Micro/nanometer secondary surface array and preparation method and application thereof

A micro-nano and array technology, applied in the field of micro/nano secondary arrays and its preparation, can solve the problems of difficult control of material microstructure, difficult large-scale production and preparation, light absorption performance attenuation, etc., to reduce the recombination of holes and electrons Chance, low cost, reduce the effect of reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a Cu 2 S "cactus" micro-nano secondary array is prepared by the following steps:

[0033] (1) Grind the copper sheet with No. 0-6 sandpaper, and then ultrasonically clean it with alcohol, acetone, and deionized water for 5 minutes; then use a potential of -0.35V relative to the saturated calomel electrode on the copper sheet, and deposit at a constant voltage for 2400s A copper film with a spherical crown periodic undulating structure is deposited on the copper sheet;

[0034] (2) Mix the product of step (1) with oxygen / hydrogen sulfide mixed gas (the volume ratio of the two is 1:2), heat at 20°C for 16h, and generate Cu 2 S "cactus" micro-nano secondary array;

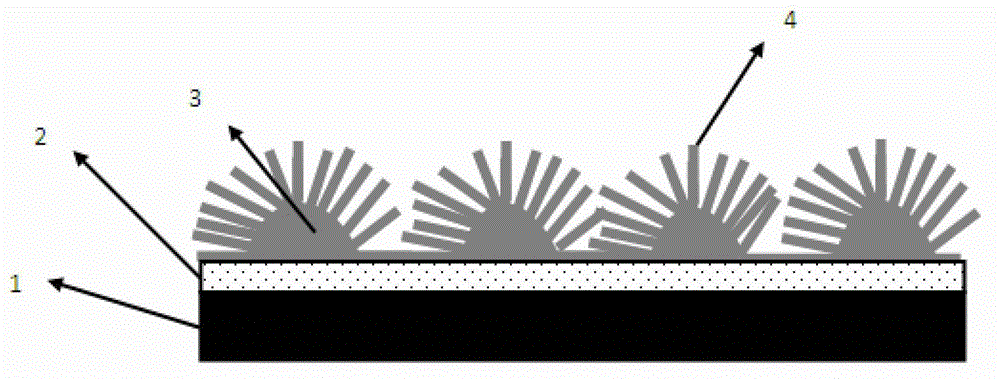

[0035] Cu produced 2 S "cactus" micro-nano secondary array, its structure is as follows figure 1 Shown: On the substrate 1 is a conductive film 2, and above the conductive film 2 are periodically distributed micron-sized Cu 2 S spherical crown 3, Cu 2 The surface of the S spherical cap 3 is nano-sized Cu ...

Embodiment 2

[0038] a Cu 2 S "cactus" micro-nano secondary array is prepared by the following steps:

[0039] (1) The glass sheet is ultrasonically cleaned with 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water in sequence, and then a layer of ITO is magnetron sputtered on the glass sheet with a thickness of 200nm. Deposit a layer of copper film with a spherical crown periodic undulation structure by constant pressure method, and the thickness of the copper film is 500nm;

[0040] (2) Mix the product of step (1) with oxygen / hydrogen sulfide mixed gas (the volume ratio of the two is 1:2), heat at 10°C for 18h, and generate Cu 2 S "cactus" micro-nano secondary array;

