Preparation method and application of silver/silver halide-loaded mesoporous titanium dioxide microsphere

A mesoporous titanium dioxide, titanium dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of short wavelength of ultraviolet light, poor penetration, poor effect, etc., and achieve good effect and low cost. , good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0025] The preparation method of the silver / silver halide-loaded mesoporous titanium dioxide microspheres of this embodiment is mainly realized by the following steps:

[0026] ① Mix 0.3mL tetrabutyl titanate and 20mL diethylene glycol, stir at 25°C for 8h to obtain a mixed solution;

[0027] ②Add the mixture obtained in step ① into 60mL of acetone containing 0.38mL dropwise, and keep stirring for 120min to obtain a white precipitate, which is filtered, rinsed and collected;

[0028] ③ Heating the collected white precipitate at 550°C for 8 hours to obtain anatase titanium dioxide microspheres;

[0029] ④Weigh 0.23g of titanium dioxide microspheres, disperse them in 20mL of pure water, stir for 1h, then add 0.15g of cetyltrimethylammonium fluoride dropwise, and keep stirring for 1h to obtain a mixed solution;

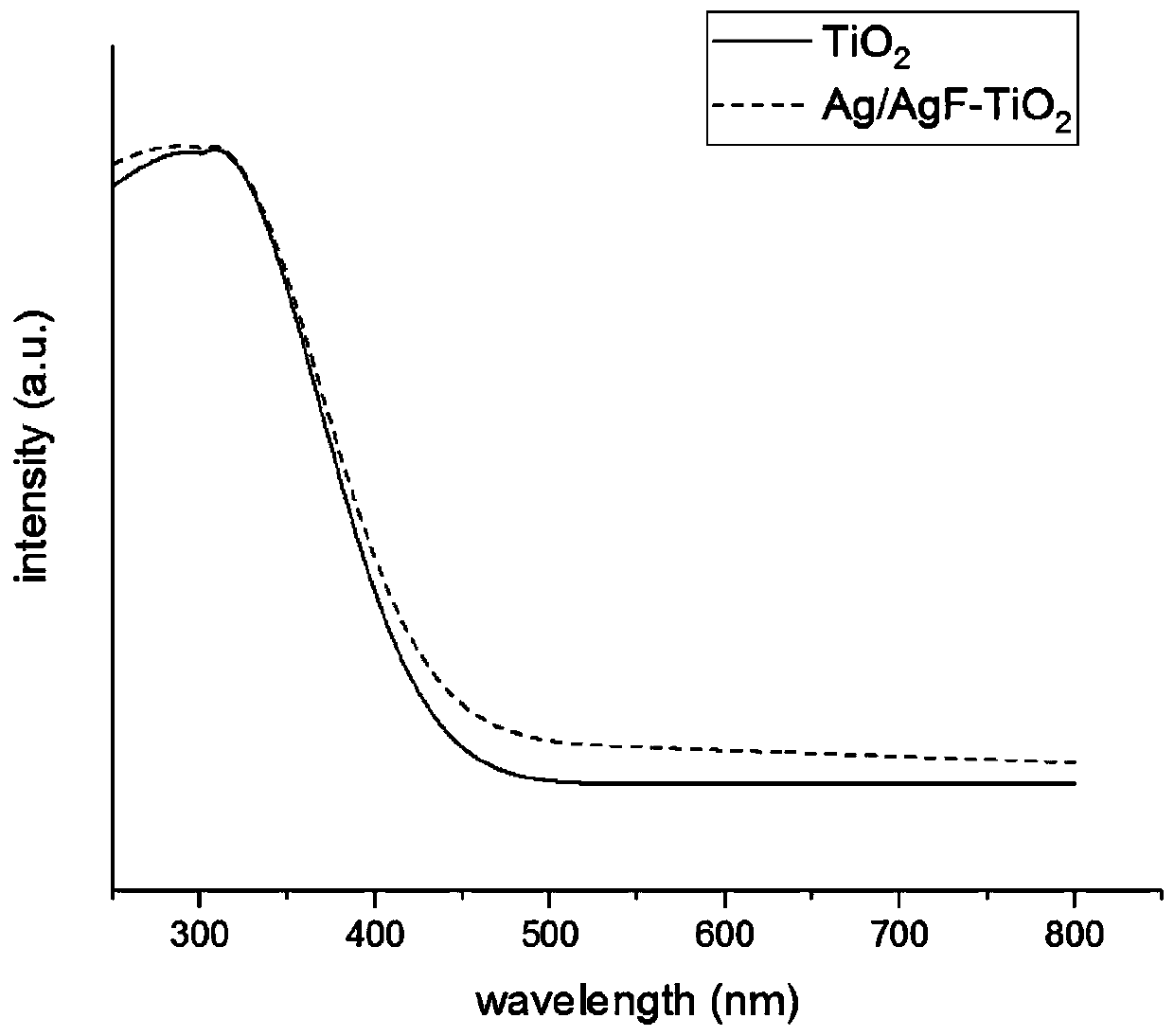

[0030] ⑤Add 800uL silver nitrate solution with a concentration of 0.1mol / L to the mixed solution obtained in step ④, and continue to stir for 1h; then use simulated sun...

