A kind of dye-sensitized solar cell and its manufacturing method

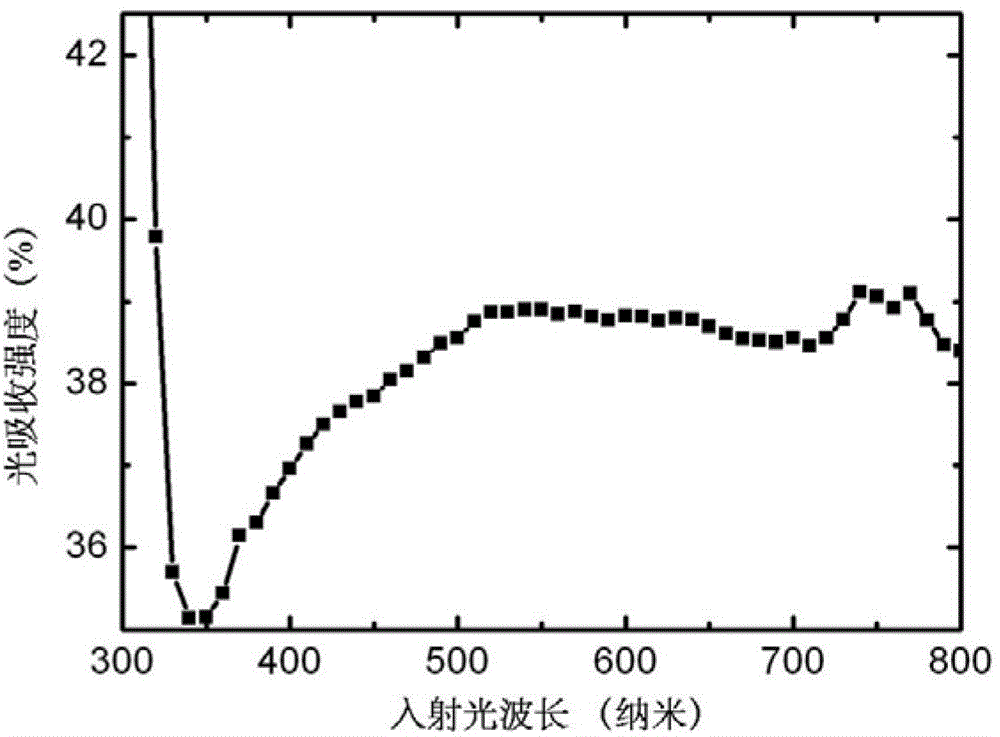

A solar cell and dye-sensitized technology, applied in the field of new energy, can solve the problems of low photoelectric conversion efficiency dye-sensitized solar cells, etc., to achieve the effects of enhancing photoelectric conversion efficiency, enhancing the probability of generation, and enhancing light absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

