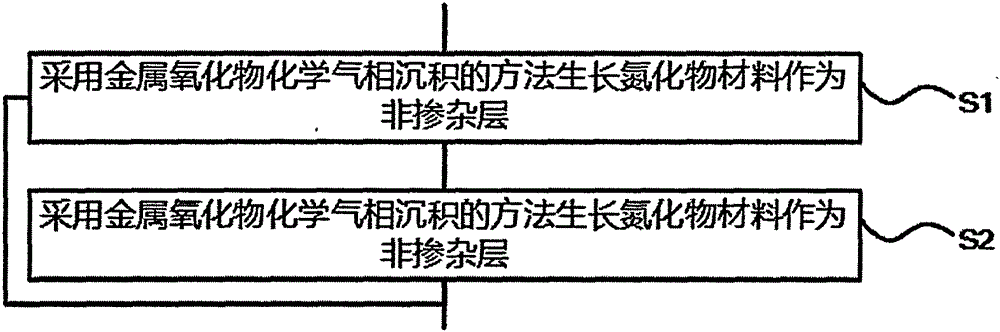

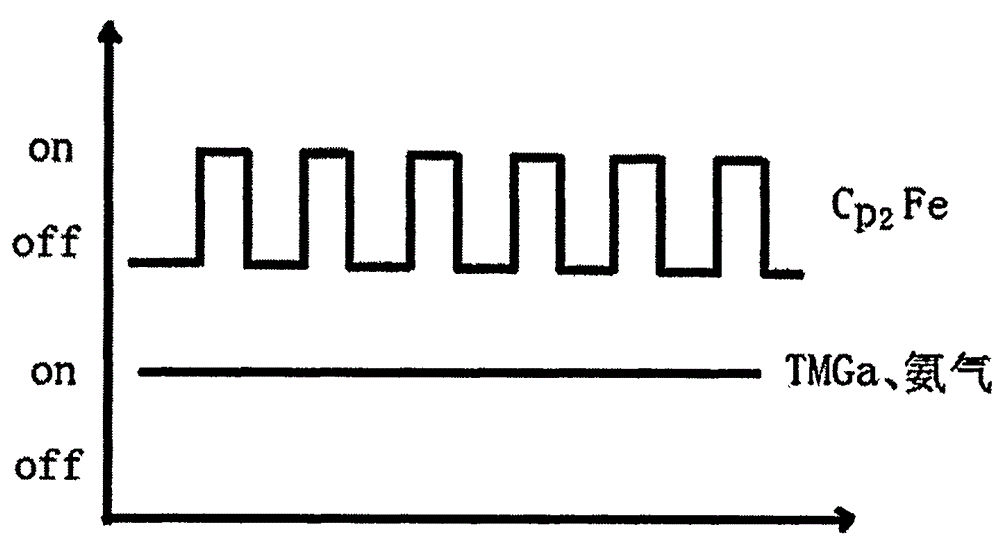

[0022] Reference attached figure 1 Shown is a schematic structural view of the high-resistance substrate for high electron mobility transistors described in this specific embodiment, including a support substrate 10 and a high-resistance layer 20 on the surface of the support substrate 10 . The material of the high resistance layer 20 is nitride. The high-resistance layer 20 includes a periodic structure in which a plurality of doped layers 21 and a plurality of non-doped layers 22 are arranged alternately. The multiple doped layers 21 and the multiple undoped layers 22 included in the high resistance layer 20 are all nitride materials, and the material of the doped layers 21 is nitride containing deep level doping elements. Deep-level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com