Embodiment 2)

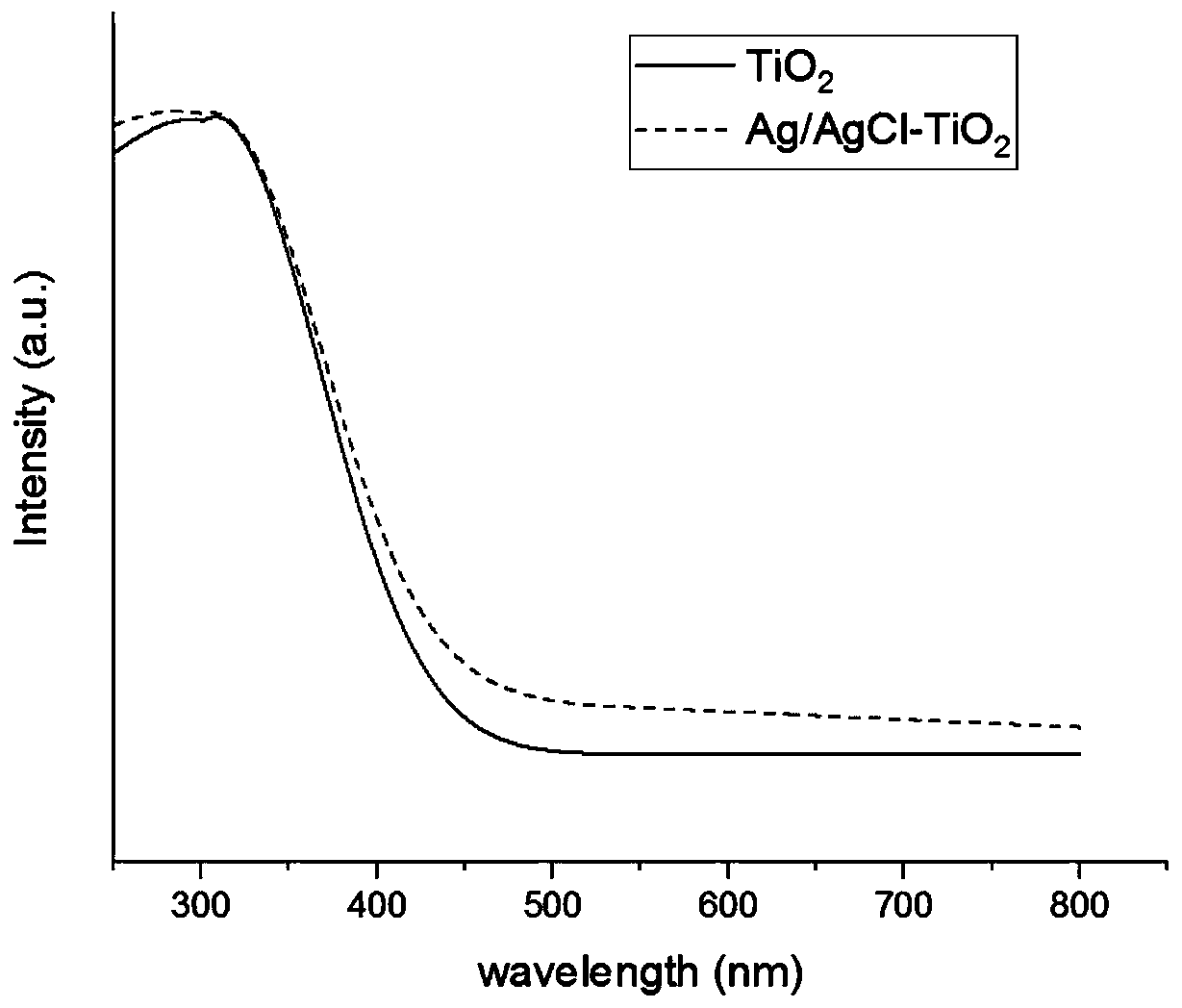

[0034] The preparation method of the mesoporous titania microspheres loaded with silver / silver halide of this embodiment is the same as in Example 1 in other respects, except that:

[0035] One, in step ④, the weight of the titanium dioxide microspheres taken is 0.35g, and what 0.15g is added dropwise is cetyltrimethylammonium chloride;

[0036] Second, what is obtained in step ⑥ is the mesoporous titanium dioxide microspheres loaded with silver / silver chloride.