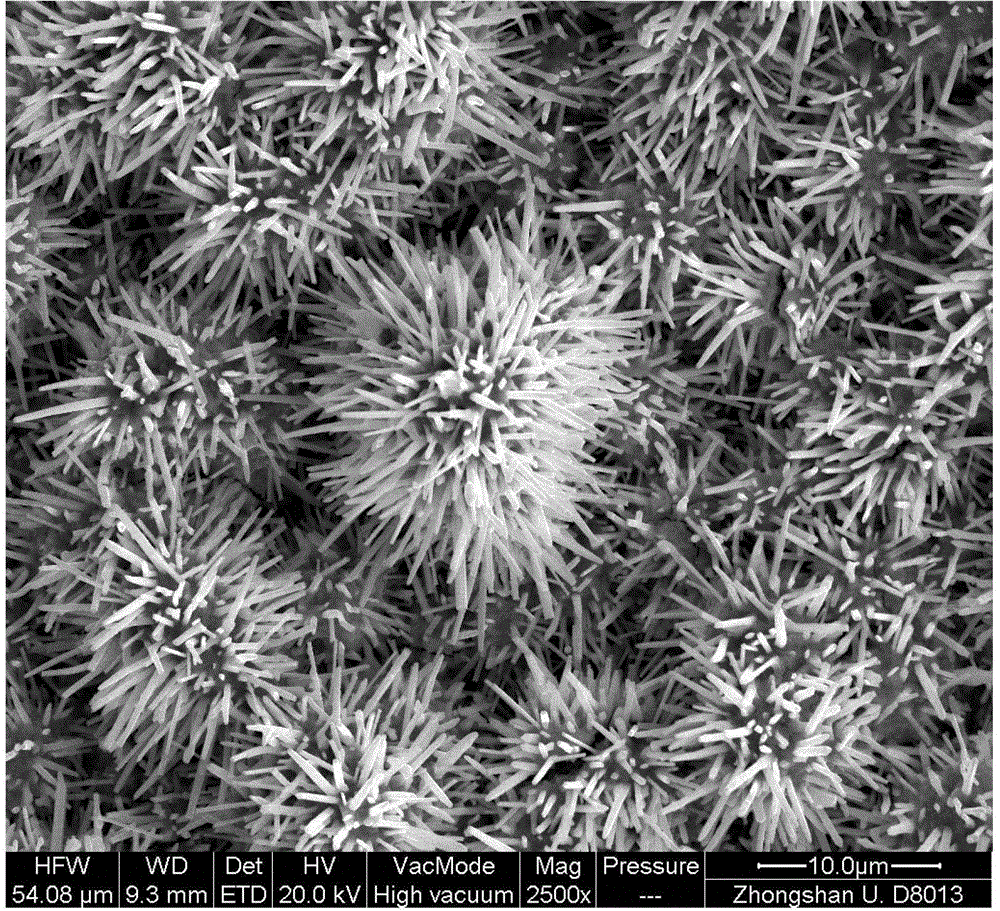

[0041] Cu produced 2 S "cactus" micro-nano secondary, its structure is as follows figure 1 shown. The diameter of the nanowire is 40nm, the length is 5um, Cu 2 The diameter of the S spherical cap is 5μm, and the interval between the spherical caps is 2um. The prepared Cu 2 The scanning electron mic...

Embodiment 3

[0044] a Cu 2 S "cactus" micro-nano secondary array is prepared by the following steps:

[0045] (1) Clean the silicon wafer sequentially with 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water; then thermally evaporate a layer of Au film on the silicon wafer with a thickness of 200nm, and then Deposit a layer of copper film with spherical crown periodic undulation structure by pulse electrochemical deposition method, the thickness of copper film is 800nm;

[0046] (2) Mix the product of step (2) with oxygen / hydrogen sulfide mixed gas (the volume ratio of the two is 1:2), heat at 18°C for 12h, and generate Cu 2 S "cactus" micro-nano secondary array;

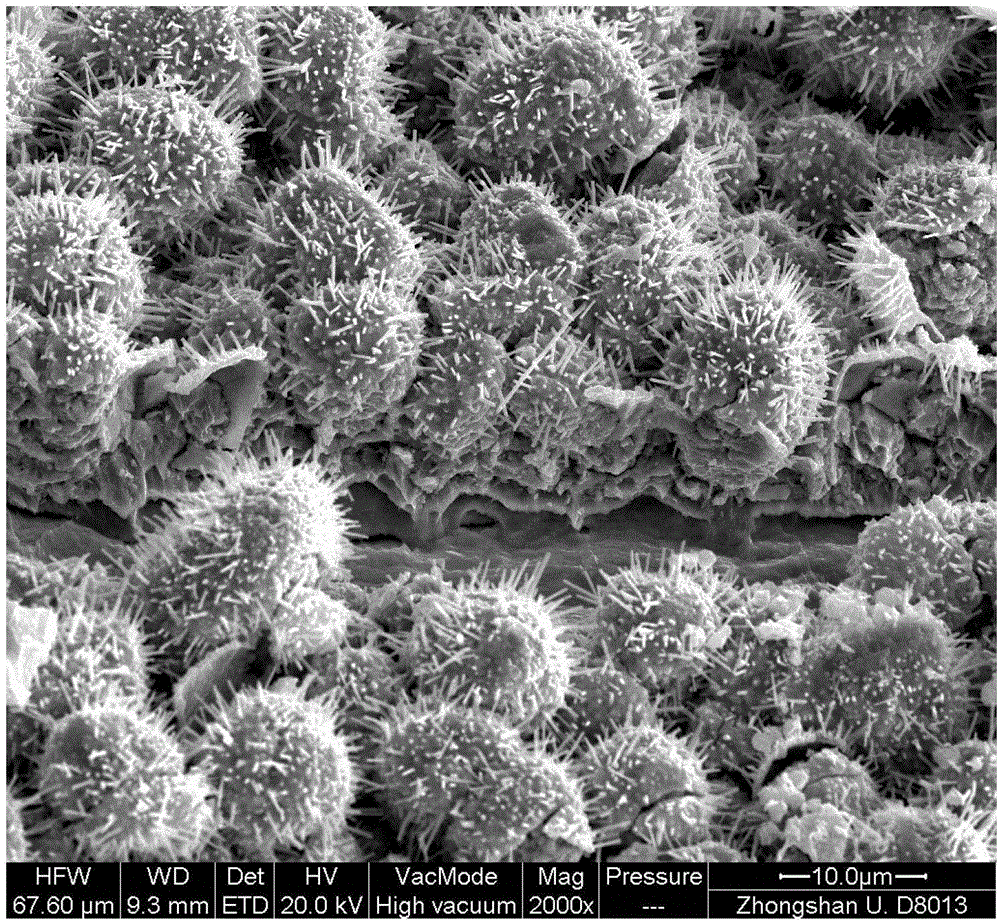

[0047] Cu produced 2 S "cactus" micro-nano secondary array, its structure is as follows figure 1 shown. The diameter of the nanowire is 100nm, the length is 12um, Cu 2 The diameter of the S spherical cap is 8μm, and the interval between the spherical caps is 5um. The prepared Cu 2 The scanning electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com