A Method for Controlling Electrodeformation Orientation of Ferroelectric Single Crystal

A ferroelectric single crystal and electro-deformation technology, which is applied in the field of ferroelectric materials, can solve the problems of practical inconvenience and achieve the effect of increasing the ratio, multiple control methods, and increasing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

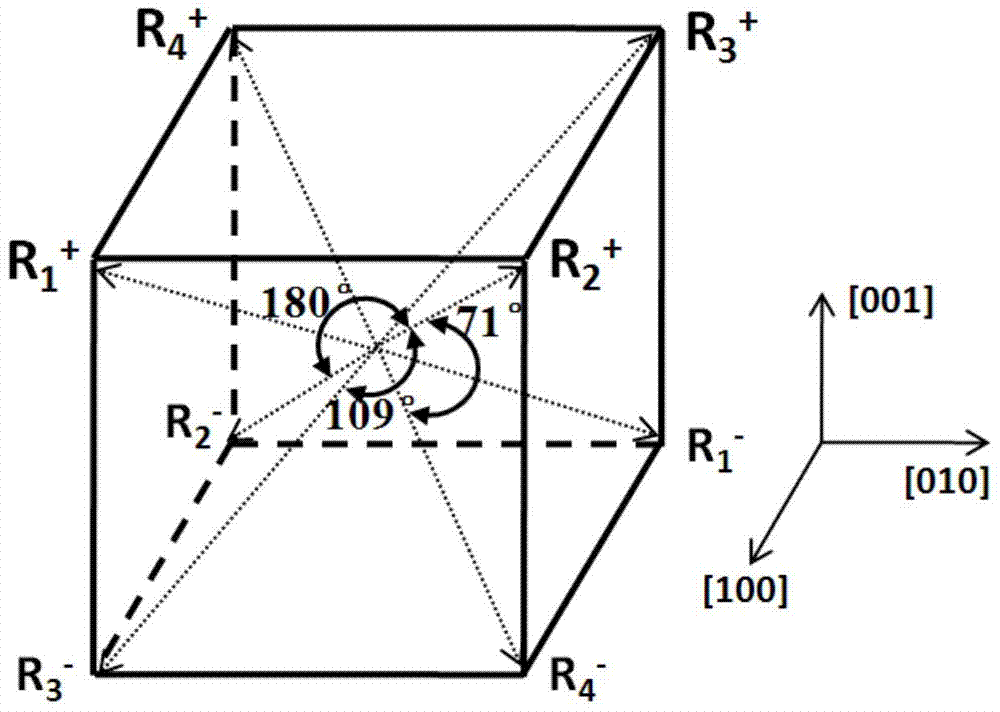

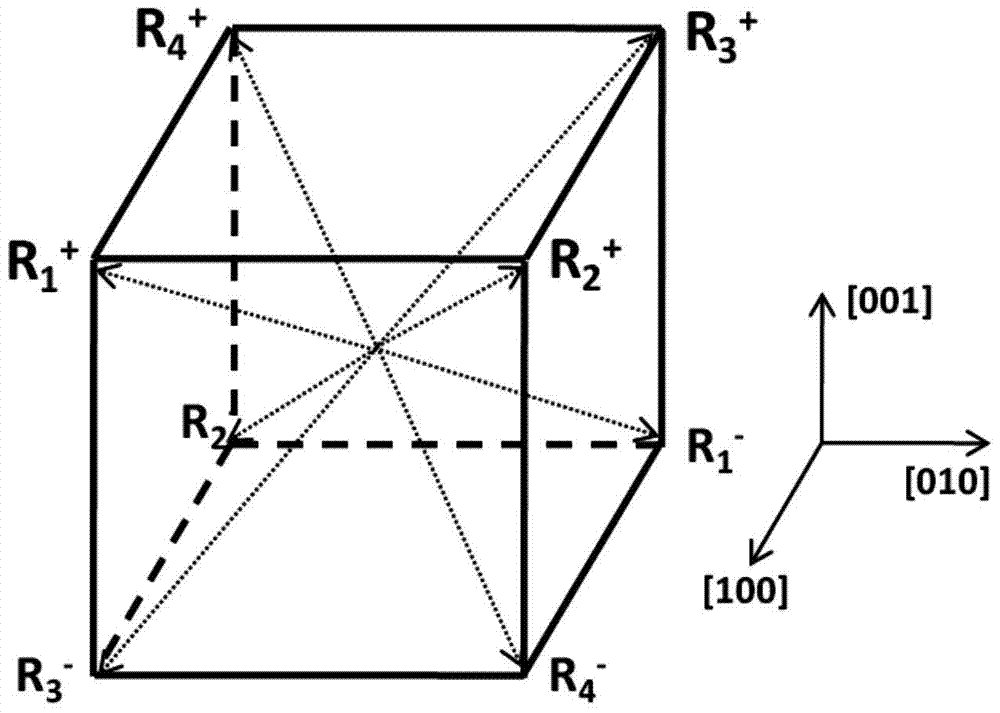

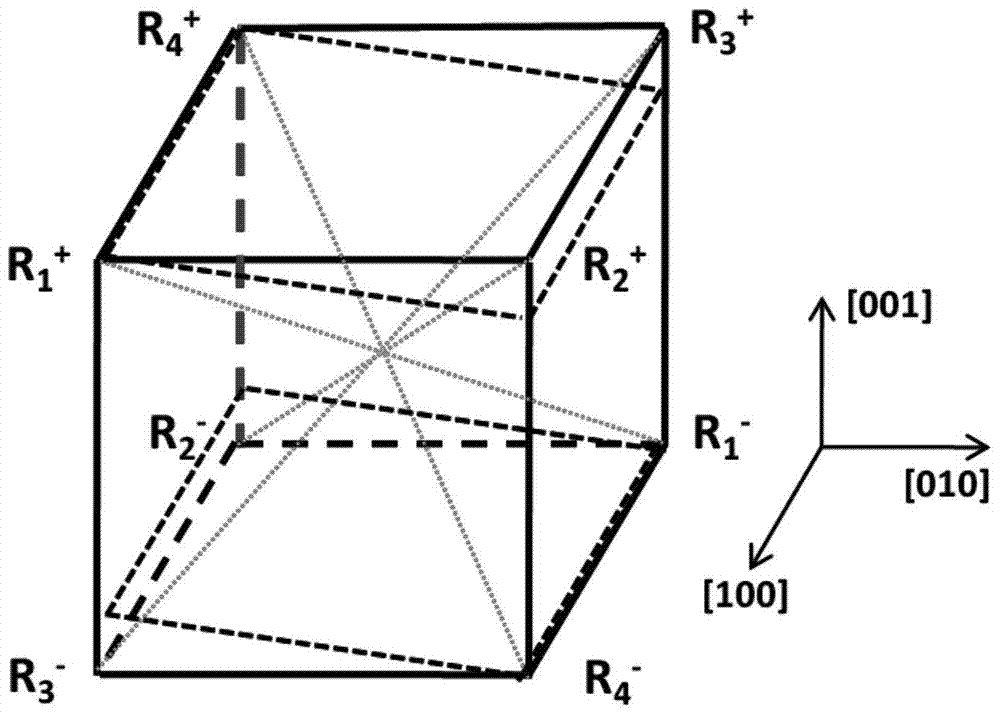

[0050] ①, figure 2 A schematic diagram of the spontaneous polarization direction in the (001) orientation PMN-0.25PT trigonal ferroelectric single crystal selected for use in Example 1 of the present invention, as figure 2 As shown, the trigonal lead magnesium niobate titanate Pb(Mg 1 / 3 Nb 2 / 3 ) 0.75 Ti 0.25 o 3 (abbreviated as PMN-0.25PT) is a representative of the tripartite ferroelectric single crystal, and its surface is the (001) crystal plane.

[0051] ②. The (001) plane of the PMN-0.25PT single crystal selected in ① is beveled in one direction along the [010] direction, and the bevel angle is 14 degrees, and the beveled single crystal is obtained, as shown in image 3 as shown, image 3 It is a schematic diagram of a single-crystal (001) PMN-0.25PT ferroelectric in Example 1 of the present invention after being bevelled in one direction.

[0052] The chamfered PMN-0.25PT single crystal was subjected to conventional double-sided polishing and cutting, and the si...

Embodiment 2

[0058] ①. The (001) plane of the selected PMN-0.25PT single crystal is obliquely cut in both directions, that is, it is first beveled along the [010] direction by 14 degrees, and then beveled by 1.5 degrees along the [100] direction to obtain the beveled single crystal, such as Figure 7 as shown, Figure 7 It is a schematic diagram of a single crystal (001) PMN-0.25PT ferroelectric in Example 2 of the present invention after bidirectional beveling is performed.

[0059]The chamfered PMN-0.25PT single crystal was subjected to conventional double-sided polishing and cutting, and the size of the obtained test sample was 5mm*5mm*0.5mm.

[0060] ②. For the obliquely cut PMN-0.25PT single crystal test sample after ① polishing, the upper electrode layer is evaporated on both sides, such as Figure 8 shown, Figure 8 It is a schematic diagram of the PMN-0.25PT ferroelectric with two-way chamfering in Example 2 of the present invention after two electrodes are plated. Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com