Titanium dioxide-based nano-composite photocatalyst for photocatalytic degradation under visible light irradiation and application of titanium dioxide-based nano-composite photocatalyst

A titanium dioxide and nanocomposite technology, applied in the field of photocatalyst, can solve problems such as the limitation of photocatalytic degradation efficiency, and achieve the effects of improving performance, increasing specific surface area, and improving degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Dissolve 1.065g of isopropyl titanate in ethanol to obtain an isopropyl titanate solution with a concentration of 0.05mol / L, disperse 0.084mL of ethyl silicate into the above system, and stir electromagnetically at 1000 rpm for 45 minutes ; Dissolve 0.0081g of cerium nitrate into the above-mentioned liquid, disperse ultrasonically for 45 minutes, then transfer it to a polytetrafluoroethylene-lined autoclave, first rise to 100°C at 10°C / min, then 4°C / min Raised to 175°C and held for 12h. Cooled to room temperature, the obtained solid was separated by suction filtration, dried in vacuum drying (-0.1MPa) at 60° for 12h to obtain a photocatalyst, denoted as C 0.5 S 10 T-0.05M.

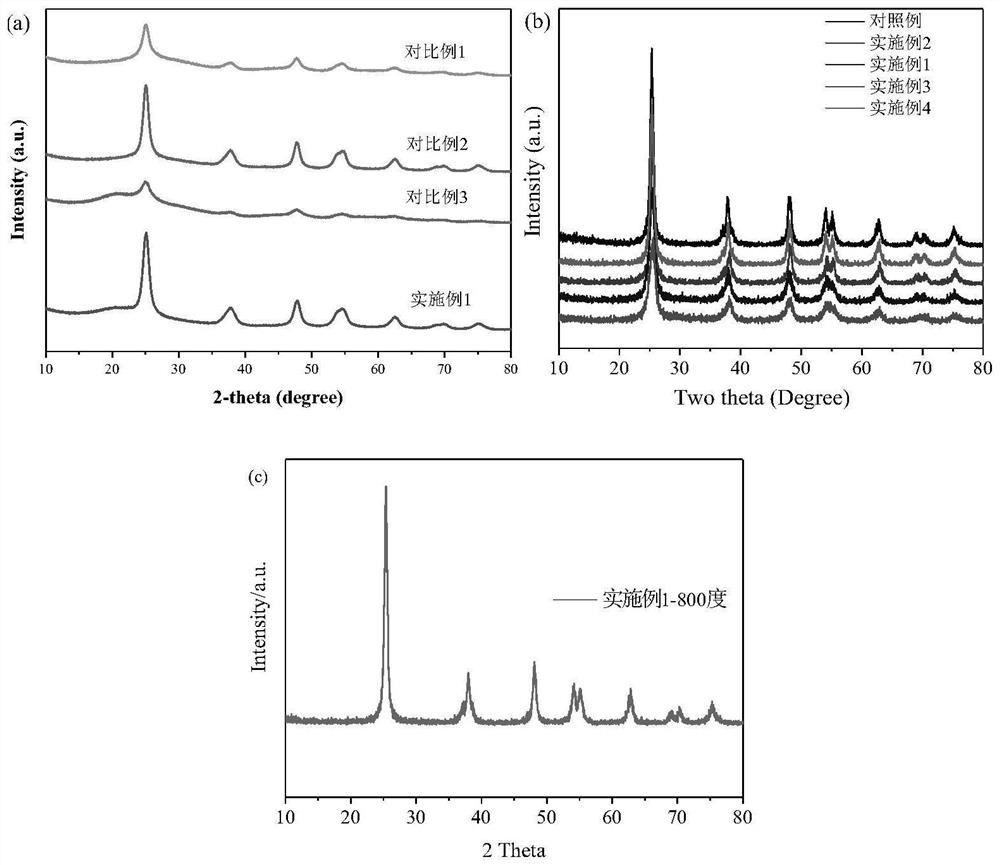

[0038] XRD results show that the C prepared in Example 1 0.5 S 10 T-0.05M is anatase phase, and no other impurity peaks are detected in its XRD diffraction pattern, indicating that the prepared samples have high purity (see figure 1 ). In addition, the composite photocatalyst has good high temp...

Embodiment 2~4

[0041] The difference from Example 1 is: the added amounts of cerium nitrate are 0.0036g, 0.0178g, and 0.356g, respectively, and the prepared photocatalysts are respectively denoted as C 0.2 S 10 T-0.05M, C 1.0 S 10 T-0.05M, C 2.0 S 10 T-0.05M.

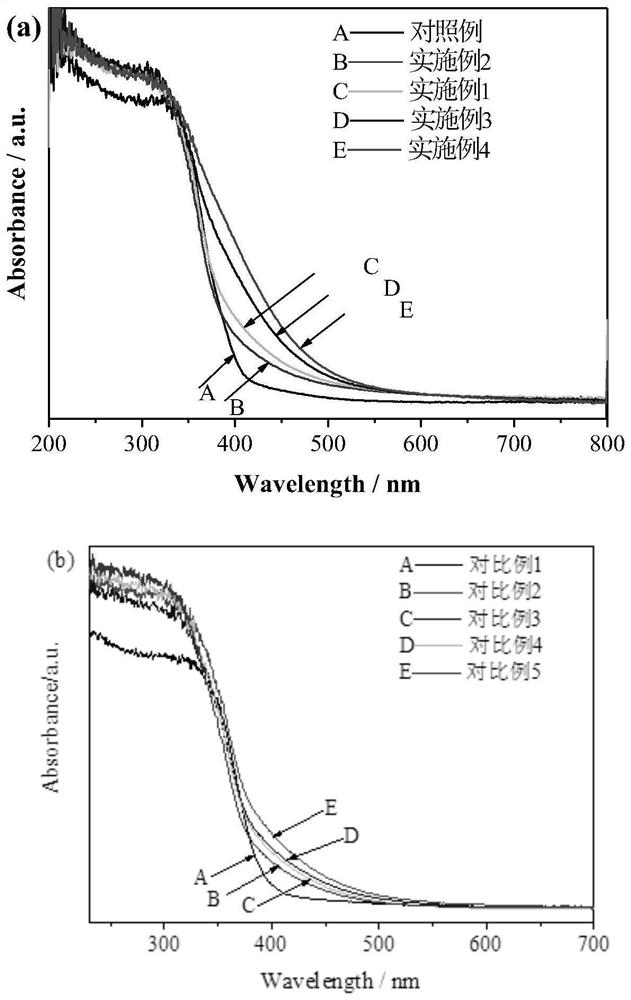

[0042] The photocatalysts prepared in Examples 1 to 4 and the undoped pristine TiO were measured by UV-Vis diffuse reflectance spectroscopy. 2 (PT) the ability to absorb light, such as image 3 As shown, it can be seen that the photocatalysts prepared in Examples 1-4 have obvious visible light absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com