A perovskite solar cell with energy band gradient based on mixed steaming process and its preparation method

A technology of solar cells and perovskites, applied in the field of solar cells, to achieve the effects of high film quality, novel and unique structure, and uniform film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

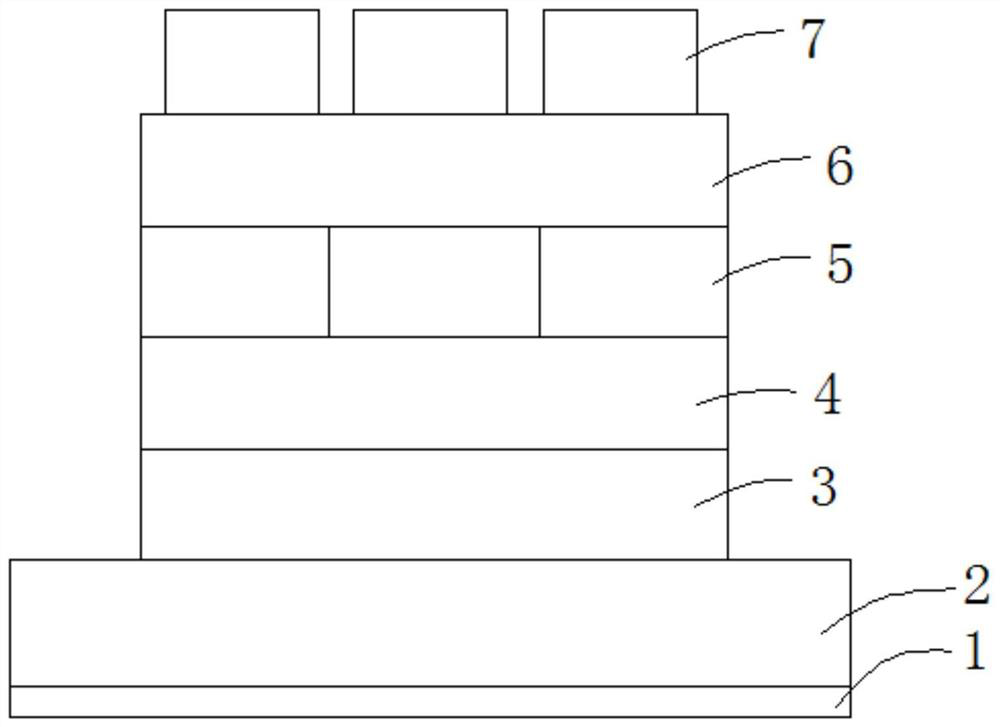

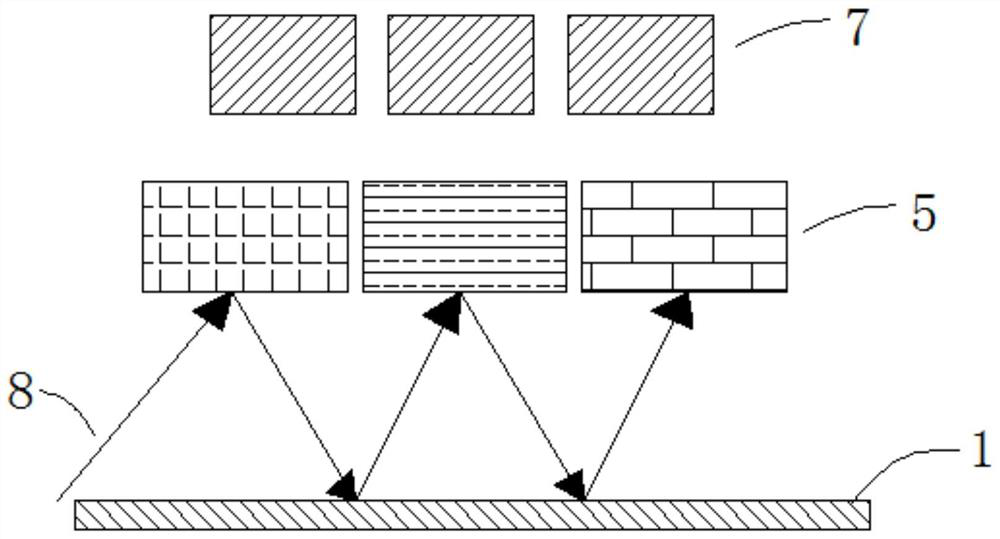

[0060] Such as figure 1 As shown, this embodiment provides a perovskite solar cell with an energy band gradient based on a mixed steaming process, including a light reflection layer 1, a transparent conductive electrode layer 3, a hole transport layer 4, The perovskite light-absorbing layer 5, the electron transport layer 6 and the metal electrode layer 7, the perovskite light-absorbing layer 5 includes several perovskite polycrystalline films with different energy band widths prepared by a blending evaporation process, and the several calcium Titanium polycrystalline films are arranged side by side horizontally;

[0061] The material of the light reflection layer 1 is metallic silver with a thickness of 100nm; the material of the transparent conductive electrode layer 3 is nano-indium tin metal oxide ITO with a thickness of 150nm; the material of the hole transport layer 4 is PEDOT:PSS thin film with a thickness of 90nm ; The perovskite light-absorbing layer 5 includes CH wi...

Embodiment 2

[0075] The preparation method is basically the same as that of Example 1, except that the evaporation of the perovskite light-absorbing layer 5 is: when the substrate C is vacuum-evaporated using the mask plate B, the evaporation rate ratio of methylamine lead iodine to methylamine lead bromine is set to 0.7:0.3, the evaporation temperature is also controlled at 250°C; then when using the mask plate C to vacuum evaporate the base D, the evaporation rate ratio of methylamine lead iodide to methylamine lead bromide is set to 0.6:0.4, and the evaporation temperature is also controlled at 250°C.

[0076] At room temperature, use a xenon lamp to simulate sunlight, and the light intensity is AM1.5 (100mW / cm 2 ), the light beam is also obliquely incident on the solar cell device, and the test results show that the reverse-scan photoelectric conversion efficiency of the perovskite solar cell with energy band gradient is 13.1%, and the forward-scan photoelectric conversion efficiency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com