[0037] The ultraviolet-visible light absorption spectra of the mesoporous titanium dioxide microspheres loaded with silver / silver chloride prepared in this example and pure titanium dioxide are compared for example figure 1 shown.

Embodiment 3)

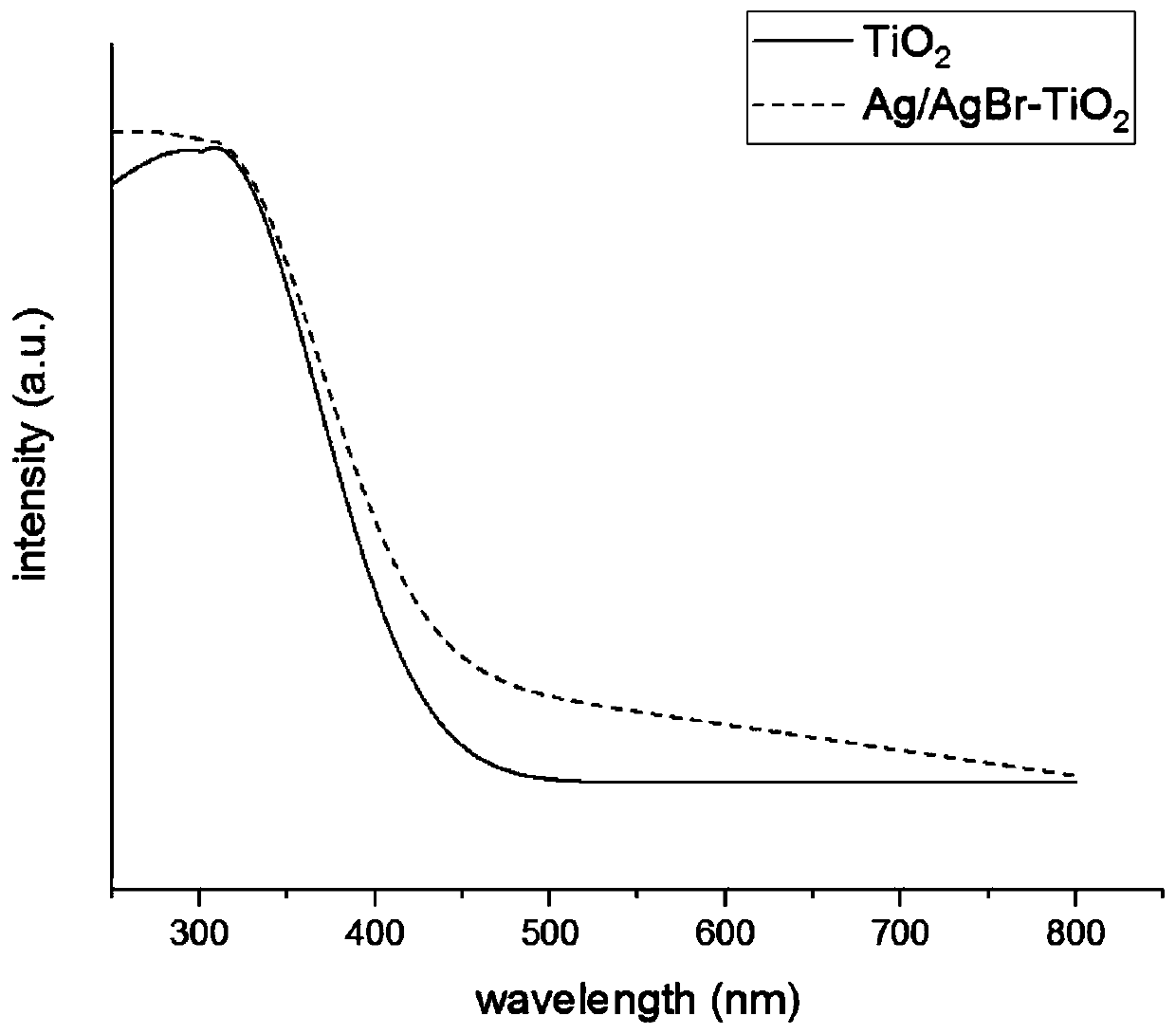

[0039] The preparation method of the mesoporous titania microspheres loaded with silver / silver halide of this embodiment is the same as in Example 1 in other respects, except that:

[0040] One, in step ④, the weight of the titanium dioxide microspheres taken is 0.30g, and 0.18g cetyltrimethylammonium bromide is added dropwise;

[0041] Its two, in step ⑤, the continuous stirring time is 2h;

[0042] Third, what is obtained in step ⑥ is the mesoporous titanium dioxide microspheres loaded with silver / silver bromide.

[0043] The ultraviolet-visible light absorption spectra of the mesoporous titanium dioxide microspheres loaded with silver / silver bromide prepared in this example and pure titanium dioxide are compared as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com