A preparation method of a high-density ternary composite material

A composite material and high-density technology, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low battery charge and discharge efficiency for the first time, affect the energy density of materials, and affect electrochemical performance, so as to avoid direct The effect of contacting with the electrolyte, reducing the probability of side reactions, and avoiding the failure of nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

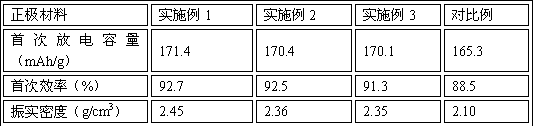

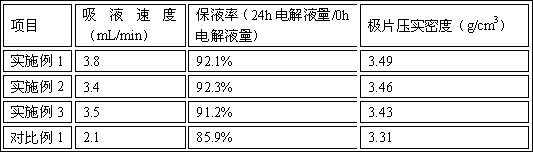

Embodiment 1

[0017] 1) Mix 100g of cobalt sulfate with a particle size of 500nm, 100g of manganese sulfate with a particle size of 100nm and 5g of nanometer zinc powder with a particle size of 500nm to obtain material A and put it into the heating part of the reaction vessel;

[0018] 2) Press 500g of nickel sulfate powder by a flat press into a block of nickel block B, then transfer it to the reactor, and place it in the receiving part of the reaction vessel, and then heat it to a pressure of 0.5Mpa under an argon atmosphere. 800°C and heat preservation for 6 hours, then cool to 300°C and heat preservation for 6 hours, then naturally cool to room temperature, deposit material A on the surface of the massive nickel block B, and grind it to 500nm in a ball mill, and finally obtain composite material C;

[0019] 3) Weigh 100g of composite material C, 10g of lithium carbonate, 100ml of sodium hydroxide lye with a concentration of 10%wt, and add it to the ball mill at a speed of 2000rpm, ball mill f...

Embodiment 2

[0022] 1) Mix 100g of cobalt chloride with a particle size of 100nm, 50g of manganese chloride with a particle size of 100nm and 1g of nano zinc powder with a particle size of 100nm to obtain material A and put it into the heating part of the reaction vessel;

[0023] 2) Press 500g of nickel chloride by a flat press into a block of nickel block B, then transfer it to the reactor and place it in the receiving part of the reaction vessel, and then heat it under an argon atmosphere at a pressure of 0.1MPa Heat for 12 hours at 500°C, then cool to 200°C for 6 hours, then cool to room temperature naturally, deposit material A on the surface of the massive nickel block B, and grind it to 10nm in a ball mill, and finally obtain composite material C;

[0024] 3) Add 100g composite material C, 5g lithium carbonate, 50ml volume, 1%wt sodium hydroxide lye to the ball mill, ball mill at 1000rpm for 72h, and sinter at 800℃ for 6h to obtain LiNi X Co Y Mn Z O 2 Ternary composite material D;

[0025...

Embodiment 3

[0027] 1) Mix 100g of cobalt sulfate with a particle size of 1000nm, 200g of manganese sulfate with a particle size of 1000nm and 10g of nano zinc powder with a particle size of 1000nm to obtain material A and put it into the heating part of the reaction vessel;

[0028] 2) Press 500g of nickel sulfate through a flat press into a block of nickel block B, then transfer it to the reactor and place it in the receiving part of the reaction vessel, and then heat it under an inert argon atmosphere at a pressure of 1.0Mpa Heat it to 1000°C and keep it for 1h, then cool it down to 500°C and keep it for 1h, then cool to room temperature naturally, deposit material A on the surface of the massive nickel block B, and grind it to 1000nm in a ball mill, and finally get the composite material C;

[0029] 3) Add 100g of composite material C, 20g of lithium carbonate, and 200ml of sodium hydroxide lye with a concentration of 10%wt to the ball mill, ball mill at 5000rpm for 1h, and sinter at 800℃ fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com