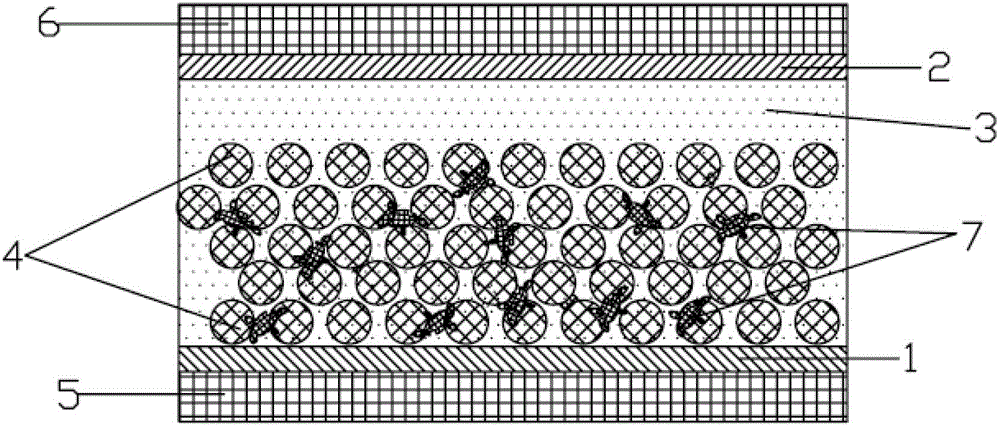

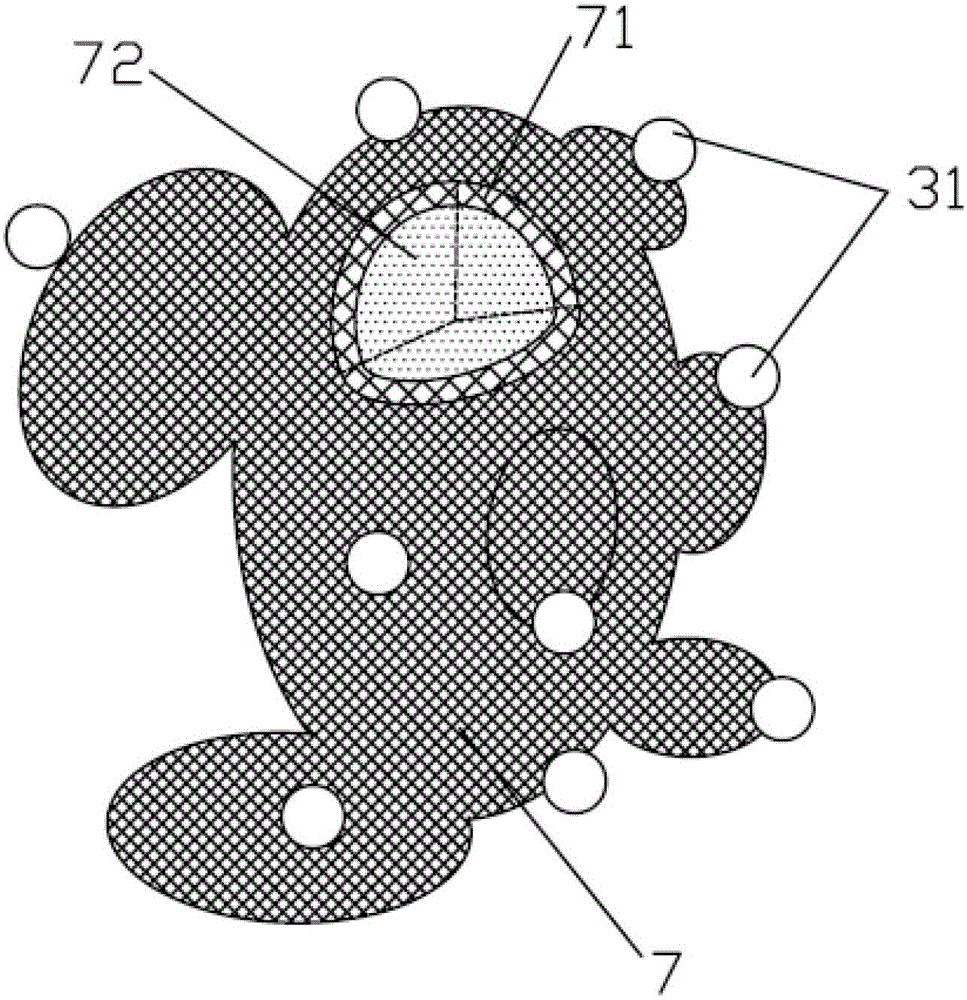

[0057] In this embodiment, a gold-silver alloy is used as the core, and the outer layer is wrapped with silver oxide core-shell structure nanoparticles (Au-Ag / Ag 2 O core-shell nanoparticles), and prepared by titration spin coating method containing Au-Ag / Ag 2 Dye-sensitized solar cells based on O core-shell nanoparticles.

[0058] First, prepare Au-Ag / Ag 2 O core-shell structure nanoparticles, its preparation method is as follows:

[0059] 1. Put 10 -4 mol / L chloroauric acid solution 100ml, 10 -4 mol / L silver nitrate solution 100ml, with 4*10 -2 Mix 2ml of mol / L sodium citrate solution, stir at a constant temperature of 95 degrees Celsius at a frequency of 500 rpm, and fully react for 6-7 minutes;

[0060] 2. Add 4*10 to the above solution -2 mol / L sodium citrate solution 8ml;

[0061] 3. Stir at a constant temperature of 100 degrees Celsius at a frequency of 500 rpm, fully react for 20-25 minutes, and then cool naturally to room temperature while maintaining stirring....

Embodiment 2

[0072] In this embodiment, a gold-platinum alloy is used as the core, and the core-shell structure nanoparticle (Au-Pt / Ag 2 O core-shell nanoparticles), and prepared by titration spin coating method containing Au-Pt / Ag 2 Dye-sensitized solar cells based on O core-shell nanoparticles.

[0073] First, prepare Au-Pt / Ag 2 O core-shell structure nanoparticles, its preparation method is as follows:

[0074] 1. Put 10 -4 mol / L chloroauric acid solution 100ml, 10 -4 mol / L chloroplatinic acid solution 100ml, with 4*10 -2 Mix 2ml of mol / L sodium citrate solution, stir at a constant temperature of 95 degrees Celsius at a frequency of 500 rpm, and fully react for 6-7 minutes;

[0075] 2. Add 4*10 to the above solution -2 mol / L sodium citrate solution 8ml and 10 -4 mol / L silver nitrate solution 20ml;

[0076] 3. Stir at a constant temperature of 100 degrees Celsius at a frequency of 500 rpm, fully react for 20-25 minutes, and then cool naturally to room temperature while maintainin...

Embodiment 3

[0086] In this embodiment, silver-platinum alloy is used as the core, and the outer layer is wrapped with silver oxide core-shell structure nanoparticles (Ag-Pt / Ag 2 O core-shell nanoparticles), and prepared by titration spin coating method containing Ag-Pt / Ag 2 Dye-sensitized solar cells based on O core-shell nanoparticles.

[0087] First, prepare Ag-Pt / Ag 2 O core-shell structure nanoparticles, its preparation method is as follows:

[0088] 1. Put 10 -4 mol / L silver nitrate solution 100ml, 10 -4 mol / L chloroplatinic acid solution 100ml, with 4*10 -2 Mix 2ml of mol / L sodium citrate solution, stir at a constant temperature of 95 degrees Celsius at a frequency of 500 rpm, and fully react for 6-7 minutes;

[0089] 2. Add 4*10 to the above solution -2 mol / L sodium citrate solution 8ml;

[0090] 3. Stir at a constant temperature of 100 degrees Celsius at a frequency of 500 rpm, fully react for 20-25 minutes, and then cool naturally to room temperature while maintaining stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com